Reasons Why Your CNC Router Machine Fails to Achieve Desired Performance

As we know that CNC machines are the most dependable, reliable and long-lasting parts of equipment for any woodworker. However, time and again, many complexities have been recorded in this durable machine. Programming complexities and due to the failure in some other components in the CNC machine have been a cause of malpractice and frustration.

Usually, there is a fact behind these issues. These small but irritating issues are compounded due to lack of attention towards the machine which can happen by either using it wrongly or poorly maintaining it.

Nevertheless, before going into the depths of the problems and their reasons; let us take a moment to understand what a CNC router machine is and how it works.

What is a CNC Router Machine?

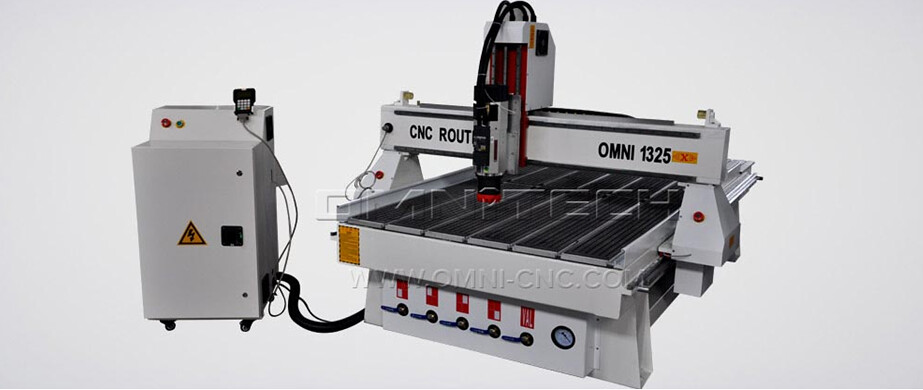

CNC stands for Computer Numerical Control. A CNC machine is an electro-mechanical device that is used to manipulate and control the machine-shop tools and devices with the help of computer programming.

Mostly, CNC machines use a platform that allows for a computer-driven cutting tool to carve a material in all the dimensions. This, CNC machine, can be used by programming it to make precise, repeatable cuts on lowly elevated or flat wood or plastic projects. For high-level usage, a CNC machine can be used by applying it to plasma and laser cutters as well.

The recent changes in technology have led to the marketing programming methods which are used by competing for machine manufacturers. However, the G-code is still something that is the core of CNC machining.

Furthermore, because of innovation and modernization scrap is being reduced which has turned out to be a time and money saver for the companies using the CNC machine. Besides, it is also eliminating the damage to their machining centers by using simulation, verification, and optimization of software. With unique innovative ideas and features, many companies have started to supply these software packages.

What’s interesting is that besides allowing the manufacturer to replicate the machining of a new part, these software packages help in verifying the tool paths to eliminate collisions and crashing and optimize production. Apart from that, they also allow the detection of inconsistency by measuring and analyzing.

How does a CNC Machine Work?

A way to transform a normal piece of material like a block of wood into a finished product with the help of controlled material removal process is called a CNC machine. Similar to other forerunner development technology, CNC works on the digital instructions it receives from the computer-aided manufacturing or computer-aided design file.

Given digital instructions are interpreted for cutting prototype parts by the CNC machine. This practice automates the highly technical and labour-intensive task and thus, becomes a reason for an increase in productivity. When the material is critical, the prototype parts can be created by providing automated cuts. These automated cuts are a reason why the speed and accuracy of the overall process are improved.

Moreover, it has quite a few similarities to 3D printing. Just like 3D printing, CNC has a computer supplied digital code that is passed onto the tool which helps in creating a finished product. Since the entire creating process is installed in a set of precisely coded directions, the process is quite faster, more efficient and less error-prone in comparison to hand-work.

Quite often these processes involve the use of different sets of multiple tools to make the solicit cut. CNC machines can combine tools into common cells from which machines can draw the required work.

Basic machines rotate in one or two axes whereas the advanced machines rotate a little more laterally in the x and y-axis and longitudinally in the z-axis and sometimes these machines rotate either in one or more than two axes.

Multi-axis machines are good enough to flip parts over automatically thus, allowing you to remove material that was below it. This process removes the need for workers to flip the stock material, hence, removing the manual intervention and increase the productive time.

