A Complete Handbook of CNC Cutting Machines

To know more about CNC cutting machine, here is the list:

1. CNC Router: One of the best computer-controlled cutting machines used for cutting numerous types of materials. This advanced machinery is exclusively operated by CNC technology with no human interference. A CNC router produces high-quality work and improves the productivity of a manufacturing firm.

Benefits of Using CNC Routers:

- Reduces the need for outsourcing the work and save time as well as money

- The rate of production is improved by 70% over manual processes

- Reduces human error and material wastage up to 30%

- Vibration-free processing of the toughest materials

- Automating business and expanding production capabilities.

This computer-controlled machine produces consistent and high-quality work thereby improving the productivity of the company. CNC routers are used producing a variety of items such as furniture, glass molds, signboards, plastic fabrication, architectural decor, cabinets & case-goods, etc.

CNC routers run on CAD/CAM systems and work seamlessly meeting unique business needs. CAM software makes CAD designs in a code called as G-Code. This code is used by a CNC routing machine to easily understand the design.

As shown in the video https://www.youtube.com/watch?v=vsyul6C_Wvg&t=1s, OMNI CNC router machine beautifully carves 8mm thick MDF lattice for decorating interiors of the home or office. This latest technology in wood carving has widened the scope of designs in the category of door and frame making.

As opposed to manual carving, a CNC router has many opportunities and benefits, including speed and less manufacturing time involved. In the case of manual operation, a lot of time is consumed in cutting, etching, and carving the wood. But with this latest technology, wood carving has become affordable and accessible.

The numerically computer-controlled cutting machine is used to cut different types of hard materials including, wood, steel, plastics, aluminium, composites, and foam. Choosing the best CNC router for the production of your interior and exterior decoration is getting increasingly popular.

CNC router machine uses V-bit Groove CNC carving floral tool path output in JD Artform software, as shown in this video https://www.youtube.com/watch?v=daj008d0u5A&t=1s, for producing stylish and trendy patterned board.

Like a CNC milling machine, computer numerical control regulates all the processes or paths in a CNC router. Cabinet case goods furniture making CNC woodworking router when combined with auto tool changing function as shown in this video https://www.youtube.com/watch?v=oi9yQTeVNXU, improves engraving and cutting efficiency tremendously thereby saving tool changing time and labor cost.

If you are a businessman and investing in this machine, then you must be knowing how amazingly the CNC machine produces unique designs. It has very limited or no scope of errors, making it a preferable machine in the cutting industry.

Therefore, if you want your business to flourish, then buying CNC routing machines from OMNI CNC can be the wise decision.

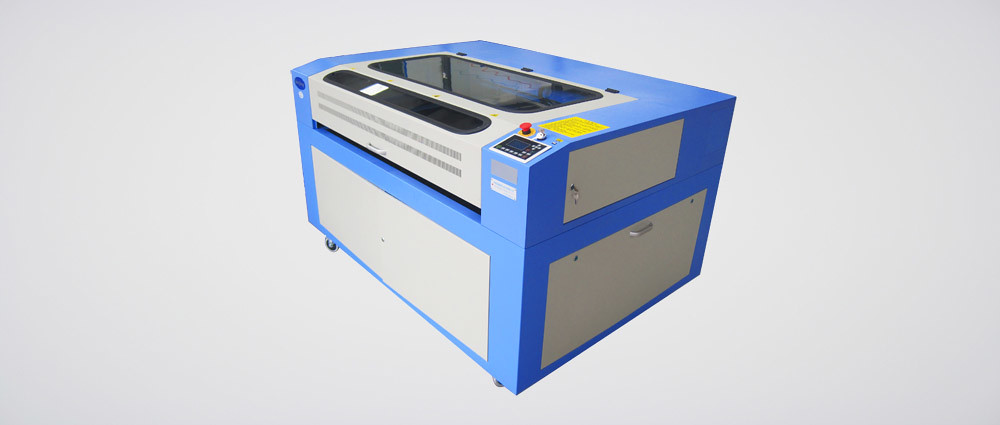

2. CO2 Laser Cutting Machine: This type of machine is extensively used for industrial needs. CO2 lasers can cut a variety of packaging materials used for final production.

