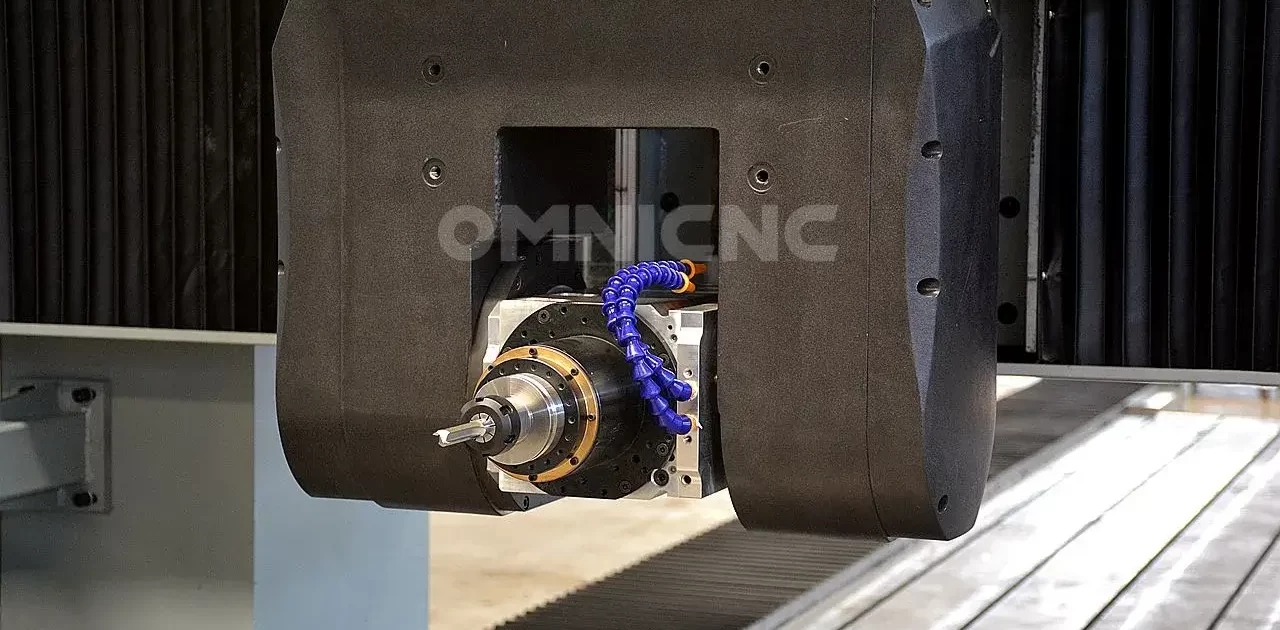

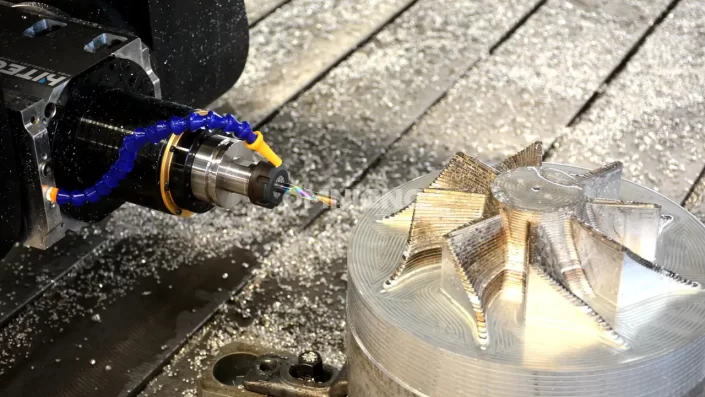

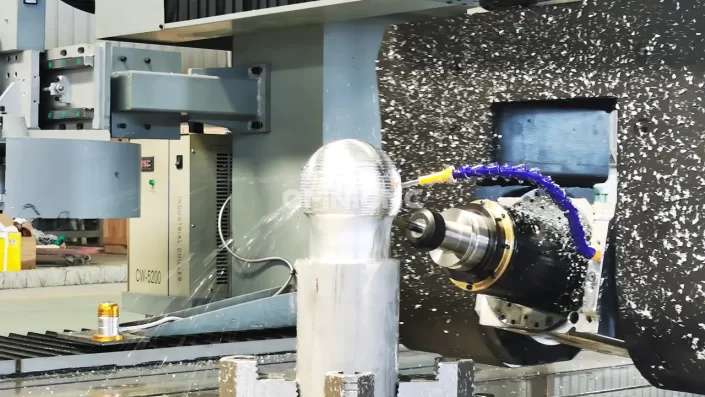

OMNI 1013XL: The Industrial 5-Axis CNC Router for Large-Scale Mold Making

Dominate large-scale mold making projects with the uncompromising power and precision of the OMNI 1013XL, a heavy-duty 5-axis CNC router engineered for professional applications.