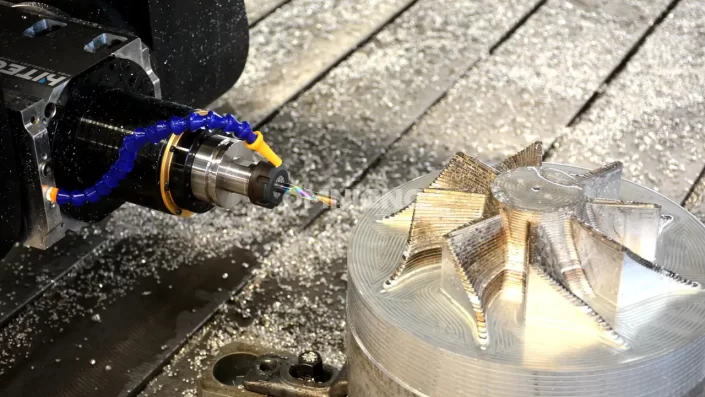

CNC Router Woodworking, Wood CNC Router and CNC Wood Cutting Machine

Request a Quick Quote Now

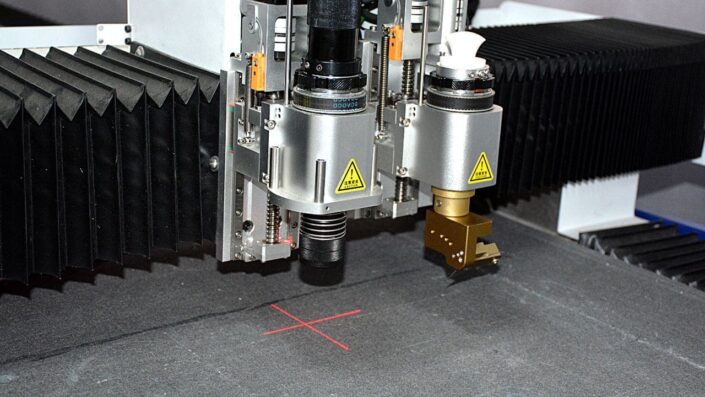

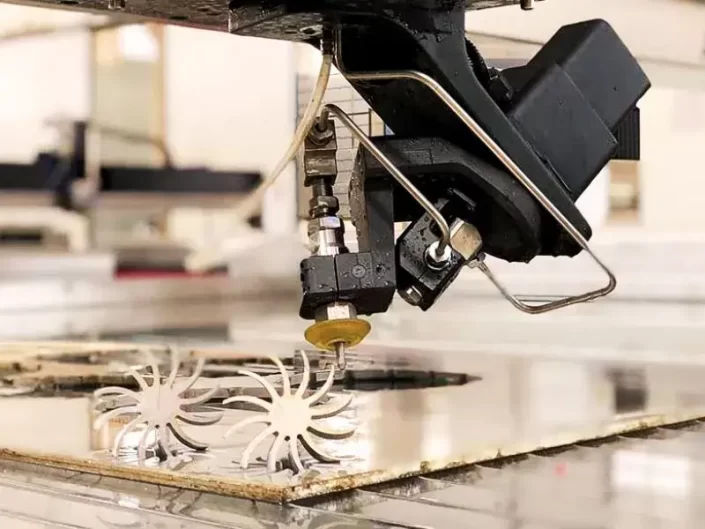

OMNI is one of the premium— and quality-focused—CNC router & cutting machine manufacturers and suppliers in China. We design, develop and manufacture a multitude of high-performance yet low-maintenance computer-controlled router, laser CNC cutting machine, plasma cutting machine, digital cutting machine and water jet cutting machine.

Quality makes the core of our organization’s philosophy, and thus, we ensure our range of products, be it a woodworking CNC router or a metallic and composite fabricating machine, comply with the international quality standards. We are an SGS, BV, and ISO9001:2015—a triage of quality qualifications—certified company, and all our made in China CNC Machines come with a certificate of CE.

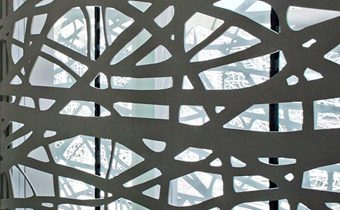

Our series of CNC routers for wood and other materials can help create elaborate carvings, including modeling decoration and 3D carving, fabricate furniture—ranging from the cabinet to closet and door panels— make signs, such as dimensional letters and directional signage, and cutouts. With a range of CNC cutting machine, we are a manufacturer that caters to industry of all scales.