How Long Does A Fiber Laser Machine Last?

Technology is changing rapidly, thereby, making it important for the industrialists to upgrade their equipment. This holds a lot of importance for those who deal with cutting and CNC machines. Companies who use laser cutting instruments understand the advantages these machines provide. Having these machines gives an edge over your competitors.

Using a laser machine is a quick and efficient way of cutting and engraving objects. Further, these machines give a cleaner cut as compared to the traditional one. Moreover, these machines require less finishing and deburring after the cuts.

When laser cutting machines are a topic of conversation, one has to understand that there are many different varieties within this segment. And, one of them is a fiber laser cutting machine.

Evolution of the Fiber Laser Cutting Machine

Well, fiber laser cutting is quite fascinating to have; however, do you know how this idea came into existence?

It was in the winter of 2007 when Salvagnini started to work on his thought of using the potential of applying fiber laser to cut metal sheets. Before this, many companies heavily invested in the manufacturing and marketing of CO2 laser cutting machines. However, he was quick to realize that CO2 laser cutting machines were reaching their stagnant stage, and the market needed an injection of new technology.

This is when his company started to research about the potential use of fiber laser technology and its benefits. Since this was tough and exciting, Salvagnini knew the project was a potential success in itself if executed well.

Although the initial part of the research belonged to IPG Photonic fiber laser and its unmatched speed while cutting and splitting thin metals. However, the same could not be achieved while cutting thicker material. While CO2 laser cutting machines kept performing well in the market and were among the first preference among China Laser Engraving Machine users, despite that, the users needed a machine that can do what CO2 laser cutting machines can’tー cutting bulk of the sheet metal fabrication market.

And, Salvagnini knew that fiber laser cutting technology had the potential of doing that. He saw that a fiber laser has five times lower cost of operation than a CO2 laser cutting machine with much higher speed. This also meant that the usage of this machine would reduce the payback time, and the return on investment (ROI) would be greater for owners of fiber laser cutters. When the research was completed, Salvagnini was clear that this idea was a pattern breaker.

Fiber Laser Cutting Machine and It’s Working:

Fiber laser cutting machine is very popular equipment among many industrialists. However, before delving into the details, here is a piece of information on what this machine is and how it works.

Fiber Cutting Machine:

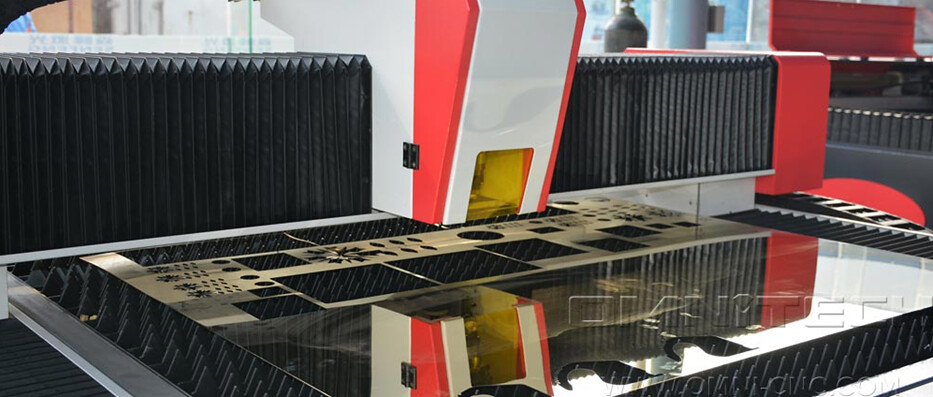

Fiber laser cutting machine is a machine that is used for precise metal cutting. This machine is mechanized by a fiber laser. The quality and capacity of the beam coming out of the fiber determine the speed of cutting. Higher the quality of the beam, more is the speed and precise the cut. What’s good with this machine is that the work produced by this machine, i.e., the cuts is accurate and explicit in comparison to some other cutting machines.

Working of the Fiber Cutting Machine:

Reading the above context makes one wonder: How does this machine work so well and how is this gaining more fans in the industry? Well, for starters, this adroit machine has a meticulous working structure, which is its trade secret. And, this trade secret is decoded here to allow others to understand its working so that they can invest in this wonderful invention.

Fiber laser cutting machine in China or some other part of the world works on the same principle. It can’t be different! It is a mere misconception. Coming back to the point, that is the working; the last generator of the machine fires a high power density laser beam through a system that is more like an optical path.

This laser beam is then directed towards the workpiece’s surface in a way that it focussed until the melting point, or the boiling point of the workpiece is obtained. While the pressure of the gas is high, the beam is aligned in such a way that it either blows away the metal in use or vaporizes for further use.

