How to Carve a Guitar Body with OMNI CNC Router?

Computer Numerically Controlled (CNC) routers are regarded as one of the best woodcutting machines due to increased productivity low manufacturing cost.

OMNI CNC routers can produce the product in minutes whereas it would take a craftsman hour if produced manually.

A craftsman arranges numerous tools to carve a piece of art and still you cannot ensure whether he will be able to carve with precision. But CNC router ensures perfection of the end-product produced. The precision and smoothness are guaranteed when carving a guitar body with CNC Router.

The entire process of cutting and carving is made easier and the time incurred in carving a guitar with CNC router is reduced as compared to the manual process of cutting.

Precision and productivity go hand in hand while carving with CNC routers. CNC machine operates on the basis of the digital instruction given by computer-aided manufacturing (CAM) and computer-aided design (CAD) software.

This machine successfully interprets the design of the object to be carved and very beautifully engrave different parts of the object. The craftsman relies on CNC machines to bring a greater degree of control and precision when cutting and shaping the end-products.

As compared to manual crafting, CNC carving machines consume less time and provide more output in a short span of time.

The versatile machine offers quick and accurate manufacturing. Manufacturers across many industries choose the advantages of CNC machining for their fabrication and manufacturing applications.

It saves a huge amount of time and provides an additional output with quality work. CNC routers are always controlled by computers and the products are produced by the routers.

Carve a Guitar Body with ATC Type

OMNI ATC series provide numerous opportunities for a variety of application needs. This machine is suitable for processing complex models and used for engraving, drilling, cutting, hollowing, edging, milling, etc.

It is with the help of the OMNI CNC routing machines that businesses have been able to reap the benefits of increased speed in production as well as consistency. This multi-dimensional tool is capable of achieving a perfect finish of the product manufactured.

If you are planning to carve a guitar body and you don’t have any budgetary constraint, then you should opt for OMNI 1325 ATC type CNC router.

This type of router is used for processing large materials including aluminum board, insulation board, MDF, particleboard, laminate, and others metal as well as non-metal and soft metal materials.

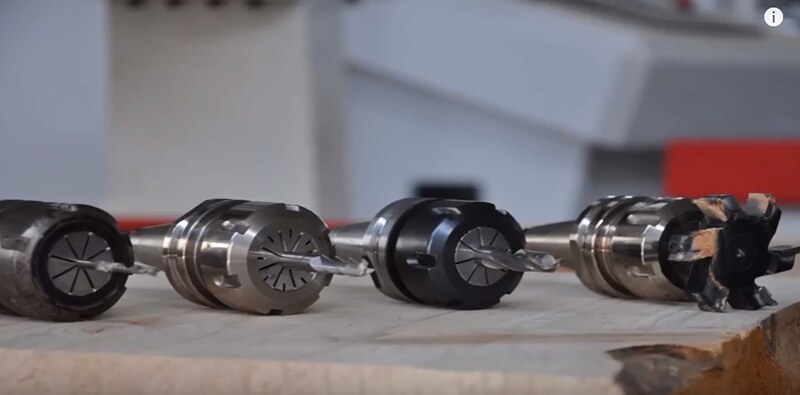

OMNI CNC router 1325 is known for its accuracy and speed. The working size of this machine is 1300mm*2500mm and for carving a guitar body, you need 3 to 4 pieces of bits.

Adjusting and calibrating bits every is a time-consuming task and you would require 2-3 minutes for changing each bit, which means approximately 20 minutes are used for tool changing and calibration. But this ATC type machine has an automatic tool changing function.

It takes only 15 minutes to complete the entire process of carving a guitar body. The software gives the command to the spindle to change and run in tandem with carving.

The automatic tool changing function ATC type router is extensively used by the manufacturing industries for optimally creating furniture, wooden doors, cabinet doors, computer desks, mahjong tables, wooden loudspeaker enclosures, etc.

OMNI 1325 carves guitar body with high precision and smoothness; let us take a look at the steps involved in carving a wooden guitar with this router machine.

