[php snippet=4]

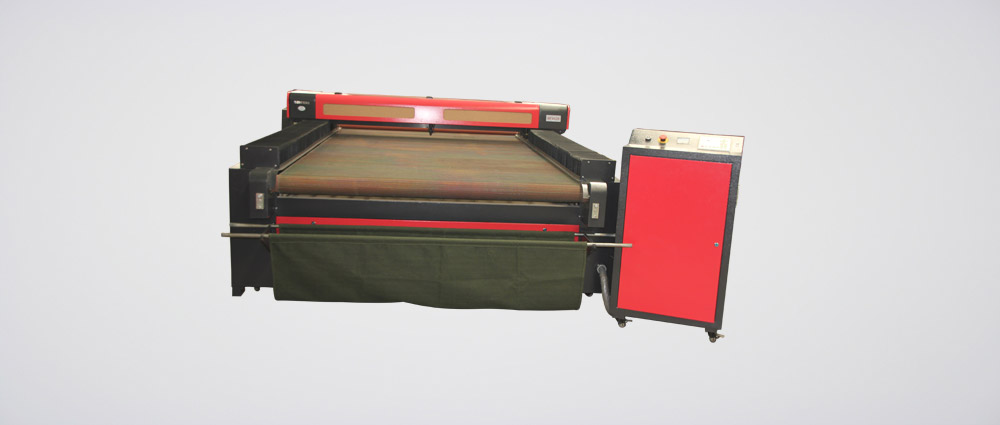

Fabric Laser Cutter for Sale

- Email: sales@omni-cnc.com

- Whatsapp: +86-18615454808

- Skype: omni-cnc

Catalog

[php snippet=3]

Details

Overview

- Limitless Patterns. Lasers are able to cut the most detailed patterns that you can imagine.

- No fraying of fabric. Some fabrics will fray easily when cut with shears or blades. OMNI laser cutting machine can seal the edges of most textiles, virtually eliminating the problem of fraying. This opens the door to limitless new techniques with textiles.

- Higher efficiency operations, less material wastage, and other cost saving benefits. Cutting precisely with scissors or blades can be very challenging, especially if high volumes are needed. With laser cutting (even on leather), you can have repeatable clean cuts with a precision unachievable with shears or blades.

- No limit for textile length. Laser Cutting Shapes can cut endless lengths limited only by the length of your roll of fabric. And there is textile roller mounted on laser machine, which could hold textile and feed textile.

- Suitable for Mass Production. If you work with textiles, you know how difficult it is to achieve consistent results when cutting certain materials with conventional methods. It’s almost impossible to cut the same shape every time.

- Full supported for CAD, COREL DRAW, PHOTOSHOP and other software, USB interface is friendly to use, meet the demand of the market.

Applicable Industry:

Clothing, embroidery cut, cloth toys, paper products, leather goods industry, the model industry, and other needs of a wide-format materials, cutting, carving industry.

Applicable Material:

genuine leather, artificial leather , soft leather, decorative leather, packaging leather etc all kinds of leather, leather materials, pure cotton, real silk, all kinds of chemical fiber, cowboy, and so on .all kinds of textile materials, or non-woven material.

Parameter

| Model | OMNI1326 | OMNI1610 |

|---|---|---|

| Working Area (mm) | 1300×2600 | 1600*1000 |

| Laser Power | 80w 100w 130w | 80w 100w 130w |

| Laser Type | Sealed CO2 laser tube | Sealed CO2 laser tube |

| Working Platform | Z steel conveyor | Z steel conveyor |

| Working Speed | ≤700mm/s | ≤700mm/s |

| Positioning accuracy | ±0.05mm | ±0.05mm |

| Graphic format supported | MP, PLT, DST, AI, and DXF | MP, PLT, DST, AI, and DXF |

| Cooling Mode | Forced water-cooling and protection system | Forced water-cooling and protection system |

| Power Supply | AC110±10% ,50~60Hz, 10A max | AC110±10% ,50~60Hz, 10A max |

| Operating Temperature | 0~45℃ | 0~45℃ |

| Operating Humidity | 5%~95% | 5%~95% |

| Driving system | Stepper | Stepper |

| Option | Double shift function | Double Head Switch |

Accessories

- Main Machine ___________________1 piece

- Laser Tube ____________________ 1 or 2pcs

- Air Pump ______________________ 1 piece

- Fan __________________________ 1 piece

- Air Duct _______________________ 1-4pcs depends on machine size

- Laser Machine Software___________ 1 piece

- Cloth Lift Support ________________ 1 piece

SPTA(Spare parts, tools, accessories)

- Cleaning Fluid-100ml____________1 piece

- Lens Wiper __________________ 1 piece

- Focus Distance Adjuster ________ 1 piece

- Ruler ________________________1piece

- Tool Kit ______________________ 1piece

- Cross Screwdriver _____________ 2pcs

- Straight Screwdriver-3*75_________1piece

- Openend Wrench ______________ 3pcs

- Allen Key 3,4,5,6 _________________4 pcs total

- Needle Nose Plier 6”______________ 1 piece

- Oil Feeder ______________________ 1piece

- Lens Spanner ____________________1piece

Marble Engraving Laser Machine

Marble Engraving Laser Machine