Take Woodworking to the Next Level with CNC Wood Router

1. CNC Wood Router and Its Work Process

CNC wood router is a machine that automatically cuts the wood in a variety of shapes and sizes without any interference of human. This computer numerically controlled machine works on the Cartesian system (X, Y, and Z) for 3D motion.

Cutting, routing, carving, drilling, grinding, and etching are some of the popular features of this machine.

Numerous woodworking projects such as cabinet making, wardrobe, furniture making, wooden toys making etc are performed with the help of this high-tech machine.

A CNC wood router cutting machine is valuable for all types of applications with a wide range of industries such as furniture, advertising, graphics & print finishing, sign making, foam packaging, metal fabrication, cabinet making, aluminum & metal composite cladding, die, and hollow.

This high-quality CNC routing machine ensures that you are investing in value for money and you get the best quality products. These applications support the configuration of the machine so as to maximize the benefits of every business operation and delivers higher productivity.

If you are an owner of a wooden manufacturing firm, then you should focus on getting the best out of the machine. In the long run, this heavy-duty type of machinery serves as an investment for your company.

This perfect machine allows users to create designs within a computerized system. These devices are equipped with a range of features that are used when you are looking to customize the wooden project.

In addition, every material on which CNC wood router operates consists of unique properties. Each material has its unique strength and weaknesses and it is important to select the best types of wood. The right selection of wood will give you a fine end-product that your customer wants.

Let us proceed further to understand which type of wood is best for cutting and how beautifully does CNC wood carving machine produce antique furniture.

2. Types of Wood For CNC Routing

Wood is a very common material. Whether you are using materials like plywood, softwood, hardwood, MDF, chipboard or timber, CNC router wood router machine work wonders.

It can easily process the aforementioned wooden materials for the production of cabinet parts, furniture, dovetail drawers, mantle, decorative carving, etc.

2.1 Hardwood for CNC Routing

Hardwoods typically come from what is known as a deciduous tree. This tree has broad leaves which fall in the harsh winter months. Some examples of hardwood are given below:

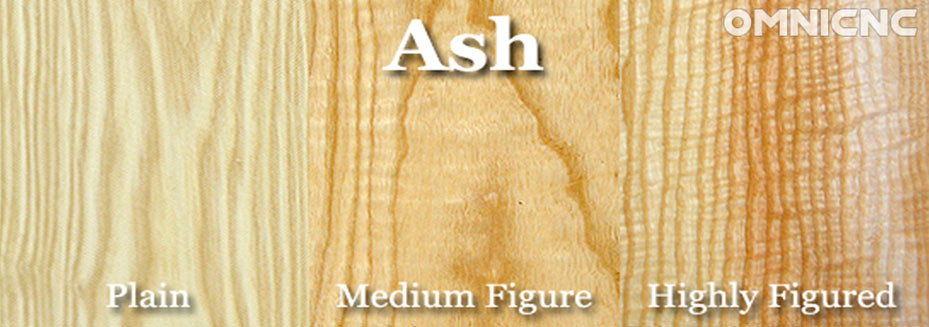

- Ash: heavy, lots of rings, light in color

- Beech: strong wood, stiff, shock resistant, has small pores, light in color

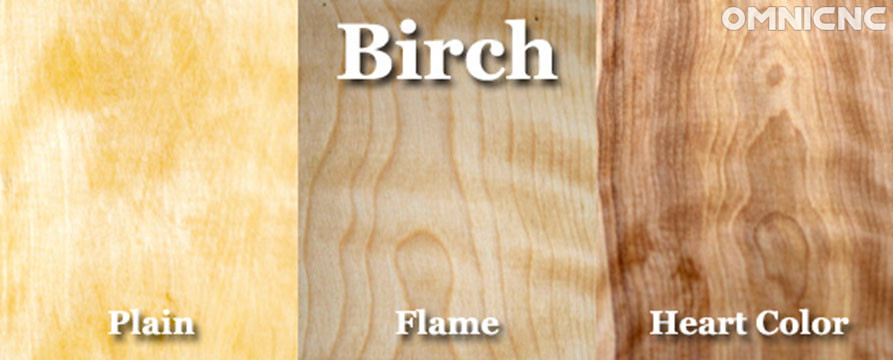

- Birch: light in color, has a wavy grain, stiff

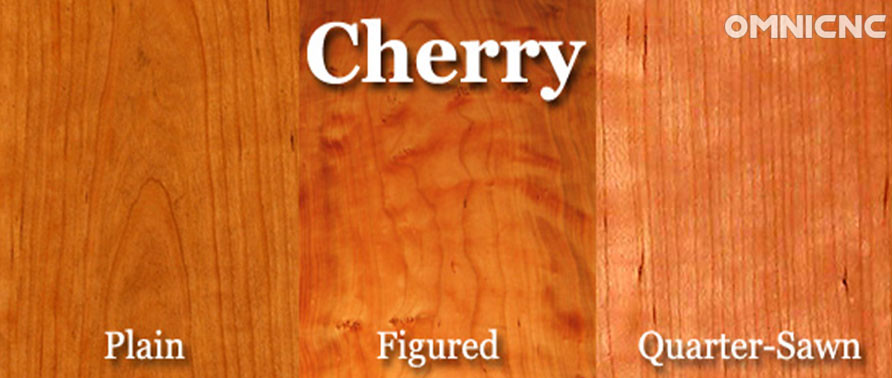

- Cherry: strong, light red/brown wood, resists warping, good for carving

- Elm: Light brown color, low decay resistance, tough

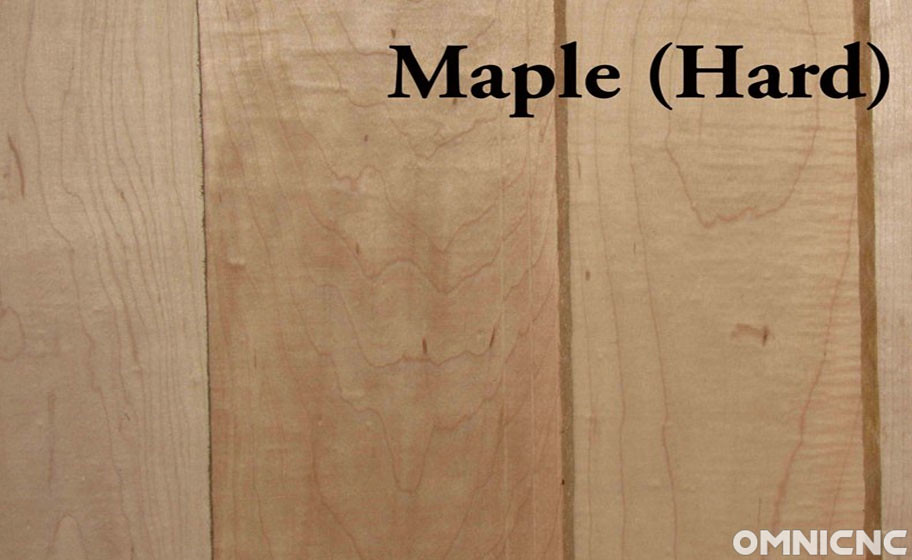

- Maple: one of the hardest woods, resistant to shock, has even pores and grain

- Mahogany: strong, reddish-brown in color, even pores, indistinct rings, good for carving

- Oak: light in color, heavy in weight, strong, prominent ring grain

- Walnut: brown in color, strong, durable, straight grain in the trunk, wavier grain closer to the roots

Maple and cherry are the most ideal types of hardwood over oak and poplar that are used for cutting, carving, and etching. They are denser, less fibrous, and subjected to lesser tear-out.

Hardwood is considered as a good option to experiment and CNC wood cutting machine will bring your designs to life in a matter of minutes.

2.2 Softwood for CNC Routing

Softwoods in most cases come from coniferous trees. Coniferous leaves are “needle-like” rather than the broad-leafed deciduous trees. These needles are designed to retain moisture all year round and thus coniferous trees do not shed their foliage in the winter.

Some types of softwoods are harder than many hardwoods.

