Fiber Laser Cutting Machines for Aluminum Sheet Cutting: What You Need to Know

What is Fiber Laser Cutting?

Fiber laser cutting machines are a versatile and powerful tool for cutting a wide variety of materials, including aluminum sheet. However, with so many different machines on the market, it can be difficult to know which one is right for your needs.

How does fiber laser cutting work?

Fiber laser cutting machines use a high-powered laser to cut through metal.

Fiber laser cutting machines use a high-powered laser to cut metal by melting or vaporizing it. They are very precise, fast, and versatile, and they produce less waste than other cutting methods.

The laser beam is focused onto the metal, which causes it to melt and vaporize.

Fiber laser cutting machines use a high-powered laser beam to cut through metal by melting or vaporizing it. The laser beam is focused onto the metal using a lens, which concentrates the energy of the beam onto a very small area. This causes the metal to heat up very quickly, until it melts or vaporizes.

The molten metal is then blown away with a jet of gas, leaving a clean and precise cut.

The gas jet blows away the molten metal and debris, cooling the cut surface, preventing re-solidification, and protecting the laser lens. The gas pressure can be adjusted to achieve the desired cut quality.

Why is Fiber Laser Cutting Ideal for Aluminum Sheet?

Precision and accuracy

Fiber laser cutting is ideal for aluminum sheet because it can produce very precise and accurate cuts.

- Focused laser beam: Fiber laser cutting machines use a very focused laser beam to melt or vaporize the aluminum sheet. This allows for very fine cuts to be made, even in complex shapes.

- Stable and repeatable machines: Fiber laser cutting machines are very stable and have a high degree of repeatability. This means that they can produce consistently precise cuts, even when cutting large quantities of aluminum sheet.

- Not affected by heat distortion: Fiber laser cutting is not affected by heat distortion. This is because the laser beam does not generate any heat itself. Other cutting methods, such as plasma cutting and oxy-fuel cutting, do generate heat, which can cause the aluminum sheet to distort. This can lead to less precise cuts.

Laser is important for many applications, such as the manufacturing of electronic components and aerospace parts.

This is due to a number of factors, including:

Focused laser beam: Lasers produce a very focused beam of light that can be used to melt or vaporize materials with great precision. This makes them ideal for cutting delicate and complex shapes, such as those found in electronic components and aerospace parts.

Heat-free cutting: Lasers do not generate much heat, which means that they can cut materials without distorting them. This is important for many applications, such as the manufacturing of electronic components, where even the smallest amount of distortion can cause the components to malfunction.

Versatility: Lasers can be used to cut a wide variety of materials, including all kinds of metals. This makes them ideal for use in a wide range of industries, including electronics, aerospace, and manufacturing.

Speed and efficiency

Fiber laser cutting is also a very fast and efficient cutting method.

This is because fiber laser cutting machines use a very powerful laser beam to melt or vaporize the material, which allows them to cut at very high speeds. Additionally, fiber laser cutting machines are very efficient because they can produce very precise cuts with little to no waste.

The speed and efficiency of fiber laser cutting make it ideal for a wide range of applications, including:

High-volume manufacturing: Fiber laser cutting machines can be used to cut large quantities of material at very high speeds, making them ideal for high-volume manufacturing applications.

Prototype development: Fiber laser cutting machines can be used to quickly and easily produce prototypes, which can help businesses to reduce the time and cost of product development.

Custom fabrication: Fiber laser cutting machines can be used to cut custom shapes and features into a wide variety of materials, making them ideal for custom fabrication applications.

This can help businesses to increase their productivity and reduce their costs.

First, fiber laser cutting machines are very fast and efficient. This allows businesses to produce more products in a shorter amount of time, which can lead to increased productivity. Additionally, the efficiency of fiber laser cutting machines means that there is less waste, which can lead to reduced costs.

Second, fiber laser cutting machines are very precise and accurate. This allows businesses to produce products with very high tolerances, which is essential for many industries. Additionally, the precision of fiber laser cutting machines can help to reduce the need for secondary operations, which can lead to further cost savings.

Versatility

Fiber laser cutting machines can be used to cut a wide variety of materials, including aluminum sheet, stainless steel, mild steel, and copper. This makes them a versatile tool for businesses that need to cut a variety of different materials.