Some issues that can arise while using a CNC Machine and their Solutions

Irrespective of the fact that CNC machines are fast and efficient, there is a thing about these machines which is not unerring.

However, just like other machines, this machine too can develop issues over time. Maybe it can be due to the user’s wrong usage or due to lack of maintenance. Like other tools, there are a few things that a user can do during the normal practice that can result in damaging these machines. Nonetheless, there are steps that a user can take to keep them in good shape for its smooth working.

As a user, one knows that they might run into several problems that can lead to an indefinite number of issues and errors within a CNC machine. Some of these issues are more of a run-of-the-mill than the big ones. Hence, these small and tiny issues are the one which gets neglected and overlooked.

From burn marks on the finishes of the machined parts to the immobilization of different moving parts to inaccuracy in machined parts or problems occurring due to improper power supply, here are a few of these small but common problems occurring in a CNC machine.

● Poor or Improper Maintenance

● Improper Settings or Tools

● Poor or Improper Programming

● Overheating of the machine

● Inadequate skills of the worker and training

● Power supply problem

● Automatic tool changing problem

● Vibration/chatter of the machine

● Clamping/unclamping problem of chunks and fixtures

Poor or Improper Maintenance

This is a mainstream problem that is ignored quite often. Modern machines that come with constantly moving mechanical parts like CNC machine tools require regular cleaning and maintenance which can keep them running in the best possible way.

Howbeit, the lack of attention in clearing the dirt materials and other debris could become a reason for the build-up in the imprecision of the machine. Thus, it provokes failure in the machine.

Measure to Prevent This Problem:

The question now arises ─ how to prevent this problem?

The prevention of this problem is quite simple, the machine holders and the operators need to understand the nuances of the machine while buying this. Moreover, they need to make sure that they go through the detailing quite thoroughly, follow the detailed maintenance regime for the tools which are being used in the machine.

Also, the operator and the owner should make sure that levels of coolants or airflow, like air filters, are regularly checked. Doing this ensures that the operations continue smoothly and are uninterrupted. It is a point to note that having an overheated spindle can result in having a choked air filter in the cooling system.

Improper Settings or Tools

Picking a wrong cutting tool, quite often, might result in a work which is poor in quality and is low with regards to its material finishes. This poor quality can be experienced by the rough edges, cutter marks on the surface, burn marks or raised marks on the material’s corners and edges. Extensive usage of a tool can also result in this kind of error.

Moreover, the poor material finishes can be due to either of the bluntness in the tool which is in use or could be due to improper feed of speed ratio. Wrong feeding of such factors can also be caused by the wrong dimensions of the toll for the job at hand when things come to sizes, quality or match with the material.

Measure to Prevent This Problem:

To solve this issue, one needs to be very attentive while handling the machine and should give importance while picking up the right tool and also, while setting the material for the job in hand.

>Poor or Improper Programming

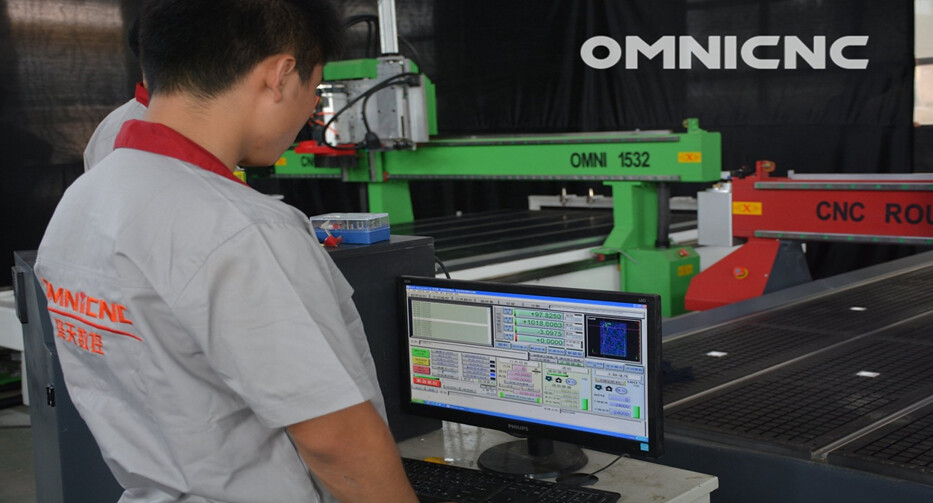

Most of the highly trailblazing equipment is controlled by CNC computers and much of the problems in the CNC machines pop-up when the programming of these machines are wrongly done. This issue may arise due to lack of knowledge of the G and M codes (which are used for the controller of the machine), by setting up the tools in a wrong manner, or the worker inputs the wrong data variables.

