Why Choose a 5-axis CNC Router Machine Over a 3-axis and 4-axis One?

Omni is one of the most premium, quality-focused CNC router & cutting machine manufacturers and suppliers in China. We specialize in the design, development, and production of high-performance, low-maintenance, and computer-controlled CNC routers.

Explore our 3-axis, 4-axis, and 5-axis CNC routers — used in machining for varying degrees of complexity and precision in the fabrication of parts.

Aiming to enhance precision in manufacturing? Choose the perfect router for your unique needs for exceptional results. Read on to know why 5-axis machining is superior to 3-axis and 4-axis options.

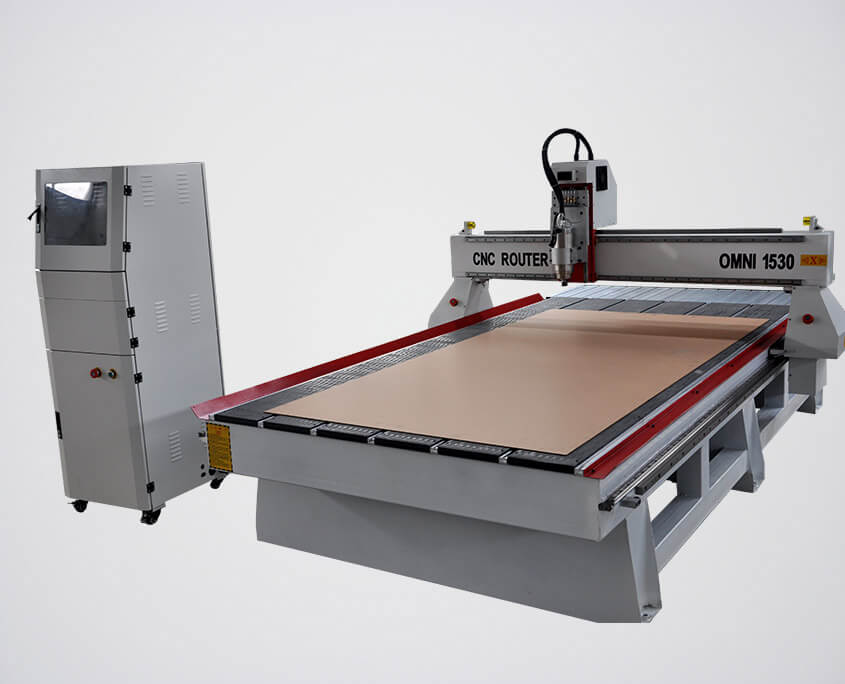

3-axis CNC Router

This CNC router is suitable for machining 2D and 2.5D geometry, handling planar milled profiles, drillings, and threaded holes.

The 3-axis router is unable to machine features at angles to the X-Y-Z coordinate system, such as angled or compound angle features.

4-axis CNC Router

The 4-axis CNC router adds rotation about the X-axis (A-axis) for increased flexibility. It can be a cost-effective alternative, reducing the need for multiple fixtures and minimizing the risk of human error.

It is capable of handling angled features, allowing for the machining of complex profiles like cam lobes.

5-axis CNC Router

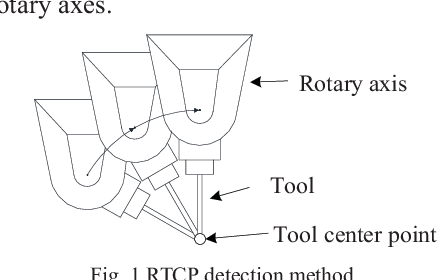

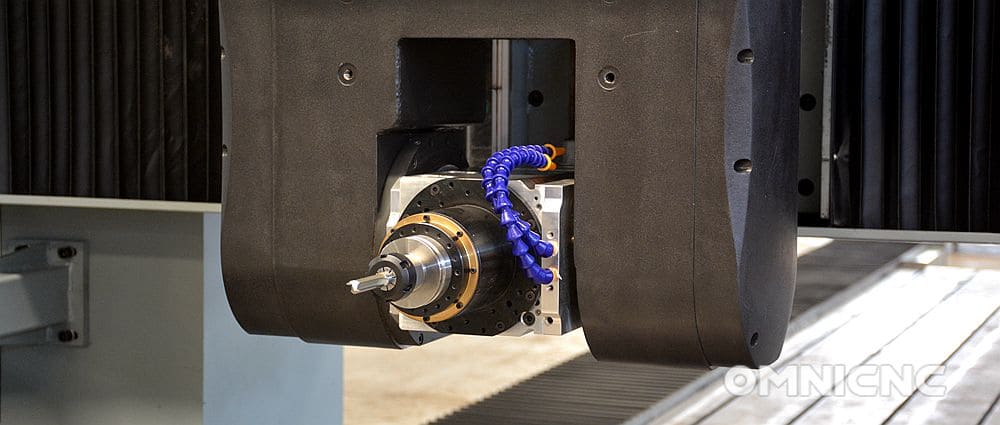

A 5-axis CNC router machine has two rotary axes and three linear directions (X, Y, Z). This router provides unparalleled precision and versatility. It can

- handle complex geometries,

- machine multiple sides in one setup,

- achieve high-speed production, and

- deliver exceptional precision,

The 5-axis CNC router stands as a top-tier solution for industries demanding intricate and efficient machining.

Differences Between 3-axis, 4-axis, and 5-axis CNC Router Machines

These days, CNC technology has evolved to include touchscreen controls, robots, and multiple-axis machines. To provide a better idea of why 5-axis CNC is the best let’s see some major differences

Axes of Movement

- 3-axis: Movement limited to three directions (X, Y, Z), suitable for simpler geometries.

- 4-axis: Introduces rotational movement (A-axis), allowing for more intricate cuts and carvings.

- 5-axis: Provides the highest degree of cutting tool movement, including rotation about two additional axes (B and C), enabling simultaneous machining from multiple angles.

Part Complexity

- The 3-axis is more limited, requiring repositioning for intricate designs.

- The 4-axis provides additional maneuverability, suitable for tasks like engraving and complex profiles.

- The 5-axis offers the most positioning options, allowing for the production of highly complex and detailed parts.

Time Taken

- The 3-axis takes the longest as it often involves multiple setups for complex parts.

- The 4-axis reduces machining time compared to the 3-axis but is surpassed by the efficiency of the 5-axis.

- The 5-axis requires the least time due to its ability to handle multiple facets in a single setup.

Material Management

- 3-axis may face challenges with certain materials, leading to accelerated tool wear.

- 4-axis and 5-axis machining excel in handling hard-to-machine materials, offering reduced tool wear and better efficiency.

Error Accumulation

- The 3-axis accumulates errors with multiple setups, potentially impacting overall precision.

- The 4-axis and 5-axis offer precision in a single position, minimizing error accumulation.

Programming

- 3-axis machines have simpler programs, while 4-axis CNC machining strikes a balance between simplicity and complexity.

- 5-axis machines require a more intricate program due to multiple directions of tool movement and increased variables.

Surface Finish

- 3-axis and 4-axis machines may require additional steps to achieve a smooth surface finish.

- 5-axis machining delivers superior surface finishes directly, reducing the need for secondary finishing.

Why Choose Affordable 5-axis Over 3-axis and 4-axis Machining

The 5-axis CNC router machine emerges as a game-changer in the precision and flexibility-dominant manufacturing industry. Unlike its counterparts, the 5-axis takes the lead by offering a host of advantages that make it the top choice for many manufacturers.

Application

Aerospace parts, medical parts, defense equipment, aircraft parts, dental implants, and other such applications require ultra-high precision. These precision parts can only be created with multi-axis machining like a 5-axis CNC router.

Production Volume

Choose the number of axes based on the production volume you want to manufacture. Small-volume manufacturing can be met with a 3-axis machining process. However, high-volume production requires 5-axis options.

Secondary Finishing

The 5-axis provides a smoother finish directly, minimizing the need for secondary finishing steps. The 3-axis and 4-axis may require additional finishing steps to achieve a polished surface.

Better Software Compatibility

Adopting an open software interface, it can be compatible with the processing codes generated by various CAD / CAM design software, such as type3 / Artcam / Castmate / Wentai, to ensure the realization of various design functions.

Less Headache, More Options

Tool breakage and collisions can be a headache in machining. The 5-axis router machine, with its multiple options for tool approach, minimizes the risk of tool breakage. It’s like having a skilled craftsman who knows just the right angle for every cut, reducing errors and ensuring a smooth operation.

Conclusion

In a nutshell, the 5-axis router offers a winning combination of precision, speed, customization, and versatility. It’s the go-to choice for those who demand the best in the world of machining. So, if you’re aiming for excellence in your projects, why settle for anything less than the limitless possibilities that a 5-axis CNC router machine brings to the table?

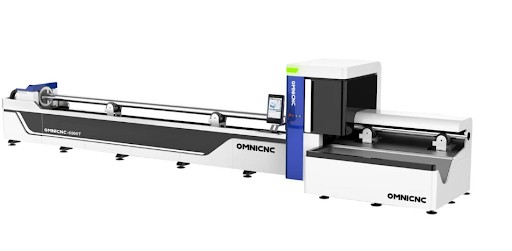

Precision Cutting From Fiber Laser Cutting Machines in Metal Tube Bevel Cutting

In the evolving landscape of industrial manufacturing, the demand for precision and efficiency continues to drive technological advancements. One such marvel in metalworking is the fiber laser metal cutting machine, specifically designed for the intricate art of metal tube bevel cutting.

