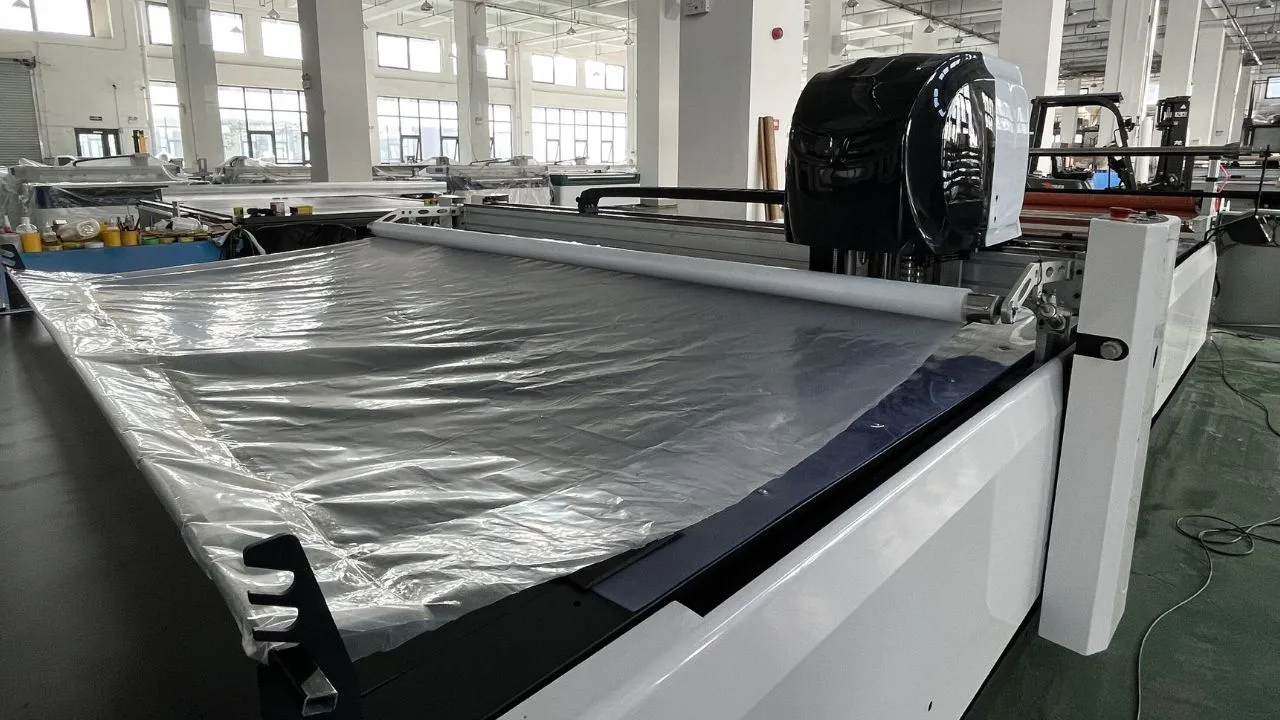

AUTOMATIC INDUSTRIAL FABRIC CUTTING MACHINE

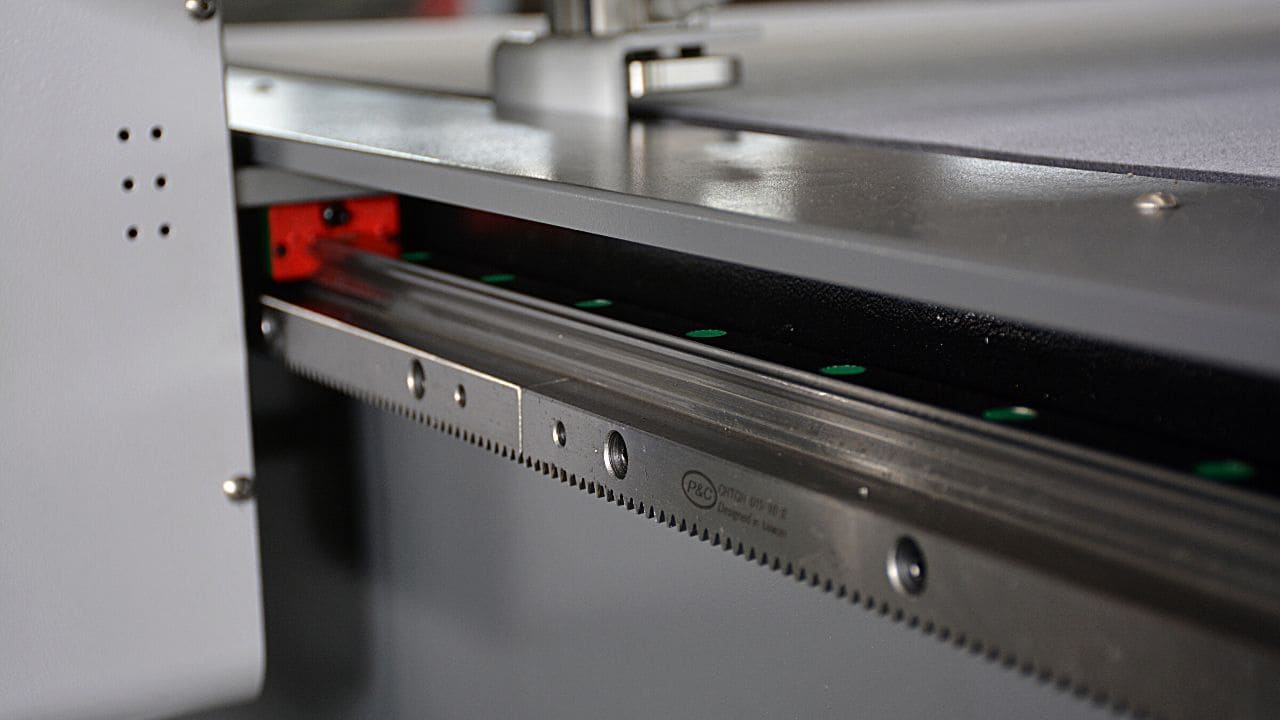

– CONVEYOR TABLE

– SPREADING TABLE (OPTIONAL)

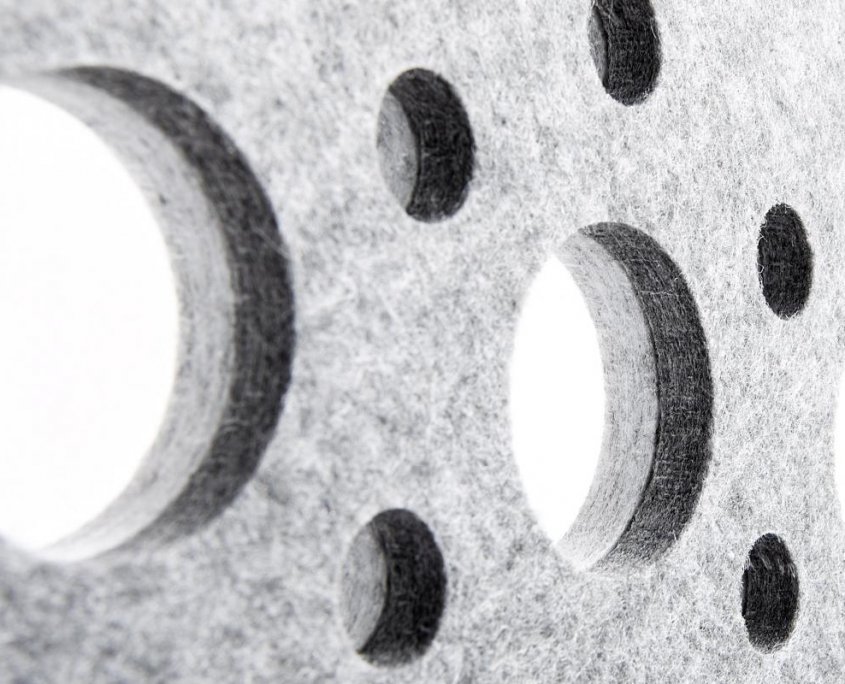

– AUTO BITS POLISHING

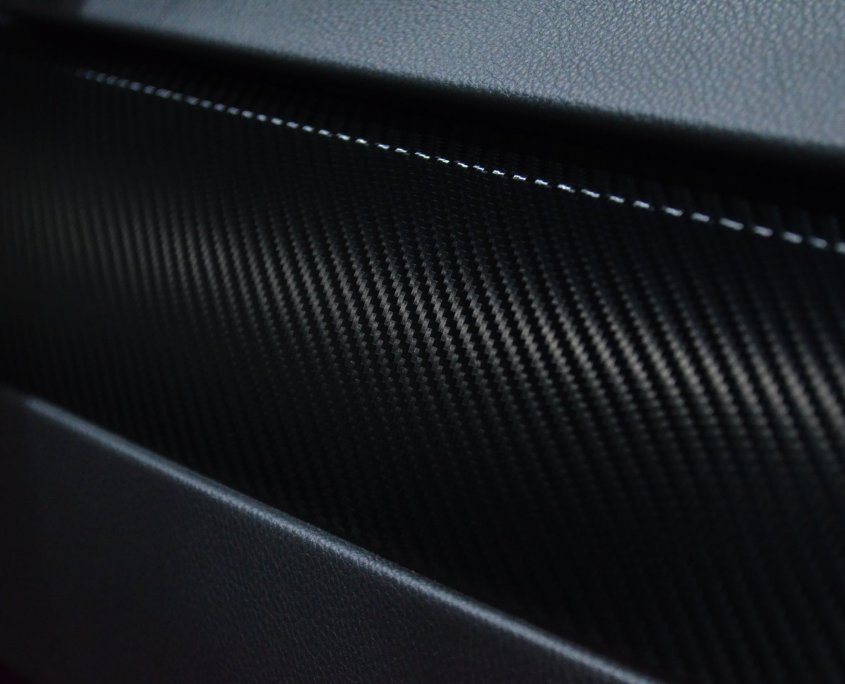

The automatic industrial fabric cutting machine: laser-driven precision that redefines prototyping speed, accuracy, and efficiency for garment manufacturer for batch production and prototyping.

- 10x faster samples & flawless cuts: Unleash your design vision without manual limitations. Intricate patterns? Effortless masterpieces.

- Slash labor costs: Streamline workflow, empower your team, watch savings soar.