Precision Cutting From Fiber Laser Cutting Machines in Metal Tube Bevel Cutting

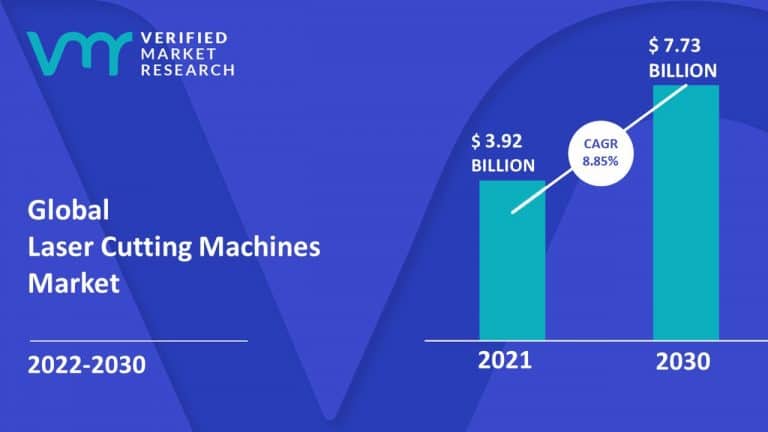

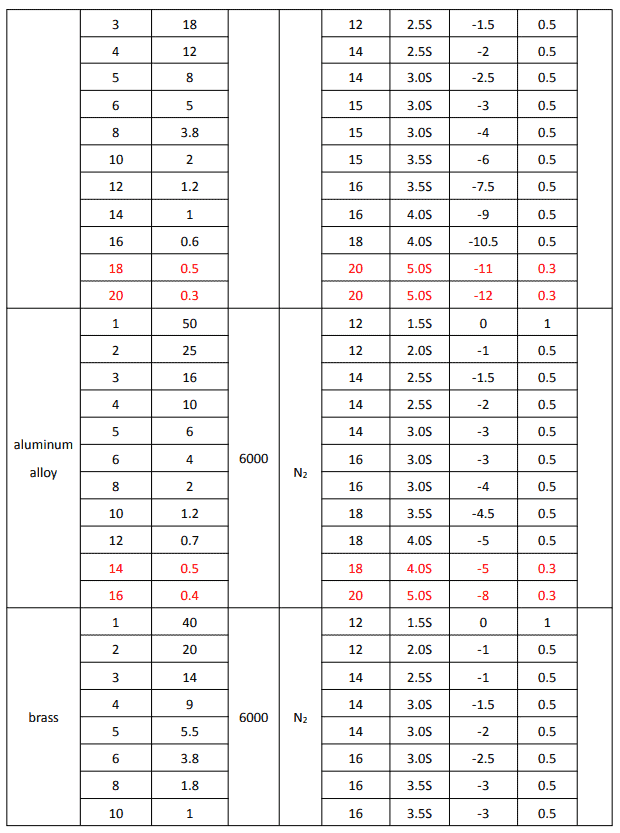

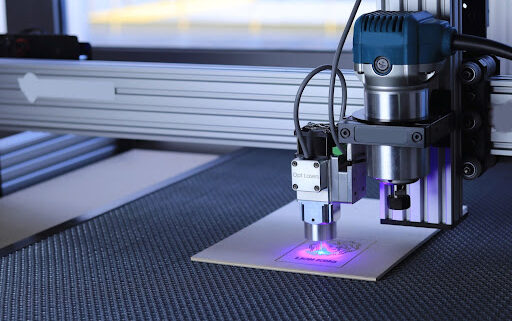

In the evolving landscape of industrial manufacturing, the demand for precision and efficiency continues to drive technological advancements. One such marvel in metalworking is the fiber laser metal cutting machine, specifically designed for the intricate art of metal tube bevel cutting.

