How to Prevent Heavy-Duty Freight Damage While Shipping?

Are you facing problem shipping heavy-duty machines to international companies? Moving heavy-duty CNC equipment across the country or just across the city can be a challenging task. Product damage during shipping has become very pervasive issue these days. Both buyer and seller face severe logistic issues. Transporting has become a very big concern.

However, it is very important to ensure that the product that is shipped reaches its destination safely with the utmost care. There are some factors that should not be overlooked. This article highlights some important pointers that are worth considering.

Industrial machinery is more complex and sophisticated; requiring specialized while shipping and transporting. Some equipment is small enough to be packaged while other items like CNC machines are large enough to be packaged. This is why; large packaged machines require dedicated truckload services to ensure safety to the product.

Some highlighting points to be considered:

1. Select Packaging to Reduce Freight Damage

One of the primary functions is to ensure that the material is packaged with corrugated cardboard. Since the logistic companies stack pallet on top of each other, so it important to ensure that the cardboard used in packaging has sufficient strength and stability to restrain the load of other boxes. Corrugated cardboard comes with varying flute patterns as well as wall thickness.

Of course, shipping heavy-duty products are perceived as a major hassle by many potential buyers. Fragile products need to be delivered safely. To ensure the safety of products, it is very important to pack the equipment or machine in corrugated cardboard to prevent the freight from being damaged.

Corrugated packaging provides cushion to any type of product keeping the item protected from constant shipping and handling. The corrugated package is specially designed to provide cushioning for vibration protection. The tear resistant qualities keep the packaging protected from exposure.

There are different types of packaging that most manufacturers use for packing CNC equipment. Let us take a look at some of them:

i. Pallet Packing and Construction: While stacking products on a pallet, there are some thumb rules that are required to be followed:

- Ensure that the pallet is not over hanged with product packaging

- Evenly distribute the weight of the heavy boxes by stacking them like bricks

- Make sure that the pallet does not have splinter or crack. Always book pallet in good condition to withstand the load of the equipment

- A well-packaged product cannot be damaged during freight transfer. Wrap the pallet properly so that the package doesn’t shift from its place

- Ability to withstand long distance and rough terrains

By following these thumb rules; the risk of damage can be reduced. So pallet packing is one of the widely accepted packaging solutions.

ii. Crate: Crates are large shipping containers often made up of wood, steel, plastic, aluminum, etc. The self-supporting structure of the crates supports the material transported.

