Best Cutting Techniques for Popular Materials

As a sign making cnc machine user, experts at Front Signs, a commercial sign making company in Burbank, CA are eager to share their knowledge of expert cutting techniques used for various materials in the fabrication of business signs.

Get all the insights from industry specialists and learn the best machines for cutting each material.

Below, we’ve selected the best cutting techniques for the most popular materials.

-

CNC Router for Aluminum and Dibond

Among the most rigid materials in the signage industry are aluminum and dibond. Both are used for various applications from outdoor advertising to interior decoration.

In order to cut aluminum or dibond sheets into custom shapes, we recommend using a powerful CNC router.

The tooling that’s used can change based on the design but overall, the CNC router is the best machine for cutting rigid materials.

The CNC router is a universal tool for cutting and engraving various types of rigid materials.

Compared with other cutting machines, the CNC doesn’t deform the aluminum edges and it’s powerful enough to cut through thick materials.

To achieve better results and make the tool as effective as possible, using shorter tooling is the best practice. This will provide more stability to the blade and ensure high accuracy in the cutting process.

Another tip for beginners using a CNC router is switching the direction of the rotation.

Sometimes you may notice that both sides of the finished product are not identical, making one side look better than the other.

You can fix this by switching the direction from climb side to conventional side in the process of cutting. With some trial and error, you’ll be able to master the CNC router to provide precise cutting on all kinds of materials.

-

CO2 Laser Cutter for Acrylic and Lexan

The best substitutes for glass are acrylic and lexan. They’re used for various applications from decorative and functional to promotional. Both materials are more durable and impact-resistant compared to glass and serve as a versatile medium for fabrication purposes.

The machine recommended for cutting acrylic and similar plastic materials is the powerful CO2 laser cutter. The cutter increases production speed by precision-melting the plastic material, providing it with clean cut edges.

Another great technique for yielding perfectly polished edges on acrylic is using a slow cutting speed with the powerful laser beam. With this technique, the laser has enough time to melt the material and provide a perfect finish. To achieve better results, using pins to elevate the acrylic on the cutting board is good practice. This will eliminate any chance of having grid marks imprinted onto the material.

Finally, using the red pointer on the machine is highly encouraged for precision cutting along ornate details. You can turn it on and off when needed. This is especially helpful for beginners to determine exactly where the laser will cut.

-

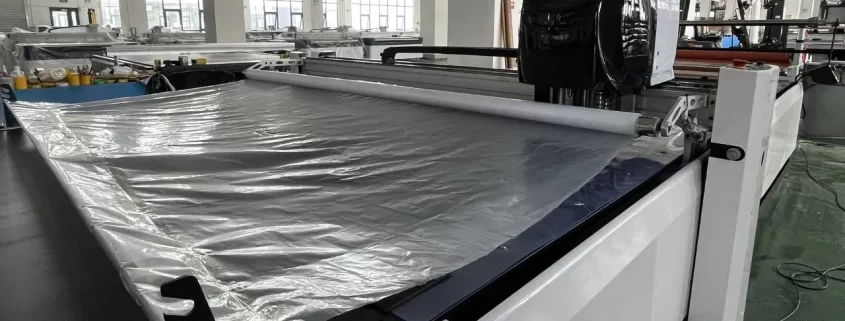

Digital Cutter for Foam Core Materials

Foam cores are lightweight but relatively sturdy materials used for promotions, decorations, presentations and many other purposes. Some of the most popular types of foam core materials are foam board, gator board and ultra board. A digital machine is a perfect tool for cutting all kinds of foam core materials. It’s a multifunctional computer-controlled machine that comes with a pen, creasing wheel and cutting tools to provide accurate designs. The machine has universal blades for different cutting techniques such as die cutting, kiss cutting and beyond.

What makes a digital cutter the best option for foam core materials is the fact that unlike some other machines, a digital cutter doesn’t heat the material. Also, the digital cutter doesn’t need to apply heavy pressure on gentle materials like foam board. This prevents the materials from being damaged in the cutting process.