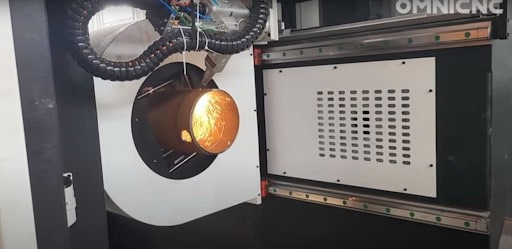

Understanding the Essence of Fiber Laser Cutting for Metal Tube Beveling

The Omni Fibre Laser Cutting Machine is a versatile powerhouse. Its primary function is to carve precise bevels on metal tubes, catering to various industries such as automotive, aerospace, construction, and more. Whether round, square, or other profiles, the fiber laser cutting machine handles metal tubes with unmatched precision.

Safety First: Operating a Fiber Laser Cutting Machine for Tube Beveling

Cutting metal tubes with a fiber laser demands meticulous attention to safety. Here are some crucial precautions:

Protective Gear

Laser Safety Goggles are essential for shielding eyes from laser radiation and bright flashes during the cutting process. Molten metal slag and particles generated during cutting can be hot and sharp. Appropriate gear prevents burns and cuts.

Ventilation and Safety

Fiber laser cutting produces harmful gases and metal vapors. Adequate ventilation and an exhaust system are essential for removing these by-products. Although the cutting process is controlled, having a fire extinguisher nearby is a prudent safety measure.

Avoiding Direct Exposure

Direct exposure to laser radiation can cause damage. Avoid staring at the laser beam and reflective surfaces, and prevent the beam from hitting your body.

Clean Optics Regularly

Clean laser optics regularly to maintain cutting performance. Use approved cleaning supplies and clothes, avoiding direct contact with bare hands.

System Inspections

Inspect all components regularly to identify issues early. Look for damage, leaks, or corrosion in gas lines and coolant systems.

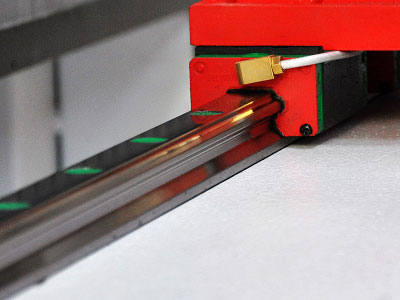

Scheduled Maintenance

Adhere to the recommended maintenance schedule. Tasks such as lubricating motion systems, calibrating sensors, and replacing filters contribute to optimal machine performance.

Workspace Organization

A clean workspace ensures efficient operation. Wipe down the machine exterior, and eliminate debris and clutter to prevent accidents and optimize cooling and gas flow.

Training for Operators

Operating and maintaining a fiber laser cutter requires comprehensive safety, usage, and maintenance training. Properly trained operators can maximize machine potential and longevity.

Custom Cutting and Wastage Reduction with Fiber Laser Machines

Their fine-tuned control through CNC technology enables the production of complex shapes with microscopic accuracy, making them ideal for both one-of-a-kind custom shapes and batch production. The efficiency and speed of the cutting process contribute to large-scale manufacturing, while minimal material waste and optimized cutting paths align with sustainable practices. Beyond mere tools for metal fabrication, Fiber Laser Cutting Machines serve as catalysts for innovation, fostering creativity and redefining design possibilities across industries.

Why Choose an Omni CNC Metal Laser Cutter?

The cutting process is a symphony of precision, efficiency, and advanced technology. Let’s understand why you should opt for this cutting-edge equipment:

Precision Cutting

The laser beam, focused on a narrow point, circumnavigates the complete circumference of the tube. This results in continuous cuts at any angle or pattern, making it a preferred choice for applications requiring intricate designs and precise geometries.

Power Options for Every Need

Fiber laser metal cutting machines come with a range of power options, allowing users to tailor their equipment to specific cutting requirements. Whether it’s a 1KW, 2KW, 3KW, 4KW, 6KW, 12kw or even 20kw machine, the power selection ensures optimal performance for different materials and thicknesses.

Automation and CNC Systems

Laser cutting machines are often equipped with Computer Numerical Control (CNC) systems, adding a layer of automation to the process. CNC technology allows for precise control over the laser’s movements, ensuring that the programmed design is executed with unparalleled accuracy. This level of automation not only enhances the speed of production but also minimizes the margin of error, contributing to the overall efficiency of the cutting process.

Speed and Efficiency

One of the most notable advantages of fiber lasers is their speed. The cutting process is significantly faster than traditional methods, leading to increased productivity and shorter production cycles. This speed is especially advantageous in high-volume manufacturing scenarios where meeting tight deadlines is crucial.

Conclusion

The omni Fiber Laser Cutting Machine for metal tube bevel cutting represents a leap forward in precision engineering. Embracing this technology, coupled with a commitment to safety and maintenance best practices, empowers manufacturers to achieve unparalleled accuracy and efficiency in fabricating metal tubes. As industries continue to evolve, the fiber laser cutter stands as a testament to the relentless pursuit of excellence in the world of metalworking.

Mastering Complex Geometry: The Power of 5-Axis CNC Routers for Precision Machining

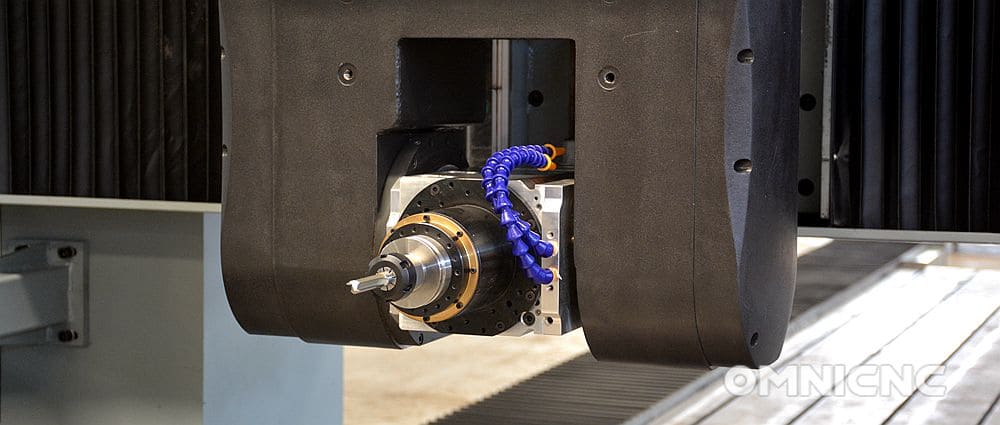

In the modern manufacturing landscape, CNC machining reigns supreme, shaping intricate parts across industries like aerospace and medicine. But traditional 3-axis routers stumble on complex curves and angles. Enter the Omni 5-Axis CNC router, a revolutionary machine that transcends flat planes with five axes of surgical precision. It sculpts impossible geometries, effortlessly navigates intricate landscapes, and achieves breathtaking detail like never before. The Omni 5-Axis CNC isn’t just a machine; it’s an invitation to push the boundaries of what’s possible.

What is 5-Axis CNC Machining?

-

Key differences between 3-axis and 5-axis CNC routers.

Cracking the Code: Deciphering the Differences Between 3-Axis and 5-Axis CNC Routers

Imagine carving a sculpture – while a 3-axis CNC router meticulously chisels away at flat surfaces, a 5-axis machine pirouettes your masterpiece into existence, dancing across angles and curves with unbridled freedom. This captivating metaphor aptly captures the fundamental difference between these two powerhouses of precision.

Think of 3-axis CNC as a skilled artisan, confined to the two-dimensional canvas of the XY plane.

It excels at tasks like cutting flat panels, engraving designs, and drilling clean holes. Its movements are restricted to left-right (X), forward-backward (Y), and up-down (Z), like a painter meticulously shading within the lines.

But 5-axis CNC enters the scene like a master sculptor, wielding five axes like nimble fingers.

Not only does it command the X, Y, and Z, but it also pivots on A and B axes, tilting and rotating the cutting tool with mesmerizing dexterity. This unlocks a whole new realm of possibilities – undercuts, intricate grooves, complex 3D geometries – terrain that 3-axis machines simply cannot navigate.

Here’s a table to visualize the key differences:

| Feature | 3-Axis CNC | 5-Axis CNC |

|---|---|---|

| Movement Axes | X, Y, Z | X, Y, Z, A, B |

| Working Plane | Flat (XY) | Multi-directional (5 axes) |

| Capabilities | Flat panels, engravings, drilling | Complex shapes, undercuts, 3D geometries |

| Advantages | Simple setup, cost-effective, precise in 2D | Versatile, efficient for complex shapes, high detail |

| Disadvantages | Limited to flat surfaces, struggles with angles | More complex setup, higher cost, programming demands |

- Illustrate the concept of 5-axis movement with simple visuals or animations.

