The basic Information on CNC Feed Rate and Speed You Should Not Miss

CNC router has infused a revolution in the cutting and carving industry. With the invention of this device, the job of cutting and carving has become quite convenient.

This computer-controlled machine reduces manual labour and saves a huge amount of time & money.

With the help of CNC Routers, you can achieve the precision which you have dreamt of. It is capable of recreating any type of design on different types of material from any angle.

This device acts as a savior for people performing tasks related to carpentry. But to make the most of it, you need to have a clear idea of the whereabouts of this machine.

Once you know how to use it, you will be able to win the hearts of your clients with intricate and delicate designs.

Here, we will talk in detail about the CNC federate and its speed; let’s start with the definitions.

Certain Important Definitions

The motive behind choosing CNC Router is to carve and cut wood in less time and with minimal or no errors. It improves the productivity as well as produces high-quality products. To achieve the best results, you need to be certain about the technicalities of the device.

Be familiar with your CNC Router and its functioning for enhanced productivity. The precision of the cut about which one can boast depends on the feeds used in the router.

Most of the time, you might have observed feeds and speeds work hand in hand. The reason is that both are crucial to reach the desired destination.

Without Speed, the feed is cannot operate and vice-versa. While one signifies the feed rate, the other cutting speed of the router. Although these two have varied velocities, they perform work for similar results.

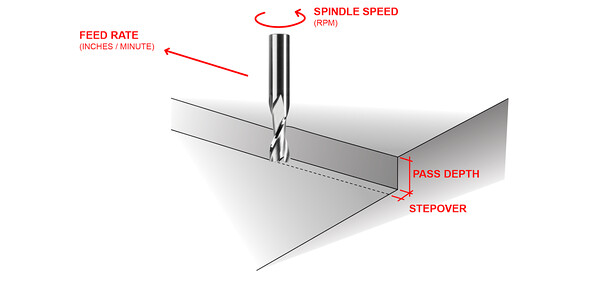

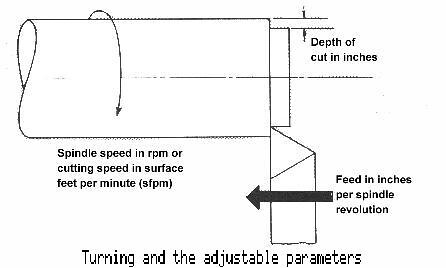

• Feed Rate: It is the velocity required by the tool during one spindle revolution. It is one of the important factors to consider while implementing CNC router. The measurement of a unit of feed rate is distance per spindle rotation: mm/rev or in/rev (ipr).

• Cutting Speed: It is the speed of the tool while cutting or carving the material. The relative velocity between the surface of the material and tool is the cutting speed. It is constant and its units are m/min (meters per minute) or sfm (surface feet per minute).

• Revolutions per minute: RPM is an important factor to measure the rotational frequency. It hints at the number of rotations completed around a set axis in one minute. This rotational speed keeps changing.

• Chip Load: It is the thickness of the material removed by cutting edge while cutting. Chip Load also referred to as Inch per Tooth (IPT).

Calculation of the Chip Load

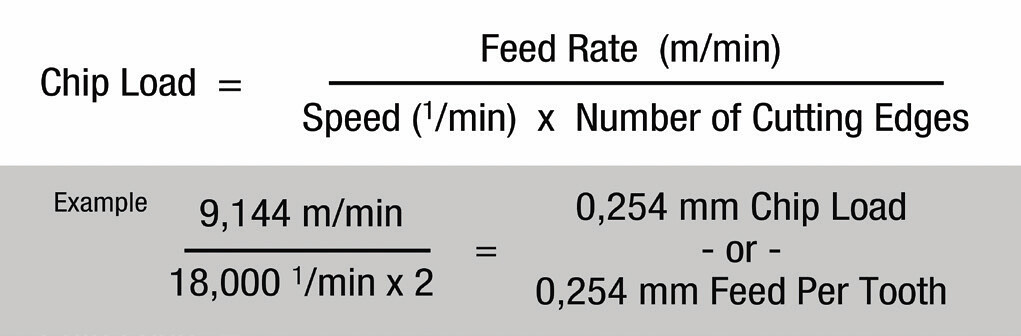

The thickness and the size of chip depend on the forward movement and spindle rotation of the tool. Thus, if you want to alter the chip’s statistics, you need to change these two factors. Here is a simple formula for the calculation of this important chip load:

Chip Load= Feed Rate/ RPM * Flute (Cutting Edges)