How to Choose the Right Fiber Laser Cutting Machine for Your Needs

Factors to consider, such as:

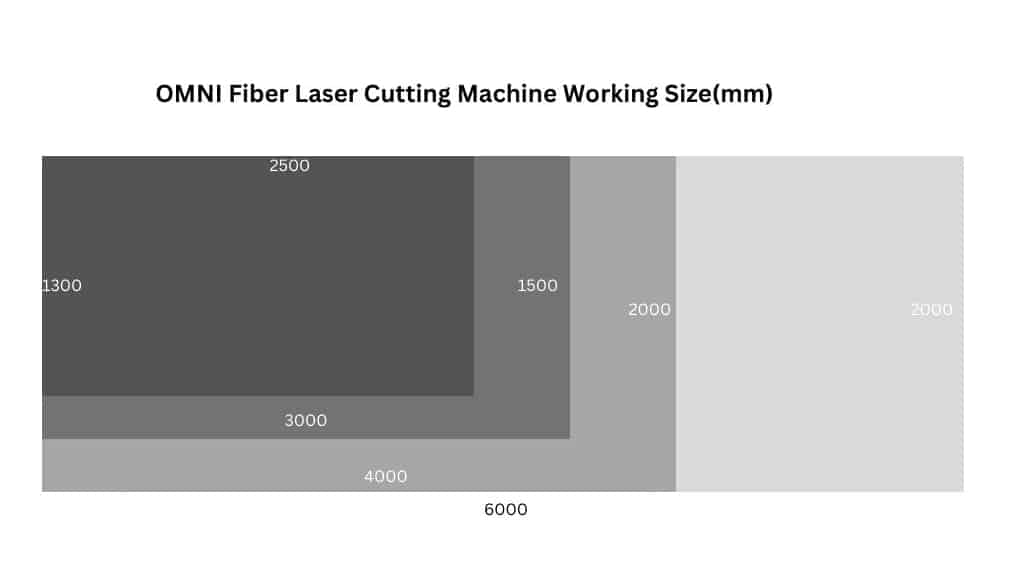

Cutting area

Omni offers a wide range of fiber laser cutting machines to choose from, with cutting areas ranging from 1500mm x 3000mm to 12000mm x 2000mm. This allows you to choose the right machine for your specific needs, depending on the size of the materials you need to cut.

Omni also offers a variety of wattage options for its fiber laser cutting machines, ranging from 1000W to 12000W. This allows you to choose the right machine for the materials you need to cut and the desired cutting speed.

Here are some specific examples of Omni fiber laser cutting machines and their capabilities:

OMNI3015E Fiber Laser Cutter: This machine has a cutting area of 1500mm x 3000mm. It is ideal for cutting thin sheet metals, such as carbon, stainless steel, galvanized steel, and aluminum.

OMNI2030E/2040E Fiber Laser Cutter: This machine has a cutting area of 2000mm x 3000mm.

OMNI6020E Fiber Laser Cutter: This machine has a cutting area of 6000mm x 2000mm.