-

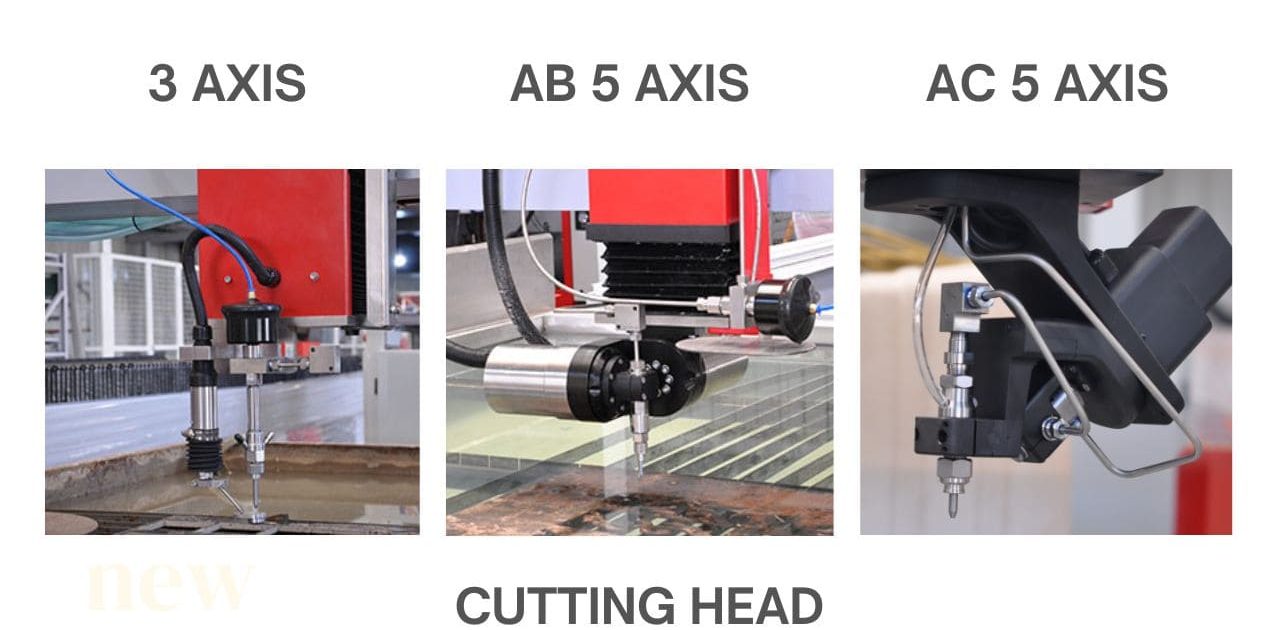

Briefly touch upon the different types of 5-axis configurations and their applications.

While all 5-axis CNC routers share the freedom of five-directional movement, they vary in how those axes are distributed, leading to different configurations and strengths. Here’s a quick glimpse into three common types:

1. Trunnion/Rotary Table: This setup features the workpiece mounted on a rotating table (B axis) while the cutting head itself pivots on a second table (A axis). It excels at machining complex rounded parts like turbine blades and impellers, where the tool needs to constantly follow the curvature.

2. Head/Head: In this configuration, both the cutting head and the workpiece mount on independent tilting platforms (A and B axes). This allows for simultaneous tilting along both axes, making it ideal for intricate undercuts and sculpting organic shapes, like medical prosthetics or artistic sculptures.

3. Gantry/Rotary Table: Imagine a traditional 3-axis gantry setup with an added rotary table underneath. This configuration combines the precision of 3-axis for flat surfaces with the rotational freedom of the B axis. It’s versatile for tasks like machining large panels with angled features or intricate housing components.

Each configuration has its own advantages and limitations, making the choice depend on the specific project requirements and desired capabilities. But one thing’s clear – the flexibility of 5-axis movements unlocks a whole new world of possibilities for complex shapes, intricate details, and pushing the boundaries of design.

III. Unveiling the Power of the Omni 5-Axis CNC:

-

Advantages of the Omni 5-axis CNC router compared to 3-axis machines.

Forget flat planes and simple cuts – the Omni 5-axis CNC router shatters the limitations of traditional 3-axis machines, ushering in a new era of precision and versatility. Imagine sculpting intricate curves, effortlessly navigating undercuts, and achieving breathtaking detail with surgical agility. Here’s how the Omni 5-axis redefines the game:

1. Conquer Complex Geometry: Where 3-axis machines stumble on intricate 3D shapes, the Omni 5-axis dances through them. Five axes of movement bend to your will, effortlessly carving undercuts, grooves, and complex angles that once belonged to the realm of imagination. Think turbine blades, medical implants, or artistic sculptures – the Omni sculpts them all with breathtaking precision.

2. Speed and Efficiency on Steroids: Time is money, and the Omni understands. Its 5-axis magic eliminates tool changes and tedious repositioning, slashing production times and boosting your efficiency. Imagine cutting intricate parts in a single setup, reducing waste and maximizing your ROI.

3. Detail Like Never Before: Forget rough edges and pixelated curves. The Omni’s pinpoint accuracy and five-axis dexterity craft surfaces so smooth, they shimmer. Intricate textures, delicate features, and razor-sharp edges – the Omni brings your designs to life with unparalleled detail and fidelity.

4. Unleash Innovation: With the Omni, the impossible becomes attainable. Complex designs that were once confined to the drawing board now translate seamlessly into reality. Whether it’s medical breakthroughs, cutting-edge aerospace components, or simply pushing the boundaries of artistic expression, the Omni empowers you to break free from the limitations of flat surfaces and embrace the future of design.

5. Cost-Effective Versatility: Don’t underestimate the value of one machine that does it all. The Omni 5-axis eliminates the need for multiple specialized machines, saving you space, resources, and maintenance costs. Its adaptability to diverse projects makes it a true investment in the future of your workshop.

The Omni 5-axis CNC isn’t just a machine; it’s a gateway to a world where imagination meets precision, where complexity becomes reality, and where your creative vision knows no bounds. So, are you ready to leave the flat world behind and embrace the possibilities of 5-axis?

-

From Aerospace to Mold making: Where the Omni 5-Axis CNC Shines

The Omni 5-axis CNC router isn’t just a machine; it’s a catalyst for innovation across diverse industries. Here’s a glimpse into how it’s transforming real-world projects:

1. Aerospace: Take flight with the Omni! Its precision machining sculpts complex aircraft components like turbine blades and landing gear with pinpoint accuracy, ensuring optimal performance and safety. Imagine fuel-efficient engines and lighter landing gear, all crafted by the Omni’s five-axis dance.

2. Automotive: Revving up the future, the Omni sculpts aerodynamic car parts and intricate engine components with unmatched detail. Its agility tackles challenging undercuts and complex geometries, shaping sleek body panels and high-performance engine parts that push the boundaries of automotive design.

3. Mold Making: Redefining Precision and Complexity: Forget the limitations of traditional mold machining. The Omni 5-axis dances across intricate cavities, undercuts, and intricate parting lines, crafting molds for everything from automotive parts to medical devices with unmatched precision and speed. Imagine flawless plastic injection molding, perfectly formed rubber seals, and detailed cast components – all born from the Omni’s five-axis magic.

IV. Beyond the Technicalities: Benefits for your Business:

-

Unleashing Tangible Benefits: How 5-Axis CNC Routers Deliver Value

Beyond the awe-inspiring capabilities of 5-axis CNC routers, their true appeal lies in the tangible benefits they deliver to your bottom line and production process. Let’s dive into how they translate innovation into concrete advantages:

1. Cost Savings:

- Reduced material waste: 5-axis capabilities significantly minimize the need for multiple setups and repositioning, leading to smaller scrap sections and more efficient material utilization. Imagine shaving off those wasteful margins and maximizing your material yield.

- Simplified tooling needs: Five-axis machines often require fewer specialized tools compared to 3-axis setups, as their versatility allows them to handle diverse tasks with increased agility. Think of streamlining your tooling inventory and eliminating unnecessary purchases.

- Lower labor costs: Thanks to faster production times and reduced setup complexity, 5-axis machines require less hands-on time from operators. This translates to potential labor cost savings and the ability to allocate manpower elsewhere.

2. Reduced Lead Times:

- Faster machining cycles: The simultaneous five-axis movement eliminates the need for frequent tool changes and repositioning, significantly slashing production times. Picture completing complex projects much faster, meeting crucial deadlines with ease.

- Streamlined workflow: Fewer setups and simplified processes translate to a smoother production flow, minimizing bottlenecks and delays. Imagine projects gliding through production like clockwork, delivering faster turnaround times for your customers.

- Improved responsiveness: With quicker production times, you become more agile in responding to changing market demands or urgent customer requests. Think of seizing new opportunities and capitalizing on short-notice projects with confidence.

3. Improved Product Quality:

- Unmatched precision and detail: The pinpoint accuracy and agility of five-axis movements yield superior surface finishes, tighter tolerances, and intricate details that 3-axis machines simply cannot achieve. Imagine crafting flawless, high-value products that set your brand apart.

- Reduced rework and scrap: Minimized setup errors and the ability to access previously unreachable areas lead to fewer imperfections and a significant reduction in scrap rates. Think of eliminating costly rework and delivering consistent, premium-quality products every time.

- Unlocking new design possibilities: 5-axis capabilities open doors to previously impossible designs with complex geometries and intricate features. Imagine pushing the boundaries of innovation and delighting your customers with groundbreaking products.

Unleashing Design Freedom: Where 5-Axis CNC Bends the Rules of Possibility

Forget flat planes and right angles – 5-axis CNC shatters the limitations of traditional machining, ushering in a renaissance of design freedom. Imagine sculpting shapes that dance across impossible geometries, carving undercuts with effortless precision, and breathing life into features that once confined to the realm of imagination. With 5-axis, design no longer bows to the tyranny of flat surfaces; it soars through a boundless realm of creativity.

