What Is Cnc Router Metal Fabrication?

CNC router metal manufacturing includes nonferrous metal milling, engraving, hollowing, and cutting. Bits are used by CNC routers to remove material from a workpiece at various angles.

When feeding a metal workpiece to a cutting tool, this procedure uses numerical code, which is significantly more efficient and precise than labor-intensive conventional machining. Aluminum and brass are common nonferrous metal materials.

How A Cnc Router Machine Works on Metal?

There are many different types of CNC routers for various production demands, ranging from small enterprises to high-volume manufacturing plants.

Metal fabrication is frequently done on the same equipment that is used for cutting and engraving non-metallic materials.

CNC routers, as opposed to traditional manufacturing equipment, are given digital instructions on how to cut, drill, carve, and insert components and products.

The procedure begins with a 2D or 3D design on CAD software.

The CAD file is then transferred to the CNC router using computer-aided manufacturing (CAM) software, right down to the smallest detail of each cut.

How To Cut Aluminum On A Cnc Router?

- Design Shape Size in CAM softwrae, like FUSION360.

- Choose HSS bits for drilling, 2D contour roughing & finishing, set tool path in the CAM software

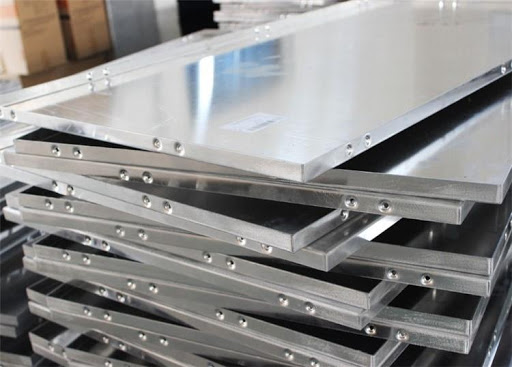

- Screw Fixturing. Fix aluminium board to the spoil board.

- Lubrication: keeps the cutter from chattering and thus improves life of the tool and quality of the cut surfaces by using lubrication sprayer

- Transfering program to controller

- Setting cutting origin

- Cutting Start

How To Cut Metal on A Cnc Router?

CNC routers are capable of cutting mild metals such as aluminum, but CNC metal mills are capable of cutting harder metals such as steel, stainless steel, titanium,brass, magnesium, and others.

To cut metal, you don’t need a particular CNC router; they all accomplish the same thing. The tools and approaches you use when developing and configuring are crucial.

However, you do not want to utilize the same procedures for cutting metal pieces as you would for other materials. For example, a CNC router can cut wood at high speeds, but doing the same with metal frequently ruins the cutting blades.The needed cutting speed is determined on the kind of metal. Aluminum, for example, has a melting point of 1,200 degrees Fahrenheit at speeds more than 13,000 RPM.

A decent CNC router for engraving aluminum should be robust enough to generate high cutting force while maintaining cut quality.

A large-sized industrial CNC produces more torque and has more stiffness. Because of the increased torque, you can deal with not just aluminum, but also harder metals like steel and titanium, as well as ordinary ACP board, plastics, and woods.

Tips For Cnc Machining Aluminum With A Cnc Router

Get Rigidity Solid Frame CNC Router

A thicken welded frame and strong gantry is necessary for avoding vibrication.

Besides this, qualified ballscrew, linear guide, rack & pinion are also important.

Use Lubrication

An air blast nozzle aimed at the cutting tool’s head, on the other hand, is more dependable since the compressed air blast forces the chips move away from the cutting region.

As a result, a strong lubrication system is required to keep the tool sharp while doing long life time machining on aluminum.

Metal Cnc Spindle

A strong enough spindle is required to sustain optimum cutting rates and RPM while milling aluminum, as well as harder metals like steel.

The 3-6kw continuous spindle is strong enough to grind metals such as aluminum,copper, steel, and titanium.

Another advantage is that the spindle is liquid-cooled, allowing the CNC metal router machine for aluminum to function for lengthy periods of time in difficult settings.

Speeds And Feeds

CNC cutting aluminum at high speeds with a low feed rate results in a clean cut with a nice surface quality.

Feed rate is determined by spindle speed, number of flutes, chip load, and material type.

As a result, depending on the kinds of CNC machine being used, knowing how to calculate speed and feed rate is critical to maintaining optimal process control.

Choose A Large Table And Travel Area For Cnc Cutting Metal

CNC cutting aluminum at high speeds with a low feed rate results in a clean cut with a nice surface quality.

Feed rate is determined by spindle speed, number of flutes, chip load, and material type.

As a result, depending on the kinds of CNC machine being used, a proper balance of the cutting tool’s speed and feed rate is critical to maintaining optimal process control.

Use A Smaller Endmill

Though CNC routers aren’t as rigid as even tabletop metal CNC mills, you may help your machine by employing a longer, stubby tool and a shallower depth of cut every pass.

Furthermore, the tremendous heat created during aluminum cutting can cause chips to be fused to the tool, destroying the workpiece surface finish and potentially breaking the tool.

Use Carbide Endmills — Either 3 Flute Or 2 Flute

Solid carbide endmills are suggested for large-scale enterprises because they are more robust, capable of producing higher cutting force, and give a long tool life with minimal maintenance.

To overcome the hurdles and produce cuts with an excellent surface polish, a 3-flute carbide endmill with helix angle (35° – 40°) and adaptable tool path is often suggested.

Because of their high speed, carbide endmills can cut through aluminum more quickly and at faster feed rate than HSS endmill.

Metal Cnc Applications

- Aerospace Industry

- Automotive Industry

- Consumer Electronics

- Defense Industry

- Healthcare Sector

- Oil & Gas Industry

- Rapid Prototyping

- Tooling

- CNC Manufacturing

How Much Does A Cnc Router For Metal Cost?

The cost of cnc router for metal and maintaining a CNC router for metal fabrication is determined by the size of your company and its production requirements.

Usually for aluminium cutting, the price is US$6000 starts up.