For precision cutting, it’s highly recommended to use its crop mark sensor. When you apply this option in the print file, the machine can detect the ‘cutter guides’ for the design. It then uses them to move the blades over the applicable areas without going over the edges. This results in highly accurate contour cutting

-

Plotter Machine for Adhesive Vinyl and Static Cling

Vinyl and static cling are thin adhesive materials often used for application on walls, windows, cars and other smooth surfaces. A plotter machine is the best tool for cutting thin materials such as vinyl. It’s ideal for contour cutting and it can cut even the most elaborate details of a design.

The best technique for cutting vinyl using a plotter is to cut the material with the blade barely touching the backing carrier. You do this by learning how to set the right blade depth, after which you’ll be able to provide a clean cut on any vinyl material.

All you need to do is adjust the blade of the plotter to make it cut through the vinyl and stop right where it touches the backing carrier so it doesn’t go any deeper. You can test the settings on a small piece of material to avoid wasting a large sheet of vinyl. This cutting technique also decreases the force on the blade and prolongs its lifespan.

The above information is intended as a guide for beginners to gain insight into various cutting machine and material combinations. We’ve learned all the ins and outs of each cutting machine through years of experience. We hope that this content will be helpful for your future endeavors with cutting machines.

Any question, do not hesitate to let us know. Hope cutting machine speed up your production.

Metal Laser Cutter – The Secret behind the Intricately Carved Furniture

It is usual to go awe-struck whenever you come across some intricately carved furniture or a perfectly designed doorway. Doorways and furniture made out of solid wood are now available in very minute and precisely carved motifs. Indeed, they are highly artistic but getting them carved with the correct precision and delivering them on time is quite challenging. The secret behind this very daunting task is the use of metal laser cutter.

This machine works with the help of laser rays and is very useful in cutting hard metallic and non-metallic surfaces. Many manufacturers are in the fray to sell metal laser cutter, but the best place to have them is Omni CNC, which is synonymous to quality. Here is why:

- The metal laser cutter by Omni ushers with high performance and very low maintenance requirement.

- It comes handy in cutting metal as well non-metal surfaces.

- The metal laser cutters supplied by Omni are of a very high standard and are available with quality certifications like SGS, BV and ISO9001:2015.

- They are energy-efficient and deliver quality service.

- These cutters are less error prone as compared to the ordinary manual machines.

- They are eco-friendly to use because the waste generated is very less as compared to the hand-driven ones.

- The work done using these metal laser cutters is extremely fast

Some Exciting Works of Metal Laser Cutter

The machine works wonder in designing inspirational motifs and hence is the foremost choice of a majority of companies operating into metal cutting business. If you are also into the same domain, it is worth buying this machine. It will help you to come up with some entrancing prices of architectural cladding, decorative screens, Laser cut metal panels, surfaces and materials, balustrade and so on.Here are few of the masterpieces carved out with the help of metal laser cutters, specifically those from Omni CNC.

This image submitted by Grace & Webb gives a wonderful example of how the metal laser cutter can create an appealing panel. Observe the design pattern and the big flower at the centre, the combination just nails the design.

This marble-clad staircase, surrounded by beautifully designed metal panels is another quality example of the work carried out through metal laser. These are just few examples of how this machine could aesthetic appeal to your place. To know more about its usability and to buy the same, feel free to approach Omni-CNC, the leading manufacturer of CNC routers and metal laser cutter machines.

Create Amazing Works of Art on Jade Stone with CNC Equipments

The natural beauty of stone has made it a popular choice for homes and construction projects for centuries. The human has been creating art from stone ever since he found he could shape it by striking. However, today this much appreciated and dimensional building material is within the reach of a number of homeowners and commercial building projects due to the application of CNC machining. Nowadays you can see beautifully designed stones everywhere from home decors to office interiors, kitchen countertops with showers, as well as flooring and inlays.

CNC machines can be processed with amazing ease for cutting, engraving, carving various hard materials, such as wood, composites, aluminum, steel and jade stones. Designing architectural components or recreation work is no longer reserved to the labors of stonemasons or craftsmen. The CNC machine can bring about the same artwork and functionality. Though the jade stone or aluminum may weigh heavy, then also CNC Machines can amalgamate intricate designs of your choice.Many people might wonder how a machine can carve designs and art panels on the ingrained texture of stone. But with the advanced technology of CNC machines, it is possible.