1. Organic Forms Take Flight: Traditional machines stumble over curves and contours, but 5-axis leaps and twirls through them. Create flowing biomimetic designs, intricate medical implants that mimic bone structure, or awe-inspiring sculptures that defy definition. The freedom of five axes sculpts the natural world with breathtaking accuracy, blurring the lines between reality and artistic vision.

2. Functional Complexity Unlocked: Unleash a new era of engineering design. Fabricate lightweight, complex aircraft components with intricate internal channels and aerodynamic curves. Craft medical devices with delicate features that seamlessly integrate with the human body. 5-axis bridges the gap between imagination and function, crafting parts that were once deemed impossible, pushing the boundaries of what’s achievable in diverse industries.

3. Undercuts and Beyond: No longer will undercuts and inaccessible angles dictate your design. 5-axis maneuvers around obstacles with unmatched dexterity, carving hidden features and intricate details with pinpoint precision. Imagine hidden compartments, self-locking mechanisms, or intricate textures – the possibilities for innovative form and function are limitless.

4. Pushing the Boundaries of Art: Let your artistic spirit run wild. Sculpt intricate jewelry that shimmers with hidden details, fashion breathtaking musical instruments that sing with complex curves, or create kinetic sculptures that dance in defiance of gravity. 5-axis is your chisel, your brush, your sculptor’s hammer, translating the whispers of your imagination into tangible masterpieces.

5. From Prototype to Production: The leap from design to reality is no longer a chasm. 5-axis CNC bridges the gap, taking your most daring prototypes directly to production with precision and efficiency. Imagine crafting flawless, complex designs with confidence, knowing your vision will translate seamlessly into reality.

5-axis CNC is not just a machine; it’s a portal to a world where design knows no bounds. It empowers creators across industries to break free from the shackles of flat planes and embrace a future where imagination sculpts reality. So, are you ready to unleash the impossible and bend the rules of design?

V. Conclusion:

We’ve journeyed through the realm of 5-axis CNC machining, a landscape where limitations crumble and imagination takes flight. We’ve witnessed the Omni 5-axis, a revolutionary machine that dances across complex geometries, conquers undercuts with agility, and crafts intricate details with surgical precision. Forget flat planes and simple cuts – the Omni unlocks a world where impossible shapes become reality, complex designs come to life, and innovation knows no bounds.

Digital Cutting Machines for Shadow Box Foam Cutting: The Best Way to Cut Shadow Box Foam

What is a Digital Cutting Machine?

Digital cutting machines are computer-controlled machines that can cut a variety of materials with precision and speed. They are used in a variety of industries, including arts and crafts, sign making, and apparel manufacturing. Digital cutting machines offer a number of advantages over traditional cutting methods, such as hand cutting and die cutting.

What is Shadow Box Foam?

Shadow box foam is a versatile and durable foam that is used to create custom inserts for shadow boxes. It is easy to use and can be cut into any shape or size, making it a popular choice for both professional and hobbyist shadow box makers.

Why is Using a Digital Cutting Machine to Cut Shadow Box Foam the Best Option?

Below are the simple comparation among the traditional foam cutting tools and digital cutting machines.

| Tool | Pros | Cons |

|---|---|---|

| X-Acto knife | * Inexpensive | * Slow and tedious |

| Hot wire cutter | * Can cut thick foam | * Relatively fast |

| Die cutter | * Can cut precise shapes | * Fast |

| Digital cutting machine | * Most precise cutting method | * Fastest cutting method |

Benefits of Using a Digital Cutting Machine for Shadow Box Foam Cutting

Increased productivity

- Speed: Digital cutting machines are much faster than traditional cutting methods, such as hand cutting or die cutting. This can significantly reduce the time it takes to produce a foam shadow tool organizer.

- Precision: Digital cutting machines are extremely precise, which can help to reduce waste and improve the quality of the finished product.

- Versatility: Digital cutting machines can be used to cut a variety of materials, including foam, vinyl, fabric, and metal. This makes them a versatile tool that can be used for a variety of manufacturing tasks.

- Reducing the need for manual labor: Digital cutting machines can automate the cutting process, which can free up workers to focus on other tasks.

- Improving the efficiency of the manufacturing process: Digital cutting machines can help to improve the flow of materials through the manufacturing process, which can lead to increased productivity.

See below examples digital cutting machine can increase the productivity:

- Quickly and accurately cut the foam to the desired shape and size.

- Createing custom foam inserts for a variety of tool organizers.

- Cutting multiple layers of foam at once, which can save time and reduce waste.

- Creating complex shapes that would be difficult or impossible to cut by hand.

Reduced waste

- Reducing the need for human intervention: Digital cutting machines can automate the cutting process, which can help to reduce human error and waste.

- Improving the flow of materials through the manufacturing process: Digital cutting machines can help to improve the flow of materials through the manufacturing process, which can lead to reduced waste and increased efficiency.

- Reducing downtime: Digital cutting machines are very reliable and require minimal maintenance, which can help to reduce downtime and waste.

Digital cutting machines can reduce waste in the manufacturing of foam shadow tool organizers by eliminating the need to purchase pre-made foam inserts, cutting multiple layers of foam at once, and creating complex shapes that would be difficult or impossible to cut by hand. This can help manufacturers to save money and reduce their environmental impact.

Ability to offer more customized products

Digital cutting machines can be used by foam shadow tool organizer manufacturers to create custom foam inserts for a variety of tool organizers, including toolboxes, tool bags, and tool chests. They can also be used to create custom foam inserts that are designed to fit specific tools, such as power tools, hand tools, and gardening tools. Additionally, manufacturers can use digital cutting machines to create custom foam inserts that are personalized with the customer’s name, logo, or other designs. This versatility allows manufacturers to offer more customized products to their customers and meet their specific needs.

How to Choose the Right Digital Cutting Machine for Shadow Box Foam Cutting

Factors to consider when choosing a digital cutting machine for shadow box foam cutting

Bed size

Choose a bed size that is large enough to accommodate the largest foam sheet or roller you plan to cut. Omni offers a variety of bed sizes, including 1600*2500mm, 1600*3000mm, 1800*3000mm, and 1800*4000mm.

Manufacturing processing procedure

Consider the specific foam type and thickness, and choose a machine with a vibrating bit of the appropriate length.

Type of foam

If you are cutting sheet foam, you will only need a static cutting table. However, if you are cutting roller foam, you will need a roller support and conveyor table. See below how omni customer cut foam on the digital cutting with conveyor table.

How to Use a Digital Cutting Machine to Cut Shadow Box Foam

Step-by-step instructions for using a digital cutting machine to cut shadow box foam

- Prepare your shadow box foam. Make sure that the foam is clean and dry. If the foam is dirty, it can clog the cutting blade and make it difficult to cut the foam cleanly.

- Load the shadow box foam into the digital cutting machine. Place the foam on the cutting bed and secure it in place with the clamps.

- Set up the digital cutting machine. Choose the appropriate cutting blade for the type of foam you are cutting. Set the cutting speed and pressure according to the manufacturer’s instructions.

- Design the cut. Use the digital cutting machine’s software to design the cut. You can either import a pre-made design or create your own design.

- Cut the foam. Once the design is complete, start the cutting process. The digital cutting machine will cut the foam according to the design.

- Remove the foam from the digital cutting machine. Once the foam is cut, remove it from the cutting bed and remove the clamps.

- Inspect the foam. Inspect the foam to make sure that it is cut to your satisfaction. If necessary, you can use a craft knife to trim any rough edges.

Tips for Cutting Shadow Box Foam with a Digital Cutting Machine

Use a sharp blade

A sharp blade will produce cleaner cuts and reduce the risk of tearing the foam.

Secure the shadow box foam to the cutting bed

This will help to prevent the foam from moving around while the machine is cutting it.

Correct right speed and pressure

The cutting speed and pressure should be set according to the type of foam you are cutting and the thickness of the foam.

Case Studies of Businesses That Have Benefited from Using Digital Cutting Machines to Cut Shadow Box Foam

Custom Shadow Boxes is a small business that specializes in creating custom shadow boxes for a variety of items, including sports memorabilia, military medals, and collectibles. The business was founded by John Smith, a former military veteran who wanted to find a way to honor his service and the service of others.

When Smith first started his business, he was cutting the shadow box foam by hand. This was a slow and tedious process, and it was difficult to cut the foam precisely. Smith knew that he needed a better way to cut the foam if he wanted to grow his business.

Smith decided to invest in a digital cutting machine. He did his research and chose omni digital cutting machine that was specifically designed for cutting foam. The machine is with 1600*2500mm working size, which allows Smith to cut large sheets of foam. The machine also has a variety of features that make it easy to cut precise shapes.

Since Smith started using the digital cutting machine, his business has grown significantly. He is now able to produce custom shadow boxes much faster and more efficiently than he could before. He is also able to offer his customers a wider variety of shapes and designs.

Overall, Smith is very happy with his decision to invest in a digital cutting machine. He has experienced a number of benefits from using the machine, including increased productivity, improved quality, reduced waste, and increased customer satisfaction.

Conclusion

Digital cutting machines can be a valuable tool for businesses that cut shadow box foam. They offer a number of benefits, including increased productivity, improved quality, reduced waste, and the ability to offer more customized products. If you are looking for a way to improve your shadow box foam cutting operation, I encourage you to consider purchasing a digital cutting machine.

