CO2 VS Fiber Laser – Which One Should You Buy?

1. Introduction

Technology is changing every day, thus, making it very important for industrialists to upgrade themselves with advance technology. Not advancing with the latest tech in the market could result in your free fall with regards to your competition. Perhaps, this is the reason why everyone upgrading to a CNC cutting machine is so much-hyped. Besides, don’t you think that your firm should have the latest cutting machine when others are also using it? Just give it a thought.

Besides, in a CNC machine, there is a machine that is gaining a lot of popularity; and, that is a fiber laser cutting machine. These machines have captured the market faster than any other machine could do! This is the reason why they are termed as path-breakers of this industry. Further, the demand for laser cutting machines is growing and is expected to grow at the same CAGR in the coming years. Moreover, the advancements made in the field of laser technology have led to the use of laser beams extensively.

Since laser machines are in great demand in different sectors like medical device technology, entertainment electronics, and photovoltaic sectors, the wind industries are widely using laser technology, ensuring offshore wind energy. The ease of automation, minimal distortion, and the versatility in cutting the material make this machine one of the highly demanded machines.

2. What is CO2 and Fiber Laser Cutting Machine?

The rapid growth and demand of the laser cutting machine have seen two methods dominating the market. Though there are many patterns and methods available in the market, yet no one can match the demand for carbon dioxide (CO2) laser cutting machine and fiber laser cutters, also known as fiber laser cutting machine.

Have you ever wondered why there is so much demand for these methods? The fact that both the process is used for its increased precision and versatility. A laser welding machine is reported as influential in terms of technology and application. It helps in automating the cutting and welding process, thereby boosting the product rates. The versatility of this machine helps manufacturers cutting the different forms of materials and developing products and components with different geometric shapes.

Laser cutting technology uses lasers such as CO2, solid-state, and fiber to cut materials efficiently. This high-tech machine has the capability to cut materials ranging from steel to plastic with absolute perfection. The laser machine has gone through different phases of improvement in terms of the quality and thickness of the cutting materials. Over the past years, laser machines have improved in terms of quality and thickness of cutting the material. The conventional cutting machines are being replaced with the latest tech-savvy laser cutting machines. The high beam quality system of the machine operates automatically, making it beneficial for both the commercial and industrial sectors.

Here in this blog, we will talk about different segments of laser cutting machines on the basis of laser types. We will discuss two laser types, one CO2 laser, and other fiber lasers.

3. What is the Difference between CO2 and Fiber Laser Machine?

3.1. CO2 Laser Cutting

A machine that works by focusing an infrared laser beam of high-intensity that comes out through a nozzle by passing a series of mirrors is called CO2 laser cutting machine. The first model of the CO2 laser cutting machine was first introduced 50 years or, perhaps, more than 50 years ago. Despite that, the CO2 laser cutting machine still remains the epicenter of the laser cutting industry.

When it comes to cutting fine features and acute angles, the CO2 cutting machine is the best. Typically, this cutting machine uses two axes with a movable table, which helps in creating a cut. Besides, it processes really fast for materials that have less than ⅜ inches. However, higher-powered machines like fiber laser cutter work far more quickly and efficiently on metal materials. Also, with the advancements and improvements in technology with a lot more focus on delivering quality with control, the CO2 laser cutting machine can give a better cut on non-metal materials and give an edge over the quality of the final product of a thicker surface as compared to a traditional cutting machine.

Having said that, the question that arises here is: what is the initial investment an industrialist has to make to incorporate the firm with a CO2 laser cutting machine?

The answer to this is that a CO2 laser cutting machine may cost anywhere around $3000 to $30000 in China. The variation in price can be seen and it happens because of the optical mirrors and the different consumables that are required for the smooth operations of the machine. Besides, the operating costs too can range at around $20 an hour, which is a nominal cost considering the shape and structure of the machine.

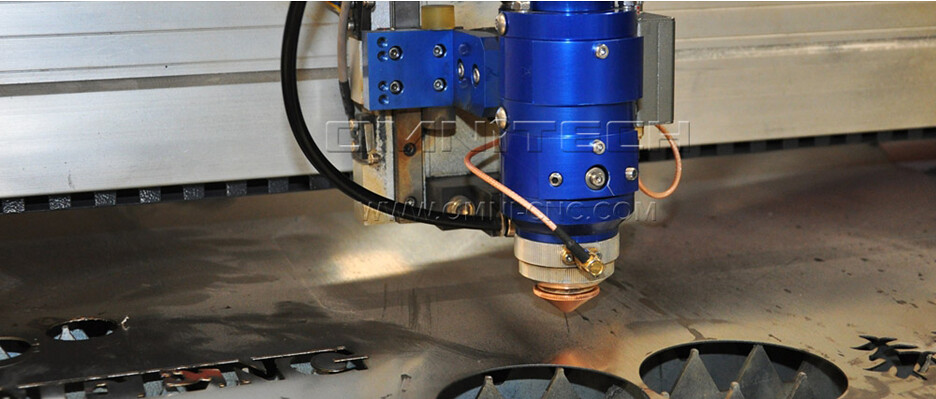

3.2. Fiber Laser Cutting

There is a famous saying that change is the only constant in this world, and, when things hover around technology, it is wise for an industrialist to upgrade their machines with the latest tech in the market. Maybe this is the reason why many industrialists are turning their attention to fiber laser cutters.

The fact that fiber laser cutting is a more recent and trending technology, fiber laser cutting machine has seen dramatic growth in its popularity. Besides, due to its superior quality over other cutting machines in terms of cutting thinner material has seen an increase in demand. In fact, the sales of fiber laser cutting machines have now exceeded the sale of those machines which use CO2 as a mode of cutting material.

