Water cleaning and replacement

The service life of the laser tube is directly affected by the water quality and temperature. Pure water is best and the water temperature should not exceed 35 degrees Celsius. It is best to use pure water and keep the temperature below 35 degrees Celsius. Ice cubes can also be added to the water to lower the temperature.

(Recommendation) Clean the water tank once a week and change the circulating water.

Important: Before the machine can work, ensure that the laser tube has enough water.

First, turn off the power and let the water flow through the tank. Next, open the water tank. Then, remove the water pump from the tank. Clean the water tank and replace the circulating water. Next, connect the water pipe to the pump to the water inlet. Finally, arrange all joints. Turn on the water pump and let it run for about 2-3 minutes.

Machine & Surrounding Cleaning

Cleaning your fiber laser cutting machine can be the easiest thing to do to extend its life. After each job, operators must clean the machine. Before you start a new job, please empty out all slag bins and drawers. It’s possible for a worker to jam a drawer if they don’t unpack it after using it. This can have a dramatic impact on the table shuttle. Before making another cut, workers must remove all slats. All scraps must be removed so that new material is flat on the surface.

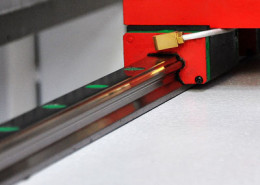

After you are certain that the drawers and slats have been cleaned, turn on the torch. The torch is the core of a fiber laser cutter machine. This part can fail and cause serious problems in the future. Workers should clean the torch body and nozzle as well as the protective window. These parts can be cleaned with lint-free towels or microfiber towels. The laser can make precise cuts by cleaning the torch.

It is important to also clean the area surrounding the equipment. Safety hazards include any debris and scraps around the machine. These items can cause serious injuries to workers if they are tripped over. Before you turn the appliance on, make sure to clean up any mess. You should also inspect the connections to make sure there are no loose wires. It is easy to clean up and can save you a lot of headaches down the line.

Lens Cleaning

The laser cutting machine has 3 mirrors and 1 focus mirror (No. The laser tube’s emission exit is at the upper left corner. No. 1 mirror can be found at this location. The left beam ends with No. 2 mirror, while the left beam ends with No. The laser beam’s left end has the No. 2 mirror, while the No. 3 mirror is at the top. The focusing lens can be found in the lower portion of the laser head. These lenses reflect and focus the laser light and emit it from the laser head. Lenses can become stained by dust and other contaminants. This can lead to laser damage or loss. When cleaning the No. 1. and 2. 2 lenses. Place the lens wiping paper, dipped into the cleaning solution, along the lens’ center. Rotating the edge wipe. Rotating edge wipe. The No. 3 and focusing lenses must be removed from the frame and cleaned in the same manner. They can then be replaced as is after wiping.

Note:

1. You should gently wipe the lens and ensure that the coating is not damaged.

2. To avoid falling, you should gently wipe the area.

3. When installing the focusing lens make sure that the concave surface is down

Coolant Level Monitoring

Similar to plasma cutting systems, sheet metal laser cutter machines vaporize metal and use heat to cut through material. Operators should do all they can to ensure that the equipment doesn’t heat up. To ensure that the coolers are working properly, operators must regularly check them. To ensure that they perform their essential functions, fans, filters and coolant levels must be maintained. The fan and filter can’t cool fiber laser cutting if they are covered with debris. Shop owners can be affected if a fiber laser cutting machine becomes too hot. It is possible to prevent major repairs by regularly checking the cooling system.

Gas Inspection

Gas is used to power fiber laser cutting machines. These gases aid the laser in vaporizing a material. The quality of the cut is greatly affected by the presence of contaminants. You want smooth cuts every time. To ensure it is free from debris, inspect the gas as often as possible. To ensure that they are doing their jobs, inspect the filters. Every time there is a gas leak, workers should change the gas bottles. Leakages not only reduce the flow rate but also impact the equipment’s performance. Leaks pose a safety risk to workers who work with the device. A fiber laser cutting machine gas leak can be fixed easily. You must first turn off the device. After you have replaced the gas bottle, you can rub the connection line with a soapy cloth. Workers should address any leak immediately they notice. You could endanger your safety and productivity by ignoring the problem.

