CNC Router Machine Glossary

A

Absolute Coordinates: It is expressed relative to a fixed position. The G90 command helps in placing the part program into an absolute coordinate mode.

However, the relative coordinates are relative to the current position of the cutting tool. G91 helps in cancelling the absolute coordinate mode and places the part program into the relative coordinate mode.

Absolute Move: The absolute move is made with the help of absolute coordinates, so it commands the motion to an exact location as specified relative to the origin of the coordinate systems. Whereas relative move is made with the help of relative coordinates and moves from the current position.

Accuracy: it is the difference between the value expected and the actual value of the measurement.

Acetal: Acetal helps in making excellent low friction material when combined with PTFE. This material is used on the Tormach CNC mill.

Acme Screw: It is one of the most common types of leadscrew found in the tool. The ACME screw has a very high friction and backlash. Both of them are undesirable attributes for the high-end CNC applications.

Active High/Low Logic: Active high and Active low refers to how electrical signals can be translated. The presence of high voltage in active high logic indicates the presence of a signal. Active high logic is also referred to as Open Collector logic.

Angular Contact Bearing: This ball bearing is specially designed to deal with heavier axial loads. Angular contact bearing deals with pure radial loads and does not support the closer the load comes to the axis of the bearing.

They are specifically used for supporting leadscrews and building precision spindles for machine tools.

Annealing: This is a heat treating process that is designed to remove the hardness of materials so that it can be machined.

Arbor: Arbor is a workholding device that helps in expanding its OD to clamp the ID of a workpiece. It is similar to the spindle and used in conjunction with grinding and buffing.

ASE: This is an extension of the file for 3DS Max ASCII export files from autodesk. It is also known as a CAD file.

ATC CNC Router: This router is extensively used by the manufacturing industries for cut, engrave, and drill materials like plastics, non-ferrous metals, and marine, kitchen cabinets, signs, etc.

Automatic Grinding Center: This tool is specifically designed to grind and sharpen tools.

B

Back Driving: It is a tendency to spin when a force is applied to the nut along the axis. Since back driving is a low friction device, it becomes possible for cutting force of the machine to back drive the ballscrew and move the table unless the force is provided to prevent that.

Back EMF or Back Electromotive Force: When a step motor or servo motor slows down, Back EMF is generated. In essence, this force would pump the electricity back into the power supply. It is true that the electricity must find its way but if it doesn’t then the situation might turn worse.

Backlash Compensation: It is a feature of the software that is used for controlling the drive motors of a CNC system. By informing the software about the backlash in the system, the software will try to compensate for the backlash.

It is expected by the software that when the axis tries to reverse the direction, it will not move until the time the backlash has been taken up.

