How Engraving Plaque Has Become Easier with OMNI CNC Router?

A CNC router is one of the most versatile types of engraving machines that make woodworking, drilling, and engraving easier. This tool is specially designed to engrave a plaque with intricate and alluring designs. To transform your artistic dream into reality, buy engraving CNC router from OMNI CNC.

Introduction

Gone are the days when individual and businesses used to rely on manual carving, molding or engraving of different materials to produce plaque, trophies, medal, etc. It was until the evolution of CNC routers that fabrication of unique designs became possible.

With the increasing advancements in the technology, numerous manufacturing companies began using CNC routers to produce products with excellent properties.

Regardless of the type of cutting, a CNC router engraves a variety of products ensuring its perfect fit. CNC engraving machine prides on its versatility.

Over the years, CNC routers have gained accuracy as compared to the past. Unlike earlier, CNC routers work on CAD files. The user has to simply arrange the CAD/CAM files and CNC router works on the basis of those set configurations.

CNC router for engraving makes a big impact on the manufacturing and engineering world. The use of an engraving machine enables people to express their creative though through precise engraving. CNC routers have the ability to churn out many pieces with the right mix of software.

CNC Routing and Engraving

Engraving is a unique process or art of etching designs on the hard surface. From brass, copper, wood, aluminum, stainless steel, etc are used for engraving both functional and stylish designs. Thanks to CNC router, engraving plaques now have become easier.

Now, it involves simply placing the plaque board in the router machine and produces the finished results. The results look stunning. The message along with graphics is etched in the plaque giving appealing look like never before.

Plaques can be engraved in different types of materials including stainless steel, anodized aluminum, brass, glass, wood, etc. Whether it is an opening ceremony, memorial, or souvenir, plaques are considered one of the best ways to express emotions.

It is suitable for exhibiting exterior and interior giving a stylish and modern touch to the place. CNC routers engrave plaques beautifully and filled with pain to make letters and design noticeable.

How CNC Routers Engrave Signs & Plaques

CNC routers have made engraving easier. To create an engraving plaque and signs, it is important to create a dimensional design in Computer Aided Design (CAD) software.

Within the CAD software, a designer can define the shape and size of signs which you want to be engraved. Along with signs, the layout, lettering, and the graphic elements also help in making up the finished product.

The manufacturer adheres to the specifications of the client and ensures that the finished product is exactly similar. After the layout of the plaque and signs has been designed, the manufacturer programmes the code of the layout on the CNC machine.

They adequately define the size and depth of the cut and place the material to engrave signs and designs as suggested by the client. The router will follow the specified route to cut or engrave the plaque to make up a design.

The machine works as per the set configuration and does the rest on its own. Depending on the design of the plaque, the manufacturer has to change the size of the cutting bit part-way through the cutting processes and sweep away the waste so as to prevent any type of clogging or blockage.

After the machine completes the engraving process, the material can be removed from the machine and remaining finishing work can be performed.

CAD/CAM Software

A right programming software will be required to turn the block of wood or a piece of metal into a shield, plaque or precisely speaking a valuable product. This CAD/CAM application is controlled by the operator and the machine is instructed to perform all necessary functions.

The process of manufacturing a product results in fewer mistakes and maintains a higher level of consistency in the items produced. CNC router is one of the most popular tools used for making nameplates, plaque, etc.

A plate or plaque gets engraved with the desired design that includes dates, names, geometrics, logo, etc.

A CNC router provides engraving services for both personal and commercial purposes. Today, modern CNC routers create endless opportunities for engraving signs with most intricate designs.

The CNC router drills or engraves in three directions such as X, Y, Z. In X-axis, the CNC router will run from left side to right, while in the Y-axis, the router runs from front to back of the panel and it is considered as one of the longest runs.

In the Z-axis, the router runs up and down thereby giving depth to the product created. These three dimensions take care of the intricacy and the quality of design created on the material.

Plaque engraving and routing is a great way to learn about CNC routers and engravers.