It also cut several materials including aluminum, stainless steel, plywood, cardboard, plastics, and fabrics.

CO2 laser machine is equipped with a laser cutter frame, laser cutting head, laser generator, reflector path, laser power supply, water chiller, control panel, and CNC system.

This machine uses a CO2 laser to cut MDF, ABS, Acrylic, Glass, Fabric, Plastic, Bamboo, Ivory, Bone, Leather and Paper, which is widely used in industrial manufacturing applications, school education, small businesses, home business, small shop, and home shop.

CO2 laser cutting machine is equipped with laser cutting frames, head, generator, reflector path, power supply, water chiller, control panel and CNC system.

CO2 laser machine passes a very high-intensity beam on the material creating a perfect design. This fantastic tool is integrated with high speed, precision, and stability. It follows very clean cuts and engraves a variety of materials including acrylic, fabric, textile, wood, leather, etc.

A CO2 laser cutting machine comes integrated with air assist pump, extraction equipment, electronic water cooling unit, laser design software, etc. It improves the efficiency of cutting, maintaining consistent beam quality without secondary positioning, and suitable for extra long and large plates.

As you can see in video https://www.youtube.com/watch?v=cBcDdXtArOY laser machine beautifully etches ceramic coasters, wooden coasters, and wall murals. There is no need to limit your imagination. This high-precision laser machine brings your idea to life and allows you to create custom products for your customers.

The versatility and reliability of CO2 laser cutting machine are unparalleled. It has the ability to engrave high-resolution designs on hard to soft materials. The wide range of possibilities allows the laser machine to engrave and customize products made with wood, glass, stone, plastic, fabric, coated metal, acrylic, etc.

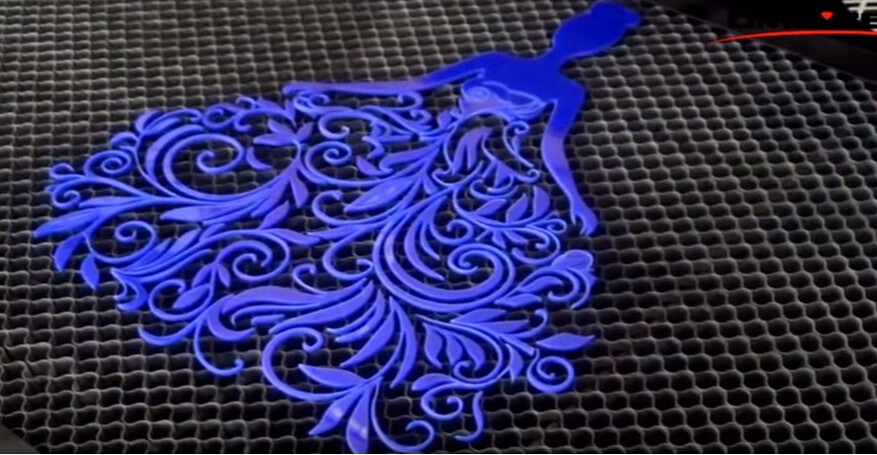

CO2 laser cutting machine is one of the latest technologies in world of interior designing and architectures. As you see in this video https://www.youtube.com/watch?v=vlZUCTIS2ss laser cutting machine is used for cutting out spring fairy pattern on acrylic board.

Acrylic cut patterns are usually used for interior decoration. With the help of the computerized program, you can get incredibly cool and flawless designs as shown in the picture. The bewitching curves and curls make it look ravishing.

These beautifully designed interiors can change the atmosphere of any indoor be it a residential place or corporate floor. Interiors can fantastically speak about your place adding warmth and depth to your space. With laser cutting machine you can add uniqueness and creative flair to the open space adding better depth, texture, and light to any room.

3. Fiber Laser Cutting Machine: If you want quick and accurate cuts, then the fiber laser cutting machine is the must-have. Fiber laser cutting machine is capable of cutting steel, brass, aluminum, etc, without the fear of the machine getting damaged.

This new technology generates a laser beam that is delivered to the laser cutting head. The laser transfers the heat for cutting metal and cut the metal sheets with matchless precision and quality.

