Fiber Laser Cutting Machine: Do Not Buy Before Read This Guide (2023)

Fiber laser cutting machine guide, it will list the brief introduction, and what elements impact the cutting quality and some maintenance tips.

Below is the details list

- Understand How Fiber Laser Work

- What Fiber Laser Can Do?

- Benefits Fiber Laser Have?

- What are the applications of fiber laser cutting machines?

- How Much Does A Fiber Laser Cutter Cost?

- Then How Laser Cut Metal With Cnc Controller?

- Fiber laser machine for sale 2023

- Laser Cutting Quality Elements

- Fiber Laser Machine Installation & Operation

- Laser Cutter Safety

- Fiber Laser Cutting Thickness & Speed Chart

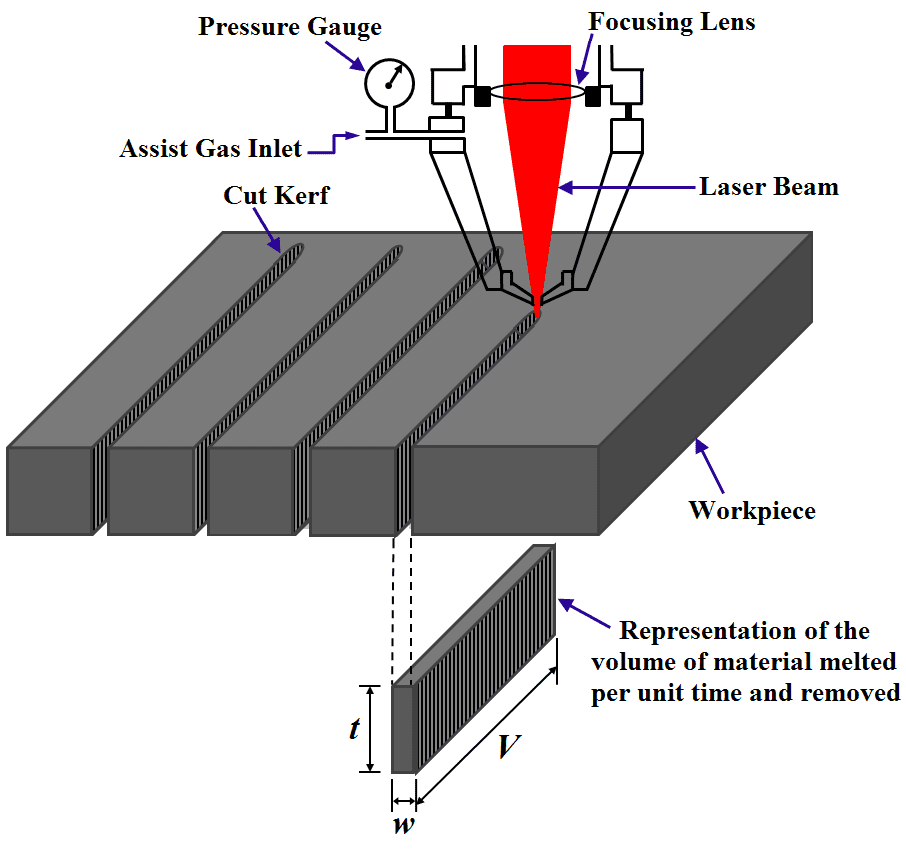

Do You Understand How Fiber laser Cutting Machine Work?

The laser beam hits the surface area of the workpiece. Then the workpiece reaches the melting level or boiling level. So the high-pressure gas that’s straightened with the beam will shock the melt or evaporated steel.

What fiber laser cutting machine can do?

A fiber laser machine can cut thin metals effectively roughly 25mm or 1 inch.

If most of your manufacturing is cutting thin metals as much as 25mm, then a fiber laser cutter will definitely be perfect.

What benefits do fiber laser cutting machines have?

It featured high accuracy, quick cutting. Also it is not restricted to cutting pattern restriction, automated typesetting saving materials, smooth cut, decreased processing cost.

Save time and money by bringing metal laser cutting capacities internal with our industrial-quality, compact, budget-friendly OMNI sheet and tube fiber laser cutter.

The fiber laser cutting machine has the least burr. The cutting surface area is extraordinarily smooth and in addition the speed is really fast.

The fiber laser cutting strategy will slowly improve or replace the typical metal cutting process machines.

What Are Applications of Fiber Laser Cutting Machines?

Laser cutting machine used in several markets including cellphones, computer systems, sheet metal processing, metal handling, electronic units, printing, packing, promotion, crafts, furnishings, design, medical device and also instruments.