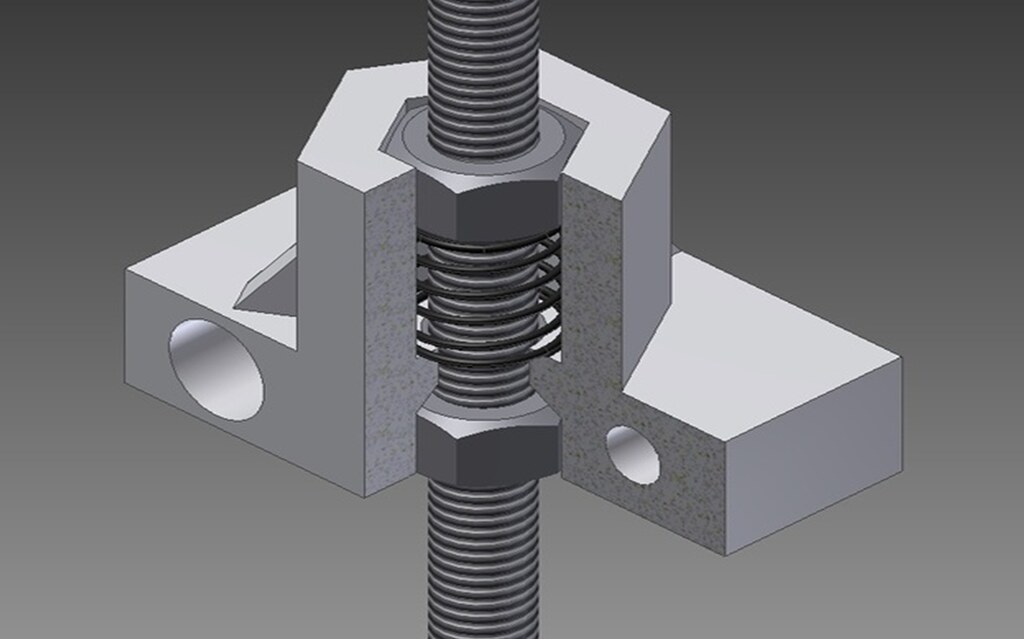

Backlash Eliminator: This device can be added to a leadscrew so as to diminish or eliminate backlash. Backlash eliminators are provided as a feature of the machine that does not have ballscrews in order to control backlash.

It could be as simple as a double nut setup with a precision spacer between the nuts for eliminating backlash on an ACME leadscrew.

Backplot: It is a feature of CAM programs where the path followed by the tool can be backplotted onto the drawing. A backplot displays all the passes all at once.

Ballscrew: It is one of the highly efficient low friction and low backlash leadscrew devices that use ball bearing rolling in a channel cut into the screw.

The low friction backlash attributes are beneficial for precision CNC applications where ballscrew is used for driving the axis of the machine.

Ballscrew Mapping: It is a feature of the CNC control software wherein a map of errors in the ballscrew is entered and the software automatically compensates with these errors.

The errors are expressed in terms of how far the screw stands from the desired position at various distances along the screw.

The ballscrew mapping can be an effective way to increase the accuracy of the machine however it requires the best method to measure the true position of the axis along the length of the screw.

Bar Feeder: This device is used to automate a continuous feed of the bar stock to a lathe so that the operator doesn’t keep loading new stock.

Bed Mill: A bed mill also known as column mill is one of the most common ways to construct a vertical CNC mill. In this design, the spindle is attached with a vertical column and slides on its way up and down the column.

Bellows: It is used to protect the ways and leadscrews of a machine from chips and coolant.

Belt Drive: It is used in machine tools to connect a drive motor to an axis leadscrew or to connect the motor to a spindle.

They can do double duty as a replacement for the leadscrew on a plasma or router table when the belt runs the entire length of the axis and the axis is attached to the belt at one point. Some common types of belts include Timing belt and V belt.

Block: It is the small operation unit of a G code program. This is a single statement of code that the machine could perform. If we consider block in the printed form, it is a line of text. Blocks are insensitive, they might ignore whitespaces.

Breakout Board: Breakout boards are generically designed to take signals that come in on a particular cable or protocol and break them out to individual connections for wiring purposes.

C

CAD: CAD is a program that is basically used for drawing programs used for creating plans or a part.

CAM (computer aided manufacturing): This software helps in generating G-Code from a drawing. This add-on module for the CAD program you are using or perhaps the CAM program incorporates the capability of a CAD.

CAM programs allow generating complex G-Code part programs easily over wiring codes manually.

Canned Cycle: It is a pre-determined cycle that helps in simplifying the CNC programming. Take, for instance, a peck drill cycle makes easier to implement peck drilling. The canned cycles commonly include drilling, boring, and tapping of cycles.

Capacitor: It is an electronic component that helps in smoothing the fluctuations occur in electrical currents. Electrolytic capacitors have large capacities and majorly used in DC or linear power supplies.

Carbide: This tough compound resists wear, heat, and extremely rigid in nature. It helps in cutting a surface in machine tools.

The entire cutter is made of carbide as in the case of a carbide end mill, boring bar, or a twist drill that may be used in indexable tooling.

Carbide is such type compound that can be run at a higher speed and feed than high speed. Carbide can be run at higher speeds and feeds than high-speed steel.

Center Cutting: The CNC milling machine has cutters and has the ability to drill a variety of materials. The center cutting has teeth that reach the center of the end face. It can plunge both vertically and downwards.

Chip Auger or Chip Conveyor: These are the features of machining centers that are used to manage a huge amount of chips and debris which these machines can produce in a shorter amount of time.