Understanding the Essence of Fiber Laser Cutting for Metal Tube Beveling

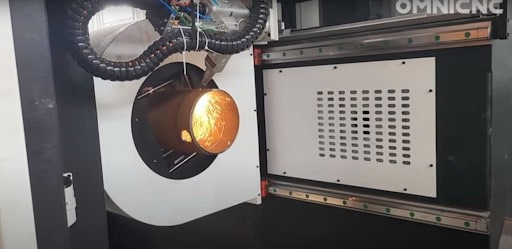

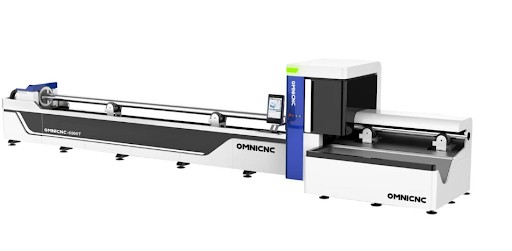

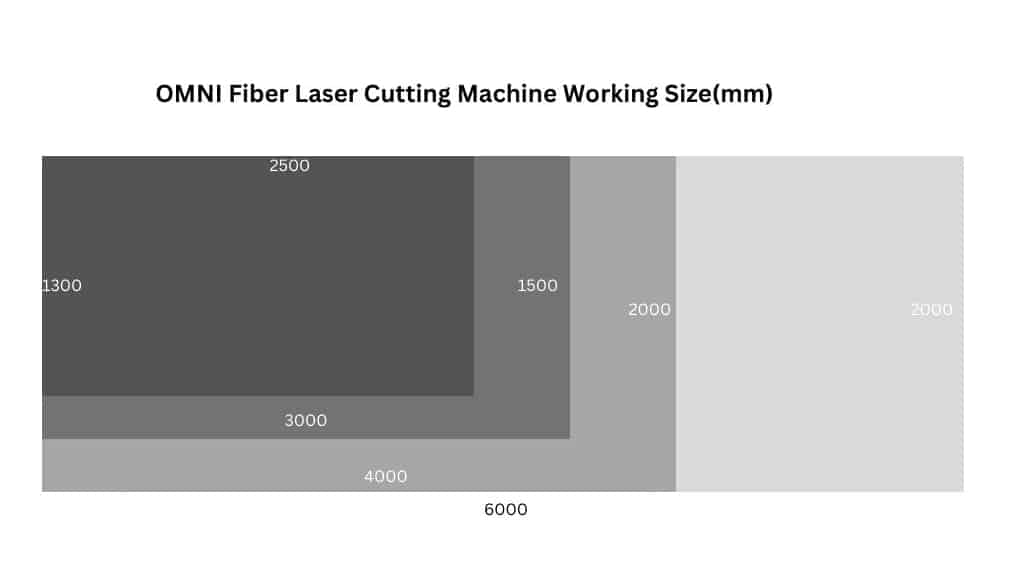

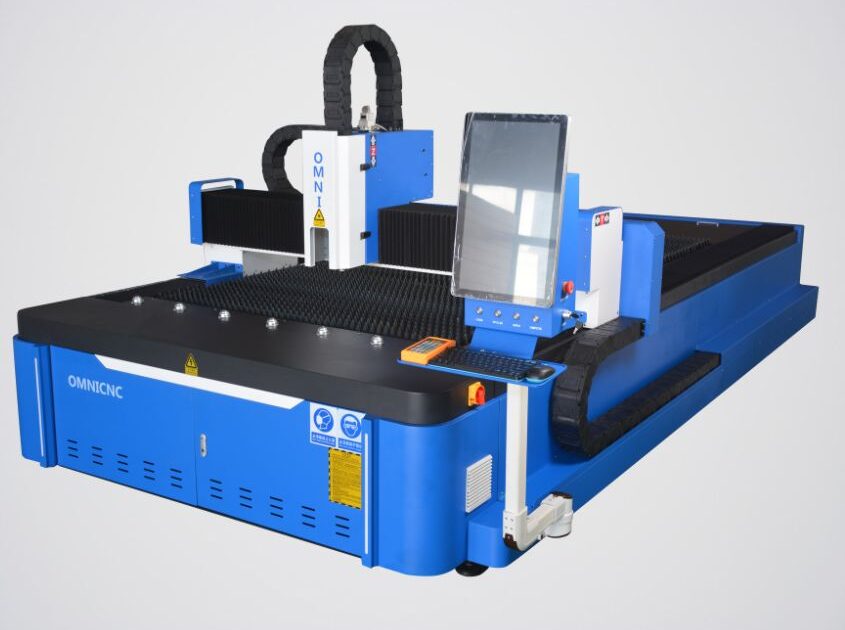

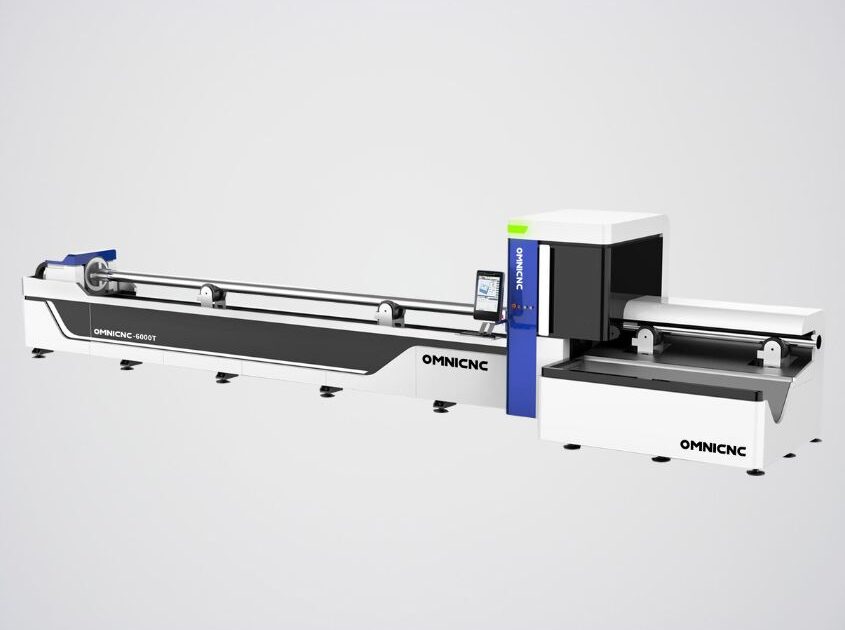

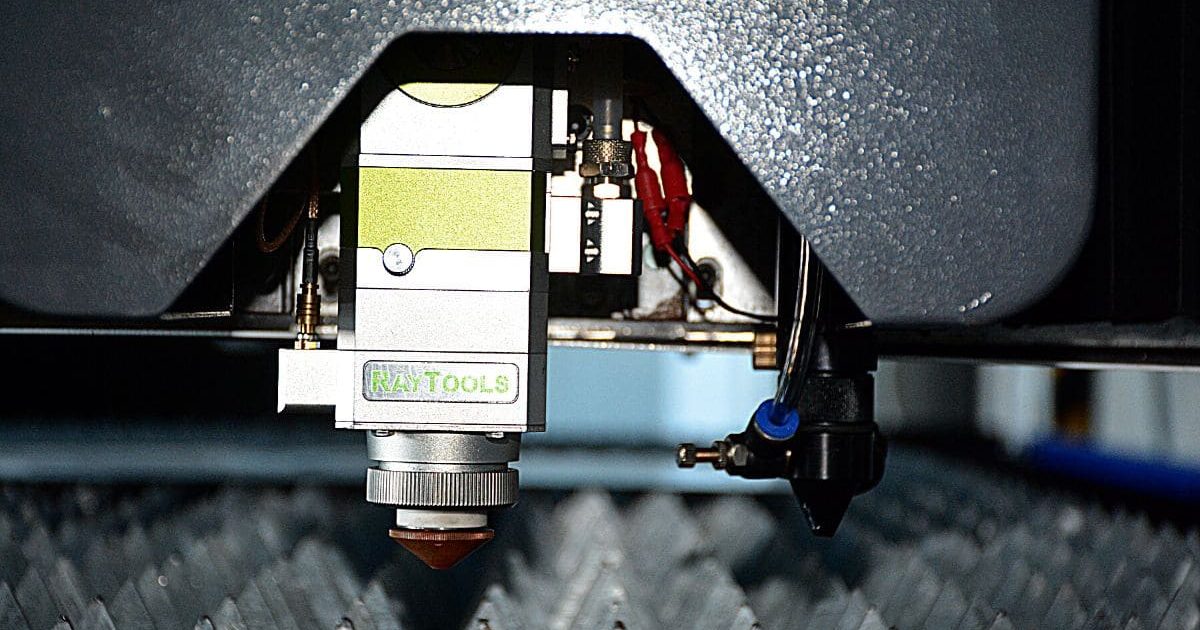

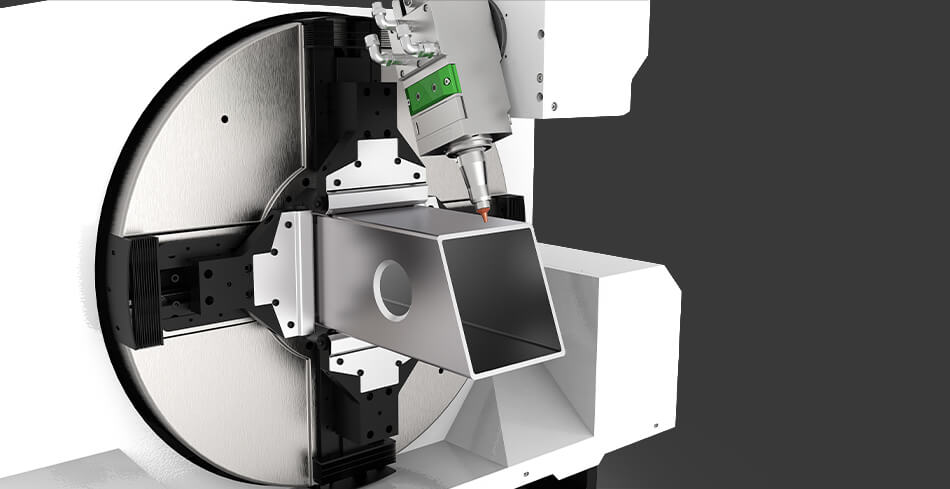

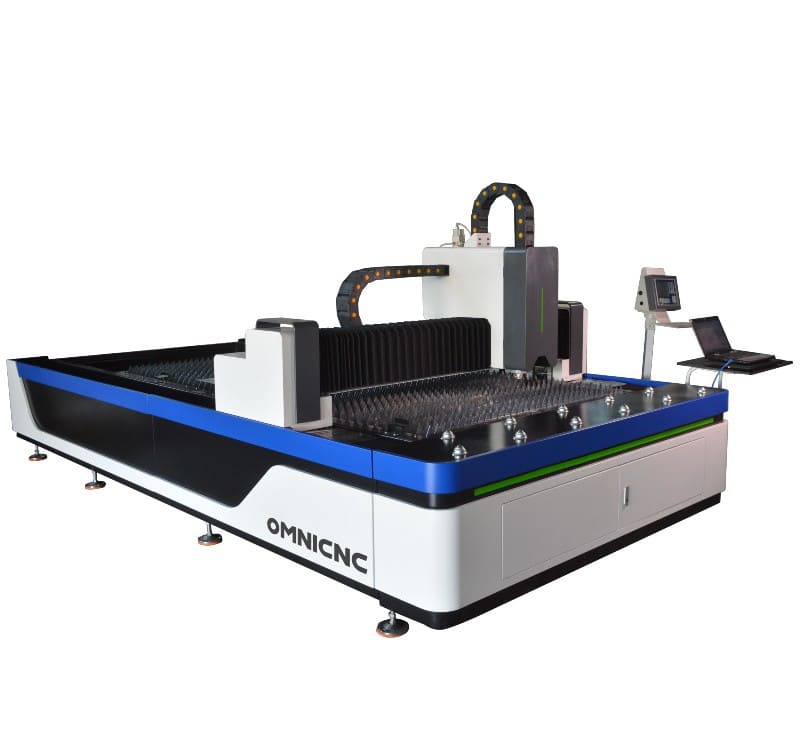

The Omni Fibre Laser Cutting Machine is a versatile powerhouse. Its primary function is to carve precise bevels on metal tubes, catering to various industries such as automotive, aerospace, construction, and more. Whether round, square, or other profiles, the fiber laser cutting machine handles metal tubes with unmatched precision.

Safety First: Operating a Fiber Laser Cutting Machine for Tube Beveling

Cutting metal tubes with a fiber laser demands meticulous attention to safety. Here are some crucial precautions:

Protective Gear

