Fiber Laser Cutter Top 10 Concerns That You May Have

Fiber Laser Cutter Cutting Quality & Precision

Fiber laser cutter are known for their ability to deliver high-quality cuts with smooth edges and precise dimensions. The cutting quality and precision of a fiber laser cutting machine depend on various factors, including the quality of the machine itself, its components, and the cutting parameters used during operation.

To ensure high cutting quality, the machine must be made of high-quality materials and components, including the laser source, cutting head, and motion control system. The laser source Raycus is powerful and stable, with a high beam quality and wavelength that is suitable for the material being cut. The cutting head Raytools is be well-designed to ensure optimal focus and alignment of the laser beam. The motion control system FSCut is precise and reliable, with high-speed and accuracy to ensure the machine can cut at the desired speed and accuracy.

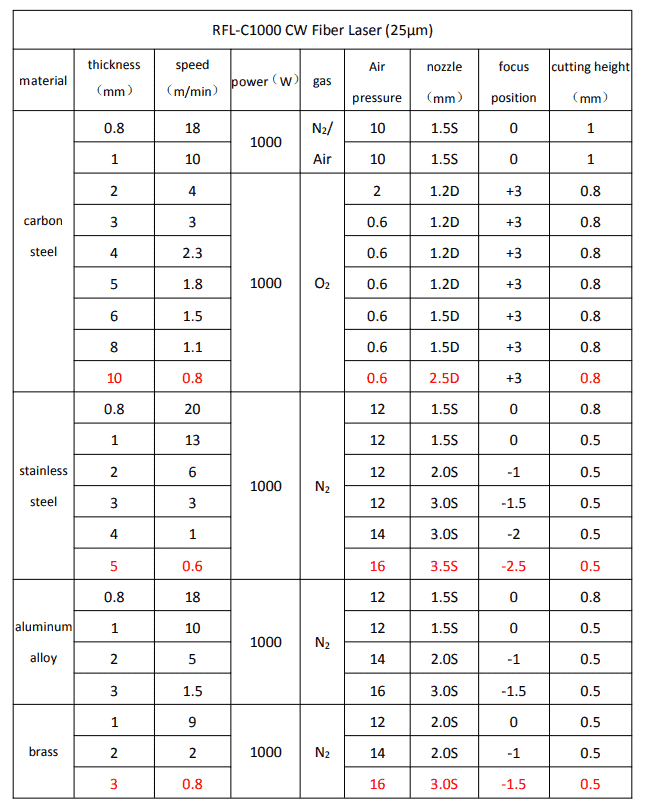

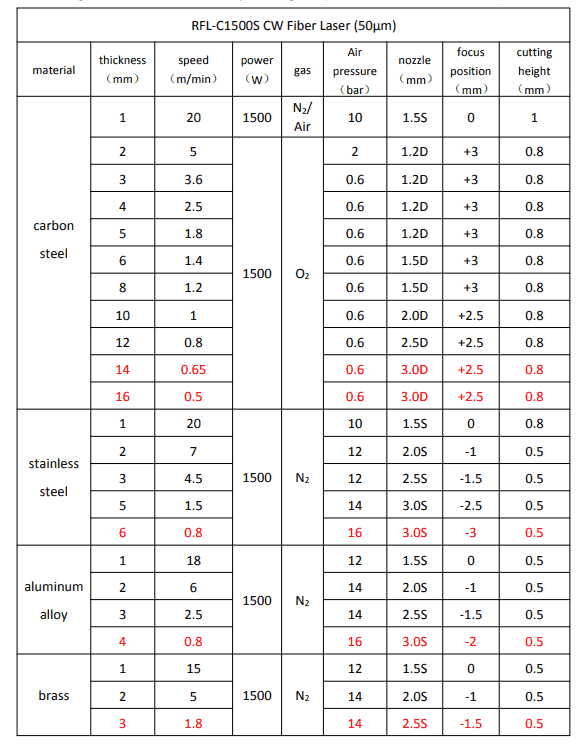

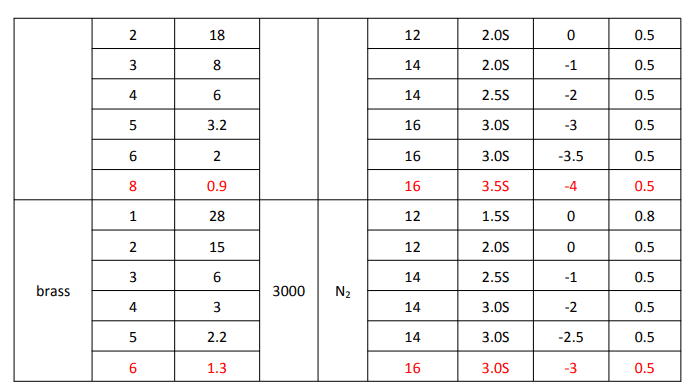

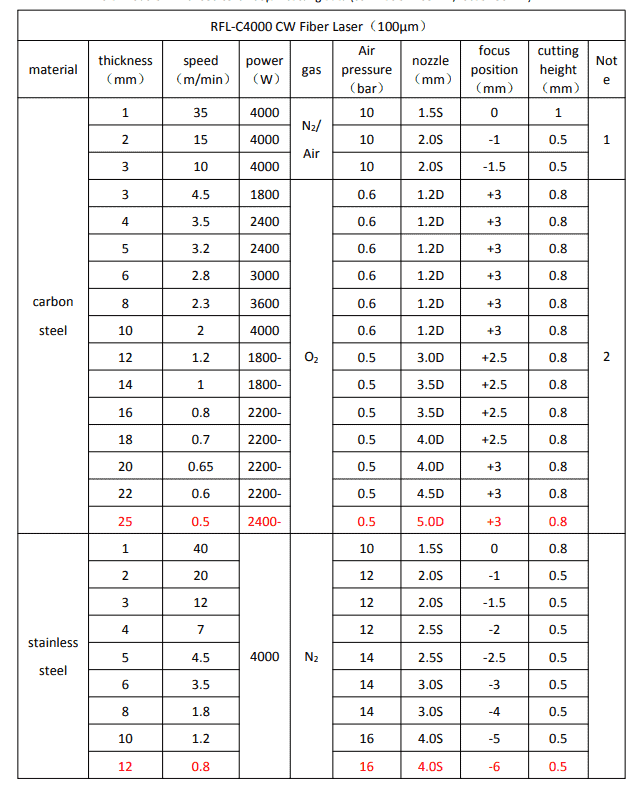

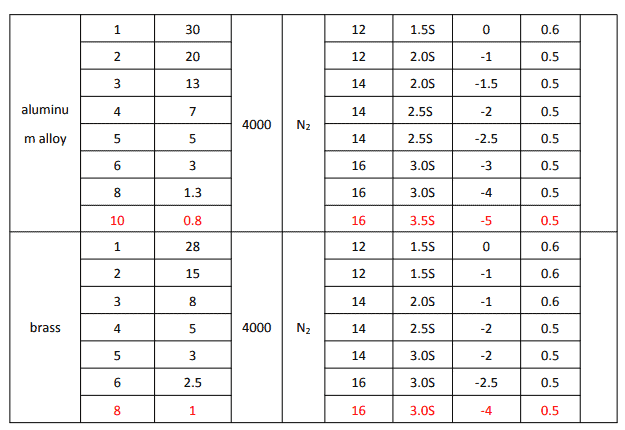

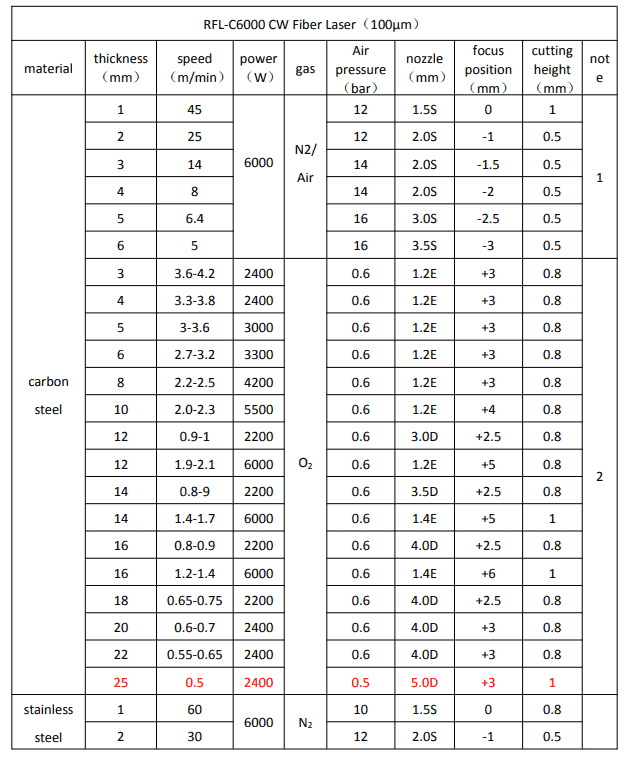

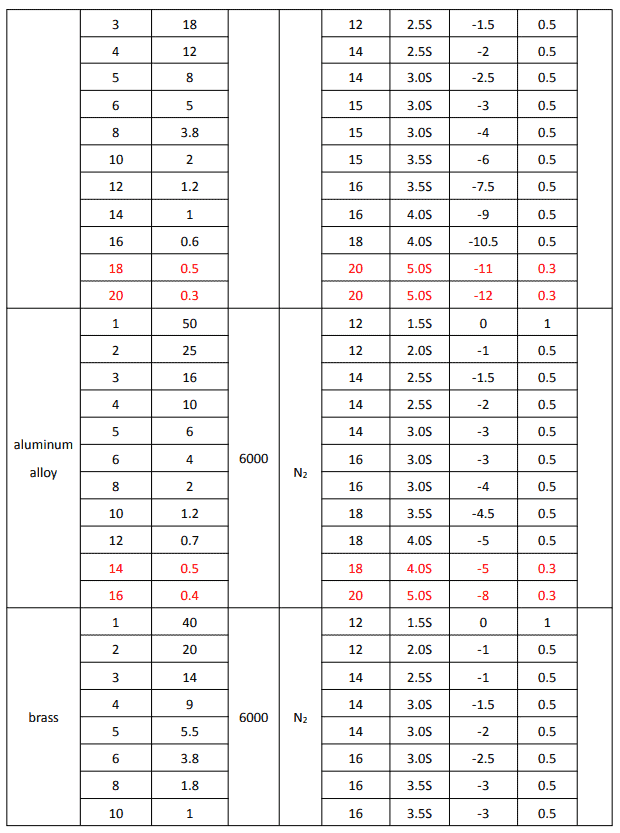

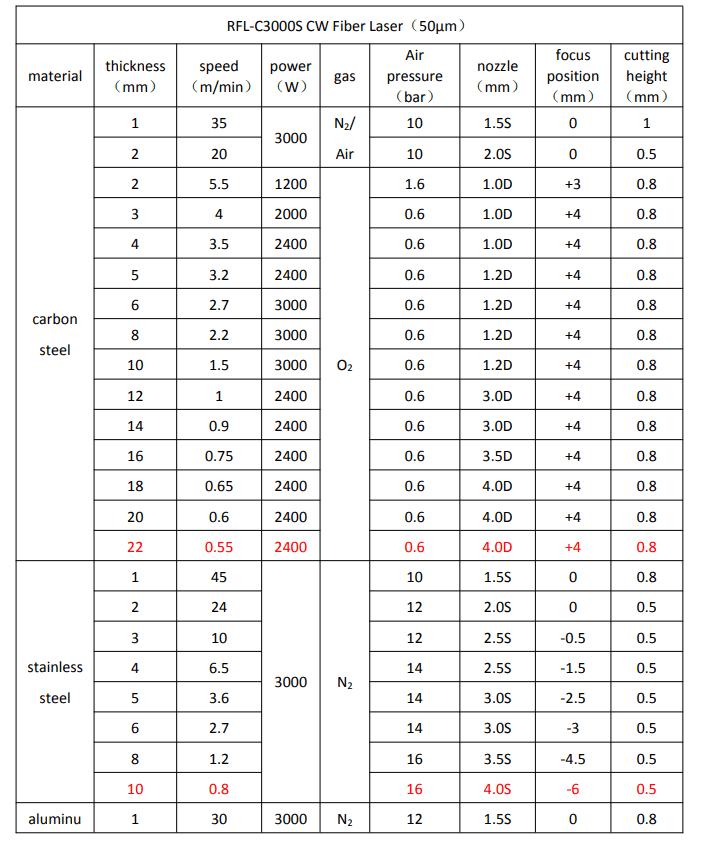

In addition to the quality of the machine, the cutting parameters used during operation play a crucial role in determining the quality and precision of the cuts. These parameters include the laser power, cutting speed, focus position, and assist gas pressure and flow rate. These parameters must be carefully calibrated and adjusted to ensure optimal cutting results for each material and thickness being cut.

1000W Raycus Laser Source

1500WRaycusLaserSource

RaycusLaserPower3000W

Raycus Laser Source 4000W

Raycus Laser Source 6000W

Users of fiber laser cutting machines must also consider the maintenance and upkeep of the machine to ensure its continued high-quality performance. Regular cleaning, calibration, and replacement of worn components are necessary to maintain the machine’s performance and avoid any degradation in cutting quality over time.