This fiber laser is designed for metal fabrication, architecture design, sign shops and corporations. They manufacture customized metal parts. This fiber laser can significantly improve their effectiveness of manufacturing.

How Much Does A Fiber Laser Cutter Cost?

The financial investment of laser cutting tools is high. It is generally used for numerous density under 25 mm consisting of stainless steel, titanium and also titanium alloy, refractory metal as well as precious metal accuracy cutting.

At OMNI, the fiber laser cutting machine cost starts from US$ 14,000 to US$ 60,000.

How Laser Cut Metal With Cnc Controller?

The laser cutting machine composed of CYPCUT CNC system.

It is predicated on the WINDOWS PC CNC system, with fast interpolation operation speed and simple operation.

The electric control system of the laser cutting machine is the main part to make sure that a range of graphics trajectory.

The electric control system of CNC laser cutting machine mostly made up of the numerical control system, servo system, as well as reduced voltage electric system.

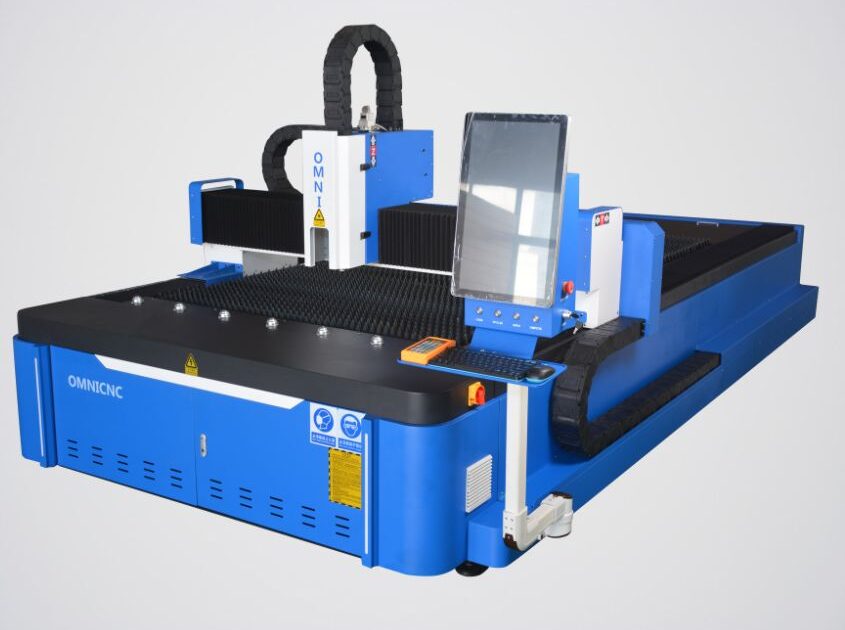

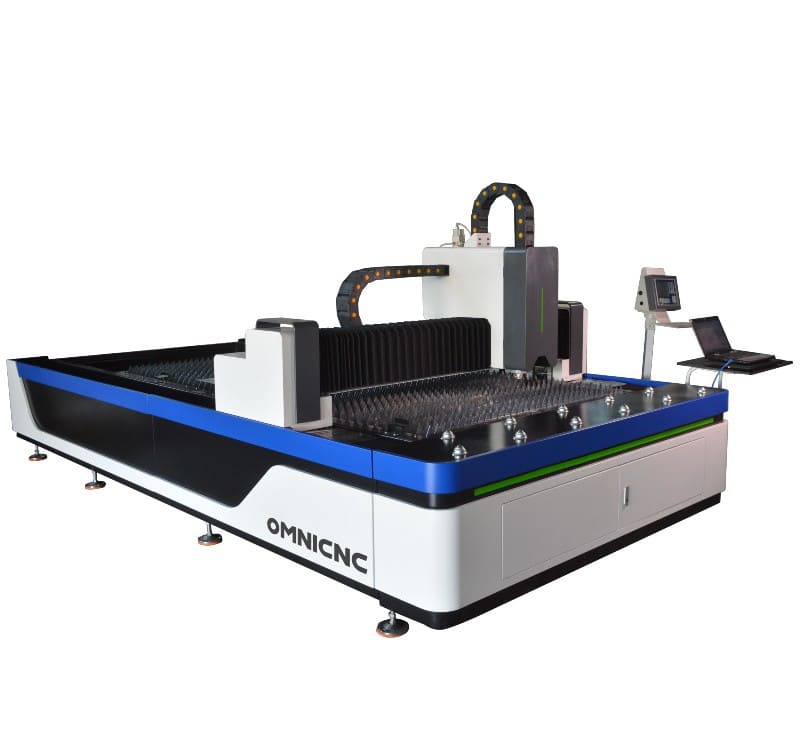

Fiber Laser Machine for Sale 2023

Fiber laser power choice: 1000w-6000w.

