Cutting solution for the Film Industry – Digital Cutting Machine

Plastic films are gradually increasing their usefulness with every passing year. In fact, they have become a crucial part of our regular lives. The uses of plastic films are multifarious, and packaging is the foremost of them. Reports reveal that the market of packaging films is all set to gain a healthy 6% CAGR during the period 2020 to 2025. Especially, China and India will emerge as the key beneficiaries of the global packaging film market during this period. This is because packaging films are usually plastic-made, which is cheaper and lightweight. Nevertheless, the use of packaging films for different products involves their proper cutting, which is difficult through mere manual intervention. This is where digital cutting machines play their part.

Delving Deeper into Packaging Films

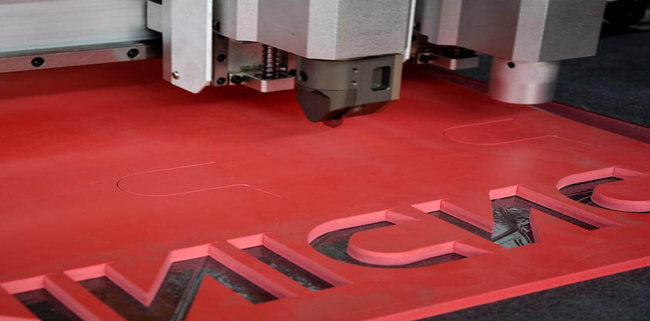

You can term packaging films as the coating of heated and non-heated layers of plastics. Major components of these materials include polyethylene, polypropylene, polyethylene, and so on. These multi-layer films find the best use in the consumer goods and food packaging industries. Nevertheless, using these films for product packaging needs their proper cutting so that they could appear fit enough for the size of the concerned products. Industries prefer using CNC machines to execute this purpose with extreme finesse. These machines offer exact cutting solutions for the packaging film industry and hence finds many takers from a range of product manufacturers. For best results, OMNI CNC cutting machines are worth using.

The Digital Cutting Machine at an Industrial Level

From regular lives to the industrial level, the use of plastic films is prevalent for many reasons. Talking about industrial levels, many companies are using these films to wrap pellets. Before any company moves its goods for shipment to fulfill any order, they need to wrap those pellets well. Mainly, the construction industry is using plastic films and sheeting for their various purposes.

Here are some of the usages of plastic films in industries:

- For packaging and shipping the parcels

- For erosion control

- For gas and moisture control

- For the insulation membrane

- For construction enclosure

Making the films ideal for all these purposes is no easy task but requires considerable effort. Manual cutting of films for packaging and other jobs is time-consuming. It does not lead to perfection, either. Digital cutting machines act as ideal solutions for the film industry in this respect.

Using packaging films give instant benefits to assorted industries; here are few of them:

- Plastic films are durable

- The plastic material is multi-purpose

- The water-resistant property of films is incredible

- Manageable for both hot and cold temperatures

- Plastics are reusable multiple times

- Recycling of films makes it environment-friendly

The polythene material withstands the pressure and handles other natural elements as well. It also offers temporary support to the structure. Plastic films are a popular choice for food packaging industries as they give an attractive look to the food items and beverages. At the same time, they also keep the food items protected.

Count on the Efficiency of Digital Cutting Machine

The efficiency of the digital cutting machine varies with the terms of the brand. Omni CNC offers a convenient way to cut the films. You need significant investment to get the best out of it. Sometimes, it turns into a price tag only to get the required service from the provider. But this is not the case anymore with Omni CNC machines as they ensure multiple plus points:

- Modular tooling

- Profitability

- Industrial adaptation

- Meet technological challenges

- Scope for improvements

- Efficiency of performance

With all these points leading to the efficiency of the digital cutting machine, you can count on Omni CNC machines and consider them as solid investments for the future. The price tags may get overwhelming for you. But you need to take it as a long-term benefit to adding the worth capability to your work.

More specifically, the CNC knife cutting machine B model focuses on flexible material cutting with its auto conveyor system. It comprises a multi-tool cutting head-fixed blade to perform the cutting tasks with ease, along with the help of a pizza wheel (rotary blade), electric oscillating blade, routing, and kiss cut. The machine is perfect for cutting the square corners of the packaging films and other materials by its tangential control.

How Digital Cutting Machine Becomes an Effective Cutting Solution for the Film Industry?

Plastic films have become almost indispensable in many regular and industrial applications due to their ability to give long-lasting protection to the products and to enhance the durability of the underlying surface. To meet the rapidly diversifying requirements of the industry, the film producing units require state-of-the-art cutting mechanisms. Yet again, digital cutting solutions offered by industry experts like Omni CNC can make a huge difference in this regard. These machines provide quality cutting solutions in terms of production and quality of finished films for multifarious applications.

Minutely Detailed Cuts

Many film layers require precision while mass-producing the same for application on a particular surface. For example, to label films, you need to cut according to precise specifications and accuracy. Digital cutting can make the process automatic, error-free, and often require minimal human intervention after the initial inputs.

Digital Cutting is Inexpensive and Economical in the Longer Term

Digital cutting can make life a lot easier for film manufacturers by making the process faster, accurate, and automated. Thus, it makes perfect sense to invest in the latest offerings of such tools from Omni CNC. While the initial costs may seem high, the long-term benefits and minimal degradation of the equipment quickly compensate for the investment.