Chip Breaker: This feature is designed to cause the chip to break off by exerting a force on it. This type of chip breaker causes the chip to curl until the time it breaks off.

Chipload: It helps in measuring the actual thickness of a chip that is produced in the machining process. It can be influenced by spindle speed, a number of cutting edges of the tool and the federate of the CNC machine. A single edge tool carries the entire chipload altogether during a revolution while the multiple edge tool divides the load over multiple edges.

A chipload can be calculated as Chipload = feedrate / (rpm x #cutting edges)

The higher is the chipload more heat can be carried as larger chips carry the heat away. In order to increase the chipload, it is advised to increase the federate and decrease the rpm or simply speaking a number of cutting edges.

Chuck: This work-holding device is used primarily for tool holding. It is designed to rotate the workpiece or tool along the axis and most commonly used on lathes, rotary table, or mill.

Circular Interpolation: It moves multiple axes of the machine so that the tool follows a circular arc as closely as possible. Since the axis moves in a straight line, a number of tiny lines are used to stimulate an arc.

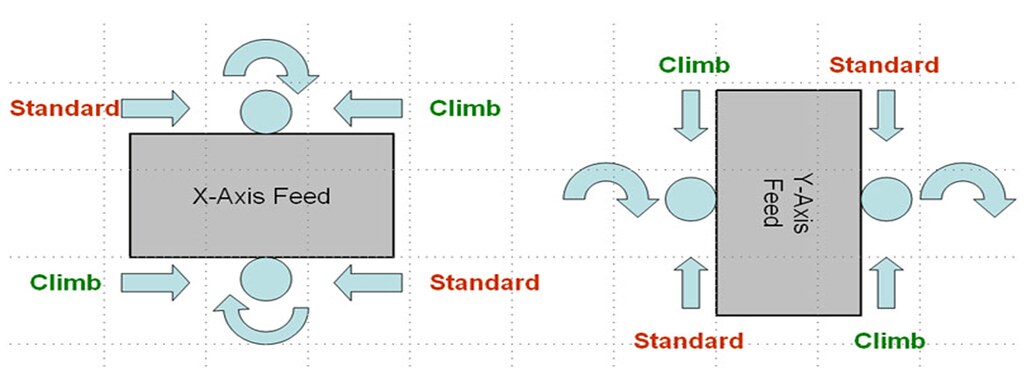

Climb Milling: It helps in reducing the load from the cutting edge and gives a better finish thereby improving the life of the tool.

Climb milling is preferred as one of the best ways to approach a workpiece owing to the fact that more and more machines compensate for backlash.

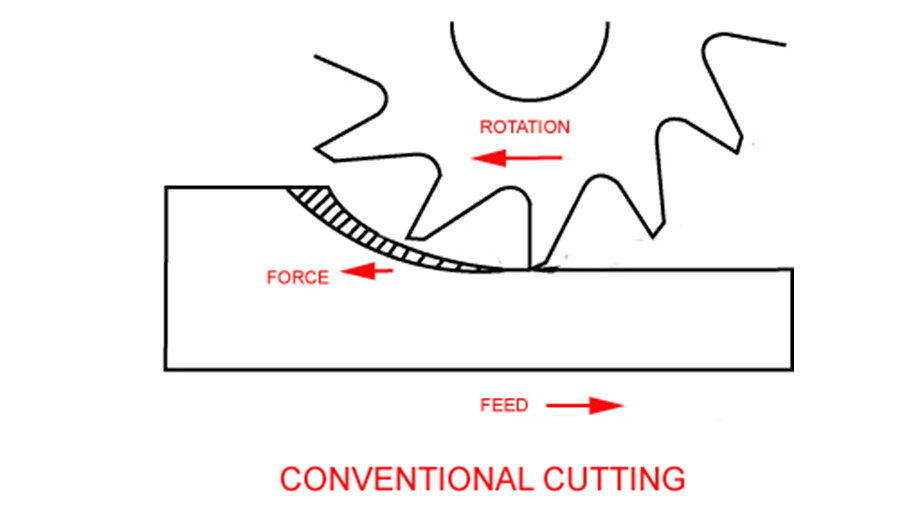

Conventional Milling: In this traditional approach, the cutter rotates against the direction of the feed. The cutter digs into the workpiece and causes the part to be cut out of tolerance.