For altering the amount of load, you need to:

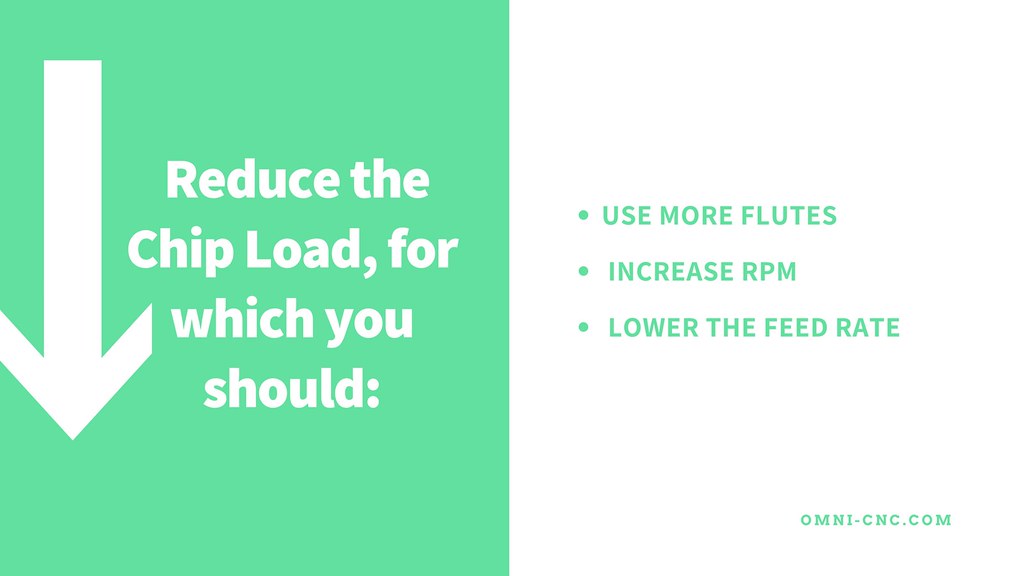

1. Reduce the Chip Load, for which you should:

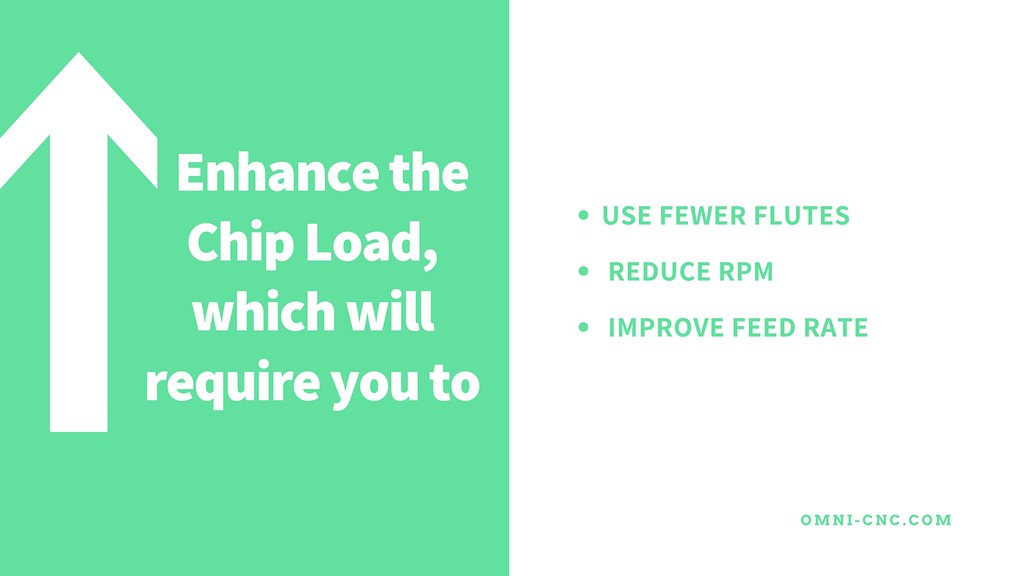

2. Enhance the Chip Load, which need you to:

For better results, it is always wise to make chips instead of dust as it has various functions. Here are some of the most embraced ones:

- It has an impact on the material surface finish.

- It controls the heat, which can lead to tool wear.

- It manages the settings to optimize the working’s materials cut.

- It has an impact on the material removal rate, which has a direct effect on machining duration.

You can also calculate the chip load online by providing the values of the other variants.

