Stainless Steel Cutting With Fiber Laser Cutting Machine – How To?

Stainless Steel Fiber Laser Cutting Machine Introduction

Fiber laser cutting machine is a popular choice for cutting stainless steel. They offer a number of advantages over other cutting methods, including high precision, smooth cuts, no burrs, no dross, and fast cutting speed.

In this blog post, we will discuss how to cut stainless steel with a Fiber laser cutter. We will cover the following topics:

- What is a stainless steel fiber laser cutting machine?

- How do fiber laser cutting machines cut stainless steel?

- Why are fiber laser cutting machines so good at cutting stainless steel?

- Benefits of using a fiber laser cutting machine to cut stainless steel

- How to set up a fiber laser cutting machine to cut stainless steel

- Common problems when cutting stainless steel with a fiber laser cutting machine

- How to troubleshoot problems when cutting stainless steel with a fiber laser cutting machine

- Conclusion

What is a stainless steel fiber laser cutting machine?

A fiber laser cutting machine is a machine that uses a laser beam to cut metal. The laser beam is generated by a fiber laser, which is a type of laser that uses a fiber optic cable to transmit the laser light. Fiber lasers are very efficient and can produce very high power laser beams.

How do fiber laser cutting machines cut stainless steel?

When the laser beam hits the metal, it vaporizes the metal. The vaporized metal is then blown away by a stream of gas, such as nitrogen or oxygen. The laser beam moves very quickly, so it can cut through metal very quickly.

Why are fiber laser cutting machines so good at cutting stainless steel?

Stainless steel is a very tough material, but it is also very reflective. This makes it difficult to cut with traditional cutting methods. Fiber laser cutting machines are very good at cutting stainless steel because the laser beam is absorbed by the metal.

Benefits of using a fiber laser cutting machine to cut stainless steel

- High precision: Fiber laser cutting machines can produce very precise cuts. This is important for applications where the accuracy of the cut is critical, such as in the manufacturing of medical devices or aerospace components.

- Smooth cuts: Fiber laser cutting machines produce smooth cuts with no burrs or dross. This makes the cuts look good and also reduces the need for post-processing.

- Fast cutting speed: Fiber laser cutting machines can cut stainless steel very quickly. This can save time and money, especially when cutting large quantities of material.

How to set up a fiber laser cutting machine to cut stainless steel

To set up a fiber laser cutting machine to cut stainless steel, you will need to do the following:

-

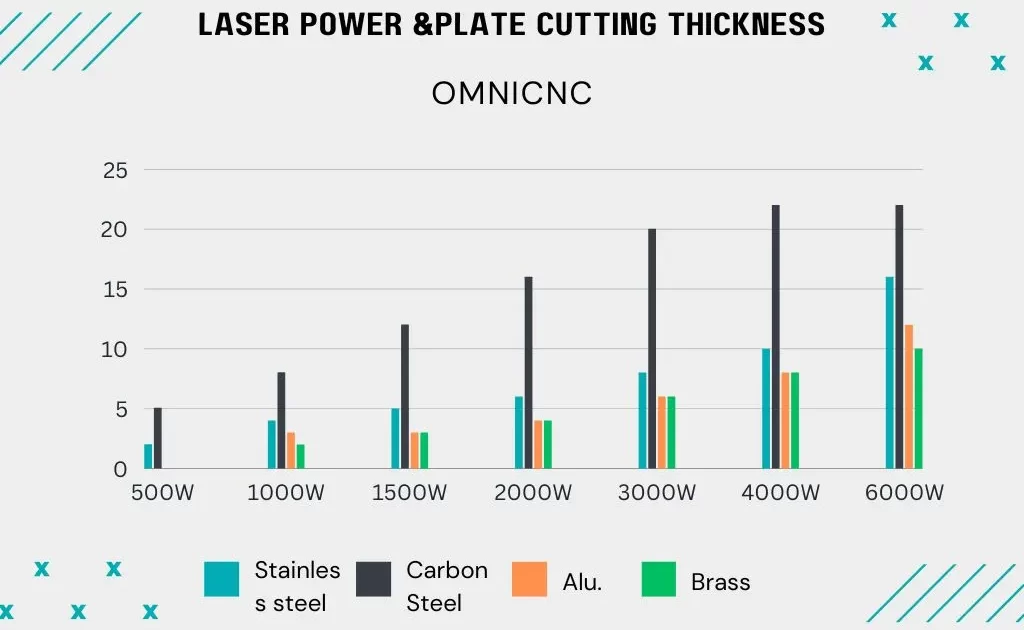

Choose the right laser power for the thickness of the stainless steel you will be cutting.

The laser power required to cut stainless steel depends on the thickness of the material. In general, you will need more laser power to cut thicker materials. Here is a table that shows the recommended laser power for cutting stainless steel of different thicknesses:

It is important to note that these are just general guidelines. The actual laser power required may vary depending on the specific type of stainless steel, the quality of the laser cutting machine, and other factors. It is always best to consult with the manufacturer of your laser cutting machine to determine the optimal laser power setting for your specific application.