FAQ

What is the best type of digital cutting machine for cutting shadow box foam?

Consider the cutting tool size, we suggest you 1600*2500mm. If your foam sheet is with larger size, consider 1600*3000mm.

If your foam is roller type, choose conveyor table as the working table. Which can save a lot of time and energy for putting foam on the table.

How can I troubleshoot problems with my digital cutting machine?

Here are some tips on how to troubleshoot problems with your digital cutting machine:

- Check the blade. Make sure that the blade is sharp and clean. A dull or dirty blade can cause problems with cutting.

- Check the cutting speed and pressure. Make sure that the cutting speed and pressure are set correctly for the type of foam you are cutting.

- Check the cutting bed. Make sure that the cutting bed is clean and free of debris. Any debris on the cutting bed can interfere with the cutting process.

- Check the foam. Make sure that the foam is clean and dry. Wet foam can be difficult to cut and can damage the machine.

- Check the machine for any errors. If you are getting an error message on the machine’s display, consult the machine’s manual for troubleshooting instructions.

If you are still having problems with your digital cutting machine, contact OMNI for support.

5 Axis CNC Router for Mold Making: Precise, Speedy, and Cost-Effective

I. Game-changing Capabilities of A 5-axis CNC Router for Mold Making

5 axis CNC router is revolutionizing the mold making industry. These machines can create complex molds with high accuracy and precision, which was previously impossible with 3-axis CNC routers. This has led to shorter lead times, lower costs, and better quality molds.

II. Understanding the Importance of Precision

The significance of precision in mold making for flawless end products

Precision is essential in mold making to ensure that the end products are flawless. Even the slightest deviation in the mold can result in defects in the final product. This is why mold makers use highly sophisticated machines and techniques to ensure that their molds are as precise as possible.

The challenges of achieving intricate details manually

Achieving intricate details manually can be challenging due to the need for precision, patience, skill, and specialized tools. In some cases, it is more efficient and cost-effective to use machines or CAD software.

Here are some examples of intricate details that can be difficult to achieve manually: fine engraving, micromachining.

By using CNC machines and CAD software, it is possible to achieve intricate details with greater precision, speed, and consistency than is possible manually.

How a 5-axis CNC router enhances precision and accuracy

A 5-axis CNC router can move the cutting tool in five axes, which allows it to machine complex shapes with high precision and accuracy. This is because the cutting tool can approach the workpiece from multiple angles and follow complex paths. As a result, 5-axis CNC routers are able to produce parts with high precision and accuracy that would be difficult or impossible to machine with a 3-axis CNC router.

III. Introducing the 5-Axis CNC Router

Overview of CNC routers and their traditional 3-axis counterparts

CNC routers are machines that can move a cutting tool in three or five axes. 3-axis routers can machine flat parts, while 5-axis routers can machine complex 3D parts. 5-axis routers are more precise and accurate, but they are also more expensive and complex to use.

Here are some of the applications of 5-axis CNC routers:

- Mold making

- Aerospace manufacturing

- Medical device manufacturing

- Woodworking

- Signs and displays

- Prototype manufacturing

5-axis CNC routers are a versatile tool that can be used to machine a wide variety of complex parts. They are becoming increasingly popular in a variety of industries, as the demand for high-precision, 3D parts continues to grow.

The concept of 5-axis machining and its advantages for mold

5 AXIS MOLD MAKING

making

5-axis machining is a type of CNC machining that allows the cutting tool to move in five axes: three linear axes (X, Y, and Z) and two rotary axes (A and B). This allows the tool to machine complex 3D shapes with high precision and accuracy.

In mold making, 5-axis machining is used to create molds for a variety of products, including automotive parts, medical devices, and consumer electronics. The ability to machine complex shapes with high precision is essential for creating molds that produce high-quality parts.

Here are some of the advantages of using 5-axis machining for mold making:

Allowing the creation of complex 3D shapes: 5-axis machining can be used to create complex 3D shapes that would be difficult or impossible to machine with a 3-axis CNC router. This is because the cutting tool can approach the workpiece from multiple angles and follow complex paths.

Improving precision and accuracy: 5-axis machining can improve the precision and accuracy of mold making by allowing the cutting tool to be controlled with greater precision. This is achieved through the use of high-precision motors and sensors.

Reducing the need for manual labor: 5-axis machining can reduce the need for manual labor by automating the machining process. This can save time and money, and it can also improve consistency and quality.

Increasing productivity: 5-axis machining can increase productivity by allowing molds to be machined faster and more efficiently. This is because the cutting tool can be moved in multiple axes simultaneously, which reduces the amount of time it takes to machine a mold.

The versatility and flexibility of a 5-axis CNC router

A 5-axis CNC router is a versatile and flexible machine that can be used to machine a wide variety of complex parts. It is capable of moving the cutting tool in five axes, which allows it to machine complex 3D shapes with high precision and accuracy.

Here are some of the ways in which a 5-axis CNC router is versatile and flexible:

It can be used to machine a wide variety of materials, including wood, plastics, metals, and composites.

It can be used to machine a wide variety of parts, including molds, prototypes, and finished products.

It can be used to machine complex 3D shapes with high precision and accuracy.

It can be used to machine parts with internal features that would be difficult or impossible to machine with a 3-axis CNC router.

It can be used to machine parts from multiple angles, which reduces the chances of errors caused by misalignment.

IV. Streamlining Complex Mold Designs

The complexity of mold designs in various industries

The complexity of mold designs can vary depending on the industry and the specific application. The factors that can contribute to the complexity of a mold design include the number of parts, the complexity of the individual parts, the materials, the tolerances, the production volume, and the cost constraints.

In general, the molds used in the automotive and medical device industries tend to be more complex than the molds used in other industries. This is because the parts produced in these industries need to be precisely made to meet demanding performance requirements.

The complexity of mold designs can also be affected by the manufacturing process that will be used to produce the parts. For example, if the parts will be injection molded, the molds will need to be designed to withstand the high pressures and temperatures that are used in the injection molding process.

The mold designer must always consider the specific requirements of the application in order to create a mold that is both effective and economical.

The limitations of traditional mold making techniques

Low precision: Traditional mold making techniques often have low precision, which can lead to defects in the molded parts. This is because these techniques are often labor-intensive and rely on human judgment.

High cost: Traditional mold making techniques can be expensive, especially for complex molds. This is because they require specialized tools and materials.

Long lead times: Traditional mold making techniques can have long lead times, which can delay the production of molded parts. This is because these techniques often require multiple steps, such as machining, casting, and polishing.

Limited complexity: Traditional mold making techniques are limited in the complexity of the molds that they can produce. This is because these techniques are often based on two-dimensional drawings, which can be difficult to translate into three-dimensional molds.

Inflexibility: Traditional mold making techniques are inflexible, which can make it difficult to make changes to the molds. This is because these techniques often involve the use of specialized tools and materials, which can be difficult to modify.

These limitations can make it difficult to produce high-quality, complex molds using traditional techniques. As a result, many manufacturers are turning to newer, more advanced mold making techniques, such as 5 axis cnc maching.

How a 5-axis CNC router simplifies the process and handles intricate mold designs with ease

A 5-axis CNC router is a versatile machine that can be used to machine complex 3D shapes with high precision and accuracy. It is capable of moving the cutting tool in five axes: three linear axes (X, Y, and Z) and two rotary axes (A and C). This allows the router to machine complex shapes with ease, even those with intricate features.

Here are some of the ways in which a 5-axis CNC router can simplify the process of mold making and handle intricate mold designs:

It can machine complex shapes with ease: A 5-axis CNC router can machine complex shapes with ease, even those with intricate features. This is because the router can approach the workpiece from multiple angles and follow complex paths. This can save time and effort, and it can also improve the accuracy of the mold.

It can reduce the need for manual labor: A 5-axis CNC router can reduce the need for manual labor by automating the machining process. This can save time and money, and it can also improve the consistency and quality of the molds.

It can improve the precision of the molds: A 5-axis CNC router can improve the precision of the molds by allowing the cutting tool to be controlled with greater precision. This is achieved through the use of high-precision motors and sensors. This can lead to the production of high-quality molds with fewer defects.

It can increase the productivity of the mold making process: A 5-axis CNC router can increase the productivity of the mold making process by allowing molds to be machined faster and more efficiently. This is because the cutting tool can be moved in multiple axes simultaneously, which reduces the amount of time it takes to machine a mold.

Overall, a 5-axis CNC router is a valuable tool for mold making that can simplify the process and handle intricate mold designs with ease. It is a versatile and efficient machine that can be used to produce high-quality molds with complex features.

V. Achieving Intricate Details and Contours

The importance of achieving precise details and contours in molds

5 AXIS CNC WOODWORKING

Here are some of the reasons why it is important to achieve precise details and contours in molds:

To produce high-quality parts: The quality of the molded part is directly affected by the quality of the mold. If the mold is not precise, the molded part will also be inaccurate. This can lead to defects in the part, such as gaps, voids, and uneven surfaces.

To reduce costs: The cost of producing molded parts can be reduced if the molds are precise. This is because the molds can be reused many times, and the molded parts can be produced quickly and efficiently.

To improve efficiency: The efficiency of the mold making process can be improved if the molds are precise. This is because the molds can be machined faster and more easily, and the molded parts can be produced with fewer defects.

