Import a Fiber Laser Cutter from China to the Russia (Step-by-Step Guide)

STEP 1: Finding a Reputable Supplier

How to find a reputable supplier for a fiber laser.

Do your research online and read reviews.

When researching fiber laser cutters online, it is important to read reviews from other users. This can help you get a better understanding of the pros and cons of different models, as well as the level of customer service you can expect from the manufacturer.

“

We use fiber laser cutting machines to create prototypes of new products. They are very fast and efficient, and they help us to get feedback from customers quickly.

OMNI’s fiber laser cutting machine has allowed cutting steel beams quickly and accurately for our construction projects.

When reading reviews, it is important to pay attention to the following factors:

The overall rating of the product

The number of reviews

The specific pros and cons mentioned by reviewers

The tone of the reviews (positive, negative, neutral)

By taking the time to read reviews, you can make an informed decision about which fiber laser cutter is right for you.

Contact potential suppliers and ask for references.

Once you have identified a few potential suppliers for your fiber laser cutter, it is important to contact them and ask for references. This will allow you to speak to other businesses that have purchased from the supplier and get their feedback on the product and the level of customer service they received.

Visit the supplier’s factory if possible.

If you are serious about purchasing a fiber laser cutter, it is a good idea to visit the supplier’s factory if possible. This will allow you to see the machines being manufactured and meet the people who will be responsible for your customer service.

When visiting the factory, be sure to ask the following questions:

How long have you been in business?

OMNI has been in CNC industry over 10 years, with rich experience on the fiber laser cutting machine building.

What are your most popular models?

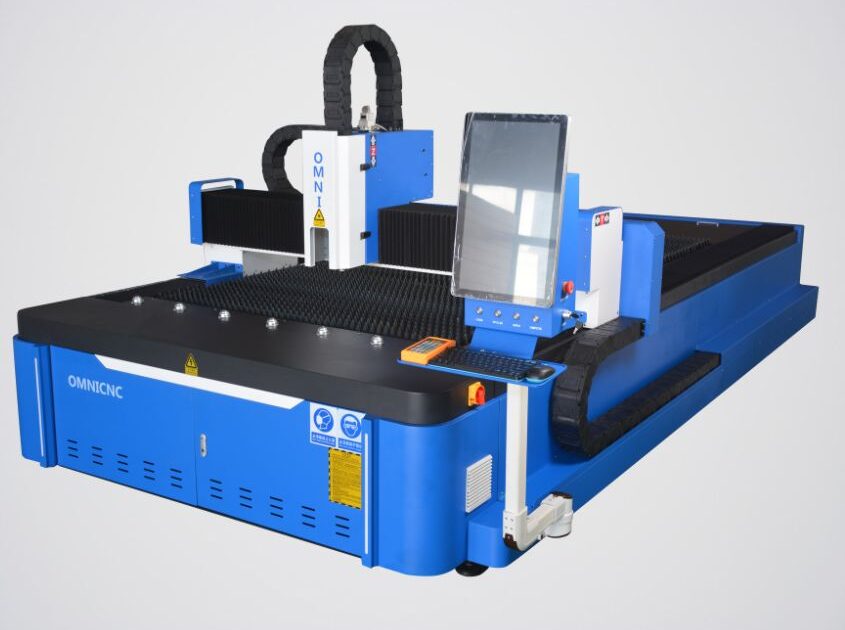

OMNI is with 3015A model for sheet cutting and sheet & integrated tube cutting.

What are the features of your machines?

What is your warranty policy?

Laser Machine-full 24 months back to base warranty on the laser machine and relevant manufacturers warranty on 3rd party add ones except consumable parts.

How do you handle customer service issues?

OMNI aftersales engineer can install, repair and offer training at your workshop. So no need worry about after sales service.

By asking these questions, you can get a better sense of the supplier’s capabilities and the level of customer service they offer.

Make sure the supplier is registered with the Chinese government.

-

How to avoid scams and counterfeit lasers.

When importing a fiber laser from China, it is important to make sure that the supplier is registered with the Chinese government. This is because only registered suppliers are allowed to export goods.

There are a few ways to check if a supplier is registered with the Chinese government. One way is to ask the supplier for their business registration certificate. This certificate will show the name of the company, the address of the company, and the registration number.

