Why Choose a 5-axis CNC Router Machine Over a 3-axis and 4-axis One?

Omni is one of the most premium, quality-focused CNC router & cutting machine manufacturers and suppliers in China. We specialize in the design, development, and production of high-performance, low-maintenance, and computer-controlled CNC routers.

Explore our 3-axis, 4-axis, and 5-axis CNC routers — used in machining for varying degrees of complexity and precision in the fabrication of parts.

Aiming to enhance precision in manufacturing? Choose the perfect router for your unique needs for exceptional results. Read on to know why 5-axis machining is superior to 3-axis and 4-axis options.

3-axis CNC Router

This CNC router is suitable for machining 2D and 2.5D geometry, handling planar milled profiles, drillings, and threaded holes.

The 3-axis router is unable to machine features at angles to the X-Y-Z coordinate system, such as angled or compound angle features.

4-axis CNC Router

The 4-axis CNC router adds rotation about the X-axis (A-axis) for increased flexibility. It can be a cost-effective alternative, reducing the need for multiple fixtures and minimizing the risk of human error.

It is capable of handling angled features, allowing for the machining of complex profiles like cam lobes.

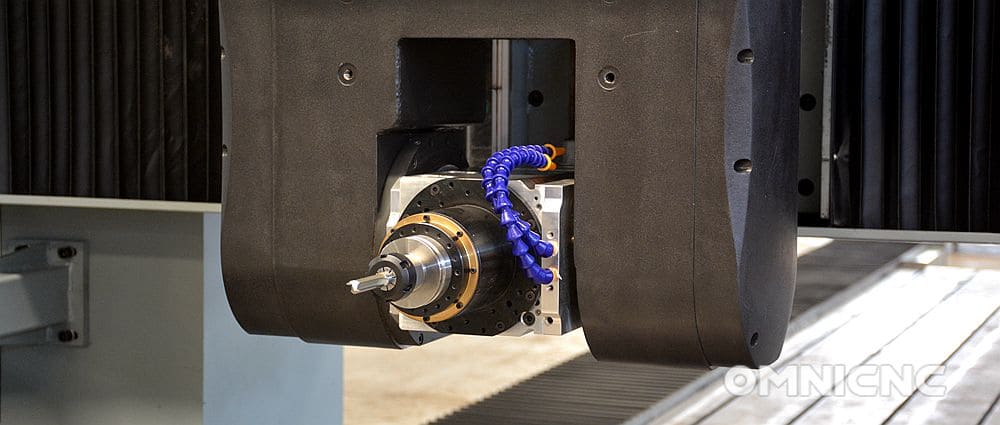

5-axis CNC Router

A 5-axis CNC router machine has two rotary axes and three linear directions (X, Y, Z). This router provides unparalleled precision and versatility. It can

- handle complex geometries,

- machine multiple sides in one setup,

- achieve high-speed production, and

- deliver exceptional precision,

The 5-axis CNC router stands as a top-tier solution for industries demanding intricate and efficient machining.

Differences Between 3-axis, 4-axis, and 5-axis CNC Router Machines

These days, CNC technology has evolved to include touchscreen controls, robots, and multiple-axis machines. To provide a better idea of why 5-axis CNC is the best let’s see some major differences

Axes of Movement

- 3-axis: Movement limited to three directions (X, Y, Z), suitable for simpler geometries.

- 4-axis: Introduces rotational movement (A-axis), allowing for more intricate cuts and carvings.

- 5-axis: Provides the highest degree of cutting tool movement, including rotation about two additional axes (B and C), enabling simultaneous machining from multiple angles.

Part Complexity

- The 3-axis is more limited, requiring repositioning for intricate designs.

- The 4-axis provides additional maneuverability, suitable for tasks like engraving and complex profiles.

- The 5-axis offers the most positioning options, allowing for the production of highly complex and detailed parts.

Time Taken

- The 3-axis takes the longest as it often involves multiple setups for complex parts.

- The 4-axis reduces machining time compared to the 3-axis but is surpassed by the efficiency of the 5-axis.

- The 5-axis requires the least time due to its ability to handle multiple facets in a single setup.

Material Management

- 3-axis may face challenges with certain materials, leading to accelerated tool wear.

- 4-axis and 5-axis machining excel in handling hard-to-machine materials, offering reduced tool wear and better efficiency.

Error Accumulation

- The 3-axis accumulates errors with multiple setups, potentially impacting overall precision.

- The 4-axis and 5-axis offer precision in a single position, minimizing error accumulation.

Programming

- 3-axis machines have simpler programs, while 4-axis CNC machining strikes a balance between simplicity and complexity.

- 5-axis machines require a more intricate program due to multiple directions of tool movement and increased variables.

Surface Finish

- 3-axis and 4-axis machines may require additional steps to achieve a smooth surface finish.

- 5-axis machining delivers superior surface finishes directly, reducing the need for secondary finishing.

Why Choose Affordable 5-axis Over 3-axis and 4-axis Machining

The 5-axis CNC router machine emerges as a game-changer in the precision and flexibility-dominant manufacturing industry. Unlike its counterparts, the 5-axis takes the lead by offering a host of advantages that make it the top choice for many manufacturers.

Application

Aerospace parts, medical parts, defense equipment, aircraft parts, dental implants, and other such applications require ultra-high precision. These precision parts can only be created with multi-axis machining like a 5-axis CNC router.

Production Volume

Choose the number of axes based on the production volume you want to manufacture. Small-volume manufacturing can be met with a 3-axis machining process. However, high-volume production requires 5-axis options.

Secondary Finishing

The 5-axis provides a smoother finish directly, minimizing the need for secondary finishing steps. The 3-axis and 4-axis may require additional finishing steps to achieve a polished surface.

Better Software Compatibility

Adopting an open software interface, it can be compatible with the processing codes generated by various CAD / CAM design software, such as type3 / Artcam / Castmate / Wentai, to ensure the realization of various design functions.

Less Headache, More Options

Tool breakage and collisions can be a headache in machining. The 5-axis router machine, with its multiple options for tool approach, minimizes the risk of tool breakage. It’s like having a skilled craftsman who knows just the right angle for every cut, reducing errors and ensuring a smooth operation.

Conclusion

In a nutshell, the 5-axis router offers a winning combination of precision, speed, customization, and versatility. It’s the go-to choice for those who demand the best in the world of machining. So, if you’re aiming for excellence in your projects, why settle for anything less than the limitless possibilities that a 5-axis CNC router machine brings to the table?