To meet customer expectations: Customers expect high-quality molded parts. If the molds are not precise, the molded parts will not meet customer expectations. This can lead to customer dissatisfaction and lost sales.

To comply with regulations: In some industries, such as the medical device industry, there are strict regulations governing the quality of molded parts. If the molds are not precise, the molded parts may not meet the regulatory requirements. This can lead to fines and other penalties.

The limitations of traditional methods in achieving complex features

Traditional methods for achieving complex features in molds include casting, milling, and injection molding. These methods can be effective for achieving simple features, but they can be limited when it comes to complex features.

Casting is a process in which molten metal is poured into a mold cavity. The metal cools and solidifies, taking the shape of the mold cavity. Casting can be used to create complex features, but it can be difficult to achieve precise details. This is because the molten metal can flow unevenly, and it can be difficult to control the shape of the mold cavity.

Milling is a process in which a tool is used to remove material from a workpiece. Milling can be used to create complex features, but it can be time-consuming and labor-intensive. This is because the tool must be moved along the workpiece in a precise manner, and it can be difficult to achieve complex shapes with a milling machine.

Injection molding is a process in which molten plastic is injected into a mold cavity. The plastic cools and solidifies, taking the shape of the mold cavity. Injection molding can be used to create complex features, but it can be difficult to achieve precise details. This is because the molten plastic can flow unevenly, and it can be difficult to control the shape of the mold cavity.

In addition to the limitations mentioned above, traditional methods for achieving complex features in molds can also be expensive and time-consuming. This is because they often require specialized tools and materials, and they can be difficult to scale up for mass production.

As a result of these limitations, traditional methods may not be suitable for achieving complex features in molds. In these cases, newer technologies such as 5-axis CNC machining may be more suitable.

5-axis CNC machining is a process in which a computer-controlled machine tool is used to remove material from a workpiece. The machine tool can move in five axes, which allows it to machine complex shapes with precision. 5-axis CNC machining is a versatile and efficient process that can be used to achieve complex features in molds.

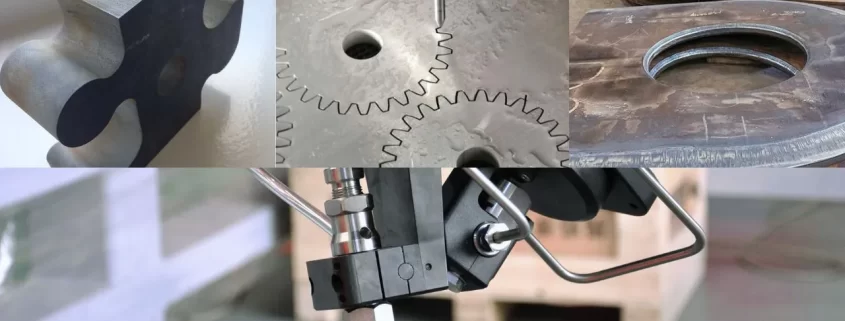

Showcasing examples of intricate mold details accomplished with a 5-axis CNC router

here are some examples of intricate mold details that can be accomplished with a 5-axis CNC router:

- Complex internal channels: 5-axis CNC routers can be used to machine complex internal channels in molds. This is essential for molds that are used to produce parts with complex flow patterns, such as impellers.

- Precise undercuts: 5-axis CNC routers can be used to machine precise undercuts in molds. This is essential for molds that are used to produce parts with complex geometries, such as turbine blades.

- Multiple cavities: 5-axis CNC routers can be used to machine multiple cavities in molds. This is essential for molds that are used to produce large quantities of parts.

- High-speed machining: 5-axis CNC routers can be used to machine molds at high speeds. This can help to reduce the production time and cost of the molds.

- Complex 3D shapes: 5-axis CNC routers can be used to machine complex 3D shapes in molds. This is essential for molds that are used to produce parts with complex geometries, such as medical implants.

Impellers are a good example of a part that requires intricate mold details. Impellers are used in a variety of applications, such as pumps, turbines, and fans. They are typically made of metal or plastic, and they have complex internal channels that allow the fluid to flow smoothly.

5-axis CNC routers can be used to machine the intricate internal channels of impellers with precision. This ensures that the impellers are able to function properly and efficiently.

Here are some other examples of parts that require intricate mold details:

- Turbine blades: Turbine blades are used in jet engines and other gas turbines. They have complex geometries that allow them to efficiently convert the energy of the gas into thrust.

- Medical implants: Medical implants are used to replace or repair damaged or missing body parts. They often have complex geometries that are designed to fit the specific needs of the patient.

- Automotive components: Automotive components, such as engine blocks and transmission cases, often have complex geometries that are required for their performance and durability.

- Electronic components: Electronic components, such as integrated circuits and printed circuit boards, often have complex geometries that are required for their functionality.

VI. Impact of 5-axis CNC Router on Mold Making Efficiency

Increased accuracy and precision: 5-axis CNC routers can machine molds with greater accuracy and precision than traditional methods, such as milling and casting. This can lead to fewer defects in the molds and the molded parts, which can save time and money.

Reduced labor costs: 5-axis CNC routers can automate many of the tasks involved in mold making, which can reduce labor costs.

Improved flexibility: 5-axis CNC routers can be used to machine a wide variety of molds, which can make it easier to adapt to changes in demand.

Improved quality control: 5-axis CNC routers can be used to monitor the machining process in real time, which can help to improve quality control.

Reduced cycle time: 5-axis CNC routers can machine molds faster than traditional methods. This is because they can machine the molds from multiple angles, which reduces the number of steps required.

VII. Exploring How A 5-axis CNC Router Ensures Consistent Rresults Across Mmultiple Molds

One of the remarkable benefits of a 5-axis CNC router is its ability to ensure consistent results across multiple molds.

By leveraging advanced digital design integration and precise machining capabilities, a 5-axis CNC router can replicate intricate details and complex geometries with unparalleled accuracy.

The router follows the same programmed instructions for each mold, eliminating variations caused by human error and ensuring a high level of consistency.

Additionally, the multi-axis movement of the router allows it to access all angles and contours of the mold, enabling precise replication of intricate features throughout the production process.

This consistency not only enhances the quality of the end products but also streamlines production by minimizing the need for manual adjustments and rework.

Manufacturers can rely on a 5-axis CNC router to deliver consistent, reliable results across numerous molds, thereby maintaining the desired standards for their products.

VIII. Embracing Innovation for Competitive Advantage

The landscape of mold making is constantly evolving, driven by the demand for innovation and higher manufacturing standards.

In this dynamic environment, adopting a 5-axis CNC router can provide a significant competitive advantage.

With its ability to handle complex shapes, intricate details, and precise contours, the 5-axis CNC router enables manufacturers to stay ahead of the curve and meet the ever-increasing demands of their industries.

By embracing this transformative technology, industries can streamline their mold making processes, improve overall efficiency, and deliver superior quality products.

It is crucial for companies to explore the potential of a 5-axis CNC router and embrace its capabilities to gain a competitive edge in the market.

Those who are proactive in adopting this advanced technology are poised to lead the way in mold making innovation and establish themselves as industry pioneers.

5-Axis Wood CNC Mchine for Woodworking: Everything You Need to Know

5-Axis Wood CNC Machine Introduction

-

What is a 5-axis wood cnc machine?

A 5-axis CNC router is a computer-controlled machine that can cut wood, plastic, metal, and other materials in five axes. The five axes are X, Y, Z, A, and B. The X and Y axes allow the router to move left and right, and front to back. The Z axis allows the router to move up and down. The A axis allows the router to rotate the workpiece around the X axis. The B axis allows the router to rotate the workpiece around the Y axis.

-

Benefits of using a 5-axis CNC router for woodworking

Here are some of the benefits of using a 5-axis CNC router for cnc woodworking:

- Precision: 5-axis CNC routers can achieve a high degree of precision, which is essential for creating complex woodworking projects. This is because the router can move in five axes, which allows it to cut complex shapes with great accuracy.

- Accuracy: 5-axis CNC routers can be programmed to cut with great accuracy, which helps to ensure that your projects are made to your exact specifications. This is because the router can be programmed to move to specific coordinates, which ensures that the cuts are made exactly where you want them to be.

- Speed: 5-axis CNC routers can cut wood quickly, which can save you time and money. This is because the router can move quickly between cuts, which can speed up the overall process.

- Flexibility: 5-axis CNC wood carving machine are very versatile and can be used to create a wide variety of woodworking projects. This is because the router can be programmed to cut a variety of shapes and sizes, which gives you a lot of creative freedom.

- Ability to create complex shapes: 5-axis CNC router for woodworking can create complex shapes that would be difficult or impossible to create with traditional woodworking methods. This is because the router can move in five axes, which allows it to cut complex shapes with great accuracy.

- Reduced human error: 5-axis CNC routers are computer-controlled, which means that there is less human error involved in the cutting process. This can lead to more accurate and consistent results.

-

Types of 5-axis CNC routers for woodworking

-

Complex furniture

-

5-axis CNC routers can be used to create complex furniture pieces with intricate details. For example, you could use a 5-axis CNC woodworking machine to create a dining table with a curved top or a chair with a sculpted backrest, or staircase with beautiful curve shape.

STAIRCASE

HANDRAIL

STAIRCASE

-

-

Mouldings and trim

-

5-axis CNC routers can be used to create precise mouldings and trim for your home. This can save you a lot of time and money, as you would not have to hire a carpenter to do this for you.