Another way to check if a supplier is registered with the Chinese government is to use the China National Enterprise Credit Information Publicity System (CNEIC). This system is a database of all registered businesses in China. You can search the CNEIC by the supplier’s name or registration number.

It is important to make sure that the supplier is registered with the Chinese government before you import a fiber laser from China. This will help to ensure that you are not dealing with a scam or a counterfeit supplier.

STEP2 : Getting Quotes from Multiple Suppliers

-

Why it’s important to get quotes from multiple suppliers.

Getting quotes from multiple fiber laser suppliers is important because it allows you to compare prices, terms, and conditions. This will help you to get the best deal possible.

Here are some of the benefits of getting quotes from multiple suppliers:

You can compare prices and find the best deal, negotiate the terms of the sale, get a better understanding of the market.

-

How to compare quotes.

Compare the prices. Make sure to compare the prices of the same features and specifications. Ask supplier the frame thickness, how they weld it, get the brand of control system, linear guide, servo motor and drive, reducer, fiber laser head, fiber laser resource, industril chiller etc.

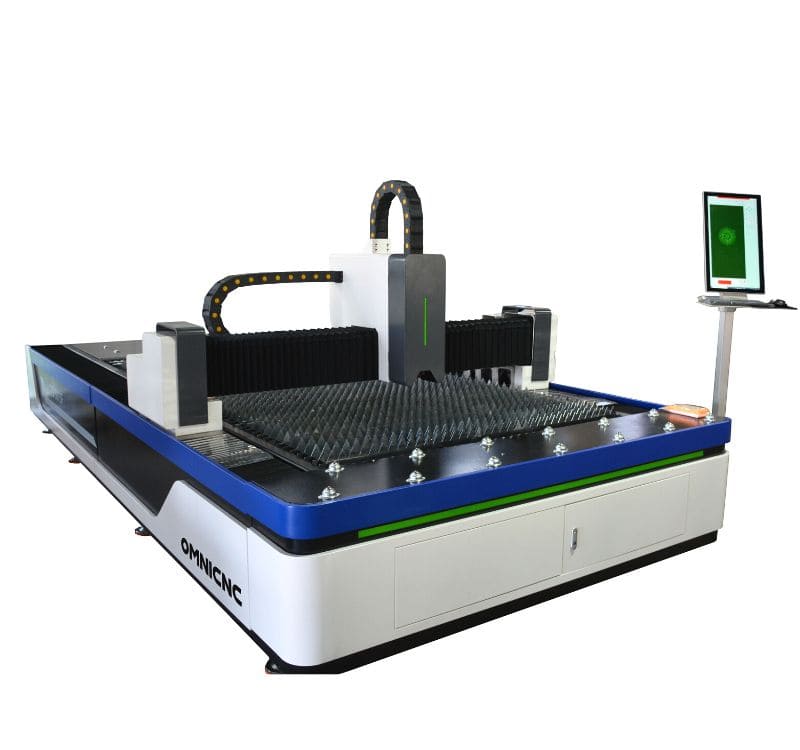

Here take reference of OMNI sheet metal fiber laser cutter:

Control System:

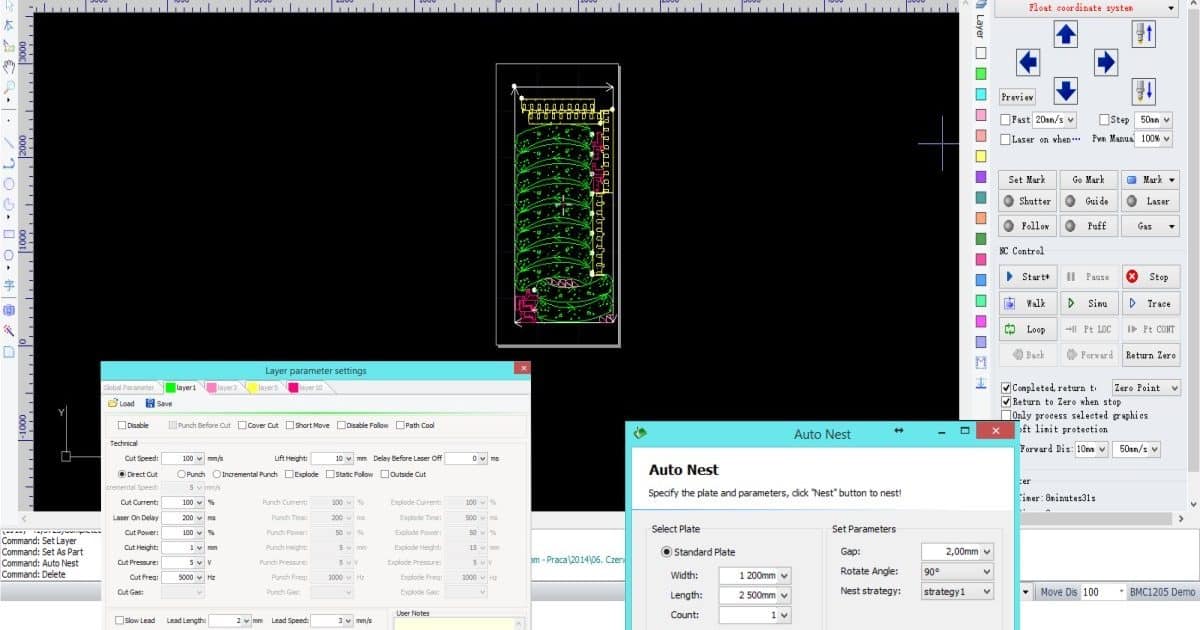

OMNI mainly offer CYPCUT and RAYTOOLS control system. This is the brain, all command are from here. An intelligent brain is with superior performance on leveraging software, connectivity, data processing and autonomous features to progressively increase the capabilities of the laser controller system.

cypcut

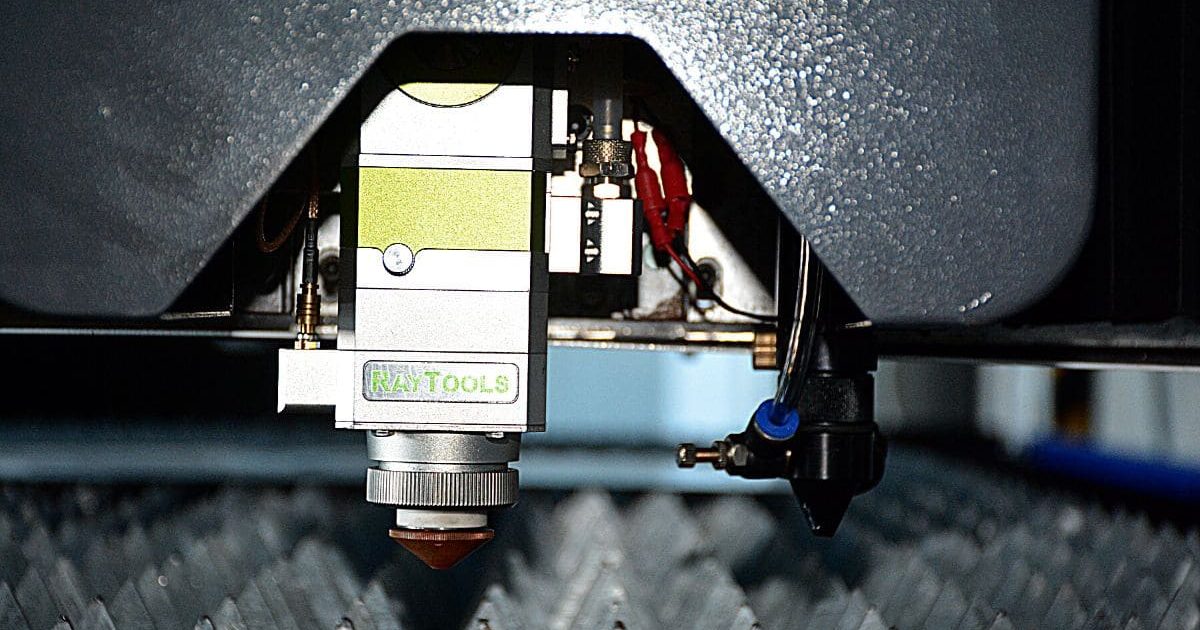

CUTTING HEAD:

Cutting (torch) head is like human arm, very crucial for cutting quality. We only use RAYTOOLS worldwide famous brand. Coordination with “brain- control system” – Our hands work seamlessly with our mind. Cutting heads achieve this through integrated controls, feedback loops and processing algorithms.