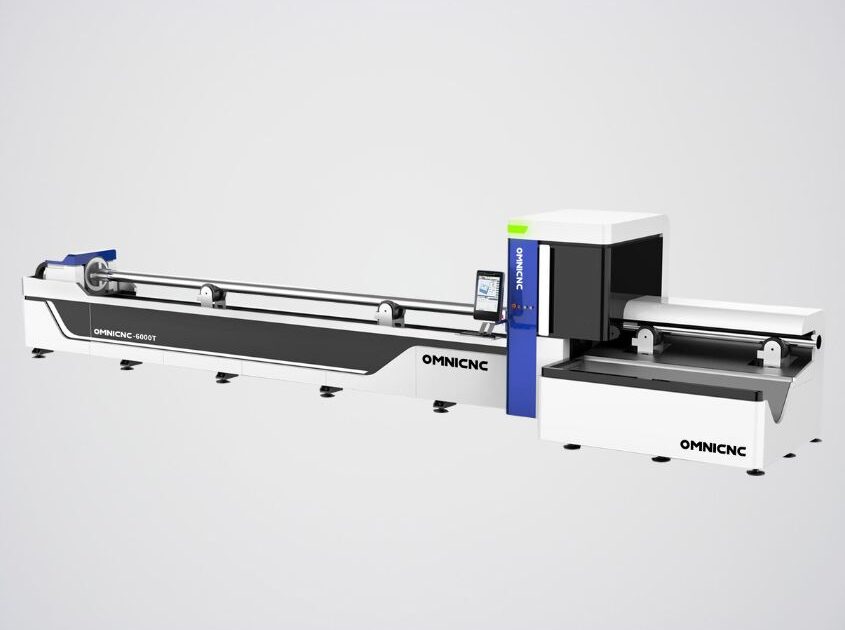

OMNI6020T Tube Fiber Laser Cutter: This machine has a cutting area of 6000mm x 2000mm.

In addition to the above machines, Omni also offers a variety of other fiber laser cutting machines with different capabilities. You can visit the Omni website to learn more about their full line of fiber laser cutting machines.

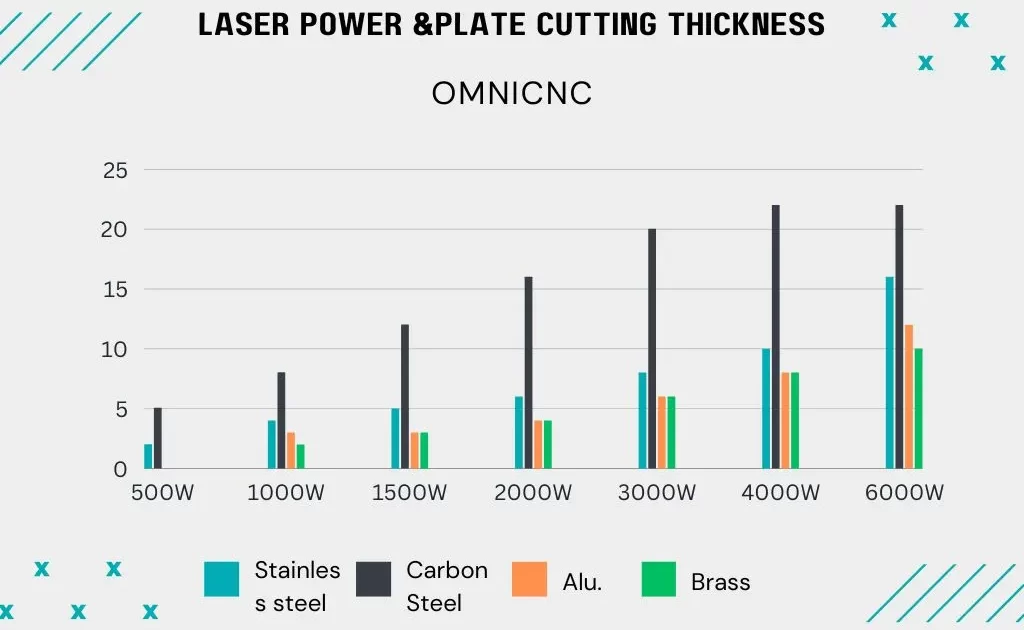

Wattage

Wattage is the power of the laser beam. It is one of the most important factors to consider when choosing a fiber laser cutting machine. The wattage of the machine will determine the types of materials that it can cut and the thickness of the material that it can cut through.

Here are some examples of how wattage affects the cutting capabilities of a fiber laser cutting machine:

1000W, 2000W, 3000W, 4000W, 6000W, 12000W

It is important to choose a fiber laser cutting machine with a wattage that is high enough to cut the materials that you need to cut. However, it is also important to consider the cost of the machine. Higher wattage machines are typically more expensive.

Here are some tips for choosing the right wattage for your fiber laser cutting machine:

Bed type

There are two main types of fiber laser cutting machines: flatbed and tube cutting machines. Flatbed machines are used to cut sheet metal, while tube cutting machines are used to cut tubes and pipes. It is important to choose the right type of machine for the materials that you need to cut.