OMNI mainly offer

OMNI3015 metal sheet fiber laser cutting machine

OMNI1530 Plate & Tube fiber laser cutting machine

Fiber Combined CO2 laser machine for cutting metal and also non-metal on one table.

FIBER LASER CUTTING QUALITY ELEMENTS

Laser Cutting Power Impact On Cutting Quality

Contrasted to CO2 laser cutting machine, fiber laser cutting machine is no optical course, only need to adjust the laser on the nozzle mouth.

When the laser power setting is also large, the whole cutting surface area is melted, the slit is also huge, and also great cutting quality is not acquired.

So set the suitable laser power, with the suitable cutting gas as well as pressure, can get an excellent cutting top quality, no fused tarnish on it.

In the cutting of stainless-steel, although the cutting gas pressure doesn’t change relative to the density of the material, the cutting gas pressure is continually in a high state.

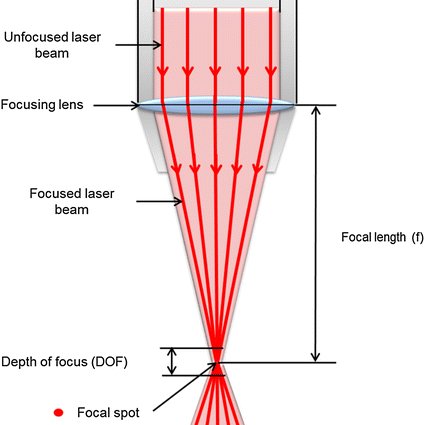

Beam Focus Adjustment

The specifications of the laser beam, the efficiency and accuracy of laser cutting machine and NC system will directly have an effect on the efficiency and high quality of laser cutting.

In the laser cutting process, the relative setting of the beam focus and also the surface area of the cutting sheet has a incredible influence on the quality of the cutting. And it is extremely important to appropriately readjust the focus setting.

The capacitance sensor (mounted on the cutting head) in the Z-axis tool detects the range from the nozzle to the surface area of home plate, feeds the signal back to the control system.

In the cutting process for the laser cutter which takes on flying ray, only the cutting head moves along the X in addition to Y path, and also the position of the table is repaired.

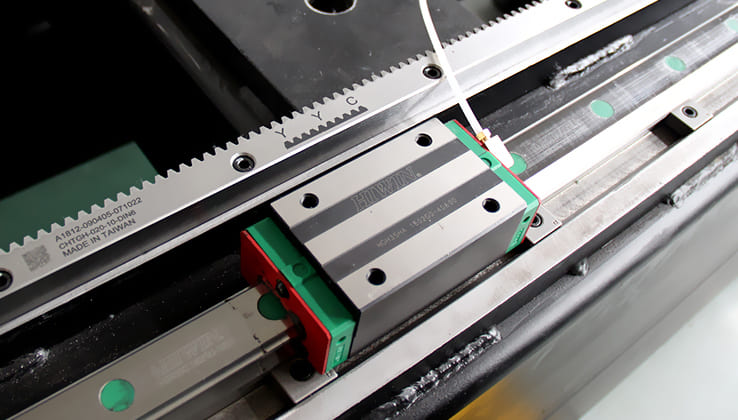

The beam is positioned on the assistance rail of the bed (the guide rail has a linear guide rail and also a level guide rail). And it is supplied with high-grade linear guide rails, and servo motor drive gear turning via the reducer. In this way, it ensures that Z-axis skateboard to achieve X-direction reciprocating movement, the activity stroke is 1450mm.

Nozzle Effect And Adjust Laser At Nozzle Mouth

In enhancement to the beam top quality as well as its control directly affect the top quality of cutting, the design of the nozzle and also air flow control (such as nozzle pressure, work surface placement in the air, etc) is likewise extremely essential variables.

The cutting head has a nut that adjustments the focal size and adjustments the placement of the focus based on the product, also thickness of the cutting product, thereby acquiring an excellent cutting area.