When fiber laser cutter is compared to the CO2 cutting machine, it is seen that fiber cutting creates its bean with the help of a bank of diodes which then is focused on the material through a fiber-optic cable; whereas, a CO2 cutting machine will simply use a focused high-intensity beam of laser to cut the material. Furthermore, fiber laser machines are blessed with much faster-cutting as compared to CO2 cutting machines; this speed helps the operator to process fine cuts of high and meticulous quality.

Nonetheless, like every other machine, this machine has a drawback. The high speed of fiber laser cutting machines may reduce for more complicated and intricate jobs. Besides, it also requires detailed and pretty specific safety measures and operating kit for the operators to prevent long-term eye damage.

3.2.1. Cost of Fiber Laser Cutting Machine

Fiber lasers are more in demand and it is expensive than CO2 at the moment. It ranges from $40000 to $200000. Furthermore, the operational cost of the fiber laser cutting machine is more than that of a CO2 laser cutting machine. In addition to that, the solid-state setup of fiber laser cutting machines doesn’t require any kind of mirror or other equipment that is needed for the setup a CO2 laser cutting machine.

3.2.2. Market Segmentation

When comprehensive market research is concerned, reports clearly show that the market of the laser cutting machine is a fan of the recent technology and can mold its applications as per that technology.

Based on this principle, the market, at the moment, is divided into two parts. The first part constitutes the use of the solid-state laser cutter machine, i.e., the CO2 laser cutting machine; and, the second part belongs to the fiber laser welding machine. Of all the reports and surveys, one thing is very clear that the fiber laser cutting machine is anticipated to capture most of the market share just because of its high efficiency and lasers that this machine uses to cut as compared to other laser cutting technologies. Fiber laser cutting machines can operate on metal materials and it is used by many industries over co2 laser.

3.2.3. Competitive Analysis

The global market of laser cutting machines is witnessing a period of new growth while constantly being a state of fluctuation. However, both the access to decent and good resources, along with an affordable labor force is assisting the overall growth of the market of fiber laser cutting machines over CO2 laser cutting machines.

There are many more external factors for this growth. The expansion of the market of fiber laser cutting machine and the strategic roadmaps which the market companies use is also a reason why this machine’s market is growing. Besides, the revolution in services and products is also intensifying the productivity of fiber laser cutting machine and its market. This has helped the manufacturers in influencing the trends in order to gain dominance in the market.

4. Types of Fiber Laser Cutting Machine

4.1. Fiber Laser Cutting Machine for Light Purposes

Stable and reliable for light path operations and control. Light deploy tube fiber laser cutter is specially designed for functions that can be easily operated with high efficiency. With a life span of around 100000 hours, this machine is the best when an industrialist is seeking an addition for light functions.

4.2. Fiber Laser Cutting Machine for Alloys and Other Metals

If you are seeking a machine that should efficiently and effortlessly cut stainless steel, alloy steel, and other metal sheets, then a middle sheet fiber laser cutter is the ideal candidate for your job. Used for advertising and high-pressure purpose, this machine comes with a low voltage cabinet that supports the machine in providing high and stable cuts to the object.

4.3. Laser Cutting Machine for Inorganic Glass Sheet

Easy operation, basic maintenance, and high performance-price ratio, if you are looking for a machine with these features, then a flatbed fiber laser cutting machine is here to end your search. This machine provides users with powerful cutting at very efficiency.

4.4. Laser Cutting Machine for Steel, Plates and Other Metallic Materials

For faster cutting, high power laser source, and optimum quality, one should opt for a high power laser cutting machine. This machine comes with a compact structure, small floor area, and promises to provide stability and reliability. This machine is best to cut steel (stainless, carbon, alloy, spring), plates (copper, aluminum), gold, titanium, and silver materials.

5. Types of CO2 Laser Machine

5.1. Single Head Laser machine

For the most practical and affordable solution, an industrialist should opt for a single head laser cutting machine. This machine offers practical and affordable solutions with a flavor of optimal accuracy and quality. A single head laser cutting machine can be used for cutting or engraving:

- Acrylics

- Leather

- MDF

- Fabrics

- Plastics

- Rubber

- Plexiglass

Single head laser cutting machine provides the best quality products. The maintenance and handling costs of this machine are pretty low as compared to other cutting machines. This machine can be used for diverse work areas and could give satisfactory results.

5.2. Double Head laser machine

A double head laser cutter is one of the highest-selling machines. This machine offers the best features like high stability, speed, and precise outputs for bulk cutting or engraving. This type of cutter is used by companies that deal with large production so as to quicken the process. Along with the glass, it works on same type of material as the single head machine.

6. Materials that CO2 and Fiber Laser Machines can Cut

Laser cutting machines, be it CO2 or fiber, offers a wide range of cutting options. CO2 laser machines can cut non-metal materials while fiber laser cutting machines can cut metal materials. Apart from this, laser cutting machines can also be used for engraving purposes. Though laser for engraving is a non-contact process; it helps in producing high-quality products.

7. Industries that use Laser Cutting Machines

Many industries prefer using laser cutting machines as a mode of achieving high-end products. Let us take a look at some of the industries that fiber and CO2 laser cutting machine uses:

Fiber Laser Cutting Machine

- Kitchenware Industry

- Advertising Industry

- Sheet metal Industry

- Automotive Industry

- Fitness Equipment Industry

- Electrical Industry

- Automobile Industry

- Mechanical Industry

CO2 Laser Cutting Machine

- Woodworking Industry

- Leather Industry

- Cardboard Industry

- Rubber Industry

- Metal Industry

- Ceramic Industry

- Electronic Industry

- Signage Industry

- Architectural Models

If you too are looking for a laser cutting machine for a specific industry, OMNI CNC can tailor-made the machine that best suits the requirements of your company.