Laser Safety Goggles are essential for shielding eyes from laser radiation and bright flashes during the cutting process. Molten metal slag and particles generated during cutting can be hot and sharp. Appropriate gear prevents burns and cuts.

Ventilation and Safety

Fiber laser cutting produces harmful gases and metal vapors. Adequate ventilation and an exhaust system are essential for removing these by-products. Although the cutting process is controlled, having a fire extinguisher nearby is a prudent safety measure.

Avoiding Direct Exposure

Direct exposure to laser radiation can cause damage. Avoid staring at the laser beam and reflective surfaces, and prevent the beam from hitting your body.

Clean Optics Regularly

Clean laser optics regularly to maintain cutting performance. Use approved cleaning supplies and clothes, avoiding direct contact with bare hands.

System Inspections

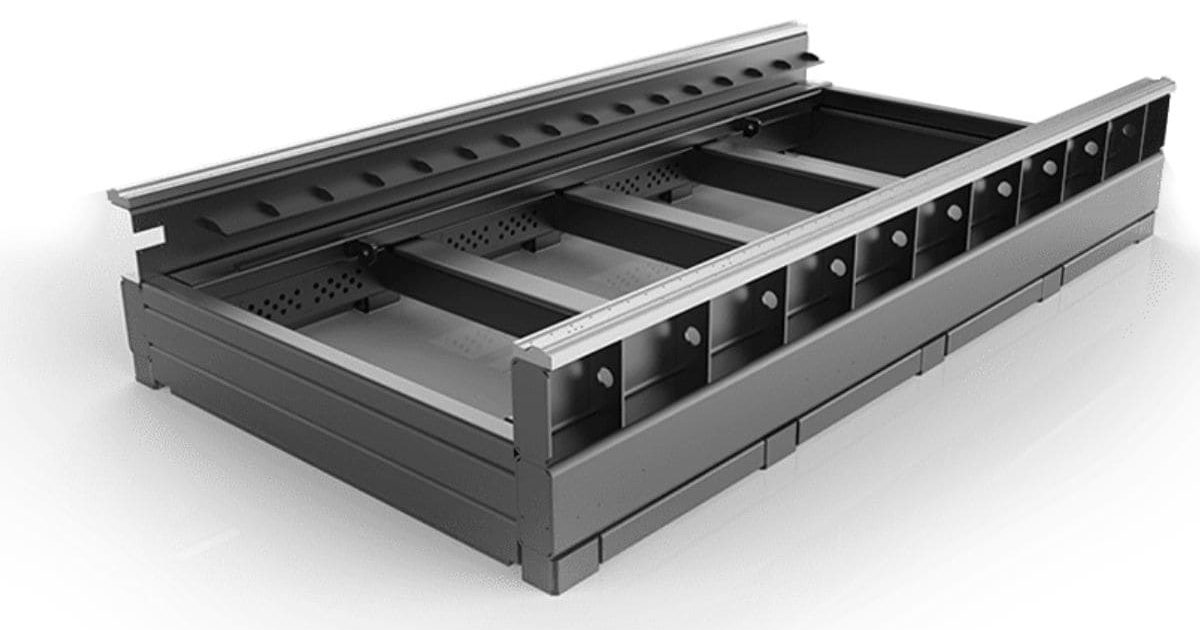

Inspect all components regularly to identify issues early. Look for damage, leaks, or corrosion in gas lines and coolant systems.

