CO2 vs Fiber Laser Technology: Which is Right for You?

Fiber laser technology is used for cutting sheet metal, whereas CO2 glass tube is mainly used to cut non metal materials like paper, bamboo and acrylic materials. You can decide on the right laser cutting system based on your current usage, needs, budget, and long term goals.

The key factors to deciding which laser to use are

- Materials – fiber lasers are faster at cutting thinner metals sheets and CO2 lasers can cut non metallic materials.

- thickness of the material – The smaller the beam, the more thickness it can penetrate.

- precision needed – smaller spot size has higher precision.

- production rate

- budget and,

- operating costs.

Out of the 2 technologies (CO2 and fiber laser), CO2 is the older one. But fiber lasers have a greater advantage over CO2 in terms of cutting speed, lower operating costs, higher outputs and more potential. The fiber laser may well be the future of laser cutting.

Difference Between CO2 and Fiber Laser Technology

Beam – The main difference between the CO2 and Fiber Laser is the beam. The wavelength of the beam decides which materials they are able to cut. The wavelength of the CO2 laser is 10.6 micrometers and fiber laser is 1.06 micrometers.

Wavelength – The smaller the wavelength the better suited the beam to cut materials. More the beam is absorbed into the material and cuts through it, the better.

Spot Size – The spot size of the laser determines the kerf width. Smaller spot size means greater precision. The CO2 laser spot size is 90% larger than the fiber laser.

Adjustment – Fiber lasers can use zoom and non – zoom cutting heads. Zoom heads allow users to adjust the focus spot diameter which contracts or expands the kerf width. CO2 machines use different heads and lenses to make adjustments to the spot size.

Industrial applications of lasers

CO2 laser machines were popularly used in the pharmaceutical, food, electronic manufacturing, fabric cutting and cutting building materials.

Fiber lasers are now being preferred in the pharmaceutical, aerospace, electronics and automotive industries because of the fast cutting speed and precision.

Materials that CO2 and Fiber Lasers Cut

CO2 lasers have dominated the market longer than fiber lasers. Currently, companies are switching to fiber lasers over CO2 lasers.

Selection of materials for cutting

A continuous wave (CW) fiber is needed when cutting metals. This gives higher average power that has the best results in cut quality and cutting speeds.

| Stainless steel | Only fiber lasers can cut stainless steel. |

| Copper and Brass | These materials are highly reflective and can damage the CNC cutting heads. The CNC cutting heads have optical heads that can be quite damaged with the laser reflection. CO2 lasers have a thicker wavelength which results in a lot of reflection and reduces the lifespan of the CNC optical cutting heads. Fiber laser is better suited to cut reflective metals |

| Aluminum | Aluminum is very reflective. Only fiber lasers can cut through aluminium. |

| Plastic coated stainless steel | It can be cut only by the CO2 glass tube laser. The CO2 laser beam is absorbed by the plastic and hence only one cut is required. Although with thicker sheets, CO2 lasers need to make 2 cuts. Fiber lasers are used only to cut through metal. |

| Non metallic materials | CO2 laser is advisable to cut the non metallic materials like textiles, wood, and paper. The smaller wavelengths of fiber lasers are not absorbed by these materials. |

Designing Surfaces

When it comes to making intricate designs on materials, fiber lasers are the best options. Fiber laser has a very small spot diameter that increases the intensity. It is able to mark surfaces with ease without damage. It can make intricate markings on metals with precision.

Fiber lasers are the first choice to trace and write on a product. It is used to mark serial numbers, barcodes and data on metal parts. Such laser machine, we call it laser marking machine.

Non metallic surfaces like plastics, wood, textiles and glass are best marked with CO2 lasers.

Cutting Speeds of CO2 and Fiber Lasers

When cutting stainless steel, fiber lasers are faster at cutting thin sheets, than CO2 lasers.

For 1 mm a fiber laser cuts stainless steel 6 times faster than the CO2 laser. The difference decreases as the material sheet gets thicker. The fiber laser cuts a 5 mm sheet only 2 times faster.

Increasing the power by 2kW can increase the speed by 2-3 times. However as the sheet thickens, the CO2 laser does much better than the fiber laser.

High power fiber laser machines achieve much faster speeds for cutting all thicknesses. High power CO2 lasers are less common.

However, the fastest speed may not be the most cost effective. It is better to save costs on the optical heads and gas.

Maintenance and Operating Costs

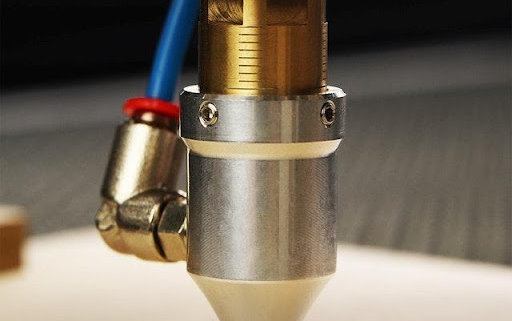

Laser Beam Delivery System – The difference in the laser beam delivery systems reduces the maintenance cost of the fiber laser, as compared to the CO2 laser. The delivery of the laser beam is through a fiber optic cable which is protected from contaminants.

CO2 lasers use mirrors with bellows. The mirrors and bellows need cleaning and replacing to keep the machine performance optimum. The performance of the CO2 laser is more susceptible to the environment (temperature, moisture).

The main difference in costs is damage to the oscillator. The CO2 laser is reflected from metals that damages the cutting head and incurs major costs of frequent replacement.

Aligning the fiber laser (only a single lens needs adjustment) is easier than the CO2 laser.

Electricity – Fiber lasers consume less energy than the CO2 lasers.

Idle time – CO2 laser takes upto 20 minutes to warm up. Fiber lasers do not have any down time.

Space – The size of the shuttle tables and the cutting table determines the space taken up by the machine. Comparing the same laser powers, the CO2 laser takes up 4 times the space that fiber laser does.

Fumes – The fumes that are released depend on the material being cut. Plastics release a lot of toxic fumes and metals emit fine particulate matter.

Key Takeaway

While CO2 lasers are still very popular, the fiber laser efficiency is a game changer.

Cutting times, cost efficiency on operations, output and maintenance are factors that favor the fiber laser.

At OMNI CNC, you can find CO2 laser cutters and fiber cutting machines in top-performance and at a best price. Get in touch.