- Cedar: Red/brown colored wood, many knots, aromatic

- Cypress: Has many knots, not particularly strong, good decay resistance

- Fir: Even, consistent patterning, easy to work with

- Pine: Pale in color, resistant to shrinking, light in weight

- Yew:Harder softwood, straight grain, medium strength, low stiffness, good decay resistance

- Spruce:Harder softwood, not resistant to decay, light in weight

- Redwood: More resistant to decay from sunlight

There are some types of softwood that are much harder than the hardwood. Hardwoods are majorly used for making furniture, flooring, and construction components.

Hardwood grows slowly and costs more than usual. While both the types of wood catch fire but hardwood has greater fire resistance.

3. What are the Types of CNC Bits and Mills Used for Cutting Wood Parts?

Router bits are considered as one of the primary tools for cutting different wooden parts with wood CNC router machine. Bits mainly determine the kind of carving that is necessary but choosing an accurate bit for carving can be confusing as there are lots of variables to consider while using the CNC router for cutting wooden parts.

Many manufacturing firms use an especial bit for a different type of material they choose for producing end-product. It can beautifully carve and engrave wood at a high speed maintaining accuracy with consistent results.

In addition, you can save a lot of time and cost incurred in creating beautiful woodwork.

Let us see what type of bits and mills are used by CNC wood router for cutting wood designs:

- If you are trying to make straight cuts in plywood, you should seek good quality spiral cutting end-mill for carving and etching intricate designs. Since end-mills come in different diameters, you can either choose to upcut or downcut the wood.

- If you are looking for etching 3D designs on the material then you should be using ball nose bit that has the appropriate size for the level of detailing that you require in the model. Ball nose bits are used to carve fantastic 3D shapes using the tip of the bit to give great detail and smooth contours. You can also use a tapered ball nose bit for intricate 3D carving.

- For sign cutting, badge making, acrylic engraving, etc., you will need a V bit, V-carving bits, V-groove bits, or engraving bits. Since they are available in a different shape; the most useful angles are 60, 90, and 30 degrees. These high precision sign cutting bits are designed with greater versatility and used for high-precision cutting of heavier flexible and semi-rigid materials.

- Moreover, if you are looking for bits for flattening boards, then you should use spoil board cutter or fly-cutter bits for a smooth and flat finish. These bits carefully skim the surface of the material giving a flat and shiny surface to the model. If you are using plywood or laminate material, the bits are designed in such a manner that they won’t mangle the outer veneer layer while bits used for plastics are designed specifically to avoid excessive melting. Also, there are many bits used for various applications but you don’t have to buy all 30 bits if you are prototyping the project.

One very important point that you should consider while choosing a bit is that the bit must be short and stout to produce cleaner and smooth cuts.

Using excessively bigger or longer bits leads to vibration bending of the bit while carving the wood with woodworking CNC router.

Moreover, if you intend to cut or carve a large amount of material, smaller bits will give you best results but they should be sharper enough for smooth and nice cuts as compared to dull bits.

4. What are the Tips and Techniques Followed by a CNC Machine for Cutting Wood

CNC routing machines have been considered as one of the powerful tools for designing and construction industries.

A CNC routing machine possesses all essential tools that are necessary for carving, etching and different designing purposes. 3D cutting, etching, carving, etc., are the most impressive capabilities that a CNC router entails.

Let us take a look at the tooling techniques to improve the operation of the CNC router:

- Smaller Tool: Select a tool that is shortest in the overall length. A high level of rigidity is maintained ensuring the best performance of the operator.

- Proper Rotational Direction: When cutting or etching the material, the tool must rotate in a proper direction so that the finished product looks good.

- Match the Diameter of the Tool: The diameter of the tool and the thickness of the material cannot be overlooked. When an operator is in the process of cutting, with every rotation the material is resisting the tool. The operator must access the project based on the material being cut.