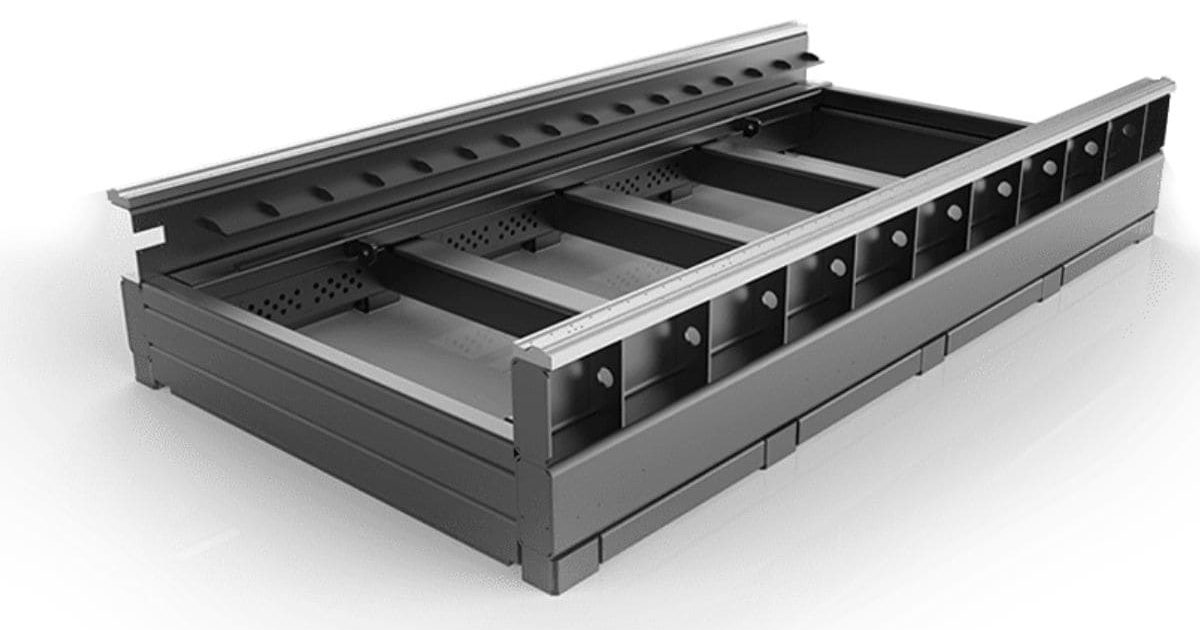

Machine Frame

Thicken 8mm steel tubes welded with HOLE-THROUGH welding ways. Ensuring machine frame working over 10 years without deform.Foundation and stability – Just as our skeleton provides the foundation and rigidity for our body, the machine frame must be a strong, stable base to support all other components without flexing or vibration.

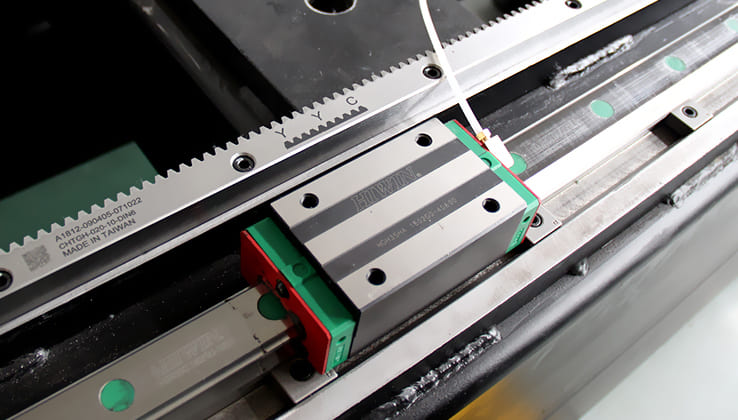

Transmission

Quality world famous brand HIWIN and YYC helical gear. Ensuring your high precision cutting performance. Just as muscles and connectors transmit force from the skeleton to enable precise movement, linear guides and ballscrews transmit precision motion throughout the machine.

Motor & Drive and other superior quality electrical parts

We all suggest customers to purchase YASKAWA servo drive and motor, and adopting superior quality electrical parts, since this is like the Arteries and veins. Motor cables distribute electrical current from central drives to linear actuators throughout the “body”.

