Waterjet Cutting Stainless Steel : Applications and Benefits

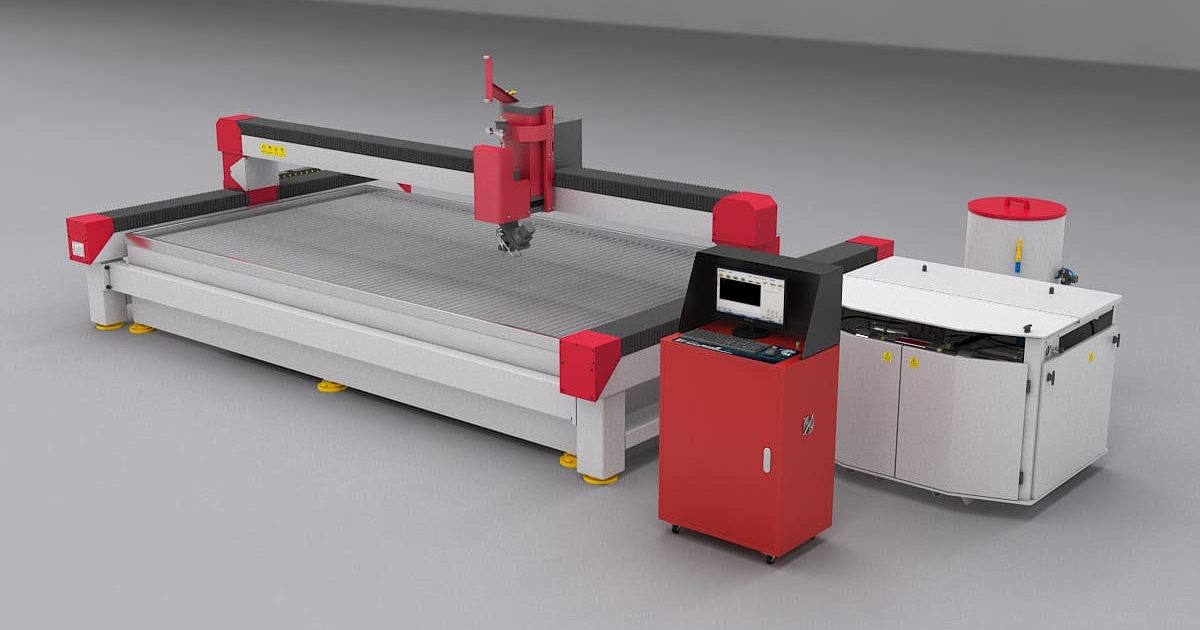

Waterjet cutting stainless steel is a precise and versatile method for cutting this material. It is a popular choice for a variety of applications, including manufacturing, construction, marine, and medical. Water jet cutting machine offers a number of benefits over other methods of cutting stainless steel, including precision, versatility, and speed. This blog post will discuss the applications and benefits of cutting 200mm stainless steel with water jet.

Applications of Abrasive Waterjet Cutting

Manufacturing

- Machinery: Waterjet cutting is a popular method for cutting stainless steel for machinery applications. It can be used to cut complex shapes and patterns for a variety of machinery components, such as gears, shafts, and housings. Waterjet cutting can also be used to create custom parts for machinery, such as fixtures and jigs.

- Appliances: Waterjet cutting is also a popular method for cutting stainless steel for appliances applications. It can be used to cut complex shapes and patterns for a variety of appliance components, such as ovens, refrigerators, and dishwashers. Waterjet cutting can also be used to create custom parts for appliances, such as trim pieces and handles.

- Products: Waterjet cutting is also a popular method for cutting stainless steel for product applications. It can be used to cut complex shapes and patterns for a variety of products, such as furniture, jewelry, and medical devices. Waterjet cutting can also be used to create custom parts for products, such as prototypes and molds.

Construction

- Beams: Waterjet cutting is a popular method for cutting stainless steel beams for construction applications. It can be used to cut complex shapes and patterns for a variety of beam components, such as flanges, webs, and stiffeners. Waterjet cutting can also be used to create custom beams for construction, such as curved beams and beams with special features.

- Columns: Waterjet cutting is also a popular method for cutting stainless steel columns for construction applications. It can be used to cut complex shapes and patterns for a variety of column components, such as bases, capitals, and flutings. Waterjet cutting can also be used to create custom columns for construction, such as columns with special features.

- Structural Components: Waterjet cutting is also a popular method for cutting stainless steel structural components for construction applications. It can be used to cut complex shapes and patterns for a variety of structural components, such as trusses, beams, and columns. Waterjet cutting can also be used to create custom structural components for construction, such as components with special features.

- Exterior Facades: Stainless steel is a popular material for exterior facades. Waterjet cutting can be used to cut stainless steel for a variety of exterior facade applications, such as panels, trim, and railings. Waterjet cutting can also be used to create custom exterior facades for buildings, such as curved facades and facades with special features.

Marine

- Hulls: Waterjet cutting is a popular method for cutting stainless steel hulls for marine applications. It can be used to cut complex shapes and patterns for a variety of hull components, such as strakes, keels, and rudders. Waterjet cutting can also be used to create custom hulls for marine applications, such as curved hulls and hulls with special features.

- Decks: Waterjet cutting is also a popular method for cutting stainless steel decks for marine applications. It can be used to cut complex shapes and patterns for a variety of deck components, such as hatches, railings, and ladders. Waterjet cutting can also be used to create custom decks for marine applications, such as decks with special features.

- Components for boats and ships: Waterjet cutting is also a popular method for cutting stainless steel components for boats and ships. It can be used to cut complex shapes and patterns for a variety of components, such as propellers, nozzles, and valves. Waterjet cutting can also be used to create custom components for boats and ships, such as components with special features.

Medical

- Surgical instruments: Waterjet cutter is a popular method for surgical instruments. It can be used to cut complex shapes and patterns for a variety of surgical instruments, such as scalpels, forceps, and needles. Waterjet cutting can also be used to create custom surgical instruments for specific applications, such as instruments for minimally invasive surgery.

- Implants: Waterjet is also a popular method for implants. It can be used to cut complex shapes and patterns for a variety of implants, such as hip joints, knee joints, and dental implants. Waterjet cutting can also be used to create custom implants for specific patients, such as implants that are tailored to the patient’s anatomy.

- Medical devices: Waterjet cutter machine is also a popular method for medical devices. It can be used to cut complex shapes and patterns for a variety of medical devices, such as pacemakers, defibrillators, and catheters. Waterjet cutting can also be used to create custom medical devices for specific applications, such as devices that are designed to be used in specific environments, such as the operating room or the intensive care unit.

Benefits Of Using Waterjet Cutting

- Accuracy: Water jet is a very accurate method, which is important for applications where precision is critical, such as manufacturing medical devices or creating custom parts for machinery.

- Smooth cuts: Waterjet cutting produces smooth, burr-free cuts, which can improve the quality of the finished product and reduce the need for post-processing.

- No heat-affected zone: Waterjet cutting is a cold cutting process, which means that there is no heat-affected zone around the cut. This can prevent warping or cracking of the material, and it can also improve the strength and durability of the finished product.

- Environmentally friendly: Waterjet cutting is a relatively environmentally friendly process, as it does not produce any harmful emissions.

Conclusion

Water jet cutting is a precise, versatile, and fast method for cutting stainless steel. This blog post has discussed the applications and benefits of cutting 200mm stainless steel with water jet. If you are looking for a precise, versatile, and fast method for cutting stainless steel, waterjet cutting is a great option.