Collet: It is a part of CNC machine that holds the bit. It is a type of sleeve attached to the spindle with a collet nut.

Constant Surface Speed or CSS: CSS has a longer life of the tool and consistent surface finish along with better cycle time. Also specified as G90 on most of the machines, it determines the appropriate spindle speed in revolution per minute (rpm).

Constant Velocity Mode: This mode helps in maintaining the constant velocity during all arc moves while accepting the parameters of acceleration. Also known as contour mode, it encourages a smooth interpolation between points making for a better finishing of the surface.

Contouring: It is the movement in two or more axes at the same time that is used for producing a smooth continuous surface or curve.

Contour Turning: A CNC lathe operation where a smooth continuous curve is machined. It is analogous to contouring on the mill, and may also be called “Profiling”.

Conversational CNC: It is a method of using a CNC machine that does not require G-code programming.

However, the operator interacts with a list of options in order to define the functioning of the machine. It is very convenient on machines that are basically used for off jobs as they help in saving programming time.

Coolant: A cutting fluid is a type of coolant which is designed specifically for metalworking processes. The life of the coolant can be elongated by using it in a proper manner. It also allows higher cutting speed thereby improving the surface finish.

Counterbore: This is a common machining operation used for recessing a bolt head down into the hole. The counterbore cutters are made for the task in particular or some folks plunge cut with end mills.

Counterweight: It is often used for balancing the weight of a vertical axis for smooth operation. In literal terms, the counterweight is used for increasing the Z-axis Speed of a CNC Machine.

It can be constructed of weights, sometimes supported with compound leverage to reduce the weight required, or from other mechanisms such as gas springs.

Cutting Force: It is the force exerted by the tool on the workpiece. The high cutting forces can potentially cause deflection, which may lead to inaccuracy and chatter. It can even break the cutter.

Datum: It is an imaginary geometric shape which is a point, circle, or cylinder shape. Datum is a physical feature of a workpiece that acts as a physical analog to the datum where measurements are made.

Delrin: It is the trade name for Acetal. Delrin is a pretty good material that helps in making light duty leadscrew nuts from it.

Deflection: It is the shift of a position or vibration of a workpiece due to insufficient hold that causes inaccuracy.

Digital Differential Analyzer: Also referred to as DDA, it is a mathematical technique or algorithm that is used to interpolate paths for motion control, computer graphics, and other applications.

While using CNC applications, the motion and axis are not precisely aligned, it is just an estimation of a smooth true motion. This estimation is calculated DDA algorithm by moving more than one axis at a time.

Digitizer: It is a mechanism that is used for recording the 3D surface of the real object and producing a computer model that is suitable for CAD/CAM program. This process of digitizing can be accomplished with the help of a Tool Probe or Laser Scanner.

DNC (Direct Numerical Control or Distributed Numeric Control): This protocol is similar to the local area network that is used for linking together CNC machines on the shop floor.

DOC (Depth of Cut): It refers to the total amount of material removed on each pass of the tool. The depth of cut is the measurement of the material used by the cutter along the axis.

This tool is specifically designed to cut the material with specific depth. It requires more power to run deeper cuts. If you want greater depth of cut, then you should run at a slower federate or spindle rate.

CNC machine helps in reaching the desired depth by reducing the depth of the cut, increasing spindle and feed rate.

Dongle: Also known as USB key, this electronic key is used to copy protect CAD and CAM software. It will not operate unless the dongle is in the place on the machine that helps in running the software.

Dovetail ways: It is commonly used in mills like dovetail is used in the wood joinery. Dovetail ways are generally used by many machine tools so that their axes slide against one another.

Drill Bushing: It is a hardened steel cylinder consisting of a hole in the diameter of the drill bit. Drill bushing is typically designed to support the end of the bit so as to enhance the precision while drilling.

This tool is used when there is a need for a precise hole of a particular diameter that can be replaced from time to time when worn out.