There are more features, see below fiber laser cutting machine demo.

COMPARE TERMS & CONDITIONS

Compare terms, and conditions of the quotes. Compare the delivery term, to see which one they offer, FOB or CIF, because different dlievery term is with different charge.

Remember, firstly, knowing your demand clearly, tell the supplier below info:

- What are the materials you want to cut? This will determine the power and wavelength of the laser you need to recommend.

- What are the thicknesses of the materials they want to cut? This will also affect the power of the laser.

- What are the shapes and sizes of the parts they want to cut? This will affect the size of the laser bed you need to recommend.

- What are your budget? This will help you narrow down recommendations.

- Do you have other requirements? This could include things like the need for a specific software or the ability to connect to a network.

STEP3: Negotiating the Price and Terms of the Sale

How to negotiate the price of a fiber laser.

- Be polite and professional. Even if you’re not happy with the price, it’s important to be polite and professional to the seller. This will make them more likely to want to work with you.

- Be patient. Negotiating can take time. Don’t expect to get the best price right away. Be patient and persistent, and you’ll eventually get the price you want.

- Get everything in writing, including the price, delivery date, and warranty.

What terms to negotiate.

You will confirm the machine configurations, like laser head, laser source, motor and drive, transmission.

Besides machine configuration, you will check the payment term, usually is with 30% downpayment.

Also you need to check delivery term, is it EXW, FOB or CIF? or DDU? We will explain the delivery term later.

STEP 4: Follow up the Production

Keep the supplier to update you the production like weekly. And be sure to receive the inspection video or images before delivery.

STEP5: Importing the Laser

-

The steps involved in importing a laser from China to the Russia.

- Arrange shipping to the Russia.

Use a freight forwarder. Hiring a professional freight forwarder will make the shipping process much smoother. They can handle all the paperwork, customs clearance, transportation arrangements, etc. Look for a company that specializes in China-Russia trade. If you can not find out, OMNI can arrange forwarder to ship your goods. We have been in this industry over 10 years, knowing forwarders who handle China-Russia delivery.

Export paperwork. You’ll need to obtain an invoice, packing list, commercial invoice, certificate of origin, and other papers from the Chinese manufacturer. These are required for customs clearance in Russia. OMNI will prepare these papers for you.

Insurance. Arrange cargo insurance to cover damage or loss during shipment. Under CIF term, OMNI will cover the insurance for you. If it is EXW or FOB term, do not forget to buy insurance from the forwarder you arranged.

I believe you can get all these terms defination of EXW, FOB, CIF, CFR, DDU. etc.

Below are main Incoterms used for importing CNC machines are:

FOB – Free Onboard (or Freight On Board): Indicates that the seller’s responsibilities end when the goods board the ship leaving the port of origin. On FOB, the seller manages inland transportation, loading, export customs clearance, and port expenses. The buyer selects the carrier and shipping route and manages import customs clearance and expenses. Usually, this is the best and most cost-effective option for new importers.

EXW – ExWorks: Indicates that the seller’s responsibilities end once the goods are made available to the buyer at the manufacturing site or warehouse facility. In other words, once the order is packaged for shipment, it’s up to you to handle the rest. If you are new for importing, do not suggest this way.

CIF – Cost, Insurance, Freight: Indicates that the seller is responsible for insuring the goods up until they arrive at the buyer’s port of destination. The seller also handles inland transportation, loading, and export customs clearance. The seller is in control of the carrier and shipping route, but the buyer manages import customs clearance and expenses. Buyer do not need to handle the shipping, just wait for be informed by the shipper and prepare for the payment of customs declaration.

Whatever which shipping term you choose, do not forget to buy insurance.

Customs clearance. The freight forwarder will handle clearing customs in Russia. You may need additional import permits, certificates, etc. depending on the type of machine. OMNI will offer CE certificate for you.

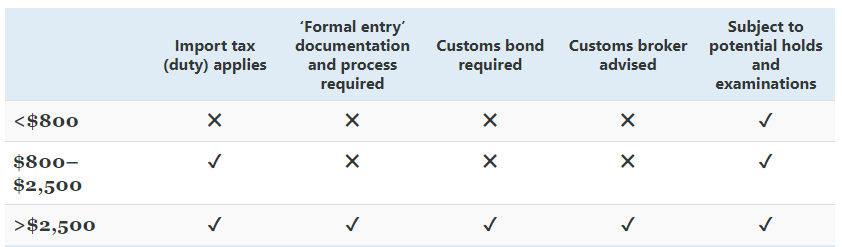

- Clear customs and import duties.

