Metal Laser Cutting Machine – Get to Know It

Sheet metal laser cutting machine manufacturers claim that their contracting clients are employing fiber lasers to free up shop space and pursue new specialized types of fabrication work.

Among these fabrication shops, many benefits fiber lasers provide to the sheet metal industry, including precision, speed, control, and reduced burn smoke.

What Is A Laser Metal Cutting Machine?

A fiber laser (or fibre laser in British English) is a laser in which the active gain medium is an optical fiber doped with rare-earth elements such as erbium, ytterbium, neodymium, dysprosium, praseodymium, thulium and holmium.

They are related to doped fiber amplifiers, which provide light amplification without lasing. Fiber nonlinearities, such as stimulated Raman scattering or four-wave mixing can also provide gain and thus serve as gain media for a fiber laser.

From Wikipedia

What Can Be Cut Out By The Machine?

Ferrous and non-ferrous metals like stainless steel, copper, aluminum, carbon steel, alloy steel, and other metals.

Features of Laser Metal Cutting Machine

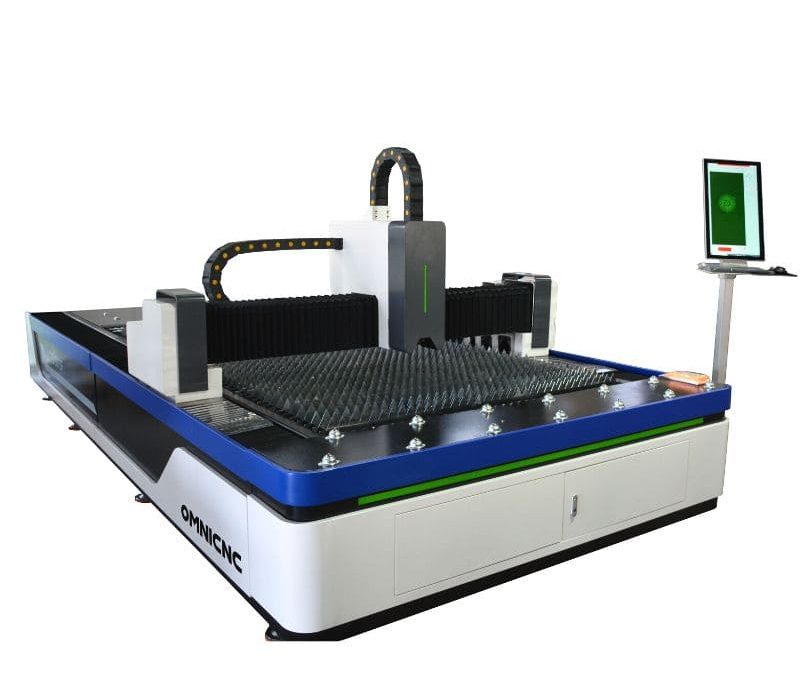

Sheet Metal Fiber Laser Cutting Machine

The OMNI Fiber Sheet metal fiber laser cutter is a modular product series of cutting-edge CNC laser cutting machines with flying optics for the sheet metal sector.

We are happy to offer solutions for all budgets and aspirations, as well as a variety of sheet sizes. Cutting dimensions range from 5′ x 10′ to 8′ x 40′, with a tube cutting attachment available.

Features

- Dimensions for cutting: 5′ x 10′ to 8′ x 40′

- Rack and pinion direct drive

- CYPCUT

- Gantry and rigid frame

- Light curtain for security purposes(Optional)

What Kinds Of Laser Metal Cutting Machines Does OMNI Supply?

How To Choose A Metal Cutting Laser Machine?

The laser’s power is related to the cutting speeds (see Figure 1). Increasing the power by 2kW, especially when cutting stainless steel, may nearly quadruple the cutting speeds. This is true for any other metals (such as aluminum) that are cut with nitrogen as the help gas.