-

Set the cutting speed and feed rate.

STAINLESS STEEL (N2)

Belwo chart is only for reference. Adjust the rate in actual cutting process.

| MATERIAL | FEEDRATES | ||||

| Fiber4.0kW | |||||

| inch | mm | in/min | |||

| Stainless | 0.040 | 1.0 | 2362 | ||

| Steel | 0.060 | 1.5 | 1654 | ||

| N2 | 0.080 | 2.0 | 886 | ||

| 0.100 | 2.5 | 610 | |||

| 0.120 | 3.0 | 354 | |||

| 0.180 | 4.5 | 197 | |||

| 0.250 | 6.4 | 138 | |||

| 0.375 | 9.5 | 59 | |||

| 0.500 | 12.7 | 39 | |||

| 0.625 | 16.0 | 28 | |||

-

Use the correct cutting nozzle.

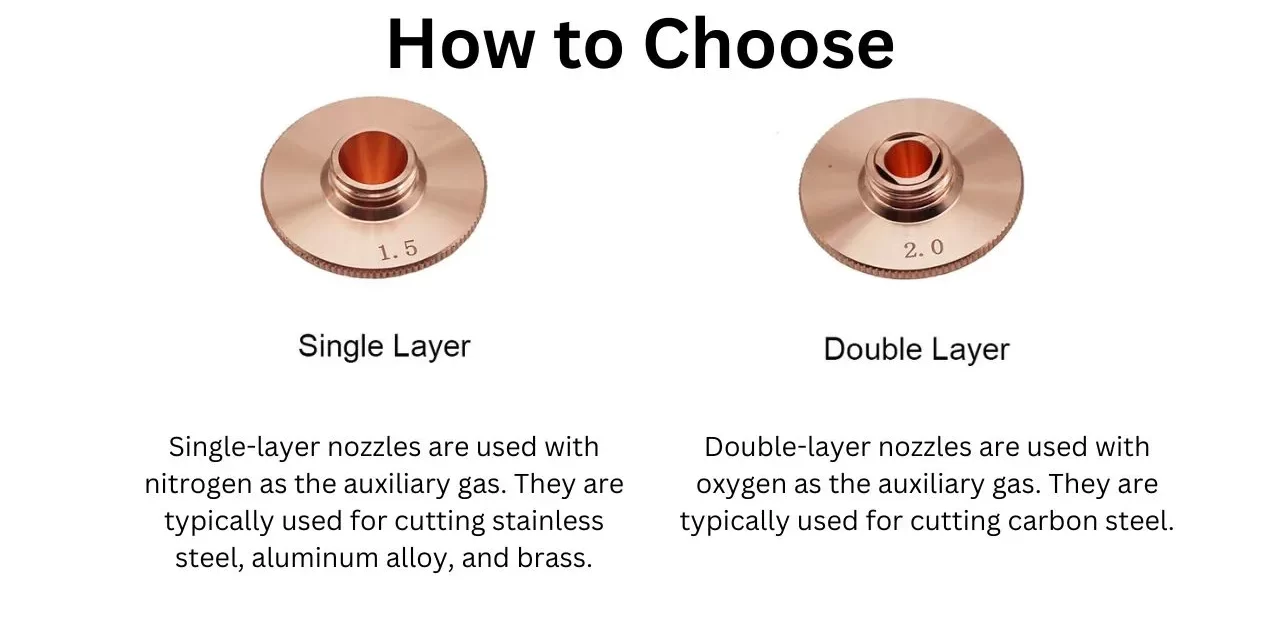

Nozzle Types

In general, laser cutting nozzles can be divided into single-layer and double-layer nozzles. Single-layer nozzles are used for melting and cutting, while double-layer nozzles are used for oxidative cutting.

- Single-layer nozzles are used with nitrogen as the auxiliary gas. They are typically used for cutting stainless steel, aluminum alloy, and brass.

Nitrogen is an inert gas, which means it does not react with the material being cut. This makes it a good choice for cutting materials that are sensitive to oxidation, such as stainless steel. - Double-layer nozzles are used with oxygen as the auxiliary gas. They are typically used for cutting carbon steel.

Oxygen is a reactive gas, which means it reacts with the material being cut. This reaction produces heat, which helps to melt and vaporize the material.

The type of nozzle used will depend on the material being cut and the desired cutting results. For example, single-layer nozzles are typically used for cutting stainless steel because they produce a smooth, burr-free cut. Double-layer nozzles are typically used for cutting carbon steel because they produce a faster, more aggressive cut.

Choosing the Right Caliber

The following factors should be considered when choosing the right nozzle caliber for laser cutting:

- Material thickness: The thicker the material, the larger the nozzle caliber should be.

- Material type: Some materials, such as stainless steel, require a larger nozzle caliber than others, such as carbon steel.

- Cutting speed: A larger nozzle caliber will allow for faster cutting speeds.

- Cutting quality: A larger nozzle caliber may result in a rougher cut.