Drip feed: It is a technique of feeding the part program into the CNC machine. If the whole program is too large to fit the memory at once, then drip feed is used to feed the program a little bit at a time.

Drive or driver: It is an electronic circuit used for controlling the energy sent from the power supply to a motor thereby having a control on the motor.

DRO (Digital Read Out): It provides a digital indication of the position of one or more axis on the machine. DRO is used in linear scales so as to measure the positions and other technologies used in the process.

This numerical indicator is used within the program that has a number of different capabilities and properties as well.

Dry machining: It is the process of machining without coolant and a strong stream of compressed air is used to cool chips. Dry machining is used for increasing the productivity as well as reducing the chip breakage at very high SFM rates.

On the other way around, the tool should be properly used or else the life of the tool can be reduced. Always ensure the parameters of the machine with tooling suppliers.

Duplex bearing: It refers to using two angular contact bearings in pairs. The bearing should not be separated and they are matched by one another and used in proper combination.

Dwell: Dwell is the visible mark in the workpiece which is known as dwell mark. Owing to these marks, dwells may be unwanted from the standpoint of the surface finish.

DXF file: it is a file extension and an Autodesk file format for Autodesk CAD drawings. DXF file is a common format used by most CAD and CNC programs that can easily read and write.

E

Edge finder: It is a device that helps in finding the exact edge of the workpiece along X and Y axis. The edge finders can rely on electrical contact, a sensitive pressure switch or mechanical.

E-stop/emergency stop: It is a controller that stops all the machining operation. This controller physically interrupts the power to the spindle and axis drive motors.

Once the e-stop controller is triggered, a special operation is required to resume the power.

F

F-code: It is a part program word that helps in determining feed during executing a program.

Feed: A feed is an act of moving a workpiece relative to the cutter.

Feed Hold: This CNC panel helps in controlling the machine from executing commands.

Feed override or Federate Override: This panel is specially designed to control the operator manually for increasing and decreasing the federate.

Feedrate override also allows the operator to fine tune the program without the need to rewrite G-code. It is a percentage of the programmed value.

Feedback or Feedback loop: A feedback loop is one where a sensor provides feedback to control motor and other devices.

In CNC machines, closed-loop systems incorporate feedback so as to increase the accuracy and performance of the machine.

Feedrate or Feed rate: It is the rate at which the cutting tool and the workpiece move hand in hand. The more is the feed rate, quickly materials can be removed but it does require more power.

Feeds and Speed: It refers to the federate and spindle speed that is used for an operation.

Finishing Pass: It is a final pass with a very thin cut that enables higher accuracy and better surface finish than a rough cut.

Fixture: It is equipment that is used to guide and hold a workpiece. Fixture guides the tool, while a fixture does not.

Flood Coolant: With the help of a very high volume of coolant chip evacuation and cooling is ensured.

Use of flood coolant requires a reservoir, pump, delivery piping, and some form of the enclosure so that the coolant does not get sprayed everywhere.

Flutes: It refers to a cutting surface. A 4-flute endmill has 4 cutting surfaces.

Flycutter or Fly Cutter: It is a type of cutter that has single point cutter which means there is only one cutting edge. Flycutters is commonly known as Single Point Cutter which is used in milling operations.

It produces a good surface finish over the broad area and makes a thumping noise due to which they are able to take an interrupted cut.

Fly cutters range in variety from specialized cutters to more general versions that use lathe tools.

Following Error: In a closed loop system, following error is the difference between where the axis is based on feedback from an encoder or another device, and where it should be, based on what the CNC control program has commanded.

Follow Turning: In follow turning two tools and two independent tool turrets are used on a CNC lathe to speed cutting. Each tool cuts at the desired depth of cut, with the second tool starting its cut where the first left off. In this way, twice as much material can be removed per pass.

G

G12/G13 Circular Pocket Milling: It is a part of the program that helps in specifying a circular pocket that can be milled. G12 and G13 are types of G-Codes in the part program.