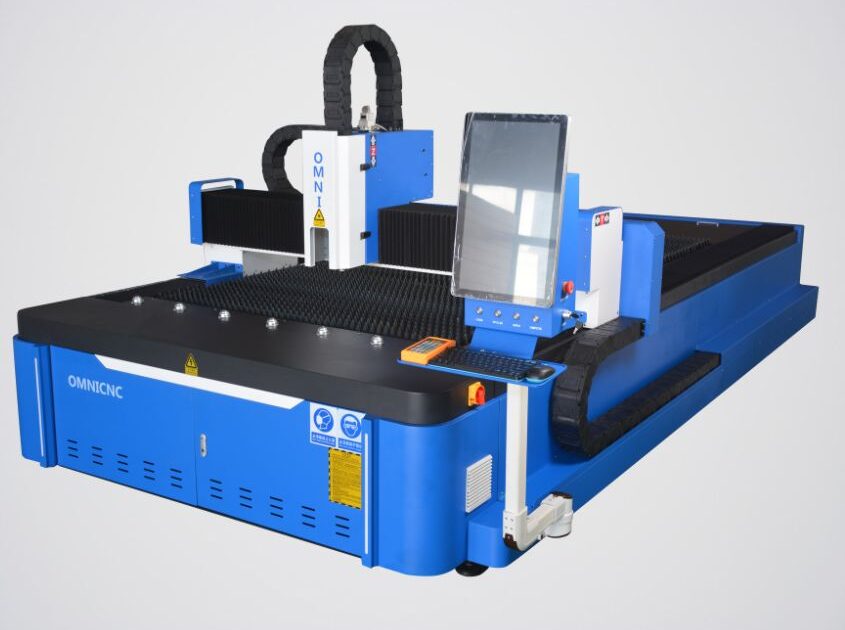

Flatbed Type Fiber Laser Cutting Machine

Flatbed Combined Tube Cutting Machine

Tube Metal Fiber Laser Cutter

H4: Budget

Fiber laser cutting machines can range in price from tens of thousands of dollars to hundreds of thousands of dollars. It is important to set a budget before you start shopping for a machine.

Consider your future needs

Don’t just choose a machine that meets your current needs. Think about what your needs may be in the future and choose a machine that can grow with you.

Talk to a fiber laser cutting machine expert to get advice on the right wattage for your needs.

Tips for Getting the Most Out of Your Fiber Laser Cutting Machine When Cutting Aluminum Sheet

Use the correct cutting parameters

To use the correct cutting parameters for a fiber laser cutter to cut aluminum sheet, it is important to consider the following factors:

Thickness of the aluminum sheet: The thickness of the aluminum sheet will determine the power, speed, and frequency settings that you need to use.

Type of aluminum sheet: The type of aluminum sheet will also affect the cutting parameters. For example, anodized aluminum may require different cutting parameters than regular aluminum.

Desired cut quality: The desired cut quality will also affect the cutting parameters. For example, if you need a very precise cut, you will need to use a lower cutting speed and a higher frequency.

Here are some general cutting parameters for fiber laser cutting aluminum sheet:

| Thickness of aluminum sheet | Power (W) | Speed (mm/min) | Frequency (kHz) |

|---|---|---|---|

| 1mm | 1000 | 1000 | 20 |

| 2mm | 2000 | 800 | 15 |

| 3mm | 3000 | 600 | 10 |

Use a sharp lens

A dull lens can cause the laser beam to scatter, which can lead to a poor quality cut.

Use a high quality assist gas

The assist gas helps to cool the cut and remove debris. Nitrogen is a good choice for cutting aluminum sheet.

Clean the material before cutting

This will help to prevent the laser beam from reflecting, which can damage the lens or the machine itself.

Use a cutting table with a good fume & debris collection system

This will help to remove the fumes and debris generated by the cutting process.

Maintain your machine regularly

It is also important to maintain your fiber laser cutting machine regularly.This will help to ensure that the machine continues to operate safely and efficiently.

Conclusion

Overall, fiber laser cutting machines offer a number of key benefits for cutting aluminum sheet. They are precise, accurate, fast, efficient, and versatile. They also produce high-quality cuts with minimal dross and heat distortion. In addition, fiber laser cutting machines are environmentally friendly and safe to operate.

Any question about aluminum sheet cutting, contact us.