5-Axis CNC Router Machining: The Perfect Solution for Impellers

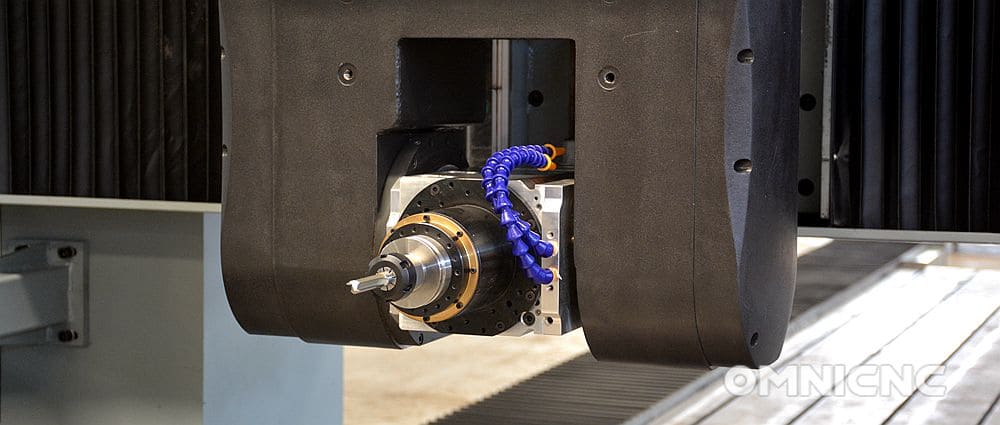

Five-axis machining is a much more effective way to generate a wide range of job, and not just incredibly complex aerospace components.

Even if you are not machining contoured surface areas, being able to get at more component functions in a single configuration can pay substantial returns in decreased complete cycle times, much better machine utilization as well as enhanced top quality. No question, a 5 axis cnc router machine is a lot more pricey than a typical VMC. However the worth of these advantages is significant. They will allow your store to a lot more cost-efficiently create a larger range of job.

WHAT IS AN IMPELLER?

An impeller is a rotating component of a centrifugal pump that accelerates fluid outward from the center of rotation, thus transferring energy from the motor that drives the pump to the fluid being pumped. The velocity achieved by the impeller transfers into pressure when the outward movement of the fluid is confined by the pump casing. An impeller is usually a short cylinder with an open inlet (called an eye) to accept incoming fluid, vanes to push the fluid radially, and a splined, keyed, or threaded bore to accept a drive shaft.

Impellers are used in a wide variety of applications, including:

Centrifugal pumps

Fans

Compressors

Turbines

Water jet cutters

Mixing vessels

The design of an impeller is critical to its performance. The shape of the vanes, the number of vanes, and the speed of rotation all affect the amount of pressure and flow that the impeller can generate.

WHAT 5 AXIS CNC EQUIPMENT CAN DO?

This includes high-performance auto port finishing, impellers, turbine blades, reducing tools, 5 axis cutting, and also undercut machining in mold and mildew as well as pass away making.

WHY CHOOSE 5 AXIS CNC ROUTER FOR IMPELLER MACHINING?

Today, a 5-axis CNC router is the only method to solve the machining of the impeller, blade, Marine prop, hefty generator rotor, wind turbine blades, large diesel engine crankshaft and so on.

The tough part of this procedure is dynamically controlling the device axis, as the tool progressively spirals down the blade.

Modern CAD/CAM systems permit you to regulate all facets of 5-axis machining: the cut pattern, the device axis direction as the device is adhering to that cut pattern and the exact get in touch with point of the device suggestion as it touches the drive surfaces. A complete package also allows you to view an online maker replicate the entire reducing process while developing it, as opposed to using a pricey 5-axis maker as a verification tool.

For example, turn the device in the side tilt instructions if it comes also close to the next blade, or withdraw the tool along a tool axis if it comes too near to the floor surface area and link these movements in a smooth integrated movement by thinking about the available maker tool capacities.

The extra movement available with 5 axis cnc router machine permits you to accomplish intricate shapes and also styles. 5 axis cnc innovation completes the impeller in a single arrangement, decreasing the number of arrangements as well as helping you save time.

A lag angle can be established between completion of a flat or hog nose device as well as the surface. It will result in a face milling problem that lowers the number of cuts in superficial locations.

For Personalized CNC Machining Turbocharger Impeller, the manufacture of intricate rotational get rid of multiple blades, such as blisks and also impellers, along with private blades, call for intricate 5 axis milling.

Machining impellers from a blank includes roughing the excess material from between the blades, semifinishing the floor. Also it includes the blades and then finishing the floor as well as the blades. If a multitasking equipment is available, these procedures can be carried out in one or, perhaps, 2 configurations.

Completing the floor between the blades is relatively straightforward when using a zig-zag cut pattern that starts from the center and also extends towards the outdoors perimeter. This motion maintains a consistent climb-cut. Prolonging the access as well as leave motions gives a smooth, uniform surface. Device axis can be regulated by forcing the facility of the tool axis along a chain positioned in the middle of the gap in between the blades.

HOW TO MACHING IMPELLER?

STEPS

OUTLINING

Roughing options include several cuts normal to the surface, several cut midsts along the device axis, full 5 axis dive roughing as well as adaptive roughing.

To obtain a great finish with a 5 axis device, the tool should have a specific angle to the surface area.

The impeller processing process is separated right into a number of processing methods. Such as impeller harsh machining, blade surface area middle processing, blade surface completing as well as runner surface finishing.

The objective of rough machining is to swiftly and successfully get rid of the empty margin. And also it is additionally the method that finest reflects the performance of impeller machining. See below tooth cavity milling and also multi blade roughing.

Semi Finishing

Semifinishing and also completing toolpaths are essentially the very same, with the exception of the amount of product left and also the step-over value. Care must be taken to leave a lot of material for finishing. If done correctly, the finish cut will precise, cost-free ; the blade progressively, avoiding any vibration, also on really thin blades. Tapered-end ballnose cutters are chosen for maximum rigidity.

Completing

The function of ending up is just how to get a good surface area high quality. It has a terrific relationship with the selection of tools, the combination of device speed and feed. See below Z degree finishing.

Finishing impeller blades is the biggest obstacle. The individual blades of an impeller are frequently slim, distorted, brief on one end, tall on the various other and also close together. It is desirable to maintain the cut pattern parallel to the center surface. It is also more effective to cut the whole blade in one constant movement to prevent leaving unwanted device marks on the workpiece.

The renovation of impeller handling effectiveness is mainly the improvement of roughing effectiveness. Utilizing the five-axis impeller roughing setting, the 5 axis cnc router roughing of the impeller can be recognized. And the material can be preserved evenly, the processing path is reasonably smooth, and also the handling performance is boosted.

TIPS

When 5-axis dive roughing, device deflection is minimal since reducing forces are lined up with the cutter’& rsquo; s facility axis, drastically expanding device life.

To prevent babble marks, we require to alter the sharpness of the cutting tool. However it will have burr on the surface. To make sure the best surface area result, we need to utilize the high Hardness as well as intensity of the reducing tool.

FINAL THOUGHT

Whether you need machining a complicated model or high-volume production, contact us for 5 axis cnc router configuration. Please experience the difference Strong Device can make in bringing your item or vision to life.

Source from Okuma