How CNC Wood Router is a Jack of All Trades for Manufacturers?

The infusion of technology into almost every sector of manufacturing has changed the world in recent times. And, its introduction in the woodworking and the interior designing sector has transformed the industry whereby making allowing it to operate at a better place. The best part of the CNC wood router is that the designers and the woodworkers are pretty happy to add this new dimension to ensure they meet the high-end requirements of their clients.

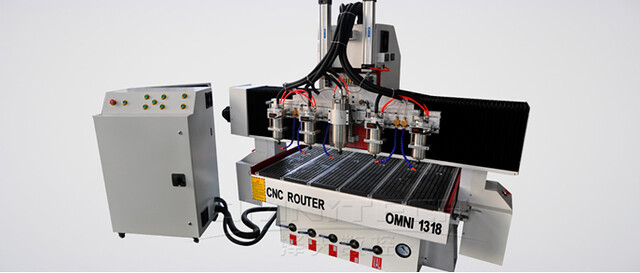

With the woodworkers embracing the technology with open arms to enhance their daily outputs, manufacturing firms like OMNI CNC are working and coming up with high-level Woodworking CNC Router. Hence, they are finding new innovative ways to redefine the industry.

Famous for cutting through various wooden surfaces, the CNC Router Woodworking has the capability of performing tasks of different machines. For instance, it can perfectly design the shapes created by a spindle molder or a panel saw.

Furthermore, a CNC router can be controlled entirely via a computer as compared to hand router. All a woodworker needs to do is to learn simple sets of coding required to run this machine. With consistent quality work, this router has the dexterity to provide identical designs with greater levels of accuracy.

A) How does a CNC Wood Router Help a Manufacturer?

Usually, at the start of their career, manufacturers and woodworkers are more comfortable with fixed-base or plunge-base router. However, with the increase in demand for the production of intricate designs, the woodworkers are forced to think of ways that can deliver quick and efficient results.

This is where they turn to the computer-based router or, as we call them, the CNC (Computer Numerical Control) wood router. As mentioned, these routers boast the capability of working and handling large chunks of materials. With incredible accuracy, these routers are perfect for cutting wood at a high speed.

If you are considering replacing your old router with a CNC one, then it is the time to do it. Withal, if you are pragmatic about adding this new dimension, try to read these features carefully which shows that a Wood CNC Router Machine is a near-perfect addition for a woodworker:

1. Improved Production Range

Industrial CNC wood routers have revolutionized the woodworking industry. This computer-controlled machine rarely produces any waste pieces and operates at high-efficiency. This machine can substantially increase the range of production of woodworking firms without requiring it to hire a qualified technician for the machine.

2. Larger Cutting Field

Be it large pieces like stair risers or small 3d carving, a CNC Router for Wood Carving is capable of producing designs that are a challenge for a standard wood router that too at a higher speed. In the case of mass production, a woodworking firm can opt for bigger CNC wood routers that have a low margin of error and produce large pieces of wood at ease.

3. Ease of Operation

Standard routing requires a woodworker to physically manipulate the wood router. This method is not advisable as it severely impacts the quality of the product and safety of the woodworker. Besides, the working of these hand routers is something that cannot be taken for granted, hence, it requires an operator with significant experience along with the training of the router.

Whereas, a CNC wood router does not require a skilled operator. It only requires a woodworker to have computer training in coding, which is could be gained in a matter of a few months.

4. Less Waste, Less Dangerous

This is a common issue among the woodworkers using standard wood routers. Their investment is significantly higher than their compatriots who are using CNC Routers for Wood. The reason being, the loss of money is directly related to the loss of material on the work floor. So, more the waste, the cost incurred is also more. Lacking in accuracy, hand routers tend to provider results on the expensive side of the spectrum. Furthermore, the chances of woodworker making a serious error are also high.

However, when a woodworker is working with a CNC wood router, the chances are that he will eliminate the extra cost by preventing the extra waste. Besides, due to the high accuracy level, the quality of the work will enhance manifold along with keeping the operator safe from any physical injury.

5. Flawlessly Accurate

As mentioned above, the best part about the CNC wood router is that it is accurate. Since it is a computer-controlled machine, the CNC router possesses the capacity of producing thousands and hundreds of finished products that too at the same time! For firms and woodworkers who value time, accuracy, and high-quality, this machine is the insurance for making your work invaluable.

B) Applications of the CNC Wood Router

Given its fair share of advantages, the CNC wood router has become quite popular within the woodworking industry. It is hard to deny that this machine saves a lot of time, money, labor, and, more importantly, it eases and quickens the industrial operations.

Regardless of what the job demands一cutting, engraving, carving, etc., – this machine can design anything and everything with utmost precision. This is the reason why it is considered the best for the woodworking industry. Here are a few applications of the CNC woodworking router:

1. 3d Carving

As mentioned, the CNC router possesses an unmatched capability of performing anything, especially when things center on the 3D carving. Wooden capitals, carved consoles, pilasters, panes, brackets, frames for mirrors, carved icons, are just some of the things that can be performed in bulk on the CNC wood router.