Measure to Prevent This Issue:

However, these issues can be resolved by providing adequate training to the new operators. The machine owners can make sure that the new operators are given proper training in different ways in which CNC machines can be programmed.

Extensive user manuals and training, operation of the machines and motion sequencing should be requisitely given to the new operators by the machine suppliers or experienced operators on the shop floor.

Overheating of the Machine

Using a CNC machine for a long duration and high volume can result in overheating. There will be instances where the CNC machine can hit a temperature of 150 degrees or more due to excessive usage. Hence, this could harm the machining which can produce poor quality work and also, could hamper the output of the machining job.

Furthermore, the variations in the rising temperature in the workshop can also play a part in CNC machine overheating. Opening doors or windows so that air/wind could come in can affect the accuracy of the work carried out by the machine tools.

Moreover, having a nice wide window where the sun can shine freely alongside a cold blowing air conditioner is good for the operators but this can affect the finished product from the machine as it can get distorted on its axis.

Also, overheating of a machine spindle could happen due to excessive use of the machine at the highest rpm. A spindle with Grease Lubrication should not be used at extensive hours for full rpm.

Measure to Prevent This Issue:

There are ways to avoid this, one can make sure that they clean all the channels and clean the dirt, soil, and material at a regular interval. Having a calendar to maintain the daily cleaning schedule of all the metal shavings as well as the liquids used during the cutting process can be quite handy in saving the machine from overheating.

To prevent overheating of a machine spindle, the operator can use a spindle with Air-Oil Lubrication or an Oil-Jet Lubrication spindle which is a better option as they have no problem in running for the longest hours.

Inadequate Skills of the Worker and Training

With the rapid increase in the usage of computers and programming, CNC machine tools need an operator who has adequate knowledge, has the skill set and is well trained to handle a different set of requirements of this machine’s programming language.

Without the right planning, organization, and programming skills the worker will be unable to fetch the required yield from these machines irrespective of them having machining skills and experience.

Measure to Prevent this issue:

To make sure that this error does not happen, the machine owner needs to make sure that they are hiring the right machine operator who is good with visualizing and is capable of designing the machining process, selects the right tool and sequences for the task and is good in writing appropriate programs.

Power Supply Problem

In many cases, it may happen that the CNC machine tool’s display or different parts might not work due to issues with the power supply.

Measure to prevent this problem:

However, to rectify this, one should make sure that adequate power and voltage is supplied to the input side. One should also check whether the output or secondary side is properly working or not.

In cases where there is no power or the voltage reading turns out to be low then considering to disconnect the output wires with the power off is a good idea. Moreover, one can check the power supply using power-up and if it wants to be sure of it then it can go through the rechecking process of the output side. They can also check whether the LED on the machines are working or not, and could also have a look at the fuses.

A stable power supply is a prerequisite for working with a CNC machine. It is the foundation for trouble-free operations performed by a CNC machine tool.

Automatic Tool Changing Problem

Often, there will be a time where a user will face challenges regarding the automatic tool changer in your CNC machine’s tool.

Prevention Methods:

Nevertheless, these minor issues can be dealt with by knowing about every step of the tool changing process and how to troubleshoot the machine by diagnosing what went wrong.

Moreover, one should also keep a check on the base, the gripper arm, tool holder, support arm and tool magazines working and ensure that they are running smoothly.

Also, they should examine the action of swiveling and mechanical arm action for their proper working. One must regularly clean the chips and coolant of the automatic tool changer and tool holder.

Vibration/Chatter of the Machine

If the CNC machine vibrates while working then there is a significant possibility that this can reduce the life of the tool, affect its durability and will undermine the quality of the machined part. This can be observed by listening to the noise generated by the machine.