Common Nozzle Caliber Sizes

The following are some common nozzle caliber sizes for laser cutting:

- 1mm: For thin materials, such as sheet metal.

- 1.5mm: For thicker materials, such as plates up to 3mm thick.

- 2mm: For thicker materials, such as plates over 3mm thick.

Use the correct cutting gas.

The type of gas used for fiber laser cutting of stainless steel and other metals depends on the material being cut and the desired cutting results. Here are some of the most common gases used for laser cutting:

- Nitrogen: Nitrogen is an inert gas, which means it does not react with the material being cut. This makes it a good choice for cutting materials that are sensitive to oxidation, such as stainless steel. Nitrogen also helps to prevent dross formation, which is a black, powdery substance that can form on the edges of the cut.

- Oxygen: Oxygen is a reactive gas, which means it reacts with the material being cut. This reaction produces heat, which helps to melt and vaporize the material. Oxygen is typically used for cutting carbon steel, as it produces a faster, more aggressive cut. However, oxygen can also cause dross formation, so it is important to use a dross-preventing nozzle when cutting with oxygen.

- Argon: Argon is a noble gas, which means it is neither inert nor reactive. Argon is typically used for cutting aluminum, as it helps to prevent the material from oxidizing. Argon can also be used for cutting stainless steel, but it is not as effective as nitrogen at preventing dross formation.

The type of gas used will also depend on the thickness of the material being cut. For example, nitrogen is typically used for cutting thin materials, such as sheet metal. Oxygen is typically used for cutting thicker materials, such as plates.

It is important to note that the type of gas is not the only factor that affects the cutting results. The laser power, cutting speed, and feed rate also play a role. It is important to experiment with different settings to find the best results for your specific application.

Here are some additional tips for using laser cutting gases:

- Keep the gas lines clean. Dirty gas lines can cause poor cutting quality. Clean the gas lines regularly with compressed air.

- Replace the gas cylinders regularly. Worn gas cylinders can also cause poor cutting quality. Replace the gas cylinders regularly, especially if they are used frequently.

- Use the correct type of gas for the material being cut. Using the wrong type of gas can cause the cut to be rough, incomplete, or even dangerous.

- Follow the manufacturer’s instructions. The manufacturer’s instructions will provide specific information on how to use the gases properly.

Common problems when cutting stainless steel with a fiber laser cutting machine

The most common problems when cutting stainless steel with a fiber laser cutting machine are:

- Poor cuts: This can be caused by using too much or too little laser power, or by using the wrong cutting speed or feed rate.

- Burrs: Burrs can form on the edges of the cut if the cutting speed is too slow or if the cutting nozzle is not properly aligned.

- Drossl: Drossl can form on the edges of the cut if the cutting gas is not the correct type or if the cutting gas pressure is too low.

- Slow cutting speed: The cutting speed can be slow if the laser power is too low or if the cutting speed is too high.

How to troubleshoot problems when cutting stainless steel with a fiber laser cutting machine

- Check the laser power setting. The laser power is the amount of energy that is delivered to the material being cut. If the laser power is too low, the cut will be incomplete or rough. If the laser power is too high, the material may overheat and warp.

- Check the cutting speed and feed rate. The cutting speed is the speed at which the laser beam moves across the material. The feed rate is the speed at which the material moves under the laser beam. If the cutting speed is too fast, the cut may be incomplete or rough. If the cutting speed is too slow, the material may overheat and warp.

- Check the cutting nozzle alignment. The cutting nozzle is the part of the laser cutting machine that directs the laser beam onto the material being cut. If the cutting nozzle is not aligned properly, the laser beam may not be focused properly and the cut may be incomplete or rough.

- Check the cutting gas type and pressure. The cutting gas is used to help remove molten material from the cutting area. The type of cutting gas and the pressure of the cutting gas can affect the quality of the cut.

If you have checked all of these factors and you are still having problems cutting stainless steel with a fiber laser cutting machine, you may need to contact the manufacturer of the laser cutting machine or a qualified laser cutting professional for assistance.

Here are some additional tips for troubleshooting problems with stainless steel cutting using a fiber laser cutting machine:

- Keep the laser cutting machine clean. A dirty laser cutting machine can cause the laser beam to scatter and the cut to be incomplete or rough.

- Replace the cutting nozzle regularly. A worn cutting nozzle can cause the laser beam to scatter and the cut to be incomplete or rough.

- Use the correct type of cutting gas. The type of cutting gas can affect the quality of the cut.

- Use the correct pressure of the cutting gas. The pressure of the cutting gas can affect the quality of the cut.

- Monitor the cutting process. It is important to monitor the cutting process to ensure that the cut is looking good. If the cut is not looking good, adjust the laser power, cutting speed, feed rate, cutting nozzle alignment, cutting gas type, or cutting gas pressure accordingly.

Conclusion

Fiber laser cutting machines are a versatile and powerful tool that can be used to cut a wide variety of materials, including stainless steel. By following the tips in this blog post, you can learn how to start up and use a fiber laser cutting machine to cut stainless steel with precision and accuracy.