Flexibility to Adapt According to Different Cut Sizes

Digital cutting solutions like lasers are easily programmable, and they enable the system to churn out a variety of designs quickly with a high degree of accuracy. Manufacturers can meet the demands for various film sizes within reduced timelines, ultimately increasing productivity.

Contactless Cutting for Quick and Efficient Film Production

These state-of-the-art film cutting systems are often contactless, thus eliminating the general wear and tear of blades or similar tools, which require physical contact with the film surface for cutting. So, the production process becomes faster and smoother while requiring minimal maintenance required for maximum efficiency.

How Digital Cutting Machine is Helpful as Compared to Traditional Cutting Machines?

Producing quality rolls for packing the products was difficult through traditional packing. Industries used to face many more challenges while packaging. Films have diminished this void appreciably. No wonder the demand for plastic films is growing steadily in numerous industries because of their advantageous properties. In order to meet this demand efficiently, the packaging film industries need to utilize state-of-the-art cutting techniques. Excellent digital cutting solutions from Omni CNC can make a whole lot of difference in this respect. Experts using the digital technique would not only be able to provide you with exceptional quality of films for diverse applications but would also give more in terms of production.

Contactless Cutting

With traditional methods, the use of blades or similar tools can lead to wear and tear of the film. On the other hand, present-day cutting systems are contactless. These CNC machines make the entire process rather smooth and quick.

Intricate Cuts

When mass-produced for the same application, precision in film cutting holds the key. The traditional method, though effective, can be rather time-consuming, hence making digital cutting the best choice. Just opposite, digital cutting can offer error-free results with minimal intervention after entering the initial information.

Flexible

With the traditional method, it was a bit cumbersome to create different designs, but with technological advancements, digital cutting can create different designs effectively. With varied digital cutting options like a laser, you can meet the demand for a variety of films within a specified timeframe, thereby enhancing productivity.

One-time Investment

The digital cutting machine can be expensive upfront but can help save a lot of money in the long run by making the entire production process quick, automated, and precise. Traditional methods not only consume much time but also cost dearer as compared to the automated process, which can produce significantly more number of films in a given time frame.

What are the Benefits of Films in Our Daily Life?

The demand for flexible packaging films is growing rapidly as manufacturers realize their valuable advantages. When it comes to packaging solutions, flexibility is itself an excellent option to consider. However, the film industry ensures many more benefits, including versatility, packaging, consumer appeal, and cost savings. Listed below are a few reasons to cite the importance of films and their selection over other packaging modes.

Packaging Film is Customizable: With the help of digital cutting machines, you can customize the film as per the requirements of the product that you want to pack. This gives you the flexibility to alter your packaging needs based on market objectives and your unique specs. The customization benefit extends to aesthetic properties, including glossiness, clarity, and more.

Reduces Production Cost: Digital cutting machines help you to customize the film to a specific size of the product; hence the need for using additional material reduces appreciably. Dynamic utilization of packaging films simplifies your packaging system, and this, in turn, can reduce the manufacturing costs. Additionally, the expense of choosing a packaging film is lower as compared to plastic or glass containers.

Versatile: When it comes to choosing packaging options, versatility is the key. Flexible packaging offers many options, and one would be able to design a package that sits on a shelf, stands up, or hangs. This means that the packaging would work for the product as opposed to the other way around. The specific designs of OMNICNC digital cutting machines for packaging film industry work as per the respective product requirements, and hence they give more precision to the cutting tasks.

Environment-Friendly: Sustainability has become crucial for Consumer Packaged Goods businesses, and hence it is important to use materials that meet the standards of sustainability. As the greatest benefit of polyethylene and polyolefin films, you can recycle them. The OMNI CNC machines need less energy to manufacture and generate a very small quantity of greenhouse gases. In the run, they provide quality film cutting solutions as well.

A Safe Investment For Future

The market of packaging films is all poised to rise by a whopping US$52 Billion worldwide, with 5.2% of compounded growth. Especially, the Low-Density Polyethylene or LDPE segment alone is prone to grow at more than 6.2%, thereby reaching above US$30.4 Billion by 2025. These healthy gains, in turn, will give rise to many associated industries, one of them being the CNC machines that offer cutting solutions for the packaging film industry. Hence, investing in CNC machines would be a safe investment for the future if you are into the business of providing cuttings solutions for films. OMNI CNC is a reliable manufacturer to help you order quality digital cutting machines to help your cause.

Bottomline

The packaging film industry finds widespread use in assorted verticals. From packing food items to good consumer products, medicines to cosmetics, and much more, flexible packaging films are useful for all these purposes. Their use is prevalent due to a range of reasons like, they make the outer packing tear-resistant, and these films protect the products during packaging, distribution, and storage. Moreover, they safeguard the contents from exposure to external agents like moisture, gas, and light, thereby retaining the freshness, aroma, and quality of the products.

Hence, equally important is to make these films usable for packaging these contents by cutting them with high degree accuracy. While traditional cutting solutions faced several challenges like producing quality rolls with films, accuracy cutting hassles, etc., CNC machines set you free from all these problems. Therefore, ordering machines from OMNICNC would be a wise decision if you are into the packaging film business. No wonder these machines offer a range of cutting solutions for the film industry. For more info on the sophisticated digital cutting machines or if you wish to buy one of them for your business, clicking through the official website of OMNI CNC would be ideal.