What are the Key Advantages of Fiber Laser Cutting Machines?

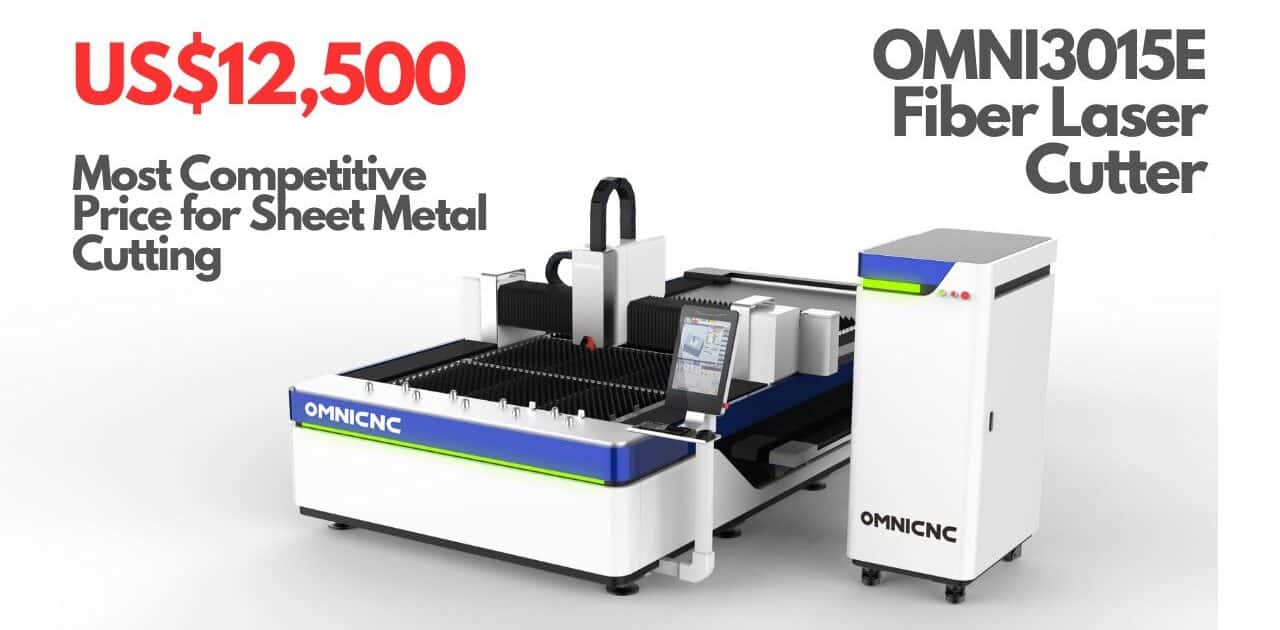

Fiber laser cutting machines are taking the world by storm. They are upgrades to manufacturing processes in many ways. The same can be said for our fiber laser cutting machine of 3000 watts.

