Tips for your Cabinet Making Production Line

Cabinet Woodworking is not an easy business to be in. Just like other businesses, it also demands time, patience and persistence. There will be times where things will be tough to come by but this will be the time where the character of the person involved will be tested.

Nevertheless, this could be the best option only if things are implemented well. Here are a few tips that could help:

1. Plan Your Business:

There should be a map for building a good house. Similarly, there should be a clear plan to reach the optimum level of cabinet making business. A plan helps by letting an individual know what the specifics of this game if he/she is missing out and enables them to discover the unknowns. It makes them understand the market and their competitors.

Helps them understand the importance of being a legal entity of their own. This also prevents the person from being personally liable if his/her cabinet making business is sued.

2. Define the Brand:

Defining a brand is the most crucial part of any business. A business is always known by its brand rather than its product.

The company stands for the Brand he/she creates. Moreover, the brand becomes the identity of the company based on how the business is perceived by the public. A strong brand will help that person’s business to out-perform its competitors.

3. Identify the Target Market:

A business model is nothing without a target market. The target market chiefly comprises of architects, contractors, and interior designers; hence, it becomes very important to get in touch with them.

These agents are the gateway to the property owner who is the ultimate payer. These agents help a cabinet maker by recommending them to the property owner for cabinets making of their property.

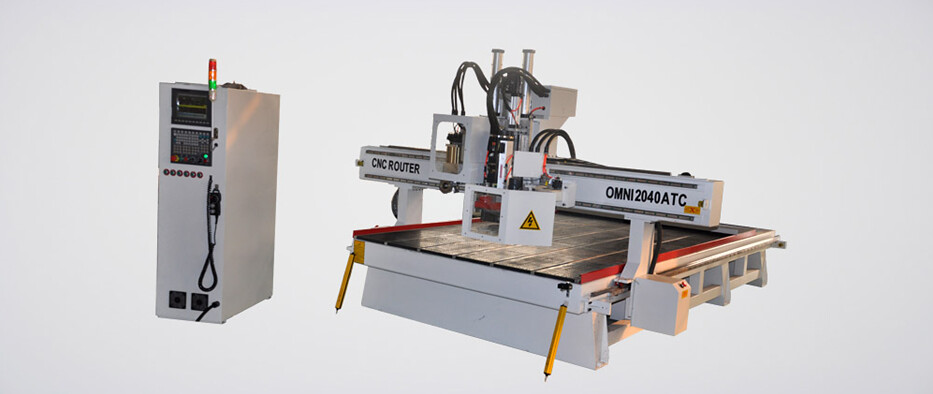

4. Tools are the Property A Business Needs:

These are just a few elementary tips that could help in the making of a cabinet making production line.

However, one needs to understand that there is a factor that is vital for this production line ー the tools.

Tools are the paintbrush of cabinet making business. They determine the position of a person in the market. Anyone who is a part of cabinet making will know to get a perfect cut for a cabinet, the right choice of tool is very crucial.

Hence, here is a list and description of the tools that every woodworker in this industry looks forward to own:

- Claw Hammer

- Tape Measure

- Utility Knife

- Moisture Meter

- Chisel

- Level

- Screwdriver

- Layout Square

● The Claw Hammer:

Perhaps this is the very basic tool that every woodwork has under their possession. The thing to keep in mind while having this is that the claw on one side should be balanced by the weight of the well-rounded finished head on the opposite side.

There is one more kind of head. That is known as the waffle-head. It is commonly used for construction purposes. The special feature of this kind of hammer is that it leaves a waffle mark on the wood while driving the nail. This mark is distinctive in its own way, giving a unique look to the hammered area.

All you have to do is direct the driving surface toward the right nail, sparing the ones on your hand.

However, one must know a fact about the claw hammer. A poorly-balanced claw hammer can twist the user’s hand. Hence, making it difficult for the hammer and the user to drive the nails properly. Normally, people grip the hammer with their hand at the back of the grip, thus, allowing the weight of the hammer’s head to do most of the work.

This allows the user to give direction to the hammer for driving the nail into the surface, resulting in less work (if the technique is right).

Usually, people buy a 20 oz size hammer. This hammer is pretty heavy and works smoothly while driving the nail into the surface and can be very handy when there is a need for pulling out a nail. It is advised that a user should use handles that are either made of steel handle or fiberglass, which is a stronger option.

Nonetheless, a hickory handle is the best when it comes to absorbing the vibrations that are generated while driving a nail. Furthermore, one must ensure that a handle should have a rubber grip which can make work for control and comfort.

Wooden hammers are the best when the work requires driving a lot of nails. They offer a comfort quotient by providing stress to the hand and the wrist.