However, the thing to keep in mind is that you should know the ball-nose bit before you start coding for etching the 3D design. Ball-nose bits are used to carve exotic 3D designs with the tip of the bit, which ensures that the design is detailed adequately besides having smooth contours. For intricate designs and 3D carving, the use of tapered nose bit s highly recommended.

2. V-bit Carving

Another form of carving which a Wood CNC Cutting Machine can perform with ease is V-bit carving. For unique and precise designs, use OMNI CNC’s exquisitely shaped v-bit creates narrow carves at the most profound part of the material.

V-bit carving provides added artistic variety by providing decorative patterns on the surface of the material. V-carving is used to facilitating folding or bending of different materials along with providing a V-shaped cut along the surface of the material. This V-shaped cut provides small bending radii with a bend of 90-degree. This kind of carving is beneficial in those situations where traditional carving, like that of free bending, becomes impractical.

3. Cabinet/Closet Door Making

Popular among woodworking industry, cabinet & closet door making is one of the most popular applications of CNC router. Cabinet makers now prefer to utilize the CNC router to reduce their overhead expenses and increase production by modifying their material handling. Besides, these highly effective and moderate routers are assisting woodworkers to process drawers, shelves, drawer fronts, counter-tops, etc of varying sizes at a time.

4. Chair Back Cutting

The CNC process is enhancing the time of production and is no longer limited to tooling and prototyping. Some of the factories are using CNC router as a means of production for manufacturing chairs of varying designs. Due to CNC’s digital nature, the curvaceous digital model of the chair is, now, designed by using computer software. This software enables 3D form, which can be altered on the screen as the requirement of the client or the woodworker.

Since a digital router is used instead of a traditional one, the chair’s back features a distinctive cut by following the shape proposed by the worker or their client. Using a CNC Wood Carving Machine for chair back cutting is more of an organic and seamless process that inspires the designer to experiment with different shapes and designs.

5. Sofa Legs/ Staircase

When it comes to Sofa legs and staircase working, OMNI CNC’s wood router has been in demand for a very long time. The reason is that OMNI’s CNC Wood Cutting Machine effortlessly gets converted into a lathe which carves unique newel posts, modillion engraving, crown molding, chair jambs, and many more things to help your imagination stretch your application.

Featuring a rotary device, this router allows the machine parts to operate in a round profile. Hence, it is fair to say that the OMNI CNC router is helping ordinary souls to design something artistic and masterful. The 3D carving on Buddha is a testimony to the efficiency and robustness of the router.

6. Fretwork, Pillar & Brackets, Frame & Triller, Grille Partition

Before technology made its way into a router, a woodworker used to have a nightmare while designing any of the things mentioned above. Besides, the timeframe was also something that added extra pressure over the woodworker. This, in turn, affected the quality of the product.

However, with the CNC router, the production of architectural screens, suspended ceilings, ornamental partitions walls, Frame & Triller, and Brackets & Pillars have become much easier than it used to be. With a few computational modifications, the methodology of the timber framework has advanced to a level where the turnaround time of producing bulk designs has become shorter and more efficient.

7. Cutting Board

When using a CNC router for board cutting ensures that the router bits are chosen very astutely. For a smooth and flat finish, a worker should opt for fly-cutter or spoil board cutter bits. Besides, it ensures that the bit is short and stout as it aids in producing smoother and cleaner cuts.

Having fly-cutter or spoil board cutter bits ensures that the router carefully brushes the surface of the material for a more flat and shiny look for the provided model. For laminate and plywood, the bits work in such a way that they keep the outer veneer intact. Though there are many bits available in the market, a woodworker doesn’t have to buy all of them if he is looking to prototype the project.

8. Newel Posts and Columns

Before the inception of routers, the newel and columns were hand-carved. The process was time-taking and boring. Besides, accuracy was also an issue to look after. However, routers, especially CNC wood routers, changed the way industry now performs.

One fine example of this is the OMNI 12S CNC wood router. This router is capable of producing newel posts and columns in a very simple yet aesthetic manner. It is more like a cakewalk for a woodworker. The finished work features unique grooving and has precision which is depicted by its helical symmetry.

9. Profile & Sculpture

Another fascinating feature of the CNC wood router is that it is able to aid cutting and carving tasks to a very artistic level. The work produced by this is flawless. Hence, this validates the craze woodworkers are having for this machine.

The machine is dexterous enough to carve intricate designs and provide profile & sculptures in a very fascinating manner. Besides, the best thing about this is that a woodworker can accommodate the use of the router to bring their out-of-the-world designs alive. However, the only thing for an operator to notice here is that he has to be very careful while choosing the bits for the router.

C) Conclusion

With the focus on quality and reliability, a woodworker can rest his trust on a CNC wood router. However, the only thing he needs to ensure is that he has covered the coding part adeptly; because the large part of the machine’s performance rests on the woodworker’s knowledge of coding.

Apart from that, OMNI CNC’s range of wood routers is unmatched in the market. They have helped many woodworkers to successfully elevate their work. Be it any kind of carving, cutting, or profile making, OMNI’s CNC router machine is versatile and reliable. Besides, it comes with a high-repeatability laser that allows a wide range of cutting and engraving functions. Hence, catering and fulfilling the unique demands of the woodworking industry.