Success by CNC Machine Technology

Omni Technology is the professional manufacturer and exporter of CNC Machines and Routers, and offers a variety of CNC cutting machines. These include tools for cutting composites, metals, stones, many more materials. Omni Tech also offers Laser Stone Engraving equipment for stonework.

Observe the heritage floral designs engraved on the jade stone in these two pictures carved with precision and detail on a textured ingrained natural stone.

As you can discern, these designs are a beautiful work of CNC router.

Omni Tech has designed Stone CNC Router for stone work that could cut, engrave and drill on marble, granite, travertine, limestone, onyx, soapstone, slate, quartzite etc. These machined and carved stone pieces are suitable for fireplace, countertop, sink, desk in kitchen, bathroom, residential, hotel, office building etc.

Like above picture, you can also represent art in engraved stones with CNC machines. Create timeless dynamic functional art forms for interiors and exteriors in the medium of stone.

CNC machines rigid structure and frame help achieve exceptional accuracy when machining aluminum and composite materials. It provides a high performance design for the fastest possible CNC controlled motion. Machining aluminum with a CNC Router is absolutely is achievable. It’s just a matter of matching your machine’s capabilities to the speeds requirements of the material through wise selection of tooling and cutting parameters. To get the best of results, make sure to approach Omni CNC, the leading company to provide superior quality CNC routers throughout the world.

CNC Router Manufacturers: The Superstars of the Alibaba Summit

Are you aware about the importance of CNC Router manufacturers? Well, the modern aero plane parts in civil and military sector are made with the help of CNC routers. They are instrumental in creating composites right from the ground up. Modern machines are made up of highly efficient mechanical parts and control systems. They work with extreme precision to deliver output with zero probability of errors. In fact, CNC routers are indispensable for various sectors of businesses right from technology to supply chain.

The showdown at Hangzhou city, China:

Alibaba invited prominent suppliers from across the country to participate in the summit at Hangzhou, China. It was a unique platform for the businesses to show case their achievements and to find new markets for their products. Alibaba exhorted the suppliers to implement innovative methods to boost the sales. The focus of the summit was to tap the requirements of the customers and understand the intricacies of the business.

Omni with its wide range of tools came out trumps and grabbed the MVP award for 2017. It is a wonderful achievement propelling the company into the big league. Thanks to the dedication of the engineers, the manufactured products are cut above the rest in terms of technological advancement and performance. Omni has become the first among equals to provide services to clients belonging to different industrial spaces.

Why Purchasing CNC is the Way to Go?

CNC router resizes and shapes the product according to the exact requirements and specifications of the clients. Suppliers displayed amazing items at the summit with varying degree of precision and accuracy. Machine processes raw materials with such finesse that it trumps the manual methods lock, stock and barrel. CNC is instrumental in performing large scale manufacturing runs to lower the overall operational cost.

Omni displayed wide range of CNC machines at the summit with durable body and flexible capabilities. In spite of complex feature, the device has an extremely simple user interface that even a layman can operate. The router is also extremely safe for the users to undertake manufacturing task without the risk of injuries.

As one of the primary CNC Router manufacturers, the company comprehends the requirements of the customers. It devises optimized solution for the businesses pertaining to diverse categories. No wonder, the company has won accolades in the recently concluded North Chinese Suppliers summit organized in Hangzhou. Its sophisticated machines are examples of exquisite brilliance of the scientific design. In fact, they are geared to achieve the business objectives of the customers.

How a 4X8 CNC Router Can Benefit Furniture Business?

The invention of advanced machines has taken our industries to a new level where we can witness continuous growth and progress. Notably, 4X8 CNC Router is one of the best machines to change the fortunes of assorted industries, especially those involved in furniture manufacturing and designing. The machine is easily affordable to small and medium business owners. Due to its variant uses and efficiency, one can prepare a complex furniture design within a short span of time.

What can a 4X8 CNC Router do?

A 4X8 CNC Router is the ideal woodcutting and carving machine that imparts excellent efficacy in manufacturing doors, furniture designs, etc. This router is widely used to cut and design on materials like wood, aluminum, etc.