Calculation of Speeds and Feeds

To get an accurate result, make sure to maintain proper chip loads. This, in turn, requires you to use the correct speeds and feeds, which depend on many factors. When you find the best feed rate and speed, you will be able to move a step ahead and get the best output from it.

The factors on which RPM and Feed Rate depend include:

- The width and depth of the cut.

- The type and design of the cutter.

- The rigidity and power of the machine.

- The sharpness of the cutting tool.

- Accuracy and finish required.

- The material used to cut through the CNC router

- Material and diameter of the bit.

- Coolant and spindle used.

Apply the following formula to achieve the desired feed Rate.

Feed= N (number of flutes/cutting edges)* Chip Load * RPM

It is evident that the feed rate is different for different materials. You need to remember the relationship between the definitions mentioned below.

About Router Bits

With the help of CNC Router, materials like steel, PCD diamond, Carbide Tipped and Solid Carbide can be cut.

Among these, the solid Carbide is the most preferred because of the following pros:

- It has the best rigidity along with the best finish

- It has reduced cycle times and high feed rates

- It comes with many re-sharpening

- It offers the widest variety of geometries

- It has long tool life with best plunging capabilities

In spite of having these advantages, this particular variety also has some minor disadvantages:

- The initial cost is quite high.

- You can’t re-sharpen the plastic and aluminum tooling.

- You will face breakage if you don’t use it in well-maintained machinery.

Omni CNC has a wide collection of CNC Routers and Router Bits for diverse applications. Let us take a look at them:

Types of CNC Router

- Most Versatile Type

- ATC CNC Router

- Multi-Head CNC Router

- Sign Making CNC Router

- Cabinet, Door & Case Goods Making CNC Routers

- CNC Turner/ Lathe

- 4 Axis CNC Router

- 5 Axis CNC Router

- 4 Axis Linkage CNC Router

- Mold Making CNC Router

- CNC Router Combined Rotary Device

- Stonework CNC Router

- CNC Glass Cutting Machine

Types of Router Bits

- Flat Bottom Engraving Bits

- Three/Four Face Engraving Bits

- Radiused Bottom Engraving Bits

- 3D Engraving Bits

- Two Flute Spiral Bits

- One Flute Spiral Bits

- Half Round Straight Bits

- Three Flute Spiral Bits

- Cleaning Bottom Bits

- Classical Ogee Bits

The tips of all the mentioned bits are different and they are used for different purposes. You can use these bits depending on the design you need.

Miscellaneous

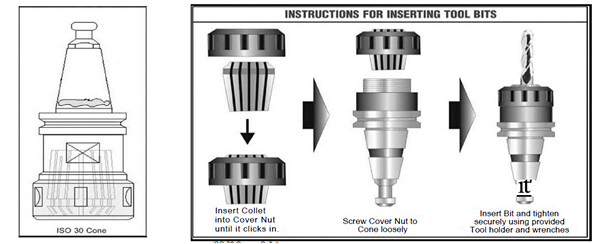

To achieve the desired design on the material, it is important to use appropriate feeds and speed. Also, you have to notice whether all the parts of the tool are proper before fitting the bits. The operator must check the bits using a wrench and tool holder before starting the tool.

Practical Application

If you are uncertain about the maintenance of the speed and feed rate of the tool, then watch this video. John Resler of Sylvan Dream Worxs, a trusted OMNI CNC client clears all your doubts with the help of this video.

He describes all the nuances and introduces to the idea of chip load and its importance. He also shows how to calculate the formulae of chip load. This video displays statistics of RPM, Feed rates, and SFM for various materials used to cut.

Besides showing theoretical terms, John also provides practical application to guide other workers. He uses the router with the same feed rates and different RPM to carve three designs on the same material. Three different types of bits include:

- 90 degree V Bit

- Core Box Bit

- Pointed Roundover Bit

These three types of bits have varying speeds of 12000, 14000, 16000 and 18000 RPM. The Core Box Bits were of perfect quality in look and appearance. 12000 and 18000 variations of the 90-degree bits were smooth while the other option was rough.

Irrespective of the speed, no variations of the third type were up to the mark. Thus, it is clear that even though the material and bits used on the material are the same, the results are different. This difference occurred because of the RPMs.

Conclusion

The reason behind opting CNC router machine is to provide your customers with the best pieces of art. Thus, to experience less wastage and a better work you must set the numerical right.

Ensure that the numerical you set are correct so that no mistake happen. Always note, do not cut the material if you are unsure about the speed and feed rate. This will not only save your material, labor, money but also your time. Thus, it is high time to combine your CNC router with the perfect Feed Rate and RPMs for reaping best results.