Thus, with the activity of the beam along with the metal or workpiece’s proportionate position, the main aim of cutting and splitting the metal is achieved.

Working Principle of this Machine

The working principle of the fiber laser cutting machine is similar to that of a laser welding. It’s just that the temperature of this machine crosses 11000 ℃ which is enough to gasify any material. Thereby making gasification an important part of the melting amid the laser cutting process.

Besides, the laser cutting process of some materials like that of carbon and ceramics is directly a part of the gasification process. This is when the inert gas flows, and the incision melts the metal helping to create smooth and straight cuts. The jet’s oxygen is then used to increase the cutting speed. This incision is mostly narrow, precise in size, smooth on the surface, and has a better cutting quality over other heat using cutting materials.

How do these Machines Attain High Speed?

Speed is the factor! It has always been like that in China’s laser engraving machine industry or in other country engraving industry. However, the utter high speed of these machines is a first-choice of customers who are looking to increase their firm’s efficiency. Though there are many cutting machines in the market, yet no one can beat the precise nature, speed, and quality of fiber laser cutting machine.

However, what fascinates everyone is how do these machines achieve this high speed? The reason for this is that these machines are designed to provide speed and aggression to the cutting process. Further, making it more powerful. Without high power and speed, getting precise cuts into deeper materials is very hard. Thus, most of these machines have a power rating around 50W, which programs fiber laser cutting machines to make depth marking with clear cuts.

Life Expectancy of These Machines

One can expect a better life expectancy of a fiber laser cutting machine over other machines in the market. The fact that the diode module in a fiber laser is three times more extended as compared to other technologies helps this machine last longer.

Apart from that, most of the laser in the market have a life around 30,000 hours, which is a lay man’s language is 15 years of proper usage. Further, one can expect a good 100,000 hours life of fiber lasers, which roughly translates to 45 years of machine use.

Advantages of Using This Machine:

So what were the features that as a reader you observed here? High precision, no limitation to the cutting pattern, fast cutting, low working cost, and smooth incision are some of the features that could be found while reading it and, perhaps, more while using it. Now ask, will you be able to find any of this if you were to use the traditional mechanical knife or machines that don’t come with laser features?

Fiber laser cutting is gradually improving and is replacing the traditional metal cutting process equipment. Further, its benefit is something that is quite a compelling one for many makers. So, let’s have a look at them:

- The best thing is that the laser’s cutter mechanical part has no contact with the workpiece. Thus, making no scratch on the surface of the workpiece.

- It has high speed and smooth incision. Thus, requiring no other processing with the workpiece.

- The area where the cutting heat act, plate deformation happens is small, and the slit is narrow.

- No burr or mechanical stress.

- High accuracy, excellent repeatability.

- Plance graph operated on numerical control programming.

- Saves time by cutting a large piece of the whole plate without opening the mold.

Where to Clean/Preventive Measures

There have been many cases where many of the users have mishandled the machine, which has resulted in a fault or a complete breakdown of the machine. Therefore, before you grab a cloth and start to clean the laser operators, there are a few preventive measures that one needs to understand for cleaning this wonderful machine.

Let’s have a look at some of the parts which should be the focus of the maintenance process:

Torch

This is part is the focal part of performing any operation related to laser cutting. There are some parts of the torch that require cleaning; these parts include the torch body, the protective window, the nozzle, and attached lines and cables. There is one more part that the laser operators need to clean and that it the cover of the Z-axis.

A clean lint-free rag with isopropyl alcohol could be considered for cleaning purposes. Using that, wipe down these areas to clean the torch of any debris. By doing so, one can achieve consistent quality in laser operations.

Drive System

This is another place where a high level of maintenance is required. The drive system comprises of the X-axis, Y-axis, and Z-axis, i.e., the three dimensions of the laser machine which navigates the torch for the cutting operations.

Belts and Bellows are the drive components to inspect. One can use a soft brush, a vacuum, or a rag to clean any byproduct left inside the machine as a result of the laser-cutting process. Cleaning belts and bellows will ensure that there is no premature failure and the component wear and tear is fine.

Slats

This is also another very crucial area that needs to inspect once in a while. Further, it is essential to measure the height of the slat regularly. Not checking the height of slat, due to wear and tear, can result in laser not initiating the cutting process. Moreover, the torch can travel below the laser’s software limit, which is an alarming signal for the laser operator.

To maintain the height of the slat, reduce the slag buildup and try to use tools that are particularly made for removing slag; else, one can manually remove it, only if the operator is experienced and knows how precisely it requires to be done.

So, here was the overview of this machine. Fiber laser cutting machine is an investor’s investment, given its durability and long life; it is hard to have doubts over this machine. Hence, if you are thinking of adding this in your firm’s arsenal, then close your eyes dive right in!