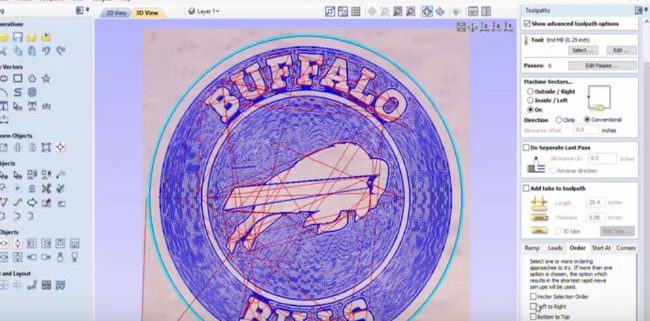

https://www.youtube.com/watch?v=9jxvOjqWhn4

This video showcases the capabilities of CNC machine and versatility of our systems to generate revenue and cost of doing business. You can figure out through this video how a football team plaque can be carved with the help of CNC router.

Let us take a look at the instructions given in this video:

Step 1: Start a new file

- Open Aspire

- Click on the ‘Create a New File’ icon and go to File Operation section

Step 2: Create vectors and set the thickness of the plaque

- Click on the draw icon- create vectors selection

- Select internal radius- corner selection

- Select figures in the radius field

- Now enter width in X

- Enter height in Y

- Job size (X and Y) section

- Enter thickness of the material in Z

- Select Z Zero on the top of the material in material section

- Click on the OK option

Step 3: More Vectors

- Create vectors section

- Enter buffalo design or desired text

- Switch to the Toolpath tab

- Click on OK button

Step 4: Profile Toolpath

- Select the toolpath operation section

- Enter the depth of the cut

- Establish a point so that you can continue cutting

- Select V-bit at 90 degrees which you are going to use for carving the plaque.

- Re-establish the point so that the user continue cutting without losing the material

- Enter the speed of the spindle

- Select inches in the federate

Step 5: V-Carve Toolpath-Order of cutting

- Click on 2D view

- Go to toolpath icon and select V-carve engraving toolpath and save the file

- Next select Pocket cutting and save the file

- Finally, click on Cut Out option and save the file

Remember: by saving the files in order, it would be easier for you to carve the files and make a clean and clear-cut from the CNC machine.

- Click on Add tabs to the toolpath

- Now adjust the inches

- Save the file, so that you do not lose the work

Step 6: Save G-Code

- Select Toolpath list

- Click on save Toolpath icon

- Now, check all the visible Toolpath to one file

- Select the document fold and select G Code

- Enter Football plaque G code in the file name

- Click on the save button and then close.

Step 7: Save the file

- This option will help saving an Aspire file with all the vectors which you created.

After you successfully save all the option, you can simply place the wooden plaque on the CNC machine and start carving the wooden board into football plaque. CNC router systematically engraves any type of material with simplicity.

Components of CNC Routers used for Engraving Plaques

There are numerous CNC routers used for engraving, let us take a look at some of them:

1. Computerized Controller: A CNC machine is operated by a computer which is considered as the brain of the machine. The machine is regulated by CAD and CAM commands that demonstrate how to cut and engrave a design on materials.

2. Spindle:

It is a type of rod or pin that can run on high speed to drill or cut a material. This component helps in cutting wooden materials and designs the material using G-code.

The spindle rotates at the speed of 9000-24000 RPM. It is important to maintain the variable speed when a craftsman uses a router to create designs.

3. Cutting Bed:

The cutting bed helps in securing the piece of wood that is being engraved. Most of the CNC routing machines make use of T-slot or vacuum table cutting bed for securing the material for panel processing.

The T-slot system makes use of bolts and clamps that secure the wooden panel or other materials to the bed.

4. Linear Drive System:

Each axis of the CNC router is regulated by a linear drive system that helps in moving the spindle.

The drive system engraves letters and signs perfectly on the wood and the different types of material. CNC machine perfectly cut letters out of the wood in a different layout.

In addition, CNC router is one of the most versatile machines used for cutting, carving, engraving, and drilling a range of different materials at an exceptional rate.

If you purchase this high-speed machine, the probability of work-related injury diminishes significantly thereby maximizing the production rate and profit.