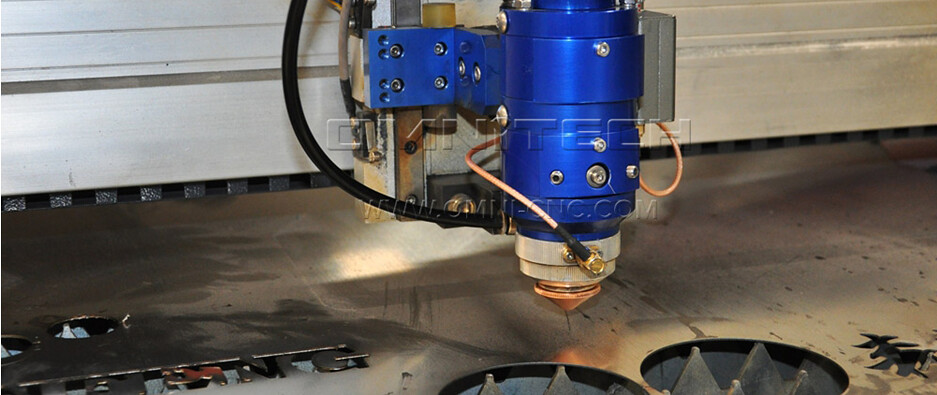

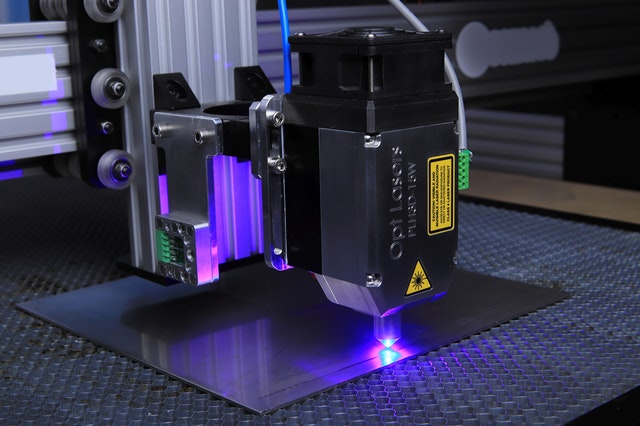

The basic application of fiber laser cutting machines is cutting through metal and other materials with the help of light beams at high temperatures that are thin enough to slice through materials with ease.

1. Less maintenance cost

This is the biggest advantage of fiber laser cutting. Although the fiber laser cutting machine is more expensive than other laser machines, the overall cost of running the technology is much lower than the other cutting machines.

In the other laser beams, the focusing lens is exposed. When the laser cuts metals and reflective surfaces, the laser reflects back into the cutter head and damages it.

In fiber laser cutting machines, since the lens is not exposed it does not get damaged, which cuts down on the operating costs. The laser optic parts are very expensive which makes using other laser machines a costly affair.

If this focusing lens is properly maintained, it will last for the machine’s lifetime, which reduces the maintenance cost dramatically.

It is said that time is money, you no longer have to spend endless hours cutting metal over and over. The fiber laser cutting machine does it for the first time with its super thin, but very hot, laser beam.

This machine runs on computer programs and can be programmed to make any design. This reduces the cost of making molds.

2. Automatic loading and unloading

Fiber laser cutting machines have interchangeable platforms that accommodate the metal sheets and the finishing sheets. These are loaded and unloaded automatically after programming the CNC machine.

This reduces the supervision required and the need for human resources. The automatic loading and unloading also help in the safety within the premises. There is no manual lifting of heavy metal sheets and hence no injuries.

This saves entrepreneurs a lot of time and effort. Fiber laser cutting machines can complete work much faster as compared to manual loading and unloading.

3. Boost in cutting speed

Fiber laser cutting machines boost the speed of cutting materials. This machine can cut up to five times the speed of a CO2 laser machine. It can cut through metals like stainless steel, chrome, bronze, and more.

Although the speed of cutting decreases as the thickness of the material increases, it is still an improvement on CO2 laser machines.

For example – When cutting a metal sheet with 1 mm thickness, our fiber laser cutting machine can cut three times faster than a CO2 machine. If you increase the thickness of the sheet metal to 2 mm, you will observe that the speed reduces by twice but it is still an improvement on CO2 machines.

4. Cut reflective material

One of the major issues with CO2 lasers is reflective material. There is a high chance that the laser beam will be reflected off the material and damage the cutting heads of the machine.

CO2 lasers were earlier used for cutting reflective materials like brass, copper, and aluminum, but not without damage. The fiber laser cutting machine has fiber optics encased in a cutting head that protects the laser parts.

Fiber Laser cutting machines can be easily maneuvered after programming. Complex designs and shapes can be cut with the help of computer programming. The ease of movement allows complex designs without any damage to the workpieces.

5. Higher electrical efficiency

CO2 lasers need a lot of energy to produce the laser beam. A 2kW fiber laser consumes a third of the power consumed by a 4kW CO2 machine. This means that the fiber laser cutting machine will not only save energy every time it is used but there will also be less damage, owing to the better-placed parts. The energy input is less which further minimizes the damage to the machine.

The laser wavelength of the fiber laser cutting machine is ten times lesser than the CO2 beam, which is more efficient for cutting. It can also be adjusted according to different metals.

Conclusion

The fiber laser cutting machine is a good alternative for intricate designs and details. It is also more efficient for cutting through thin sheet metals.

The machine produces less noise pollution and operates cost-efficiently. There is a lesser need for parts replacement as compared to the CO2 laser.

You may not even need to replace any parts if the technician is well trained in the ways of optimizing machine output.

If you are looking for an environmentally friendly machine, our fiber laser cutting machine makes the cut. It does not let out any harmful fumes and ensures very less wastage.

Contact Omni-CNC for more information on CNC machines. We, one of the best CNC cutting machine manufacturers, build, install and service CNC machines.