Application of Lasers in the Fabric Industry

Since the 19th century, laser technology has been implemented in the fabric industry for manufacturing. Laser technology was introduced to reduce the percentage of human error in tasks like cutting, engraving, and embossing.

The accuracy of the laser pointer combined with software support like CAD, Corel Draw, and Photoshop gives better results and products. Laser-cutting machines are becoming more and more popular in the textile, leather, and garment industries because of the –

- Accuracy of laser machines

- Efficiency of laser machines

- Simplicity of laser machines

- Scope of automation in the future

Let’s take a deeper look at the application of laser machines in the fabric industry.

CONTENTS

- Fabric fault detection

- Laser cutting

- Evaluation of Seam Pucker

- Mass Customization

- Denim Fading

- Laser engraving

- Welded garment production

- Bar code scanning

- Laser marking

Laser Cutting Machines- Detailed Study

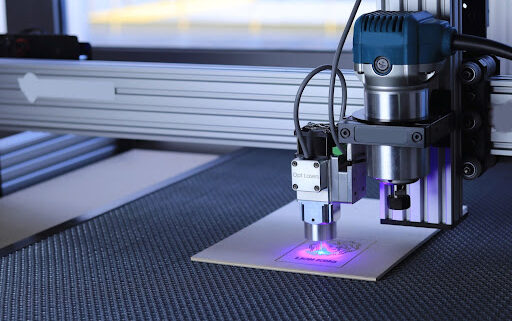

Laser-cutting machines are rising in the fabric industry. With the implementation of laser-cutting machines, companies have been able to increase their production. Along with this, the laser cutting machines help in the process of fabric fault detection.

While the industry benefits from high-speed cutting and accuracy, the trade came with additional expenses. The tool life, complex laser components, labor training, and downtime during machine maintenance are some drawbacks of the trade.

Laser-cutting machines are operational in the majority of textile industries. The purpose of the machine is to achieve precise tailoring in reduced time as compared to manual labor. As a relatively new introduction in the fabric industry, laser cutting machines have vast potential.

Fabric Fault Detection

When the fabric is received by the manufacturers in a production unit, the fabric is checked for damages. This check is done using morphological image processing which is carried out by a laser. The machine uses a laser to capture the diffraction grating of the thread in the fabric.

Multiple lenses with similar focal lengths magnify the test sample images and then invert them. These images are then stored in the computer where the software programs compare the images with the standard images. Any change in the measurement leads to the rejection of the fabric.

Laser Cutting

Using a beam of laser and computer software, the operators input the design details into the system. Once started, a very fine beam of laser is focused on the fabric surface which increases the temperature. This rise in temperature leads to the cutting of the fabric.

This operation is faster and cheaper than a mechanical cutting machine. However, the number of fabric layers that you can cut is lesser as compared to the traditional methods. The laser cutting machine offers high precision with the cuts.

Evaluation of Seam Pucker

Let’s understand what seam puckering is before we know the laser evaluation method. Seam puckering refers to the gathering of seams during the sewing, after sewing, or after laundering for a wrinkled seam on the clothing.

The laser method is used to measure the wrinkle formation in the fabric using laser triangulation. The wrinkle percentage is measured with the help of a laser line on the object and then capturing its reflection at a known distance.

This detail is then used to understand the defect in the fabric. The formation of a seam in the fabric leads to quality deterioration and reduces the aesthetic look of the garment. This eventually leads to a bad name for the brand.

Mass Customization

Mass customization is the industrial term that is used when making customized garments based on body dimensions and individual choices. Laser scanning technology helps in the accurate measurement of an individual’s body.

The machine uses various thin laser stripes with the assistance of cameras to measure the body size. To keep it a safe procedure, only eye-safe lasers are used. The machine focuses on the human body for digitization and the number of optical systems depends on the position of the body.

Denim Fading

Gone are the days of using sandblasting to give a rugged fade to your jeans. Manufacturers now use laser machines for laser fading designs on markings that require fading. Commercially, there are two kinds of laser machines that are being sold- solid-based and gas-based.

The degree of fading on the jeans depends on the wavelength, power density, and pulse of the laser. Laser marking causes less harm to the environment as compared to sandblasting or acid washing. Laser fading also offers a precise and smart look to the denim.

Laser Engraving

Laser engraving is a complex process that is done by computerized laser machines. It is done to engrave or mark an object. Despite being complex, laser engraving can deliver precise engravings with a high rate of production. There is no physical contact between the laser and the operator.

You can use a single machine to produce clean, crisp engravings and cuts. Laser machines are used to engrave on printing screens, create patterns, engrave leathers, and more. Engraved pictures of leather products add value to the products. The advantages of laser engraving are:

- High-speed operation

- Minimum wear and tear

- Reduced wastage

- Same design and color on all fabrics

Welded Garment Production

Garment welding is another process that is done using high-power lasers. During the production process, the thermoplastic parts of the fabric are joined together with the help of heat. The welded garment is weaker than sewn parts but gives a better appearance and offers flexibility.

Bar Code Scanning

Earlier, manufacturers used helium-neon lasers to scan the barcodes to identify the products. This bar code would contain information like the article number, product pricing, and more information related to it.

However, more and more manufacturers have moved to RFID (radio frequency identification) tags. The reason is that RFID tags can be processed faster and they avoid any physical contact with the product.

Laser Marking

Laser marking includes high precision and fast marking of products of different make and hardness. These can be used for products that have a complex design. Laser markings last long and can be used for various products like clothing, leather, metals, and more.

This process is accepted by several brands for marking their clothing precisely and for marking fashion accessories during their production phase.

Conclusion

Laser cutting can be used widely in the fabric industry on various materials. The process brings several advantages with itself that help in revenue generation while cutting costs at the same time. It also offers the flexibility of cutting or engraving any design you wish for, unlike the traditional methods.

To get the best deal on fabric laser cutting machines, visit us.