- Smearing engine oil on linear guide, round orbit, spindle, rack, etc

- Robust wood packaging solution

- Protect equipment from vibration

- Heat and water resistant

- Safe transit of goods and equipment

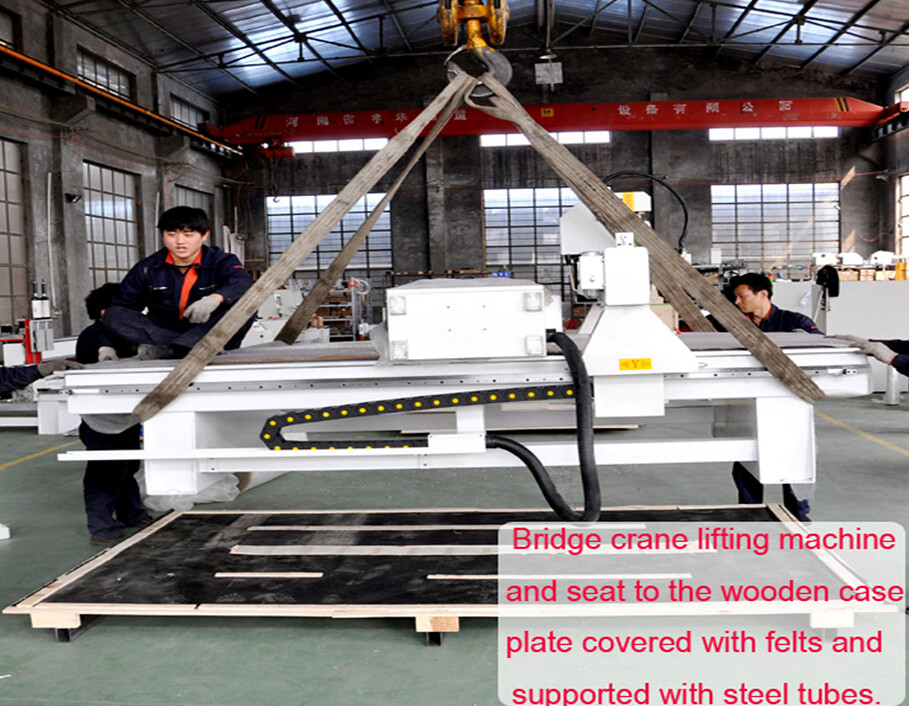

iii. PE stretch film and Wooden Case: This multi-layer elastic polyethylene film to cover the machine. This film is used for protecting the products, ranging from loads bundled on pallets to individual items of large overall dimensions.

Owing to the low thickness of the film and high durability, the film guarantees the stability of the load. Stretch film is the most efficient way of wrapping the products.

- Wrap the equipment with stretch film and bubble wrap

- Bubble wrap spear parts and control cabinets

- Cover the CNC machine a plastic bag to protect it from humidity.

- Tighten the PE bag with the stretch film once again

- Fasten the equipment with wooden case and nail it properly

- Once the package is packed properly, fasten the wooden case with yellow elastic belt

- For gantry moving, fix blocks on X, Y, and Z axis

- Lastly, mark the wooden case or container with a shipping note

2. Environmental Impacts

Logistic company should make sure that when the package is shipped, there is a possibility of environmental impact. Unfortunately, moisture and heat can damage the package. It is said that around 71% of the freight gets damaged due to the highly humid environment causing damage to the product.

To ensure that the package reaches its destination safely, every package should be wrapped with a durable plastic wraps such as shrink wrap or bubble wrap to keep the package on the pallet secure.

The logistic company can also add another level of protection to the package by securing the pallet to the walls of the shipping container or cargo area.

3. Inside the Box

To deliver CNC router door to door, it is very important for the package to be shipped ensuring that the package is in good condition. The way your products are packed in the boxes is the key to prevent the freight from getting damaged.

You can also use partitions or other types of packaging materials to separate and provide cushion to the product.

Packaging with partition can reduce the fear of damage. If shipping fragile items, partitions can protect the items from getting damaged. Cutting down on damage would mean reducing the number of returns and replacements and ultimately diminishing the headache of shipping costs and packaging consumption.

The partitions can be reused as it is made from durable corrugated material. Partition often adds additional durability and better crush resistance to the package. Moreover, it also reduces the hassle of unpacking the items providing better user experience.

The packaging of the products is retail ready. You only need to pick the product and place it on the sales floor, so that it becomes easy to cut open the plastic outer wrapping and place without any hassle.

4. Trucking Logistics

It should be noted that many heavy load carrier companies are less than full load carriers. These types of carriers transmit smaller shipments to their final destination but due to numerous stops, while delivering, there can be a chance of damage.

So, it is suggested to seek the help of smaller cargo style trucks or you can seek the help of a logistic company that can provide the right trucking solution for your heavy-duty equipment.

Moreover, it is advised to use the trucks or vehicle that has air ride suspension to handle fragile products. You should be very careful while unloading heavy machines.

As one side of the machine is heavier so it is important to use fork-lift to lift the machine from the center. This high powered industrial truck is used to lift and move the materials over the short distance.

Apart from this, do you have the right transportation and packaging solution? Mode of transportation is an important consideration when you are planning to ship CNC equipment. Let u take a look at the right transport packaging solution for transporting heavy duty machines and how to prevent it from getting damaged.

As shown in the given link https://www.youtube.com/watch?v=N3WLp4aAhP0&t=1s, OMNI CNC ships CNC 1325 machine to California from China. It is with the help of trucking logistics that many manufacturing companies have been able to deliver heavy-duty machine overseas.

When deciding to import equipment overseas, it is advised to seek the help of the best trucking logistic to deliver your product without any hassle.

Apart from this, there are different types of truck available for the job. Depending on the variety of items that you are planning to ship, one type of truck will be more suitable.

When shipping your products via road transport, it is important to choose the right package designs that give cushioning to the product to prevent it from the vibration caused by the road.