It runs on the CAD software that enables a user to cut detailed designs with utmost precision on a preferred material. The process of producing complex designs manually demands a lot of time and other resources. Just opposite, this wonder machine can perform carving and cutting in three axes to come up with the design you want.

Usually, it is cumbersome for manual processes to offer such precision and they incur huge material loss as well. With the aid of the driving software, you can convert complicated designs into a reality with the aid of 4X8 CNC Router.

Testimonials of a Genuine Customer

This YouTube link shows how CNC router can benefit a furniture business. Vijay Patel a businessman operating into furniture manufacturing bought OMNI 1325 CNC router in 2013. He is still reaping high-end benefits from the machine after 4 years. In this testimonial video, Vijay talks about how the CNC router has been instrumental in making multiple types of doors and designs. Because of the capability of this machine, Mr. Patel has managed to enthrall many customers in his vicinity. He also shows the carving work performed on the doors with the help of the CNC router. He is all full of praise for OMNI CNC to send him such exemplary machine, which performs at its best even after 4 years, without any of its parts being replaced or repaired.

Advantages of using 4X8 CNC Router

• Timely execution: Apart from the wide range of materials that can be cut by this machine, the CNC router provides a flexible cutting approach to achieve any kind of complex design. The execution is impeccable and the owner does not have to spare too much time for the outcome. In fact, the use of such machine reduces the downtime to a considerable level and speeds up the order execution.

• Perfection: A 4X8 CNC Router enables a furniture business to produce impressive designs and carvings with an impeccable finish. The productivity of the floor increases considerably. Due to perfection, a business gets highly rewarded in terms of customer satisfaction and long-term relationship.

• Less human intervention: Manual wood designs and carving processes take too much time and involve significant person-hours. By introducing a 4X8 CNC Router in the manufacturing process, you can easily do the same volume of work within a very short span of time and involving a lesser headcount.

To sup up, by introducing a 4X8 CNC Router, you can easily achieve highest productivity as per quality and quantity. Moreover, you can get the best machine from OMNITECH and progress to a brighter future.

Investing in CNC Wood Carving Machine – A Profitable Affair!

Generally, the woodworking organizations and cabinetmakers are in a dilemma whether to invest in customised CNC wood carving machine or not. The choice is not a simple one indeed.

CNC Wood Router – Finding Its Use in a Range of Amazing Applications

Wood CNC router is an amazing machine. However, before putting your money into it, you must evaluate your needs regarding equipment budget, production capacity and lifespan.

Determining the Authenticity of CNC Router Supplier from China

Do you want to purchase CNC Router? It is quite difficult to find out the best CNC router supplier in China as there are many brands! Perhaps, Omnitech could be of great help in this regard.

CNC Router Woodworking – Contributing to Enhanced Competence

CNC routers have the ability to produce small artistic designs at extremely fast rates. In order to increase your production rate, you should rely on CNC Router Woodworking to produce non-intricate and large-scale production.

Order Laser Metal Cutting Machine from China for Enhanced Business Value

Omni CNC is one of the hubs where you can find high-quality laser metal cutting machine in China with high durability and efficiency. It deals with laser metal cutting machine of varying configurations used in different industrial fields.

Achieve Elegance with Woodworking CNC Router at Ease

When there is a need of delicate woodworking then a CNC router cutting machine can deliver a promising design within a very short span of time.

4 Axis CNC Router: Here is why you should install it?

The 4 Axis CNC Router is ideal for doing 3D processing, contour moulding, preparing European styled furniture and automotive exterior and interior works etc.

Top 5 Reasons that Account For Immense Popularity of Metal Laser Cutters

Due to the highly-efficient process and very low material loss, the laser cutting machine is the newest technology edge adopted by most of the industries. It requires delicate finish using optimum resources within a stipulated time.

CNC Engraving Machine – Embraced with Equal Zeal by Artists and Industrial Workshops

CNC engraving machines are instrumental in cutting through or engravings various metal and non-metal surfaces. While workshops use them to create various machine parts, artists prefer using these machines to engrave appealing designs on wood, marbles and other surfaces.

OMNICNC

Full CNC Cutting Solution

© 2023 OMNICNC - All Rights Reserved