5. Software used by CNC Wood Router

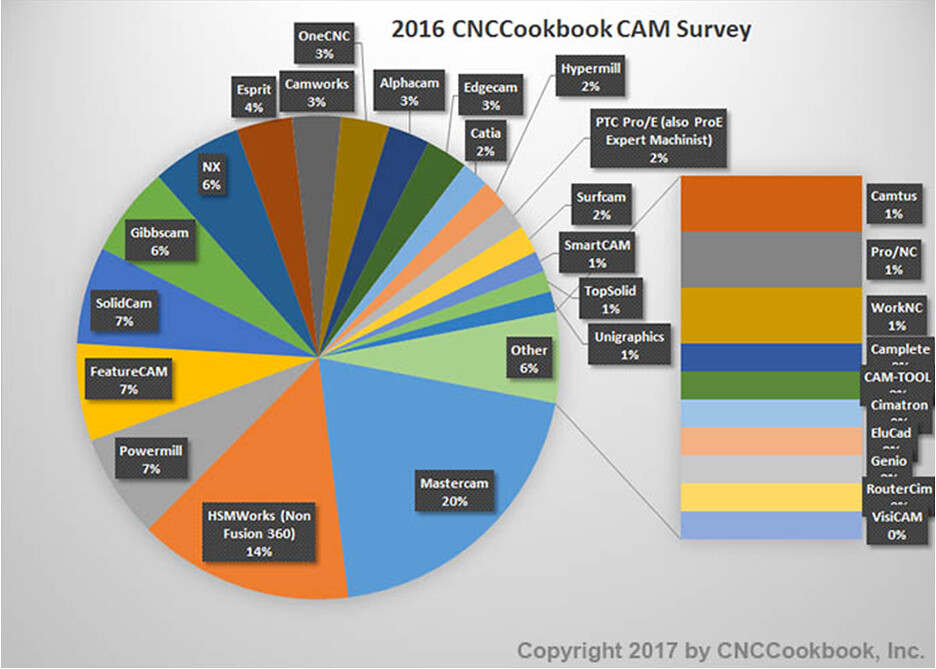

Above is the CAM software market analystic, how about also share a cost analystic? https://www.cnccookbook.com/results-2016-cnccookbook-cam-survey/ See this link. We could mark the resource.

A CNC wood router for sale helps in creating a variety of objects from wood. Most parts of the object are designed with CAD (computer-aided design)/CAM (computer aided manufacturing) program which is later cut with the CNC wood router.

The CAM program is basically used for converting the CAD design into G-Code and this code controls the bits and helps in making the clear design. With the coding language, a lot of functions can be performed such as cutting, engraving, making joints, etc.

The CNC wood router spins faster at a rate of 18000 moving up to 24000 RPM. Along with wood routing machines, CAD/CAM applications such as Artcam, Mastercam, Bobcad, and AlphaCam are used. These applications are specially designed to use with wood routers.

CNC wood routers are generally bigger in size over their metal counterparts. A higher degree of automation, higher productivity, consistent quality, processing complex shapes, and implementing CAD/CAM applications are some of the few advantages of CNC wood router.

Endless Possibilities of a CNC Routing Machine

This computer-controlled routing machine uses all sort of wooden materials and cuts out the most intricate shapes including logos, emblems, fonts, etc. A CNC router offers speed and precision at the same price that is affordable to the craftsman.

This advanced routing machine jeopardizes the authenticity of the product and adds uniqueness to the furniture design. CNC wood router also has a wide range of accessories to customize and meet specific business needs.

Both precision and efficiency are improved dramatically during production with CNC router wood engraving machine.

The hardness of wood makes it difficult for the worker for intricate woodworking. However, as technology advances, CNC machines are in rage these days.

The woodworking industry relies heavily on CNC (computer numerical control) machine now as it offers many capabilities.

It relates to the handheld router used for cutting wood and can perform the tasks of many carpentry shop machines such as cutting and producing complex shapes that would be nearly impossible to create manually.

The CNC machine uses computer software to operate the machine smoothly. It works on the Cartesian coordinate system (X, Y, and Z) for 3D motion control, in almost perfect unison, which makes it easier to carve out complex shapes out of wood. Whether you do wood carving out of the hobby or it’s a part of your business, CNC machine work wonders.

The task of wood carving and etching becomes a lot easier with the wood CNC cutting machine. You just need to design the parts using CAD/CAM software and the machine automatically route or cut the surface with perfect finishing.

CNC machines are in high demand these days. If you too are looking for perfect precision and speed at the price of a craftsman, then it is advised to buy CNC wood router for producing complex shapes and designs.