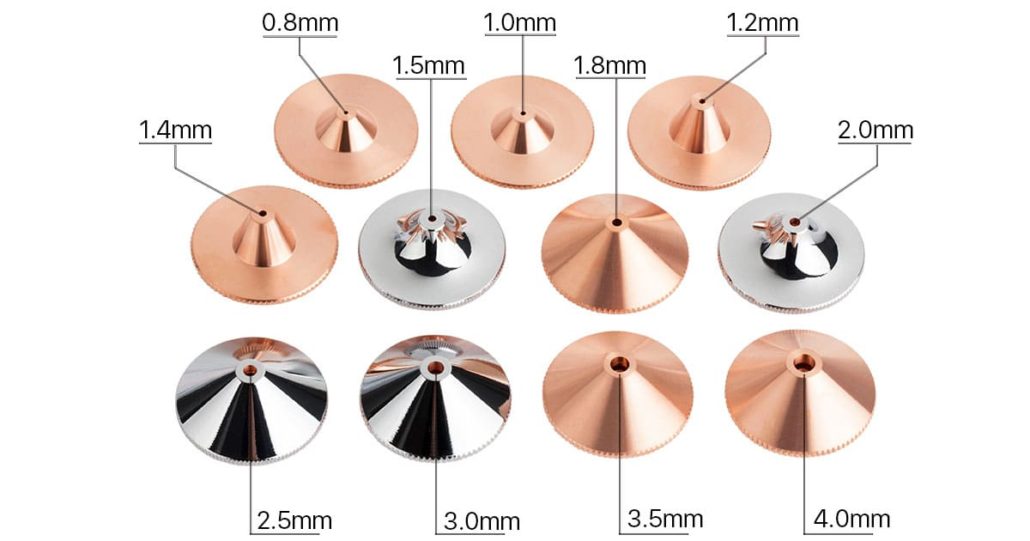

Effect Of The Nozzle On Cutting Quality And Nozzle Size Selection.

The nozzle can transform the cutting gas discharge situation, can control the gas diffusion location and size, therefore impacting the cutting quality.

Because the laser facility is repaired, the facility of the nozzle is transformed by adjusting the adjustment screw on the cutting head deal with to correspond to the laser.

In summary, the facility of the nozzle and also the concentricity of the laser is among the many important elements contributing to the quality of cutting, particularly when the work surface is thicker, its impact can be higher.

Laser Cutting Gas And Pressure Effect Cutting Quality & Selection Instructions

On top of that, the pulse perforation should likewise have a good gas course control system to recognize the control of gas kind, gas pressure switching and also opening time.

1) When the gas pressure is also lowered, the laser is difficult to pass through the cutting plate, piercing time rises, causing low efficiency.

2) When the gas pressure is expensive, causing penetration point melting, layout a bigger melting point, thus affecting the top quality of cutting.

3) laser exploration general usage high sheet metal punching pressure, while the thick plate of the punch uses lower gas pressure.

4) in cutting common carbon steel, the thicker of the material, the fairly reduced pressure of the cutting gas.

Basically, the selection of laser cutting gas and pressure should change according to the real circumstance. It needs to decide on varied cutting criteria based on the specific conditions in particulars purposes.

Machine Linear Guide Impact on Cutting Quality

CNC laser cutting machine is normally geared up with the high precision linear guide, and furnished with an automatic lubrication gadget.

Equipment rack and also linear guide take on closed dust-proof system, included light-weight dust cover and also reliable operation.

Machine Motor & Driving Mode

Via the numerical control system to control the AC servo motor drive, coaxial drive beam to achieve the reciprocating movement of Y-axis, and also attain fast movement along with fast feed movement.

The X and also Y axis are chosen with the servo motor as well as outfitted with the corresponding reducer, which is driven by the high accuracy gear rack.

The lifting movement of the cutting head is understood by the numerical control system manage the servo motor.

As the Z-axis servo control is managed by the CNC system, so the accuracy of the servo control is relatively high and stability is better, therefore making sure the top quality of cutting.

Laser Cutting Machine Installation & Operation

Installation Environment Requirements

The installation and commissioning of the laser cutting machine are extremely vital for each manufacturing facility. So please maintain checking out the complying with details prior to the operation.

Machine Location

Plan out the location of the machine and also other devices.

The site where the machine is to be installed need be clean.

The floor needs to be tidy and also.

Uncrate all machine parts and also put them peroperly.

The head cleanup and help gas bottles need to be positioned and secured as not to tip over.

Electrical Requirements

Power has to be provided to the disconnects for the adhering to components.

Laser power supply.

Chiller

Products to be supplied by the client:.

LAN Cable with 3 static IP addresses.

Oxygen assist gas, 1 connection.

Nitrogen help gas, 1 link.

Air aid gas, 1 link.

Nitrogen for head cleanup, 1 connection.