OMNI CNC laser cutting machine has superior cut quality with the ability to cut materials like titanium, brass, mild steel, copper, aluminum, stainless steel, etc. while operating the fiber laser machine, you can see that a beam travels through the collimation lens with the help of optical configuration and passes through the lens to give shape to the metal. It gives desired shape to the material ensuring proper finishing to the material.

As you can see in this video https://www.youtube.com/watch?v=5CXKcmOSqbo&t=4s, fiber laser cutter uses metal sheets for processing advertising trademark, high/low voltage electrical cabinet, mechanism parts, kitchenware & cars etc. It very efficiently etches the material and carves beautiful design adding significance to the material.

Furthermore, the laser cutting machine is very easy to operate. All you need to do is follow 3 step methods:

- Create a page in graphics software and import the design which you would like to carve or create your own custom design.

- Setup your laser machine by sending your design to the laser. Now, move onto the print driver and select the laser parameters which you want to use or select the default material setting from the database.

- Lastly, select your file and place the material on the machine, close the door of the machine and then proceed with the cutting process.

4. Plasma Cutting Machine: From creating commercial to personal signage, wall art, murals, etc., this machine etches design with perfection and precision giving clean cuts and smooth edges.

Specially designed for cutting thick metals like stainless steel and aluminum, it is also widely used in many workshops and factories to create attractive designs. CNC plasma cutter uses a straight barreled torch and gets automatically controlled by the CNC machine with the help of an interface.

This metal cutting machine uses a plasma torch to cut a variety of metal materials giving different shapes. Plasma utilizes electricity to expand and ionize gas so as to create heat and effectively slice conductive materials jet of hot plasma.

A computer is employed to direct CNC plasma cutting machine and cut the metal sheet in a variety of shapes and sizes.

As shown in the video https://www.youtube.com/watch?v=EizgeW-DWuc&t=8s, OMNI CNC plasma cutting machines increase productivity, efficiency, and cost-effectiveness of a company. Plasma cutters do not leave any stone unturned in creating a prototype of the objects.

If you are investing in a plasma cutting machine, then you must look at the unique advantages of this machine. The cutting speed of the plasma cutter is significantly faster than the manual torch.

Compatible for cutting metals with hot plasma, OMNI CNC plasma cutting machine is good at clean and smooth cuts. The high-velocity ionized gas blows away the molten metal leaving behind high definition design.

So, if you are looking to increase the productivity and efficiency of your workplace, then buying CNC plasma cutting machine is worth an investment.

5. Flame Cutting Machine: This flame cutting machine help in producing a high amount of heat during the process of cutting the steel. The heat speeds up and intensifies while cutting the material.

CNC flame cutting machines is used by many industries like metal profile cutting industries, heavy fabrication industries, special purpose machine manufacturer, jigs & fixtures manufacturer, sheet metal industries, agricultural equipment manufacturing, and auto parts manufacturing industry.

CNC flame cutting machine consists of paraphernalia which includes cutting torches and plasma torch. Before using this CNC machine, information regarding cutting is fed into a file and then to the system from the input method.

CNC flame cutting has the ability to cut the material like paper. This robust method is prone to lesser chances of damage and helps in improving the efficiency of the machine.

Furthermore, the speed and accuracy of the machine are achieved with the help of a programmable controller. The flame cutting machine is dependent on a few parameters which you should take care of while operating the machine.

- Select proper cutting tips

- Oxygen pressure should be optimum

- Proper heat should be transferred

- Ensure the cutting speed

- Select proper fuel gas

- Measure the supply of both fuel and oxygen

Most of these parameters depend on the material and surface of the material to be cut.

6. CNC Knife Cutting Machine (Oscillating Cutting/ Tangential Cutting): It is designed specifically to provide accuracy while cutting heavier flexible and semi-rigid materials.

The tangential cutting capacity of the machine helps in accurately cutting the corners thereby maintaining the accuracy. Controlled by the motor, tangential knife is robust in nature and cuts thicker, heavier, and hard materials very efficiently.

It allows the machine to accurately cut square corners and maintain part accuracy. The tangential knife system has a range of optional and interchangeable blade holders which allows it to cut rubber, composites, duct liner and a mixture of soft and semi-rigid materials.