● Tape Measure:

A precise tape measure is a substantial tool for a woodworker. Pro tip: one should have a 25 feet long retractable tape measure. Anything longer than that could end up having a user with issues of rolling it back.

Considering the fact that the measurements on the large scale projects could likely or liable to be influenced to the slightest measurement fluctuation. Hence, one needs to ensure that the “hook” or tab at the end of the tape is securely attached, assuring not measurement errors.

● Utility Knife:

The woodworker will use the utility knife when cleaning out mortise joints or scribe wood, as well as many other uses.

A good working utility knife is a precious gem for a woodworker. There are a variety of knives available in the market. Out of them, knives with disposable blades are quite popular among woodworkers. The blades pullback in the grip for safety.

A utility knife is a priceless addition in the list for a woodworker. It can be quite handy for tasks like hanging wallboard, cutting cardboard or plastic sheets, and a dozen other jobs.

The utility tool should be handled with respect. It has a design that allows the blade to retract into the body of the tool. There are knives with a button that allows with the flick of the thumb built into the top of the case that slides the blade in and out.

● Moisture Meter:

For the success of any woodworking project that a woodworker undertakes, a quality wood moisture meter is very necessary. If the wood is harvested in a wet region and is being transported to a dry region for the use of the project, there is a probability that the wood will get dried up by the time it is ready to use.

Moreover, it is a well-known fact that the wood needs to have the correct amount of moisture level as per the requirement of that particular area to make a woodworking project a successful one.

There are two types of moisture meters – with pins and without pins.

Using Moisture Meters with pin leaves holes on the surface of the wood while penetrating. These holes require filling.

The pinless moisture meters have sensing plates that scan the wood beneath them. Nonetheless, not all the pinless moisture meters are the same. One must look for the technology that the meter uses. There are meters with IntelliSense technology which enables the moisture meter to not get affected by the moisture present in the woods.

Some of the moisture meters have in them which could be altered for different kinds of woods. Therefore, a woodworker must check each kind of wood they are using for the woodworking project. Also, they should make sure that there is a sufficient amount of moisture content before they start to work to produce their ultimate product.

● Chisel:

A miscellaneous collection of chisels should be a part of every woodworker’s workbench. Every woodworker needs a chisel to clean out saw cuts and joints. Chisel is made up of high-alloy carbon steel or chromium-vanadium alloyed steel.

When it comes to holding a chisel, hardwood grips with metal caps are the best. This prevents the end of the handle from becoming distorted whenever a woodworker hammers on it.

The use of chisel requires the operation of both the hands. The use of both hands allows for power and control of a chisel when it is cutting away the wood. A claw hammer will damage the butt end of the chisel if it is not used properly.

● Level:

No matter who is the woodworker, there is a surety that the woodworker will require a couple of levels. A woodworker might not need a 6-foot level but a 48” level is a good length for almost all the woodworking projects that one handles.

A level can be of different types. One of them is a torpedo level. It is an 8” level. Mostly, the pick of a level depends on the plumb of the woodworker’s construction work is there to be done. The horizontal part is called level and the vertical part is called plumb.

It is observed that the levels are mostly made up of either brass-edged wood or of metal. For level, there is a bubble reading and the other one will be for plumb.

To detect whether the surface is a level surface or a plumb surface, check for the bubble. If the bubble is precisely

between the lines, it means it has a level or plumb surface.

Two more levels are available in the market, they are – string levels and laser levels.

● The Screwdriver:

One of the essential components of a woodworker’s set of tools. The quality of construction needs a good set of screwdrivers.

A woodworker needs a very heavy duty long screwdriver with a square blade. This provides a lot of torque. A small and medium screwdriver also works fine for the woodworker. To screw the screws sitting deep inside a hole requires a screwdriver with think shank especially when functioning on tight places or cabinets in woodworking.

A woodworker probably can grind a high-quality screwdriver material flat when it gets worn out. One thing to keep in mind is that too much heat could change the temper of the metal, thus, weakening it so much that it could not drive a screw.

● Layout Square:

A combination of the square which comes in 6” and 12” sizes is known as a layout square. Mostly, people use a 6” model just for a simple reason and that is the convenience of carrying it everywhere. The layout square is a triangle that is used to mark square cuts on the stocks a woodworker is assigned to use.

Once the length of the cut is measured, the woodworker needs to line up the layout with the edge of the board. The short side of the square will give you a straight and square cut across the end grain.

A woodworker can also measure angles with the layout square. It can also be used to find the existing angles.

The thing to keep in mind is that one should use a metal layout square as the plastic are fragile and the reading on them tends to fade away, thus, making them useless.

There are a lot of things to ponder when a person is looking to invest in a woodworking business, especially when it comes to cabinet making production line. However, there is no hiding from the fact that the above tips and tools description is necessary to lay a solid foundation of a cabinet making woodworking business.