5 gallon pail for draining antifreeze from cooling down system.

A 3/4″ minimum airline at 125PSI provided to the work cell location. This will certainly need connected to the machine as well as dust collector.

De-ionized or distilled water 20 gallons for the refrigerator.

Fiber Laser Cutting Machine Operation.

Prior to using this laser cutting machine, please realize the machine-related operation technique and comprehend the procedure of the numerous parts of the machine, the correct operation is the reliable measures to make certain the normal work of the laser cutting machine and also individual security.

Check Before Use

A. Check related water and gas channel, ensure there is no leak, no water contaminated.

B. Ensure laser beam ejected from the center of gas nozzle.

C. Check the gas nozzle if could meet the demand of cutting materials.

D. Check gas type, gas pressure is approprite.

Turn On Machine

A. Turn on extermal main power

B. Turn on water cooler

One particular thing to note is the cooling system of the laser cutting machine– the cooling cupboard.

Linked to the inlet and outlet pipes according to the join the refrigerator shell, connected with the inlet as well as electrical outlet door of the laser, must not disjoint the direction of the inlet and also outlet of the pipes.

Before connecting the pipes, must make sure that the outside pipe of the chiller with out garbage and also foreign matter.

C. Turn on emergency stop, “servo”, “laser” button

D. Turn on computer/ control system

E. Import cutting program

F. Check cutting material types, thickness

G. Adjust cutting head position, and nozzle center.

Laser Cutter Safety

This post primarily focuses on laser safety notice, electrical safety, laser cutting machine protective measures, common knowledge must be understood by the operators.

Electrical Safety

To stop electric shock damage, non-professional upkeep workers is purely restricted examination, maintenance of the electric control part of the laser cutting machine.

The area of the laser cutting machine outfitted with lighting indicators means these parts have high electrical voltage or electric components, the driver close to these components or open maintenance ought to be careful to avoid electric shock.

Common Knowledge Should Be Known By The Operators

Machine commissioning calls for expert team, need to be strictly in accordance with the relevant provisions of the application. Please understand the performance of the laser cutting machine prior to analysis as well as check out the relevant random technological details.

Specify the laser safety and security administration location, in the management area of the entry to set up a warning card.

This card info should include laser processing machine power, laser type, restrict outsiders to go into, pay attention to safeguard the eyes as well as safety supervisor name.

The operator need to use protective glasses, the driver is banned to leave during the procedure of the laser cutting machine.

The general power supply voltage of handling laser cutter is a number of thousand volts to 10s of countless volts, should protect against the laser high voltage as well as X-ray produced by the electron tube under high voltage.

Keep the laser cutting equipment clean and tidy, refueling according to the provisions to make sure practical lubrication; to follow the change system, handle the devices as well as devices well, do not shed; stop the machine for inspecting quickly when discover malfunction, if can not be taken care of by the driver, must timely notification associated designers to offer it a thorough overhaul.

Laser Cutting Machine Protective Measures

The driver of the laser cutting machine or the person near the laser during the use of laser cutter, must put on suitable laser goggles and wear protective apparel, in the location of using protective safety glasses, need to have great indoor lights to ensure the smooth procedure of the operator.

The laser-equipped on the laser cutting machine is 4 level laser products, the laser is unnoticeable light, the shot beam, lens representation and scattered light might trigger damages to the body (specifically the eye), the personnel at the website should pay attention to defense, and also to stop fire event.

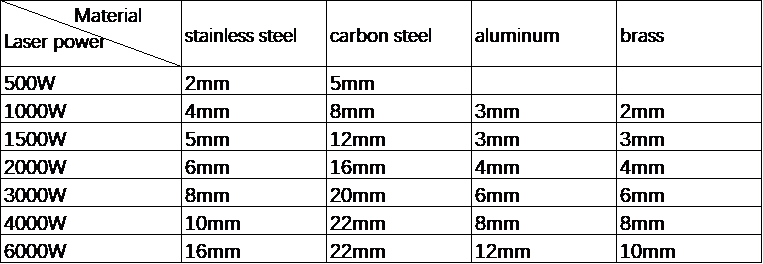

Fiber Laser Cutting Thickness & Speed Chart

Pick the appropriate cutting speed both can enhance the effectiveness of the laser cutting machine, but additionally get a good cutting top quality.

The cutting rate of the laser cutting machine is chosen according to the cutting plate product, the thickness of the plate, various cutting rate will trigger a wonderful effect on the high quality of the laser cutting machine.

Notice: Above data is for reference, the cutting thickness and power value may different in production.