Power Output

The power output of a fiber laser cutter is a critical factor that determines its cutting capabilities. The power output is measured in watts and determines the machine’s ability to cut through different materials and thicknesses efficiently.

The higher the machine’s power output, the greater its ability to cut through thicker and denser materials, such as metal. However, it’s important to note that higher power output machines also come with a higher price tag.

When you choose a fiber laser cutting machine, they need to consider the types of materials they will be cutting and the thicknesses they will be working with. This will help them determine the minimum power output they need for their cutting needs. For example, cutting through thin sheets of metal may only require a machine with a lower power output, while cutting through thicker sheets of metal may require a higher power output machine.

It’s important to note that a machine with a higher power output may not always be the best option. Other factors such as the machine’s cutting speed, accuracy, and reliability also play crucial roles in determining its cutting capabilities.

Operating Speed

Operating speed is an important factor to consider when choosing a fiber laser cutting machine. A faster cutting speed increases productivity, which can be beneficial for businesses that require high-volume production without sacrificing cut quality.

However, it’s important to note that the cutting speed is not the only factor that determines the machine’s productivity. Other factors such as the machine’s acceleration and deceleration rates, the type of material being cut, and the thickness of the material also play crucial roles in determining the machine’s overall productivity.

When choosing a fiber laser cutter, we suggest you look for a machine that provides a balance between cutting speed and cut quality. A machine with a high cutting speed may sacrifice cut quality, resulting in a rough or uneven cut. On the other hand, a machine with a slower cutting speed may provide a higher quality cut but may not be as efficient in terms of productivity.

Additionally, you should also consider the machine’s ability to handle different types of materials and thicknesses. Some machines may only be suitable for cutting specific materials or thicknesses, while others may have a broader range of capabilities.

Fiber Laser Cutting Machine Ease of Operation

It is suggested that you choose machines that have intuitive controls and user-friendly software, as it makes it easier to learn and operate the machine, regardless of the operator’s skill level.

Fiber laser cutting machines with easy-to-use software Cypcut, Cypone, Cypnest, Tube Pro and controls like Fscut can help reduce user errors and improve productivity. User-friendly software can simplify the design and cutting process, allowing operators to create and modify designs quickly and easily. Intuitive controls can also make it easier to adjust cutting parameters and settings, allowing operators to optimize the machine’s performance for different materials and thicknesses.

In addition to user-friendly software and controls, other factors that can contribute to ease of operation include the machine’s accessibility and maintenance requirements. Machines that are easy to access for maintenance and repairs can help reduce downtime and improve overall productivity.

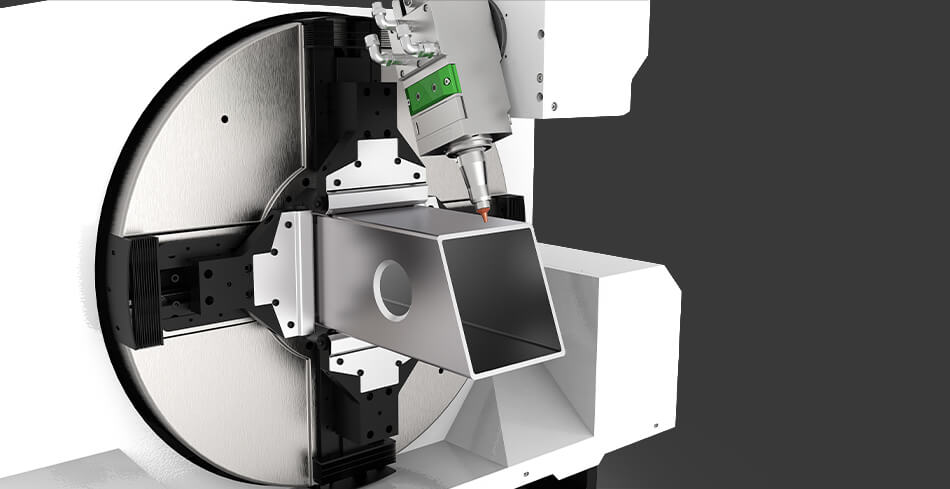

Material Compatibility

Different materials have varying properties, such as density, thickness, and melting point, which can affect the machine’s cutting capabilities.

Fiber laser cutting machines are commonly used for cutting metals, such as steel, aluminum, and copper. Some machines may be more suitable for cutting certain materials than others, depending on the machine’s power output, wavelength, and other factors.