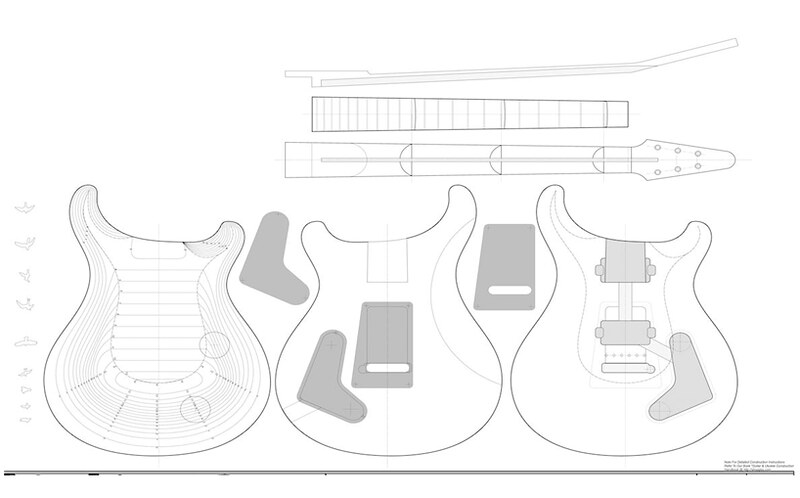

Step 1: Programming and Routing

The first and foremost thing that you need to do before carving a guitar is to configure codes in the software and check whether the codes which you have entered are accurate or not.

Draw a 2D model and create vector files tracing the contours and interior curves. After this, use an extrude command to 3D shape and ensure that the shape and size of the guitar are accurate. Once you are sure about the codes, you can finalize it and set the machine to operate.

Step 2: Create Toolpath

Next, create a toolpath. 2D flat bits are used to milling the pocket by hallowing and 3D ball end for contouring. As shown in the video, you will need 3 types of bits with the diameter 8, 4, 3mm to cut the guitar body.

A. The milling cutter is 60mm in diameter and the working speed of the tool will be 5m/min, 9000RPM

B. Flat flute bits

(a) 10mm/ 3/8’’ down flute for 2d milling, 5mm per pass, working speed 6m/min

(b) 8mm for drilling 8mm holes, 1.2m/min for drilling down

(c) 4mm for drilling 4mm holes, 1.2m/min for drilling down

(d) 3.17mm for the smallest pocket milling, 3m/min

C. Ball nose end, the diameter is 10mm=3/8″, the diameter for contour cutting.

Trace out the 2D shape of the guitar including the contour, curves, and then we extrude it to the 3D shape.

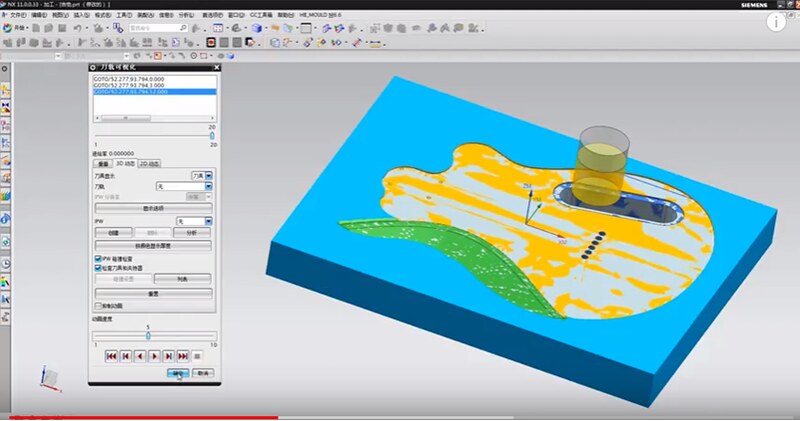

Simulation Function

Now, the whole process of the upper side of the guitar body gets started.

As shown in the below image, the pocket is carved with 10mm flute down cutter, contour shaping with 10mm ball nose end, troller with 8 mm, and miller 60mm.

After creating a simulation for jig making and setting the toolpath for the front end of the guitar body, it’s time to work on the other side of the guitar.

For the backside/downside of the guitar body, 6 pieces of bits are used. After configuring the bits needed to be used for carving the guitar body, the next part is a simulation.

Carve pockets, shape the contours, and cut the sides meticulously. You can easily trim away the upper area and design the drilling holes. After the operation, the guitar body is ready to be mounted.

Step 3: Secure to Wasteboard

Once, the toolpath is completed and you have the outline of the guitar body, you can take over the control and initiate the process.

Before starting the process of cutting and carving, you can give a thought to the design and redesign the outline as per the look you want.

After that place, a wooden panel on the OMNI ATC type CNC router and secure the waste part of the wooden board with screws from all four ends.

