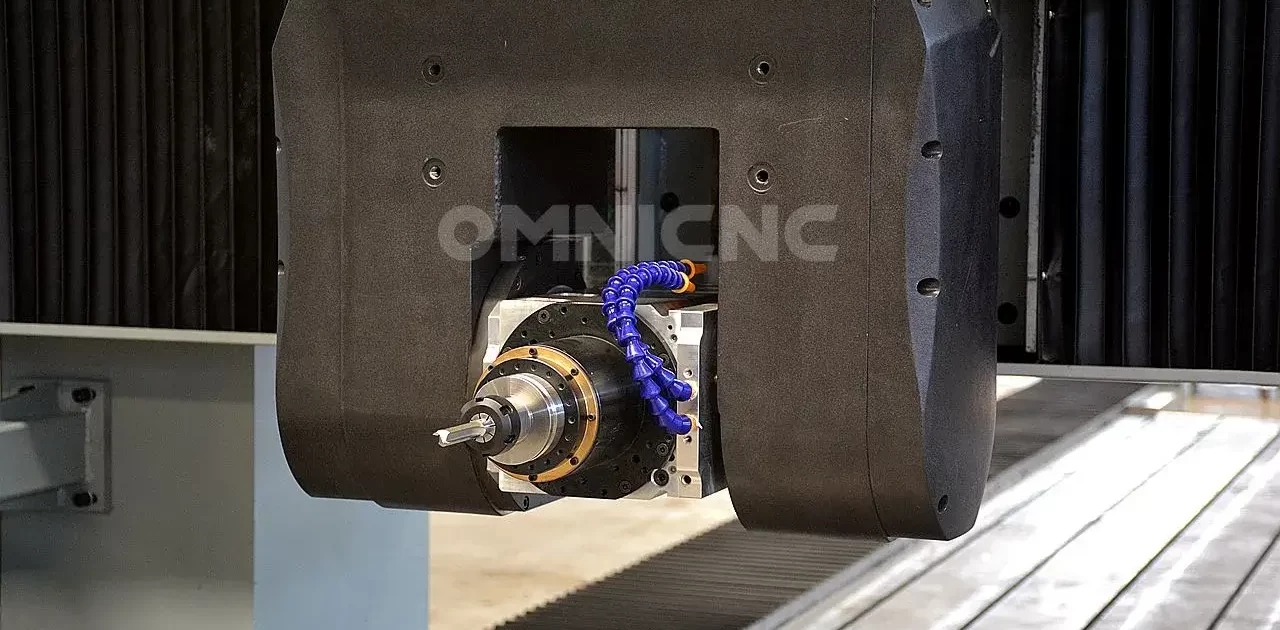

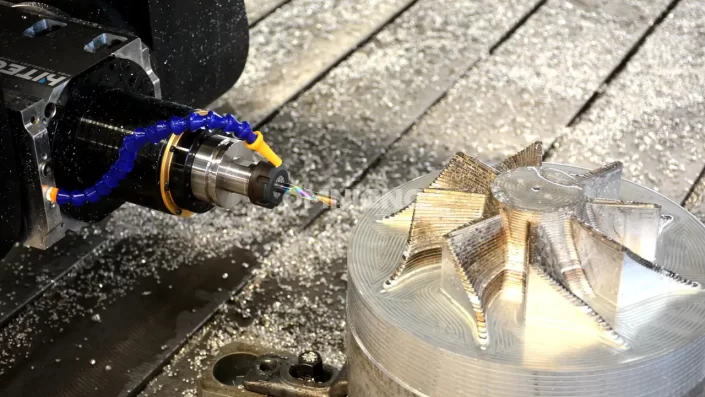

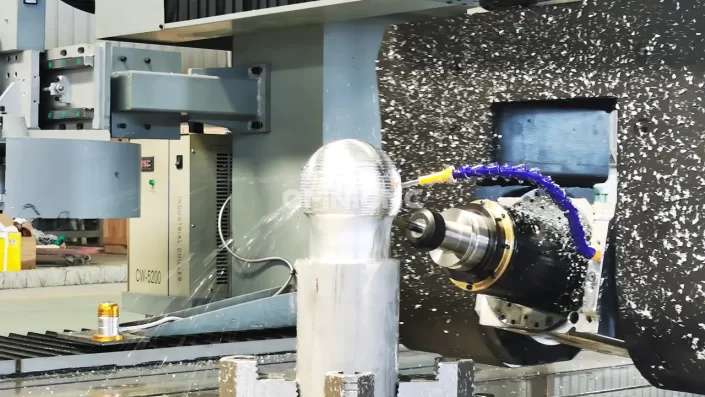

OMNI 2026 Enterprise: Unleashing Potential in Large-Scale Machining

Conquer large-scale machining challenges with the monumental OMNI 2026 Enterprise.

This industrial-grade 5-axis CNC router boasts a massive 6m x 8m working area.

It is ideal for large-scale mold making, aerospace, railway, and diverse machining applications.