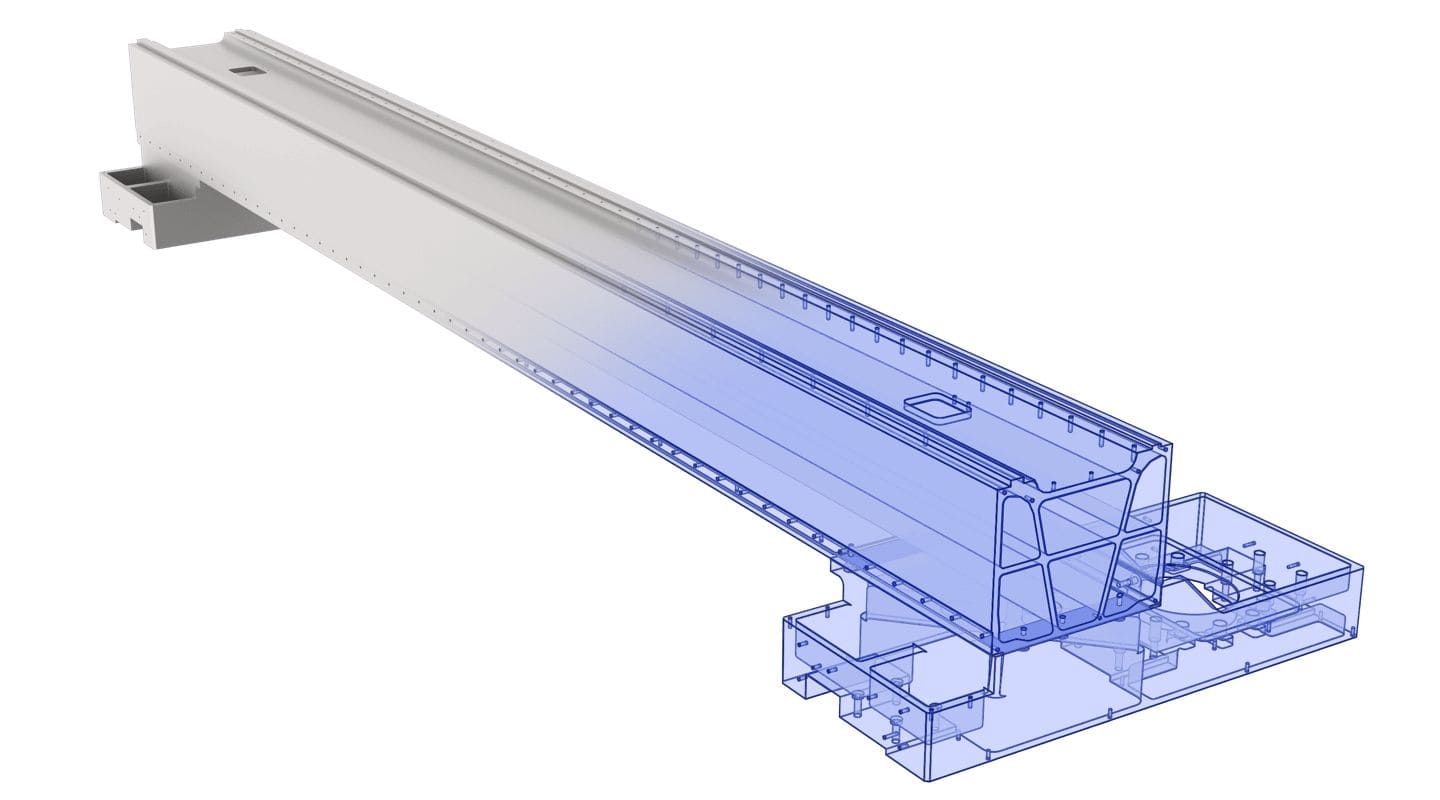

Track Inspection

To achieve the best quality cut, a fiber laser cutter needs to be straight. Workers must inspect the track’s verticality and straightness every few months. The machine will not cut accurately if it is uneven. The edges of the material might be jagged or not smooth. The material might not be cut through all the way. These issues can be fixed by operators who make minor adjustments. To straighten things out, workers can tighten bolts or screws. To prevent lagging, operators should make sure the steel belt is tightly fitted. Operators should immediately contact manufacturers if the problem persists. Mac-Tech’s expert team is committed to making every shop as efficient and productive as possible. We understand how dangerous device malfunctions can be. We want you to get back up and running quickly so that you don’t lose any revenue.