Once the board is secured properly, start the machine by cutting the neck pocket and electronic pocket.

Step 4: Hallowing Out

The routing machine works on the basis of the instruction given to the tool. In the below image, you could see that CNC router is hallowing pockets and drilling holes. The CAD-CAM software is used for creating a design, automatic creation of the program and simulation of the machining operation.

Step 5: Cutting the Outer Shape

Finally, carve the outer shape of the guitar body. The razor-sharp bits engrave the guitar body with higher precision. The more pointed are the bits, higher is the longevity of the tool.

The tendency of the bits are to stay sharper, mirror like carbide finish, and excellent carbide brazing. Also, give a proper shape to your guitar with bandsaw or jigsaw whichever is convenient for you.

Step 6: Round over Edges

Alignment is the key to machining the guitar. While milling the guitar body, it is necessary to used high spindles to give a smooth look to the end-product.

This automatic ATC type routing machine improves both the speed and accuracy for creating a product. Each CNC machine has a difference in strength and behavior along with depth pass, feed rate, bit size, and fitments.

Moving further let’s take a look at different components of the guitar and examine how OMNI CNC router helps in cutting and making different parts of the guitar?

Different Parts of Guitar

- Headstock

A headstock is a crucial part of the guitar that helps in holding the strings at the head of the instrument. CNC router beautifully cuts and shapes the headstock using CAD and CAM software.

In addition, if you want to add a logo to your headstock, then you can add the specification to your file and proceed accordingly. CNC router can beautifully engrave the signature or logo and then fill with paint as per your liking.

The Headstock logo varies from brand to brand, so you can paint the logo accordingly. Once you are done with the painting, finish the headstock as normal and carefully wipe the excessive color from the sig.

Headstock lies at the end of the guitar’s neck and its purpose is to support the tuners, which eventually terminates the string of the instrument.

- Bridge

A bridge is a device that supports the strings on the instrument and superbly transmits the vibration of the strings to other structural components of the instrument.

- Neck

The neck of a guitar includes fret, fretboard, tuner, truss rod, etc. The neck is an integral part of the instrument; let us take a look at the topside and backside of the guitar.

Topside of the Guitar Neck:

- Drill reference holes so as to align the fingerboard when gluing and reference holes

- Contour the outline of the neck with a flat bit

- With a flat bit rough out the headstock

- Give a parallel finishing to the guitar with a headstock

- Cut the truss rod channel with a flat bit (slot or pocket)

- Make a slot for the nut to align and fit well

Backside of the Guitar Neck

- Make a rough out of the neck

- Ensure to leave a bit of extra stock to avoid cusps after finishing.

- Make use 0.25mm to 0.5mm depending on the type of wood used.

- Give a parallel finish to the neck with a large ball mill and tiny stepover

- Pick-Guard

It is a piece of plastic or other material that is firmly placed over the body of the guitar. The purpose of this guard is to protect the finishing of the guitar from getting scratched by the pick of the guitar. Pick-guards are available at various designs and shapes but usually, designers try to match the headstock and pickguard design.

- Soundboard

The soundboard is the top of the guitar. It helps in determining the tone and projection quality of the instrument.

However, consider purchasing OMNI CNC router 1325 for making a DIY guitar in very little time and increased efficiency. The machine has a one-head design, and it is equipped with a carousel-type automatic tool changer.

This ATC type machine has the ability to hold up to 10 different router cutters and automatically change the bits.

If you are a new user and not sure how to use OMNI CNC router, then let me tell you, we have a specialized team of experts who will help you learn about the fundamentals of the routing machine and train you to operate the machine.

With the help of our computer-aided design program, OMNI ATC Type CNC router, you can skillfully cut or carve a guitar in a matter of minutes.

Conventional woodworking would have required lots of hands but with the help of this advanced technology, the process of cutting wood and carving it in the shape of a product is possible.

You can also customize guitars in term of personal look, style, physical appearance, specifications, etc. Improve the productivity of your business with a CNC router.

If you want to make only 1 guitar then you may consider buying OMNI CNC router mini model 6090 and fix it on the table with clamps or jig but if you have a huge consignment then you must choose OMNI ATC type CNC router as it saves a huge amount of time and money.

If you are a manufacturing firm and cutting and carving is the part of your job, then it’s time to give chance to a new technology and seek the best machine for your company.

Review from omni6090 guitar maker