HS code is 8456.10.101.0 in Russia.

Import duty is 5% of CIF price, VAT is 20% of CIF price.

Take example, if the CIF price is €1000, the exchange rate is 1 €= 100 RU₽, then Import Duty is ₽50, VAT is ₽ 200, total is ₽ 260.

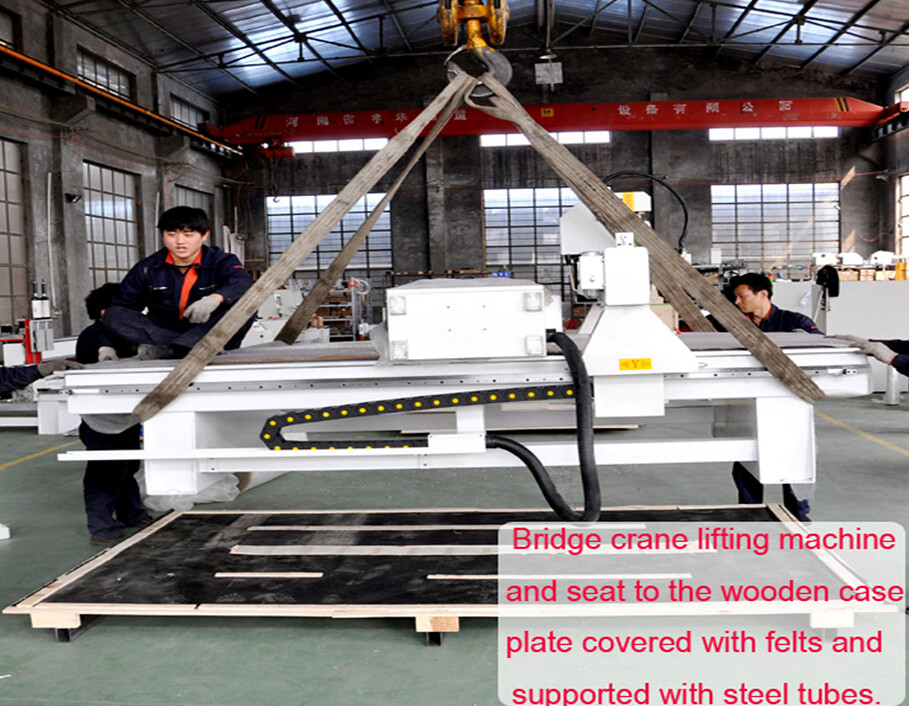

- Receive the laser and start using it.

Check the package is damaged or not. Incase there is broken issue, file to the insurance company at once. And contact the supplier, let them to handle the process for you.

If the package is well. After open the package, read the mannual and safety tips. Then start installation.

-

What to expect during the import process.

- Notify freight forwarder of expected shipment arrival. They will provide estimated arrival date based on transport mode.

- Forwarder submits pre-alert to Russian customs with basic shipment details prior to arrival.

- Upon arrival in Russia (seaport or airport), forwarder handles customs clearance with proper paperwork.

- Russian customs will inspect shipment against documentation for tax/duty assessment. Physical checks may be done.

- Forwarder pays applicable duties, taxes and fees on importer’s behalf. Ensure payment terms agreed in advance.

- Once cleared, forwarder arranges inland transport to delivery location in Russia.

- Shipment transported by truck, train or smaller vessel depending on destination. Transit times vary.

- Final delivery notification provided. Forwarder handles any claims or loss/damage reports.

- Import VAT is filed and can be recovered later if goods are not sold in Russia.

-

How to avoid delays and complications.

- Use experienced carriers with good track record for the China-Russia trade lane. Avoid unreliable options.

- Obtain cargo insurance cover for full shipment value against losses.

- Consider arriving into St. Petersburg or nearby ports rather than far eastern ports for quicker clearance.

- Allow a minimum 2-week buffer for potential customs/clearance delays, especially during holidays/weather issues.

If there is any question about fiber laser cutting machine or import issues to Russia, do not hesitate to let us know.