-

-

Signs and displays

-

5-axis wood CNC routers can be used to create custom signs and displays for your business. This is a great way to add a touch of personality to your business and to make your products stand out from the competition.

-

-

Models and prototypes

-

5-axis CNC routers can be used to create prototypes of new products. This is a great way to test out new designs and to get feedback from potential customers before you start mass-producing your product.

-

-

Art and sculptures

-

5-axis CNC routers can be used to create beautiful art and sculptures. This is a great way to express your creativity and to create something truly unique.

If you are serious about woodworking, then a 5-axis CNC router is a valuable tool that can help you to take your projects to the next level.

-

Features to consider when choosing a best 5-axis CNC router for woodworking

-

Budget:

5 axis CNC routers can range in price from ten thousand dollars to several hundred thousand dollars. It is important to set a budget before you start shopping so that you do not overspend.

-

Workpiece size

CNC routers come in a variety of sizes. It is important to choose a router that is large enough to accommodate the workpieces that you will be working with. Usually, OMNI offer 1300mm *2500mm, 2000mm * 3000mm, 1500mm * 5000mm working size. Also support custom working size building.

-

Accuracy

CNC routers are capable of achieving a high degree of accuracy. However, the accuracy of a router will vary depending on the model. It is important to choose a router that is accurate enough for your needs.

-

Speed

CNC routers can cut wood quickly. However, the speed of a router will vary depending on the model. It is important to choose a router that is fast enough for your needs

-

Tool changer

A tool changer allows you to use multiple tools with the same router. This can save you time and money.

-

Dust collection

Dust collection helps to keep your work area clean, which can improve safety and reduce the risk of fire.

-

Support

It is important to choose a router from a company that offers good support. This way, you can get help if you have any problems with the router.

Once you have considered these factors, you will be able to choose a 5-axis CNC router that is right for you.

-

Safety tips for using a 5 axis wood cnc machine for woodworking

Here are some safety tips for using a 5-axis CNC router for woodworking:

- Always wear safety glasses: Safety glasses are essential for protecting your eyes from flying debris.

- Use a dust mask: Dust from woodworking can be harmful to your lungs. A dust mask will help to protect your lungs.

- Keep your work area clean: A clean work area will help to reduce the risk of accidents.

- Avoid loose clothing: Loose clothing can get caught in the router, which could lead to an accident.

- Keep your hands away from the router: The router can move very quickly, and it is important to keep your hands away from it at all times.

- Never leave the router unattended: The router can continue to operate even if you are not there. It is important to never leave the router unattended.

- Turn off the router when you are not using it: This will help to prevent accidents.

- Make sure the router is properly grounded: This will help to prevent electrical shock.

- Read the safety manual: The safety manual will provide you with additional safety information.

By following these safety tips, you can help to prevent accidents and injuries when using a 5-axis CNC router for woodworking.

Here are some additional tips for using a 5-axis CNC router safely:

- Make sure you are familiar with the router’s controls before you start using it.

- Use the right tools for the job.

- Start with a slow speed and gradually increase it as you become more comfortable with the router.

- Be aware of your surroundings and make sure there are no obstacles that could interfere with the router.

- Take breaks often to avoid fatigue.

If you follow these safety tips, you can help to ensure that your woodworking projects are safe and productive.

Conclusion

-

Where to buy a best 5 axis wood cnc machine for woodworking

Direct from the manufacturer: omni can sell 5-axis CNC routers directly to consumers. We know 5 axis very well, we can offer lifetime support, which is superior than get it from local shop or reseller.

-

Resources for learning more about 5-axis CNC routers for woodworking

- Online forums: There are many online forums where you can ask questions and get advice from other woodworkers who use CNC routers. Some of the most popular online forums include:

- YouTube channels: There are many YouTube channels that offer tutorials and demonstrations on how to use 5-axis CNC routers for woodworking. Some of the most popular YouTube channels include:

- The Wood Whisperer

- Chris Schwarz

- StewMac

- Books: There are also many books that can teach you about 5-axis CNC routers for woodworking. Some of the most popular books include:

- The CNC Router Handbook by Jim Brunner

- CNC Made Easy by Mark Weems

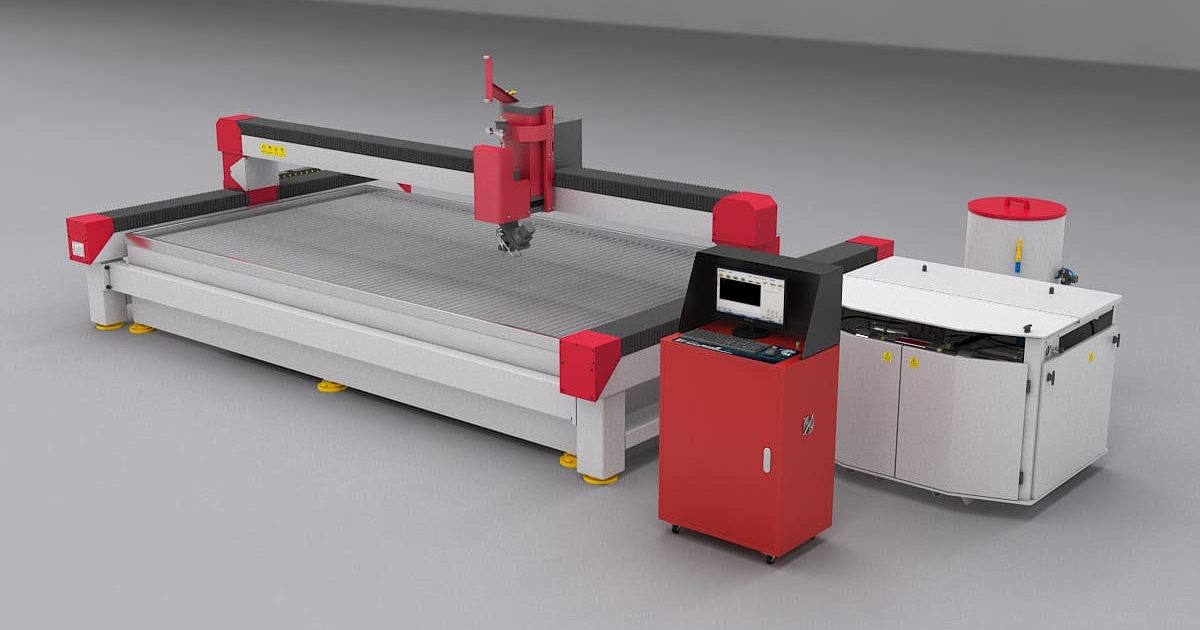

Waterjet Cutting Stainless Steel : Applications and Benefits

Waterjet cutting stainless steel is a precise and versatile method for cutting this material. It is a popular choice for a variety of applications, including manufacturing, construction, marine, and medical. Water jet cutting machine offers a number of benefits over other methods of cutting stainless steel, including precision, versatility, and speed. This blog post will discuss the applications and benefits of cutting 200mm stainless steel with water jet.

Applications of Abrasive Waterjet Cutting

Manufacturing

- Machinery: Waterjet cutting is a popular method for cutting stainless steel for machinery applications. It can be used to cut complex shapes and patterns for a variety of machinery components, such as gears, shafts, and housings. Waterjet cutting can also be used to create custom parts for machinery, such as fixtures and jigs.

- Appliances: Waterjet cutting is also a popular method for cutting stainless steel for appliances applications. It can be used to cut complex shapes and patterns for a variety of appliance components, such as ovens, refrigerators, and dishwashers. Waterjet cutting can also be used to create custom parts for appliances, such as trim pieces and handles.

- Products: Waterjet cutting is also a popular method for cutting stainless steel for product applications. It can be used to cut complex shapes and patterns for a variety of products, such as furniture, jewelry, and medical devices. Waterjet cutting can also be used to create custom parts for products, such as prototypes and molds.

Construction

- Beams: Waterjet cutting is a popular method for cutting stainless steel beams for construction applications. It can be used to cut complex shapes and patterns for a variety of beam components, such as flanges, webs, and stiffeners. Waterjet cutting can also be used to create custom beams for construction, such as curved beams and beams with special features.

- Columns: Waterjet cutting is also a popular method for cutting stainless steel columns for construction applications. It can be used to cut complex shapes and patterns for a variety of column components, such as bases, capitals, and flutings. Waterjet cutting can also be used to create custom columns for construction, such as columns with special features.

- Structural Components: Waterjet cutting is also a popular method for cutting stainless steel structural components for construction applications. It can be used to cut complex shapes and patterns for a variety of structural components, such as trusses, beams, and columns. Waterjet cutting can also be used to create custom structural components for construction, such as components with special features.

- Exterior Facades: Stainless steel is a popular material for exterior facades. Waterjet cutting can be used to cut stainless steel for a variety of exterior facade applications, such as panels, trim, and railings. Waterjet cutting can also be used to create custom exterior facades for buildings, such as curved facades and facades with special features.

Marine

- Hulls: Waterjet cutting is a popular method for cutting stainless steel hulls for marine applications. It can be used to cut complex shapes and patterns for a variety of hull components, such as strakes, keels, and rudders. Waterjet cutting can also be used to create custom hulls for marine applications, such as curved hulls and hulls with special features.