Scheduled Maintenance

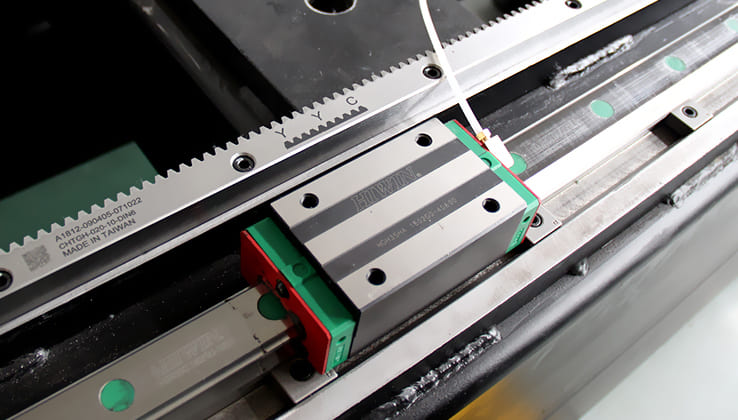

Adhere to the recommended maintenance schedule. Tasks such as lubricating motion systems, calibrating sensors, and replacing filters contribute to optimal machine performance.

Workspace Organization

A clean workspace ensures efficient operation. Wipe down the machine exterior, and eliminate debris and clutter to prevent accidents and optimize cooling and gas flow.

Training for Operators

Operating and maintaining a fiber laser cutter requires comprehensive safety, usage, and maintenance training. Properly trained operators can maximize machine potential and longevity.