G12 causes the pocket to be milled in a clockwise direction while G13 mills in counterclockwise. The variants of clockwise and counterclockwise are provided so that the user can select climb versus conventional. This tool also is used to cut grooves or slots

Gang Tooling: It is a type of tooling arrangement on lathes, where different cutters are mounted altogether on the cross slide which is then relocated to allow each tool to access the part.

Gang tooling allows the best way to implement multiple tools when a turret is not available.

Gantry Mill: It uses a bridge like an arrangement so as to support the Z-axis that travels across the bridge for Y-Axis motion.

They are also very common for router and plasma applications, and somewhat less so except for large configurations when milling steel.

G-Code: It is a general slang term used for the program that helps in controlling a CNC machine. G-Code is a geometric code used in the programs to determine the type of operation the machine will perform.

Geometric Dimensioning & Tolerancing (GD&T): It is an inclusive set of conventions for communicating geometry requirements aptly.

The benefits of using GD&T is that it provides a clear and concise technique for defining a reference coordinate system and datums on a component or assembly that can be used throughout the manufacturing and inspection processes.

GD&T also reduces the need for drawing notes when describing complex geometries.

H

Handwheels: It is designed to manually operate the axis of a CNC machine. Handwheels are connected to an electronic device known as a manual pulse generator (MPG) that helps in sending a signal to the drive motors through CNC controller.

Hardness: It is the resistance of the material to plastic deformation and scratching. It measures how difficult it is for the cutting tool to cut materials.

It is important to know about the hardness of the material to decide how to go about machining it. There are a variety of scales that help in measuring the hardness of the material.

Harmonic Drive: It is a gear drive of a novel design that provides only minimal backlash. The harmonic drive is ideal reduction drive that goes between stepper or servo motors and machine axis.

Heat treatment: it is a process of using the heat in a very controlled manner so as to change the properties of a material. Take for instance; heat treatment can be used to coagulate alloys of steel.

High-speed machining (HSM): It requires the ability of CNC machine axes to accelerate, decelerate, and move quickly to make up for the time lost in making lighter cuts.

The high efficiency, faster cycle time, and more accuracy make HSM one of the desired tools. It facilitates high federates and spindle speed. The cutting force is reduced in HSM thereby improving the life of the tool.

High speed steel (HSS): It refers to the steel used to make cutters. This tool is called high speed steel because it has the ability to withstand the heat of cutting better than milder steels.

I

Idle Current Reduction: It is a driver feature that passes the electricity to the motor at a reduced rate so as to conserve power and reduce heating.

Initial Graphic Exchange Specification (IGES): It is a vendor that follows an independent standard for exchanging CAD information or files.

Index Pulse: It is usually associated with spindle indexing that determines when a point on a rotating shaft has been passed.

Indexable Tooling: This tooling use carbide inserts as the cutting edges. When the insert breaks off, it gets replaced with a new one for a fraction of the cost of replacing the whole tool.

Insert: This is one of the easily changeable cutting surfaces that can be used with indexable tooling. Inserts are very economical when compared to the cost of replacing the entire cutting tool.

Insert Drill: It is a type of indexable tooling that makes use of carbide insert to bore a hole. Insert drill is designed for a specific size of a hole.

Insert drills have coolant passages that allow coolant to be easily pumped through the drill and down to the bottom of the hole.

J

Jig: It is generally used to guide and hold the workpiece. A jig helps in guiding the tool but a fixture does not.

Jog Mode: It is a mode in which the operator manually causes the axis to move under the power. Jog mode causes the axis to move under power.

It is often convenient to jog using a handheld pendant control. This mode is used to control the speed of jogging.

K

Keyboard Emulator: It is an electronic circuit that accepts a number of inputs and converts them to keystrokes which are then fed into the PC’s keyboard input.

IPAC is one such example of a keyboard emulator board. Keyboard emulator is one of the convenient ways to add additional control panel inputs on a system that uses a parallel breakout board to conserve scarce input lines on the parallel port.

L

Lapping: It is a process of rubbing two abrasive surfaces together ensuring that they fit smoothly and closely together. Lapping cannot ensure flatness rather it may achieve just the opposite effect unless carefully applied.

Laser Interferometry: This is one of the very high precision methods of measuring dimensions that is often used to align commercial CNC tools.