Let u take a look at different types of trucks:

i. Dry Van

This type of truck is enclosed with a trailer that helps in protecting the freight from getting damaged by harmful elements of weather or the road. It is not an ideal transport system for tall equipment or machines as it would exceed the dimension of the trailer.

This type of standard trucks is available very easily but they are not safe for heavy-duty machines.

ii. Flat Bed Trailer

This type of truck is known for its versatility. It is used for carrying all types of items from steel grinders and concrete pipes. The height of a CNC router flatbed truck is 8.5 feet. The items loaded onto the flatbed will require a form of assistance.

The items will be covered with a tarp so as to prevent freight from getting damaged due to weather. Freight damage never happens on a flatbed truck because the machine rarely moves once it is loaded on the truck. One week is normally considered to book a flatbed truck over the standard truck.

iii. Lowboy Trailer

This option is used to haul taller freight that cannot be carried on a flatbed trailer owing to height limitations. Also, this item need not be lifted as high to place into the trailer, therefore it’s an easier loading process.

Moreover, the items in the flatbed trailer will be covered with a tarp to offer protection from the weather.

Also, it should be noted that if the machine or equipment is very long and heavy then it should be shipped on a flatbed truck over the standard truck so as to avoid loading and unloading again and again. Flatbed lorry allows quick and easy loading of goods and transports heavy load with care.

The accurate measurement of the oversized cargo can save your time and effort. Miscalculation can result in hefty monetary consequences. One should always measure the products and items before shipping them so that mode the transportation is available as per the size and shape of the product.

Owing to the weight and size of the heavy sized equipment, some special shipping considerations are required. Tractors, forklift, cranes, etc., are some of the important types of carriers used for hauling or delivering CNC routers or other needs.

iv. Forklift used for Loading and Unloading of CNC Machinery

Loading and unloading of CNC machine from one location to another is a very important task. Many industries and warehouses use tractors, forklift, and similar type of carriers for flawless, smooth, and damage free transaction process.

Of course, moving heavy machinery from one place to another is a difficult task but backed by a proficient and highly qualified team, loading and unloading become an easier task.

Many industries use a forklift for carrying the machine from the dockyard to truck and truck to its destination. This to and fro of the heavy duty equipment ensuring 100% safety is worth valuing.

A forklift is an industrial powered truck used to move materials over a short distance. This 20th-century truck serves the needs of various industries and warehouses.

Powered by electric battery or combustion engines, forklift allows the operators to sit and operate the machine. A forklift is used across the industry for transporting material and goods.

It is mainly used for loading and unloading trucks. Based on the load capacity, CNC router forklift safely lift at different mast angles. The load capacity, height, load center distance, brand, and model number are a few specifications that you should take care of. Inadequate knowledge of the LB forklift leads to serious risk.

Forklift operators should be aware of the following factors:

- The effects of a load, shape, and size on a forklift

- The correct way that a load should be fitted

- Load capacity plate of the forklift

These important factors should be paid heed by forklift operators. If you are buying or hiring a forklift, you should always acquire the load capacity bigger than actual capacity needed. If the load exceeds then you should counteract the load by reducing the weight of the load. You should never exceed the load of the forklift from its capacity.

Train operators also use the load plate to measure the weight rather than assuming the forklift weigh capacity. No matter what type of forklift you are looking for, this equipment handle different capacities required in the workplace.

Unlike earlier, shipping or transporting and loading or unloading CNC machines have become possible with little effort. If you too are looking to ship heavy duty material overseas then this blog is for you.

5. Insurance

It is very important for companies or businesses importing products or equipment overseas to get insured. Marine insurance is very cheap. It roughly charges 50-100 US dollars based on the invoice value of the shipment.

With little additional money, you can ensure your consignment from the transportation damage. But transportation damage doesn’t cover quantity or quality issue, it only carries physical damage to the product.

6. Points to Remember When Your Product Gets Damaged While Shipping

If you are importing CNC routing machine and you received a damaged product, then it is advised to not overlook below-mentioned pointers:

- Take photos and videos of the damaged product

- Make a calculation of the total value loss

- Ensure that this should be supported by the value stated on the commercial invoice

- Contact your insurance company

If such type of problem persists, then it is advised to submit photos of the damaged product. The manufacturing firm will replace or fix the problem.