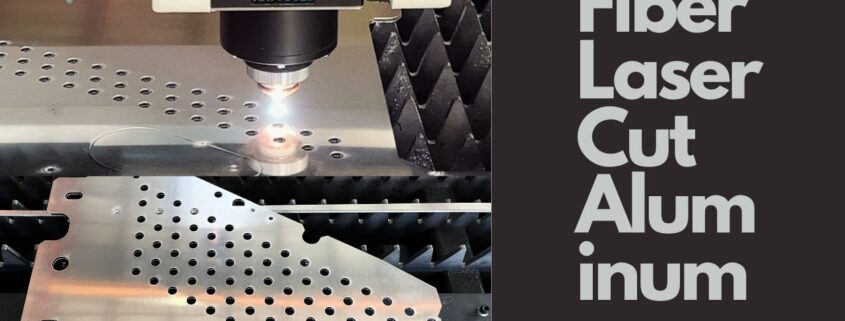

Custom Cutting and Wastage Reduction with Fiber Laser Machines

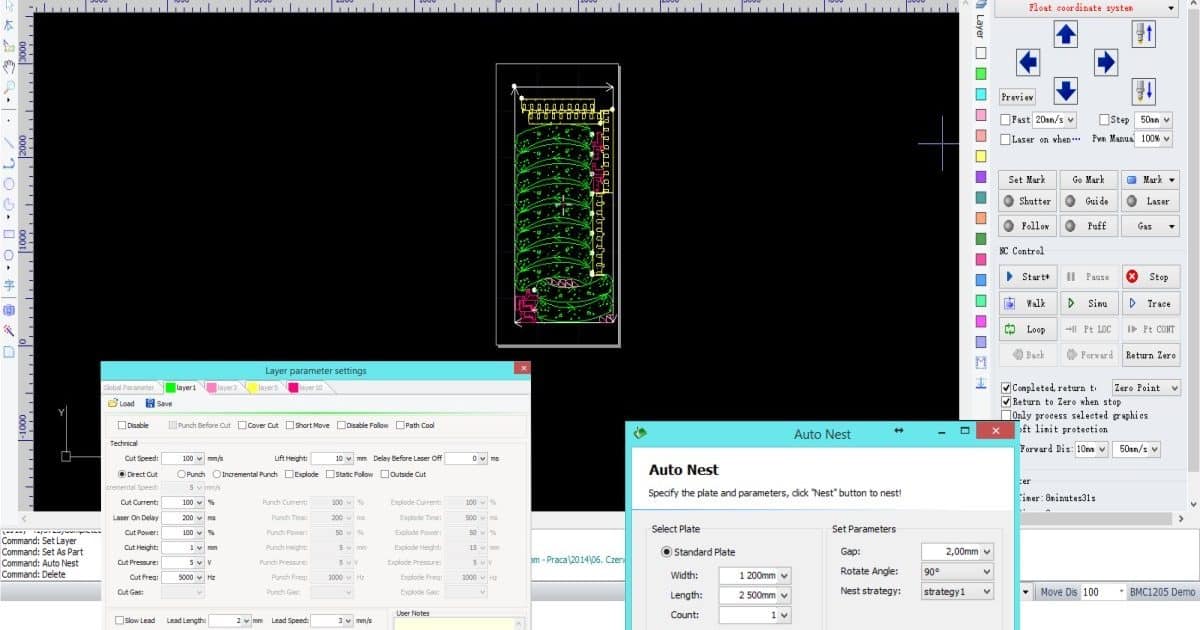

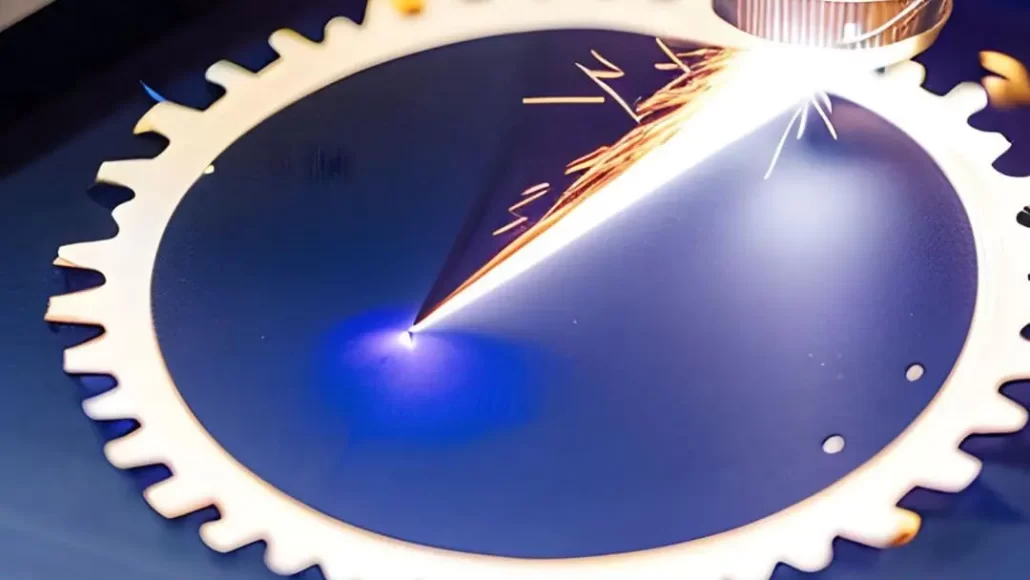

Their fine-tuned control through CNC technology enables the production of complex shapes with microscopic accuracy, making them ideal for both one-of-a-kind custom shapes and batch production. The efficiency and speed of the cutting process contribute to large-scale manufacturing, while minimal material waste and optimized cutting paths align with sustainable practices. Beyond mere tools for metal fabrication, Fiber Laser Cutting Machines serve as catalysts for innovation, fostering creativity and redefining design possibilities across industries.

Why Choose an Omni CNC Metal Laser Cutter?

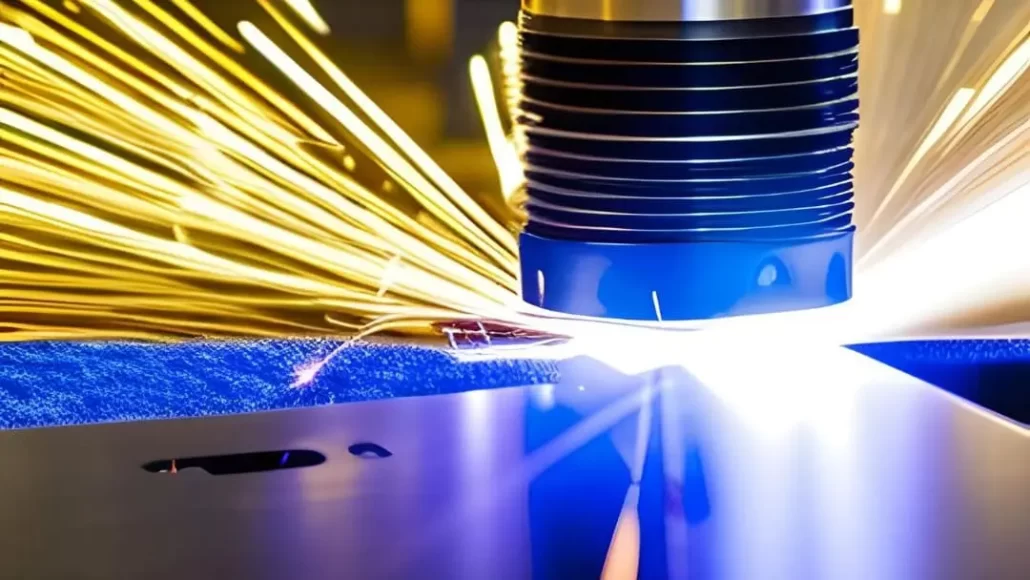

The cutting process is a symphony of precision, efficiency, and advanced technology. Let’s understand why you should opt for this cutting-edge equipment:

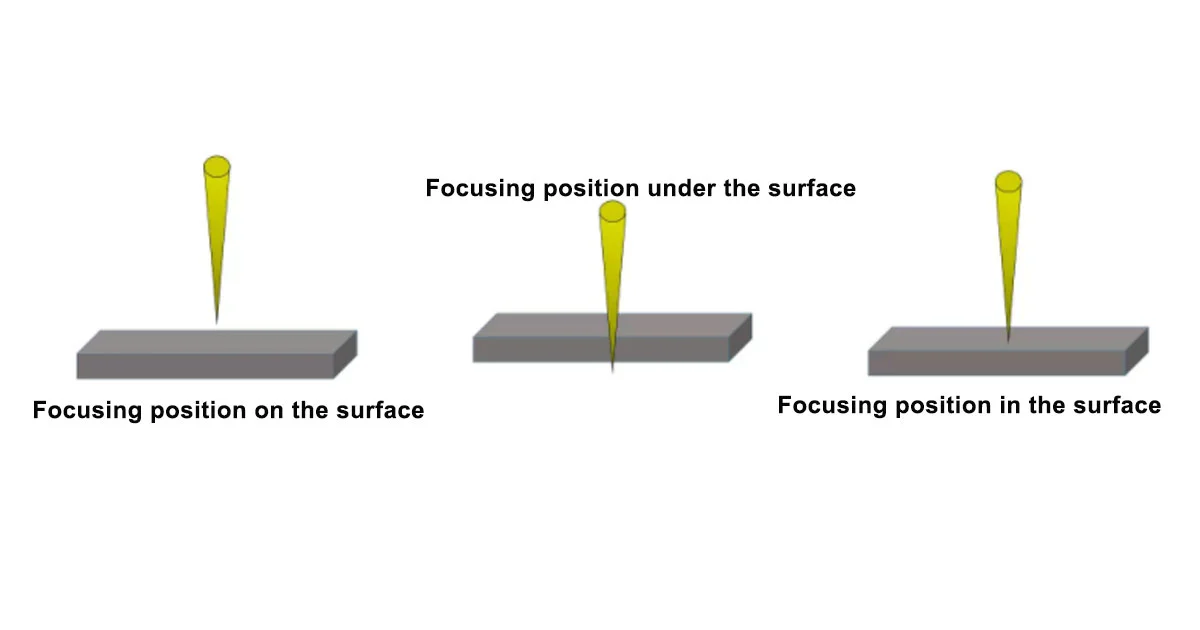

Precision Cutting

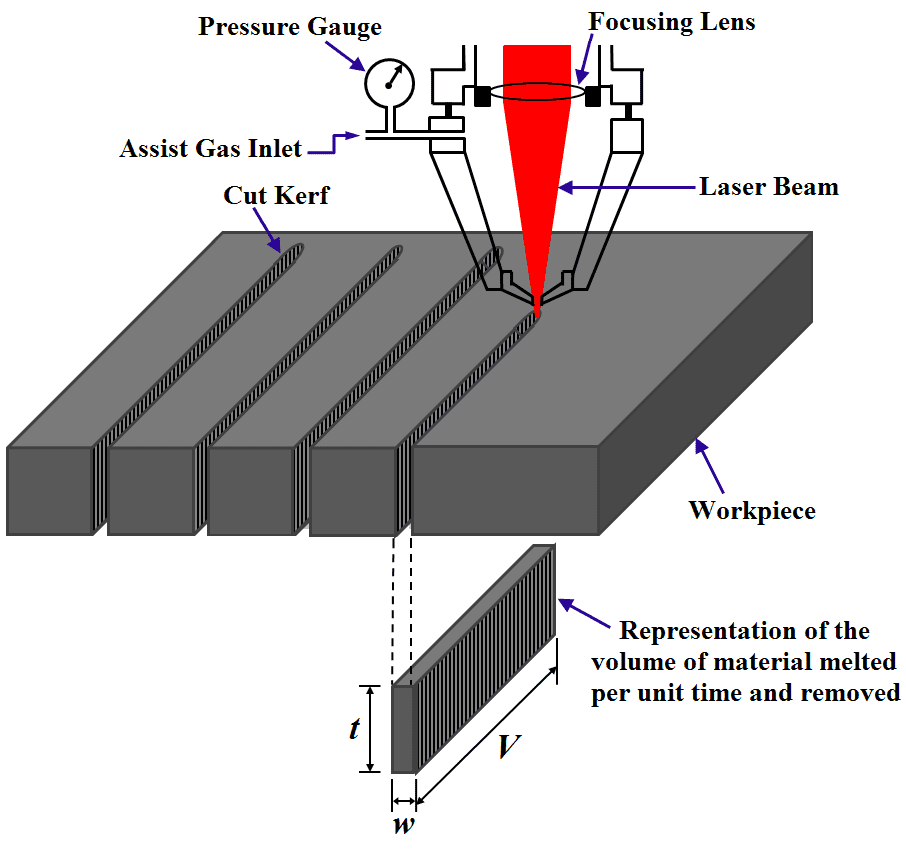

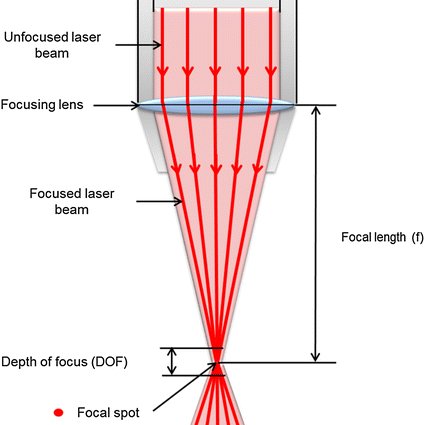

The laser beam, focused on a narrow point, circumnavigates the complete circumference of the tube. This results in continuous cuts at any angle or pattern, making it a preferred choice for applications requiring intricate designs and precise geometries.