As shown in the video https://www.youtube.com/watch?v=lnWPEdItNDQ&t=6s, tangential knife cutting machine uses a V bit groove for cutting corrugated paper, cardboard, leather, foam, fabric, snowboard, carbon fiber, etc. The flexibility to cut the materials with high precision is commendable as compared to manual operation.

Versatility is one of the biggest advantages of the oscillating knife cutting machine. It has the ability to cut a wide range of materials maintaining small detail and curves without making excessive cuts.

As elaborated in the video https://www.youtube.com/watch?v=6e_pACBtnxY, oscillating knife cutting machine slices the material with ease and almost 0% abrasion rate. This machine is designed to cut soft material, like carpet, film, foam, snowboard, composite, corrugated box, veneer layer and excellent solution for digital printing cutting, sign, and graphic, fashion pattern making, automobile interior mat cutting, etc.

Since knife cutting machine combined with CNC router spindle rotating head, this machine is perfect for almost all type of soft and hard materials.

From routing aluminium and acrylic to cutting and trimming paper, vinyl, foam board, and rubber, CNC knife cutting machine makes it easier to cut any depth of material. When all the features are combined together, the CNC knife becomes the most versatile, configurable machine in the industry.

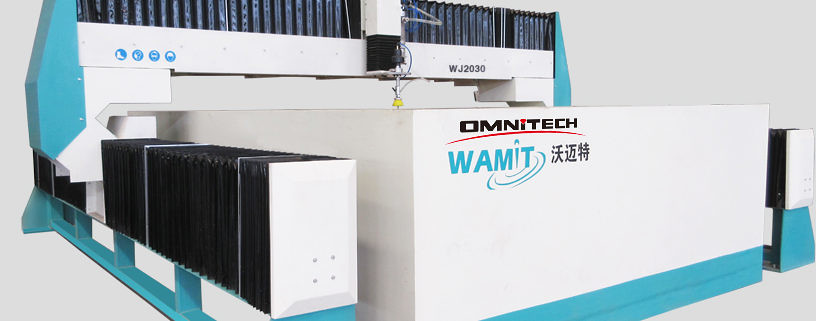

7. Water Jet Cutting Machine: This industrial tool is capable of cutting a variety of materials with the help of high-pressure jet of water and an abrasive substance. This water jet cutting machine cut almost any material up to 8” thickness at a maximum cutting speed.

To achieve higher productivity with lower costs, it is very important for a business to incorporate a type of machining solution inclusive of multi-function capabilities.

Good quality machines can reduce your production set-up, lead time, and also reduce manufacturing time.

OMNI CNC provides the industry with innovative solutions with the mission to automate the cutting process and increase the productivity of the industry.

When it comes to industrial manufacturing, water-jet cutting systems have unique properties that make them very adaptable. As we know that water-jet utilizes cold cutting processes and there are typically no heat affected zones (HAZs), so the physical properties of the workpiece remain unaffected while cutting.

Since waterjet is one of the most versatile machines, it has the ability to cut any type of materials without the need of changing its tools. While cutting any type of materials with waterjet cutting machine, you will witness no harmful airborne debris rather a clean and perfect edges.

OMNI CNC waterjet cutting machine offers a comprehensive cutting solution to its customers and serving a wider range of industries. Businesses that are looking to grow themselves are using this high-tech machine that offers remarkable flexibility and capability of abrasive waterjet technology.

The tools used for cutting stainless steel are water and abrasive power as shown in this video https://www.youtube.com/watch?v=44y8cYzSxkM&t=6s.

No heat is transmitted or created during the process of cutting the material and the swarf gets washed away in the water enabling the machine to cut clean and clear edges.

Also, as you can see this video https://www.youtube.com/watch?v=AqjdlZwYRrw&t=3s, waterjet cutting machine uses a very high-pressure jet of water or a mixture of water and an abrasive substance for artistically cutting ceramic tiles giving beautiful shapes to the material.

It can cut 8” thick materials at the maximum speed of the water jet machine that lasts longer with less maintenance time involved.

OMNI CNC waterjet cutting machine is specially designed for cutting, engraving, and drilling materials like marble, granite, limestone, soapstone, quartzite, limestone, etc. Different working size and configuration is offered by the machine to meet the production requirement and budget.

If you too are looking for different types of cutting machine for your industry, then this comprehensive guide can be beneficial for you.