How to Get Started With Laser Cutting?—Beginners Guide

Laser technology has been utilized in numerous industries for various purposes, from deep penetrating welding to hardening & cladding. Now lasers are widely employed for cutting metal plates. The laser cutting process delivers accurate & yields excellent cut quality on aluminum and stainless steel plates. It ensures a small kerf width with minimal heat-affected zone; therefore, best-suited for cutting intricate holes and shapes.

In this next segment, we discuss how a laser cutting machine works, so scroll down and have a look at:-

How Does a Laser Cutting Machine Work?

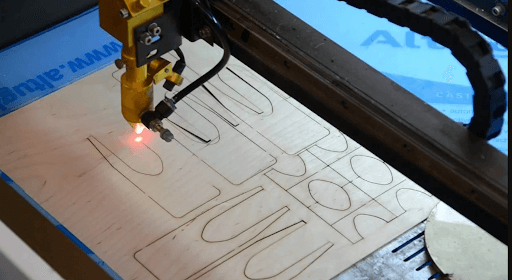

In a laser cutting machine, the fundamental component is the high-powered laser. The precise laser beam is directed via the Optics and Computer Numerical Control (CNC) to the material to be cut.

Typically, the laser cutting machine employs a motion control system to adhere to the G-route. The focused laser beam vaporizes, burns, or melts the material to ensure a pinpoint surface finished edge.

The lasing materials are responsible for creating the laser beam via the lamp inside the closed container or electrical discharges.

The lasing material is amplified through internal reflection via a partial mirror until it has enough energy to escape as a coherent monochromatic light stream.

The laser is focused by the mirrors/fiber optics that directs the beam via the lens that intensifies it. The laser beam is under 0.0125 inches at the narrowest point, and the kerf width as small as 0.004 inches.

Types of Laser Cutting

The laser cutting process is broadly divided into three categories. One is CO2, the second one is Crystal Laser Cutting, and lastly, Fiber Laser Cutting.

CO2 Laser Cutting

CO2 cutting is achieved through a gas laser. The gas here is the carbon dioxide mixture, which has been stimulated electrically.

The CO2 laser machine is highly recommended for materials, which are non-metal, since it has a wavelength of 10.6 micrometers.

Crystal Laser Cutting

The crystal laser cutting is an amalgam of neodymium-doped yttrium ortho-vanadate & neodymium-doped yttrium aluminium garnet lasers. Crystals that belong to solid-state laser groups and have wavelengths similar to fiber lasers. Thus, they are suitable for cutting metal and non-metal.

The crystal laser cutting machine is manufactured out of pricey pump diodes; and costly replacements ( typically after 8,000 – 15,000 hours of use). It has a shorter service span.

Fibre Laser Cutting

Now, comes the final type of laser cutting which uses fibre laser that ensures accurate metal & non-metal cutting. The fiber laser beam is created using the “Seed Laser,” which is then intensified using pump diodes & glass fibers. It means the beam is approximately 100 times higher than the CO2 laser in terms of intensity. The fiber laser cutting machine has a lifespan of 25,000 usage hours.

With efficient production rate & speed, our fiber cutting machines work with numerous materials.

The History of Cutting With Lasers

Despite being a process that is prevalent across the globe, cutting with a laser is a relatively new technology. The first laser cutting machine was developed in 1930, and later with time the technology evolved.

In 1965, laser cutting was used in diamond mines, and it was the British that pioneered the use of this laser cutting machine. In the 1970s, laser cutting machines were popular in the aerospace industry.

Over the years, the technology improved, and now laser cutting is used in various industries.

Advantages of Laser Cutting Over Conventional Metal/Non-Metal Cutting

There are numerous benefits, and some of these are as follows:-

- Laser cutting is a non-contact process, therefore the damage is minimal to the target object, as only a precise area is affected.

- It has low maintenance costs, and the replacement part costs are minimum.

- The laser cutting process significantly reduces material wastage.

- It works with different materials & applications.

- Laser cutting is a much safer process, as the leam beam is confined within the lightbox.

- You have complete control concerning the heat output, beam intensity, and duration of the laser cutting process.

What Materials Can Be Cut?

Thanks to beam intensity, length & heat output control as mentioned above, lasers are suitable for cutting different materials.

Below are the materials that cut well with the laser cutting process:-

- Metals such as Copper, gold, nickel, silver, steel, titanium, tungsten, and more.

- Reflective metals

- Safely and precisely cutting silicon.

- Various ceramics

- Different glass types

- Woodcutting

- Gemstone materials.

How To Get Started with a Laser Cutting Machine?

-

Find a Laser Cutter

First, you need to invest in a high-quality laser cutting machine.

-

Choose a Material to Cut or Engrave

Laser machines are capable of cutting & engraving a variety of materials. Only inflammable materials cannot be cut. The power of laser cutting machines are measured in watts, typically in the range 30 Watt and 120 Watt. Laser machines with higher power meant for industrial applications.

-

Create Your Design

Most laser cutting machines come with specific drivers. The function of these drivers can convert the image from the computer into a format which can be read by the machine. When working with a laser cutting machine, one needs to understand the difference between raster and vector images.

A vertical image stores all the colors & lines in a mathematical format whereas a raster image is pixel-based. The vector images can be scaled without compromising on the quality.

The vector images are available in the formats such as PDF, AI, DXF, and SVG. On the other hand, for raster images, the formats are PNG, GIF, and JPG.

-

Cut or Engrave It

Once your design is ready, the final step is to cut. Adjust the power output of the laser machine, the speedm frequency, and then test it before making the actual cut.

How Accurate is Cutting With Lasers?

One of the biggest perks of the laser cutting process is the accuracy & precision that it delivers. With a narrow & focused beam, it ensures the ultimate level of accuracy. Slits with widths as minute as 0.1mm are achievable with laser cutting.

Will Cutting Damage the Material?

No, it is the biggest of laser cutting. Since the process is non-contact, the focused beam hits only the minute area into consideration, and what damage is quite minimal to the entire surrounding area.

In Which Industries Can You Find Laser Cutting?

The laser cutting process finds its application in multiple industries, and these industries are listed below:-

The Automotive Industry

Several benefits of laser cutting in the automotive industry include cutting carriage components fit together and cutting airbags.

The laser cutting process finds its use in the e-mobility industry like battery foil cutting, stator plates cutting, etc.

The Aerospace Industry

Laser cutting is widely used for cutting high-strength aluminum alloys to provide a good finish, and minimal heat-affected zone, which was previously not possible.

The Electronics Industry

Electronic parts in the last two decades have become much smaller and complicated than ever, and only laser cutting can produce the desired results.

Within the electronic industry, a laser machine is best to cut circuit boards and USD cards.

The Medical Sector

Within the medical sector, laser cutting is used for precisely cutting high-grade sheets, tube cutting, and various medical applications.

Finally, Omni CNC is the No.1 manufacturer of highly efficient laser cutting machines in China. Our range of high-precision laser cutting machines is best-suited for a myriad of applications. These include sheet fabrication, outdoor advertising, vector cutting, sign making, raster engraving, textile fabrication, and so much more.

Our industrial CNC laser cutting machines are designed to eliminate costly blunders, lower material waste, and improve your overall productivity.

Omni CNC provides installation and training solutions across the globe; if you or your team is not familiar with the machine, we’re ready to help.

If you want a FREE quote, connect with our sales team at +86-531-89003210/ 85938856, or you can Inbox your query at sales@omni-cnc.com.