- Decks: Waterjet cutting is also a popular method for cutting stainless steel decks for marine applications. It can be used to cut complex shapes and patterns for a variety of deck components, such as hatches, railings, and ladders. Waterjet cutting can also be used to create custom decks for marine applications, such as decks with special features.

- Components for boats and ships: Waterjet cutting is also a popular method for cutting stainless steel components for boats and ships. It can be used to cut complex shapes and patterns for a variety of components, such as propellers, nozzles, and valves. Waterjet cutting can also be used to create custom components for boats and ships, such as components with special features.

Medical

- Surgical instruments: Waterjet cutter is a popular method for surgical instruments. It can be used to cut complex shapes and patterns for a variety of surgical instruments, such as scalpels, forceps, and needles. Waterjet cutting can also be used to create custom surgical instruments for specific applications, such as instruments for minimally invasive surgery.

- Implants: Waterjet is also a popular method for implants. It can be used to cut complex shapes and patterns for a variety of implants, such as hip joints, knee joints, and dental implants. Waterjet cutting can also be used to create custom implants for specific patients, such as implants that are tailored to the patient’s anatomy.

- Medical devices: Waterjet cutter machine is also a popular method for medical devices. It can be used to cut complex shapes and patterns for a variety of medical devices, such as pacemakers, defibrillators, and catheters. Waterjet cutting can also be used to create custom medical devices for specific applications, such as devices that are designed to be used in specific environments, such as the operating room or the intensive care unit.

Benefits Of Using Waterjet Cutting

- Accuracy: Water jet is a very accurate method, which is important for applications where precision is critical, such as manufacturing medical devices or creating custom parts for machinery.

- Smooth cuts: Waterjet cutting produces smooth, burr-free cuts, which can improve the quality of the finished product and reduce the need for post-processing.

- No heat-affected zone: Waterjet cutting is a cold cutting process, which means that there is no heat-affected zone around the cut. This can prevent warping or cracking of the material, and it can also improve the strength and durability of the finished product.

- Environmentally friendly: Waterjet cutting is a relatively environmentally friendly process, as it does not produce any harmful emissions.

Conclusion

Water jet cutting is a precise, versatile, and fast method for cutting stainless steel. This blog post has discussed the applications and benefits of cutting 200mm stainless steel with water jet. If you are looking for a precise, versatile, and fast method for cutting stainless steel, waterjet cutting is a great option.

Digital Cutter – The Ultimate Guide: Everything You Need to Know

Digital Cutter Introduction

What is foam sheet cutting?

Digital cutter can cut foam sheet precisely. Here we introduce main foam sheet cutting ways. Foam sheet cutting is the process of cutting foam sheets into desired shapes and sizes. It is a versatile process that can be used for a variety of projects, including crafting, modeling, and signage.

There are many different ways to cut foam sheets. Some common methods include:

- Hand-cutting: This is the simplest method and can be done with a sharp knife or scissors. However, it can be time-consuming and difficult to get precise cuts.

- Die-cutting: This method uses a die, which is a custom-shaped cutting tool, to cut foam sheets. Die-cutting is a more precise method than hand-cutting, but it can be more expensive to set up.

- Digital cutter: This method uses a digital cutter to cut foam sheets. Digital cutting machines are the most precise method of cutting foam sheets, but they can also be the most expensive.

Why use a digital cutter for foam sheet cutting?

- When precision is critical: Digital cutting machines can cut foam sheets with great accuracy, even on complex shapes. This is important for projects where precision is critical, such as signmaking and prototyping.

- When speed is important: Digital cutting machines can cut foam sheets quickly, which can save time and money on large projects.

- When versatility is needed: Digital cutting machines can be used for a variety of projects, including signs, prototypes, packaging, and more. This makes them a valuable tool for businesses of all sizes.

- When ease of use is desired: Digital cutting machines are easy to use, even for beginners. This makes them a great option for businesses that need to cut foam sheets but don’t have the time or expertise to learn how to use a more complex machine.

If you are facing any of these conditions, then you might need to use a digital cutting machine.

Here are some examples of projects that might require the use of a digital cutting machine:

- Signmaking: Digital cutting machines can be used to cut foam sheets for signs, such as business signs, store signs, and event signs.

- Prototyping: Digital cutting machines can be used to cut foam sheets for prototypes, such as new product designs, architectural models, and engineering models.

- Packaging: Digital cutting machines can be used to cut foam sheets for packaging, such as product boxes, shipping boxes, and display boxes.

If you are working on any of these types of projects, then you might need to use a digital cutting machine.

What are the different types of digital cutter?

Universal digital cutter: A universal digital cutter can cut a variety of materials, including paper, fabric, vinyl, and foam.

Dual beam digital cutter: A dual beam digital cutter uses two cutting beams to cut through materials. This makes them more accurate and precise than single beam cutters.

Digital cutter for fabric cutting: A digital cutter for fabric cutting is designed to cut fabric with precision. They typically have a sharp blade and a variety of cutting speeds to accommodate different types of fabric.

What are the different types of foam sheets?

There are many different types of foam sheets available, each with its own unique properties and uses. Some of the most common types of foam sheets include:

- Polystyrene foam sheets: Polystyrene foam sheets are lightweight and easy to cut, making them a popular choice for a variety of projects, such as packaging, insulation, and crafting.

Polystyrene foam sheets

https://www.youtube.com/watch?v=_2oqmuuLY1s&t

- Extruded polystyrene foam sheets: Extruded polystyrene foam sheets are stronger and more durable than polystyrene foam sheets, making them a good choice for applications where strength and durability are important, such as building models and making signs.

Extruded polystyrene foam sheets

- Polyurethane foam sheets: Polyurethane foam sheets are more expensive than polystyrene foam sheets, but they are also more versatile and can be used for a wider variety of applications, such as making furniture, soundproofing, and creating prototypes.

Polyurethane foam sheets

- EVA foam sheets: EVA foam sheets are a type of closed-cell foam that is known for its durability and shock-absorbing properties. They are often used for making sports equipment, such as mats and protective gear, as well as for crafting and other DIY projects.

When choosing a foam sheet, it is important to consider the specific properties and uses that are important to you. For example, if you need a lightweight and easy-to-cut foam sheet for packaging, polystyrene foam may be a good option. If you need a strong and durable foam sheet for building models, extruded polystyrene foam may be a better choice. And if you need a versatile and durable foam sheet for a wide variety of applications, polyurethane foam may be the best option.

How to Cut Foam Sheets with a Digital Cutter

Choose the right digital cutter for your needs.

Here are some factors to consider when choosing a digital cutting machine:

- Your budget: Digital cutting machines can range in price from a few hundred dollars to several thousand dollars. It is important to set a budget before you start shopping so that you do not overspend.

- Your needs: What materials do you need to cut? How thick are the materials you need to cut? How accurate do you need your cuts to be? How much material do you need to cut on a regular basis? Answering these questions will help you narrow down your choices.

- Your skill level: If you are a beginner, you may want to choose a machine that is easy to use. If you are more experienced, you may want a machine with more features and capabilities.

- The size of the machine: Digital cutting machines can range in size from small desktop models to large industrial machines. Consider the amount of space you have available when making your decision.

Once you have considered these factors, you can start looking at specific machines. There are many different brands and models of digital cutting machines available, so it is important to do your research and compare features and prices.

Prepare the foam sheet for cutting.

Here are some tips on how to prepare a foam sheet for cutting:

- Choose the right type of foam sheet. There are many different types of foam sheets available, each with its own unique properties and uses. Some foam sheets are more durable than others, while some are easier to cut. Choose a foam sheet that is appropriate for your project and that will be easy to cut with your digital cutting machine.

- Measure and mark the foam sheet. Once you have chosen the right type of foam sheet, it is important to measure and mark the foam sheet before you start cutting. This will help you ensure that you are cutting the foam sheet to the correct size and shape.

- Use a sharp blade.

- Apply pressure. When cutting foam sheets, it is important to apply pressure. This will help ensure that the blade cuts through the foam sheet cleanly.

- Be careful. When cutting foam sheets, it is important to be careful. Foam sheets can be sharp and can cause injury if you are not careful.

With a little practice, you will be able to cut foam sheets with your digital cutting machine like a pro.

Load the foam sheet into the digital cutting machine.

Here are the steps on how to load a foam sheet into a digital cutting machine:

- Prepare the cutting mat. Make sure the cutting mat is clean and free of debris.

- Place the foam sheet on the cutting mat. The foam sheet should be centered on the cutting mat and should be aligned with the cutting lines.

- Secure the foam sheet to the cutting mat. You can use tape or vacuum pump to secure the foam sheet to the cutting mat.

- Load the cutting mat into the digital cutting machine. Make sure the cutting mat is aligned with the cutting head.

- Start the cutting process. The digital cutting machine will cut the foam sheet according to the design that you have loaded.

Set the cutting parameters.

- Blade: The type of blade you use will affect the quality of your cuts. A sharp blade will produce cleaner cuts, while a dull blade may cause the foam sheet to tear.

- Speed: The cutting speed will affect the quality of your cuts and the amount of time it takes to cut the foam sheet. A slower speed will produce cleaner cuts, but it will take longer to cut the foam sheet. A faster speed will cut the foam sheet more quickly, but it may not produce as clean of cuts.

- Pressure: The amount of pressure you apply will affect the quality of your cuts. Too much pressure may cause the foam sheet to tear, while too little pressure may not produce a clean cut.