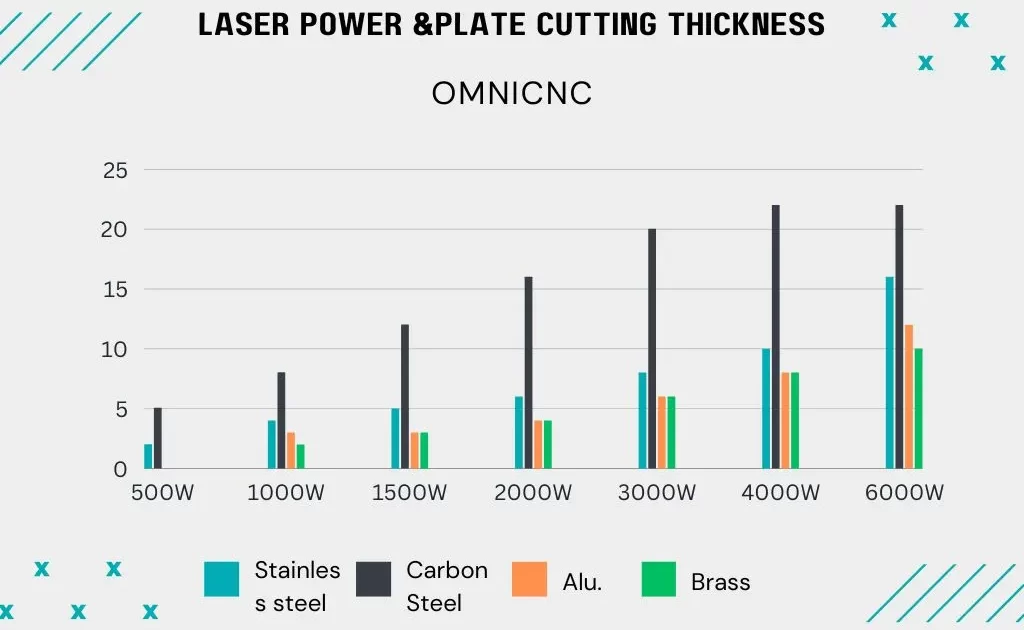

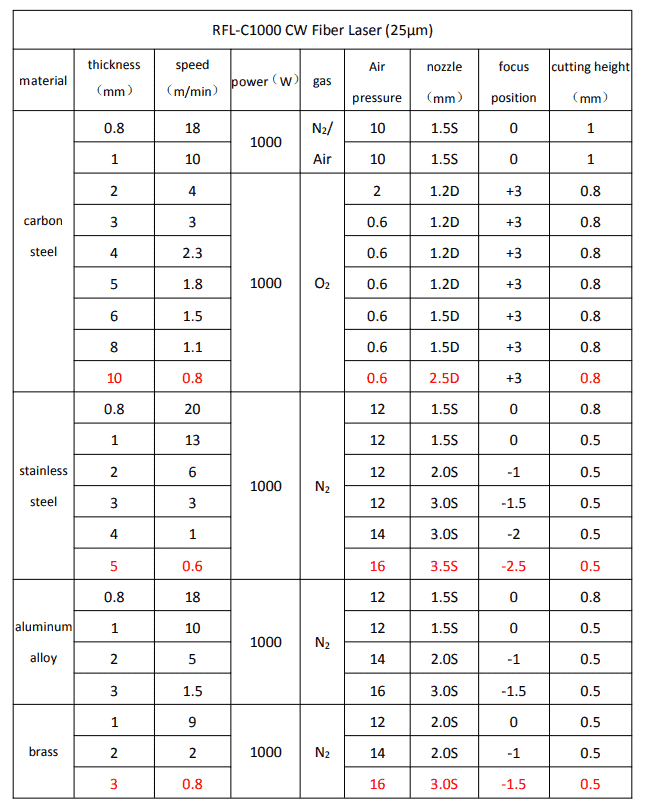

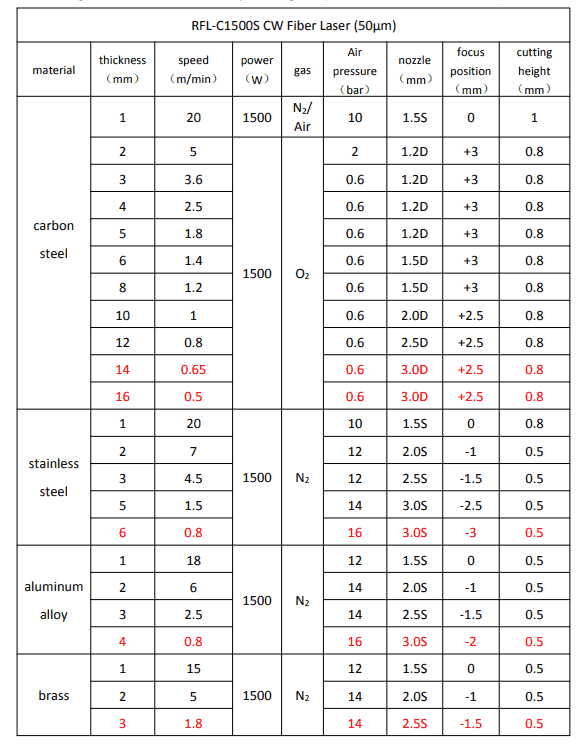

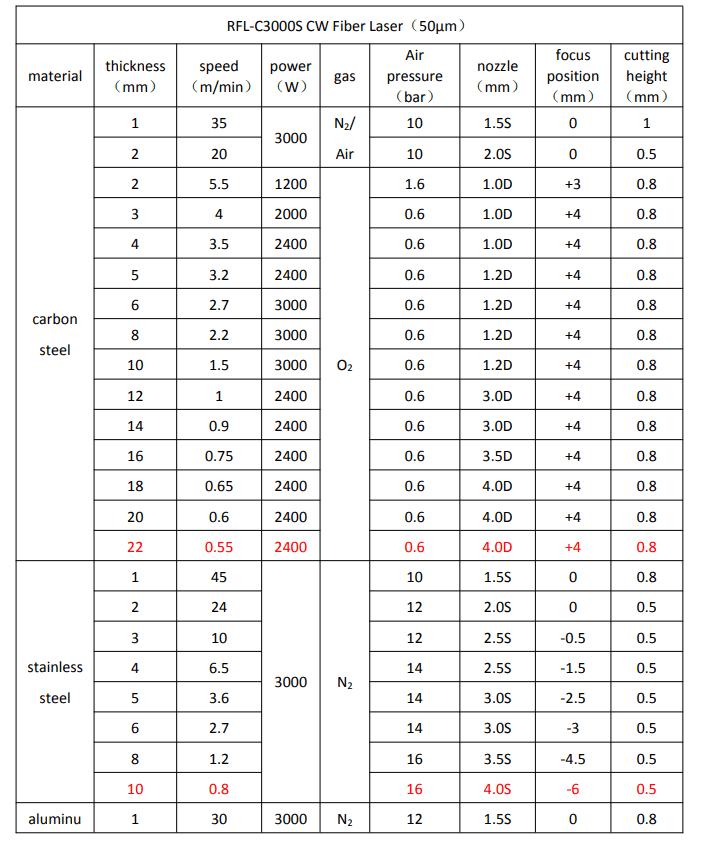

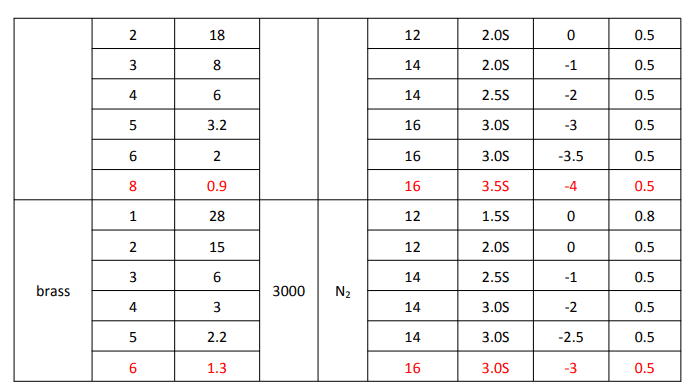

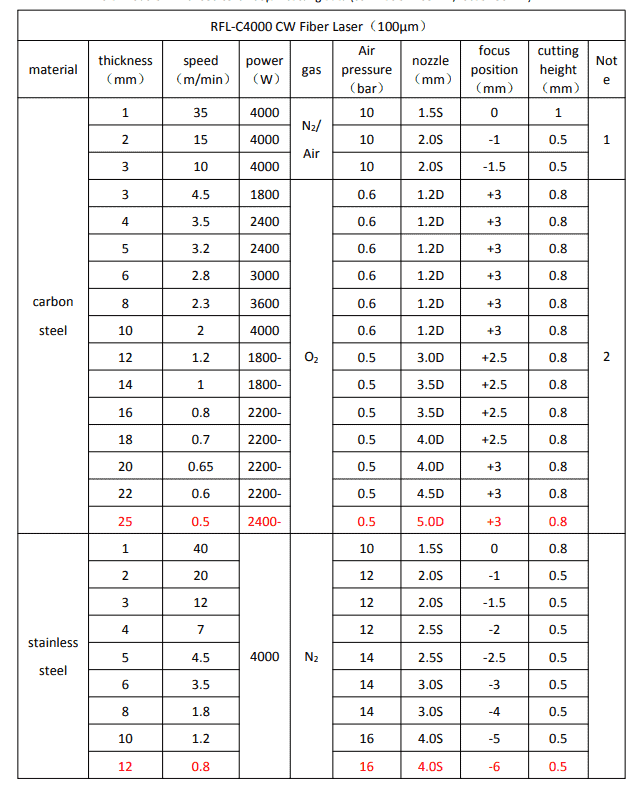

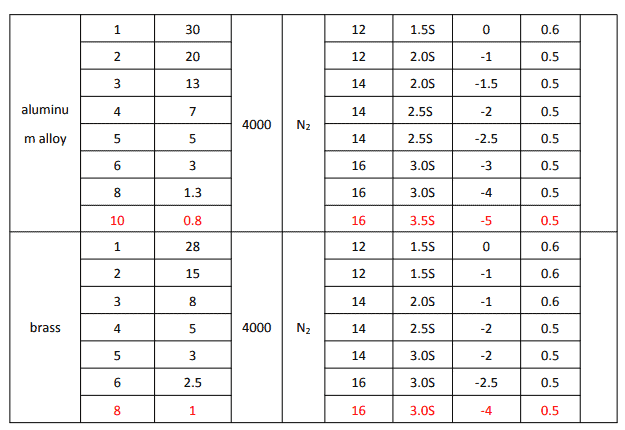

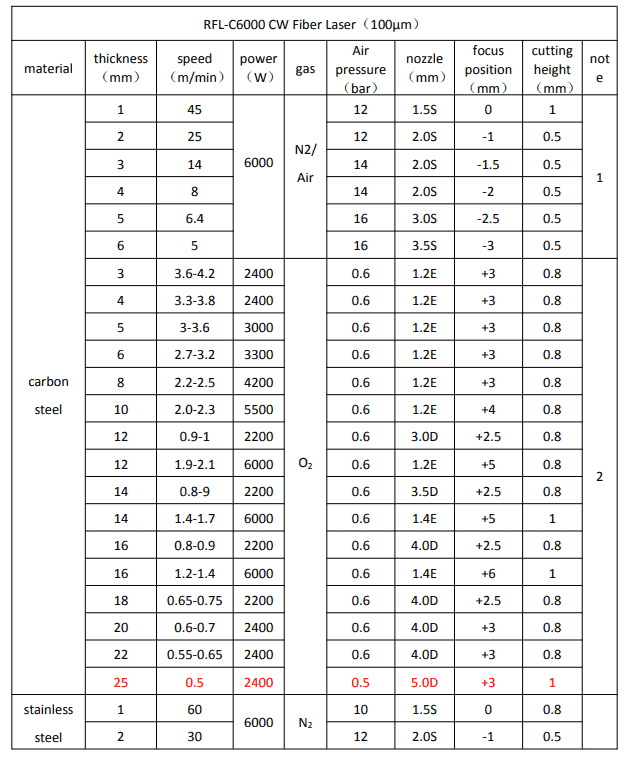

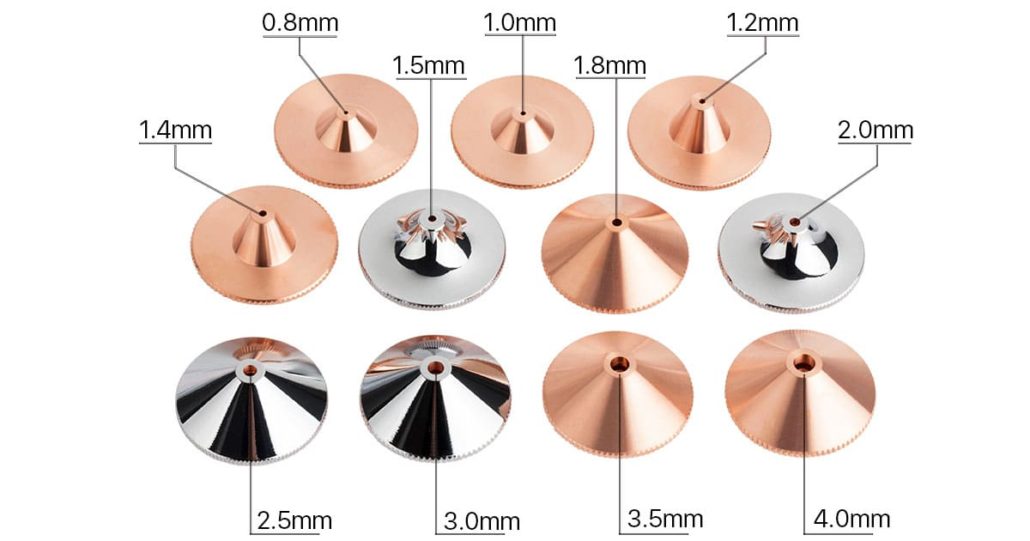

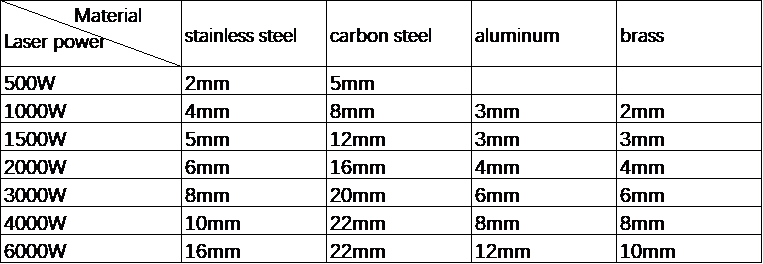

Power Options for Every Need

Fiber laser metal cutting machines come with a range of power options, allowing users to tailor their equipment to specific cutting requirements. Whether it’s a 1KW, 2KW, 3KW, 4KW, 6KW, 12kw or even 20kw machine, the power selection ensures optimal performance for different materials and thicknesses.

Automation and CNC Systems

Laser cutting machines are often equipped with Computer Numerical Control (CNC) systems, adding a layer of automation to the process. CNC technology allows for precise control over the laser’s movements, ensuring that the programmed design is executed with unparalleled accuracy. This level of automation not only enhances the speed of production but also minimizes the margin of error, contributing to the overall efficiency of the cutting process.

Speed and Efficiency

One of the most notable advantages of fiber lasers is their speed. The cutting process is significantly faster than traditional methods, leading to increased productivity and shorter production cycles. This speed is especially advantageous in high-volume manufacturing scenarios where meeting tight deadlines is crucial.

Conclusion

The omni Fiber Laser Cutting Machine for metal tube bevel cutting represents a leap forward in precision engineering. Embracing this technology, coupled with a commitment to safety and maintenance best practices, empowers manufacturers to achieve unparalleled accuracy and efficiency in fabricating metal tubes. As industries continue to evolve, the fiber laser cutter stands as a testament to the relentless pursuit of excellence in the world of metalworking.