Another laser-related consideration is the type of cutting head. Zoom or non-zoom laser heads are available. You may alter the focus spot diameter and hence the kerf with a zoom head. This implies that thicker sheets may be sliced with the same laser power.

There are more factors to consider, and make sure to consider how to choose a metal cutting laser machine before place order.

What Makes High Precision Metal Laser Cutting Possible?

Rails provide the precision of movement of the metal laser cutting machine.

Because it enables high accuracy laser metal cutting, high speed, and a high price-to-profit ratio.

Laser cutting delivers exceptional precision and greater safety while making cuts since it is computer-guided. Some of the qualities that make laser cutting so precise are as follows:

Coherent Photons

To boost precision, laser-cutting devices use a constant stream of photons synced to a single stable and powerful energy beam. The constant stream of lights meticulously cuts through metal, glass, and other materials.

Low Laser-Cutting Tolerances

Laser-cutting mechanisms often produce cuts with a very narrow range of deviation from the intended design. When compared to hand cutting, laser cutting is far faster and more precise, with guaranteed similar and swift cuts each time.

Precision with Fiber Optics

Modern and sophisticated laser cutters use fiber optic lenses to direct and control laser location from the laser head. This guarantees that the laser beam’s accuracy point is significantly clearer and more direct.

Less Material Damage

Unlike other methods, laser cutting does not damage the material around the cut since the laser beam does not come into direct contact with your material. Ideally, the material is being sliced by heat. Material damage is reduced, resulting in more consistent outcomes.

Because of their assured fidelity, unrivaled control, and low tolerance, laser-cutting machines are suitable for completing very complex and delicate work.

What Laser Power Brand For Metal Laser Cutting?

Raycus laser power is less expensive and performs better than standard lasers in the marking application procedure.

Raycus’ MOPA series, laser welding series, and CW series devices are also widely utilized in cutting, welding, laser cleaning, and other applications. And this tech also be used for laser welding robot.

Of course, OMNI offer IPG, JPT, MAX laser source for option.

Raycus fiber lasers excel in all areas, including cutting quality, accuracy, and marking capabilities.

The fiber laser machine is well-known for its high efficiency against all metals and a restricted spectrum of polymers.

Furthermore, the laser outsources produced are very stable and capable of penetrating the material.

What Is The Power Of Laser Fiber Source OMNI Offer?

The laser source is at the heart of a laser metal cutting equipment, and it has a significant impact on the cost.

The 1-1.5 kW laser source, which can cut stainless steel sheets up to 6 mm thick, is now the most used fiber source.

Furthermore, the 3 -4kW fiber laser optic source is appropriate for those who cut sheets of steel or other material in big quantities with continuous loading at high speed cutting.

Laser Head For Metal Cutting Machine

A metal cutting machine’s laser head is a device that contains a number of optical components that focus the laser power in the cutting zone.

What Does A Metal Cutter Laser Head Consist Of?

It has a focusing lens, a collimator, and focusing blocks that are all protected by glass on the top and bottom. The major consumable is the bottom protective glass.

The metal cutter’s laser head is engaged in providing gas to the cutting zone. Most ferrous metals are cut with air or oxygen, stainless steel and non-ferrous metals with nitrogen, and titanium with argon.

A ceramic ring and a nozzle make up the third component of the metal cutter’s laser head. The nozzle is responsible for supplying gas to the cutting zone. Its diameter is determined by the thickness of the material to be cut as well as the needed gas pressure.

What Are The Dimensions Of OMNI Metal Cutting Machines?

OMNI offer below working size for metal cutting machine (Unit: mm) :

1500*3000 (Hot Sell)

1300*2500

1500*4000

1500*6000 and more

How Much Does a Steel Laser Cutting Machine Cost?

The price of a fiber laser sheet metal cutting machine is determined by its frame, travel speed, and emitter.

The cost of an OMNI fiber laser sheet metal cutting machine with a working area of 1325 and a minimum power of begins at $12,500.