Prevent This issue:

To solve this issue, the operator needs to diagnose the workpiece chatter or the tool chatter. They can also alter the RPM of the machine. By doing so, they ensure that the frequencies of the machining process do not resonate with the material frequency.

Clamping/Unclamping Problem of Chunks and Fixtures

This can be a considerable issue when the piece required to be worked upon cannot be securely gripped by the chunk or continually shifts or vibrates in the process.

Measures to Prevent this issue:

This can be resolved by:

● Checking whether the parts are correctly positioned for a secure clamp.

● One should also check the hydraulic pump and its pressure.

● If the chuck is working based on the MDI M-code command.

● Check whether or not the lubricant is adequately used for gripping the material.

● Avoid the point gripping instead should opt for wider surface gripping.

● Must check whether there is dirt or not, cause dirt and debris to can play a part in malfunctioning of the machine.

● Check for the working output of solenoid. If the output is working then a broken wire at the connector could be a problem.

● If the chuck does not open/close, check to see if the footswitch is working – see if the contacts are still working and that the wires are not broken.

● Look for whether the drawtube connecting the hydraulic cylinder and the chunk is working or not.

How To Choose The Right CNC Bits?

Moving on from the errors and solutions, the question now stands here is, how one can choose the right CNC bits?

As discussed above, CNC is solely responsible to provide good quality to the finished work; hence, taking a risk in choosing the CNC bits could turn out to be risky. Here are a few ways in which a right CNC bit can be chosen:

Application and Material

The material under the cutter has a lot to do with the type of CNC bit an operator needs. Probably, the woodworker might be working with wood or is manufacturing a large amount of plastic or aluminium; for these materials, the CNC router is required.

Picking the wrong bit for the chosen material can hamper the processing of the machine and can destroy the bit and the machine. Some materials require the use of multiple CNC bit types but it is best to use just one type.

When melamine or plywood is placed under the cutter, it is advisable to use compression bits to avoid chipping or tearing of the material.

If the operator is a new entrant in the world of CNC routing then they should prefer for a multi-purpose CNC bit, which uses two-flute spiral bits. The versatile bits can be used on a variety of materials.

Speed and Finish

While making smooth cuts is a priority, there are some projects which demand a quick finish. Speed and accuracy are the most important consideration while picking the type of bit for processing.

For a speedy finish, one must know that feeds and speed depend on a few factors.

● Horsepower of the spindle

● Panels held down by clamps or vacuum

● Stability of CNC machine

● Condition of collet

One should gradually increase the speed of the cutting rate as instantly cutting at high rate makes difficult to gauge the optimal speed.

It is crucial to keep in mind that chips that are too large might break a router bit. Whereas, chips that are too small can turn your waste to powder and dull the bit.

When things come to finishing, the primary goal is to make quality cuts. The more flutes a bit contains, the higher the quality of work the machine gives.

Daily Needs of a CNC Machine:

Apart from choosing the right CNC bit, the operator should understand that the machine also has its daily needs to process the work smoothly. Here are a few daily needs of the routing machine and the operator must follow these needs:

1. Keep the machine clean: After the end of every shift, check the rack, ball screws and linear bearings, clean them if there are any chips surrounding the sensors.

2. Change worn tooling: Change the damaged or worn collets, cover nuts and tools as they can affect your cut quality.

3. Keep a check on the machine: Look for broken parts that affect can the machine’s output or safety of the employees.

4. Close the machine at EOD: Avoid using the CNC machine all year long, as it can get extremely hot. Turning off the machine can reduce the chance of burning the connectors and keep the employees safe from unexpected power surges.

5. Delete old files: Efficiency of the machine should be a top priority of the owner. Hence they should make sure that they delete the old files from the system and keep a back-up in an external file.

6. Timely greasing of the bearings: It’s recommended to oil the bearings at the end of every shift and grease them appropriately.

7. Replace the vacuum pump oil: One should change the vacuum pump oil after every 20,000 hours of use.

So, here was the cover of things that could affect the working of a CNC machine and also, were some of their treatments. Machines are also like humans, they require nurturing and caring. Excessive use and a little carelessness can harm the working of the machine. However, a proper diagnosing of the problem can help prevent a huge loss.