When choosing a fiber laser cutting machine, buyers should ensure that the machine is compatible with the materials they plan to work with. This may involve consulting with the machine manufacturer or supplier to determine the machine’s capabilities for cutting specific materials and thicknesses. Additionally, buyers should also consider the machine’s cutting speed and accuracy for the materials they plan to work with, as these factors can affect the quality and efficiency of the cutting process.

It’s important to note that some materials, such as reflective metals, may require special considerations and additional equipment, such as a beam splitter or a special cutting head, to ensure optimal cutting results.

Maintenance & Service about Fiber Laser Cutter Machine

Like any industrial equipment, fiber laser cutting machines require regular maintenance to ensure optimal performance and durability over time.

You should ensure that the machine you choose has a well-documented maintenance schedule and that the manufacturer provides adequate support and training for maintenance procedures. Regular maintenance may involve tasks such as cleaning and lubrication, inspection and replacement of worn components, and calibration of the machine’s cutting parameters.

In addition to regular maintenance, you should also consider the availability of technical support and replacement parts from the manufacturer. Machines that are backed by a reputable manufacturer with a strong customer support team can help ensure that any technical issues or part replacements can be resolved in a timely and efficient manner, minimizing downtime and maximizing productivity. OMNI offer onsite training and lifetime after sales service, and also have professional installation and training team for offering machine installation and training at your workshop.

You should also consider the machine’s warranty and service agreements when making their purchasing decision. A comprehensive warranty and service agreement can provide added peace of mind and protection against unexpected repairs or downtime.

Cost

Budget constraints are always a concern, and you will look for a machine that offers the best value for your investment, considering both the initial purchase price and ongoing operational costs.

The initial purchase price of a fiber laser cutting machine can vary widely depending on its capabilities, power output, and other factors. Higher-power machines with more advanced features will generally have a higher price tag, while lower-power machines with fewer features may be more affordable.

You should also consider the machine’s efficiency and productivity when assessing ongoing operational costs, as a more efficient machine can help reduce energy consumption and lower overall operating costs over time. Of couse, if with limited budget, we are for sure you will be very interested to see OMNI fiber laser cutter on sale.

Safety Features of Fiber Laser Cutter

These machines use high-energy laser beams that can pose safety risks to operators and other personnel in the surrounding area if proper safety measures are not in place.

To ensure operator safety, fiber laser cutting machines OMNI have built-in safety interlocks that prevent the machine from operating if safety features are not properly engaged. Protective enclosures should also be in place to prevent accidental exposure to the laser beam and to contain any potential hazards. OMNI offer full cover fiber laser cutting machine for high power fiber laser cutter, especially over for the one over 6KW.

You should also ensure that the machine is compliant with relevant safety standards and regulations, such as those set forth by CE or FDA.

Software Compatibility to Fiber Laser Cutting Machine

The ability to integrate the machine with popular CAD/CAM software packages can help streamline workflow and improve efficiency by allowing users to easily import and modify designs.

CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) software packages are commonly used in the manufacturing industry to design and produce parts or products. These software packages allow you to create 2D or 3D designs and generate cutting paths for machines such as fiber laser cutting machines. CypCut sheet cutting software is an in-depth design for fiber laser cutting industry. It simplifies complex CNC machine operation and integrates CAD, Nest and CAM modules in one. From drawing, nesting to workpiece cutting all can be finished by a few clicks.

To ensure optimal efficiency, you should look for a fiber laser cutting machine that is compatible with popular CAD/CAM software packages. This compatibility can help streamline the design and cutting process, allowing users to easily import and modify designs and generate cutting paths without the need for manual programming.

In addition to software compatibility, you should also consider the machine’s software capabilities, such as its ability to optimize cutting parameters for different materials and thicknesses or to generate reports on cutting performance and efficiency. When you only cut 2D work, suggest you Cypcut, and if you also cut tubes, then add Tubepro software to your package.

Scalability & Future-proofing on Sheet Metal Fiber Laser

As businesses grow and expand, you may need to upgrade your machines to accommodate higher production volumes or more complex projects.

To ensure scalability, you should look for fiber laser cutting machines with higher laser power or bigger working size to meet changing production needs.

In addition to scalability, you should also consider the machine’s compatibility with industry advancements and emerging technologies. Fiber laser cutting technology is constantly evolving, and machines that are compatible with the latest advancements in laser technology, software, and automation can help ensure that the machine remains competitive and efficient over time.

You may also consider the machine’s ability to integrate with other equipment or systems, such as automation or material handling systems, to improve productivity and efficiency. OMNI offer robotic laser welding machine for enhancing your metal handling capability.