How Closet Doors are made by a CNC Machine?

Woodworking has always been there, it is just the technology that’s changing. Closet designers always yearn for the latest technologies, fashion, and lifestyle to stay ahead of the designing trends. This is where manufacturing companies and industries seek the help of a CNC machine for processing woodwork and manufacturing products from the raw material. From manufacturing closets, interior fittings, windows, doors, etc., the CNC machine shows how well it can meet the requirements of the customer with increased efficiency and productivity. CNC carving machines work smoothly on woods and make motifs with great ease. Besides wood, CNC routing machine can work on different types of material, such as plastic, foam, PVC, acrylic, glass, stone, jade, marble.

1. Use CNC machine to Customize Closets

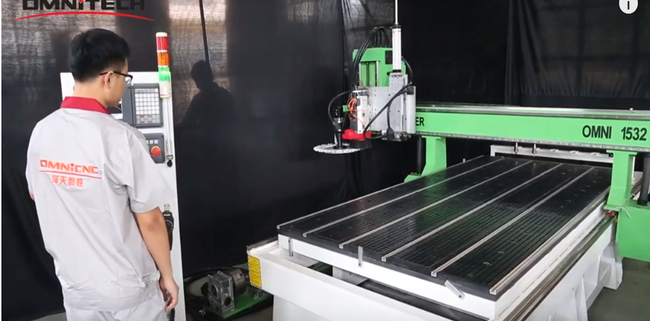

CNC machine is used for manufacturing both small and large closets, cabinet, doors, desks, and much more. It produces detailed and finished drawings, 3D design, user-defined cultists, the material used reports, financial charts and reports, and panel optimization. OMNI CNC uses software to produces G-code to run CNC machines to provide 3D renderings, drawings, bids, cultists, etc. There is a broad range of CNC machinery helps in accelerating the design of custom closets, kitchen, and bathroom cabinets. This advanced technology allows designers to embrace creativity while giving room to manufacturers to relax knowing that the CNC settings are already defined for smooth operation.

While designing a closet, there are three things that you should not avoid.

a. Keep an Eye on the Designs and Patterns

As per the recent trends, designers prefer neutral to bold colors, attractive patterns, and designs to keep an eye on the runway. Apart from the color and patterns, designers also focus on intricacies such as inlays, cornices, moldings, and materials used for making closets. CNC machine cut closets components with perfection and precision. Whether you require CNC machines for short or long-run production, OMNI CNC machines stand the test of time in performance, labor savings, and production.

b. Customize Closets for your Client

A closet is not only an enclosed storage space for storing particulars rather it is a place where you can maximize and organize the storage space in every room. Every person wants its wardrobe or closet to be spacious wherein you can keep particulars according to the activities such as jogging clothes to business attire from shoes to jewelry, vest, etc. The designers should comprehend the requirements of the customers and keep up with the design. Also, the CNC machine uses designing software that enables designers to keep up with the latest trends and help to improve the ways that clients are actively looking for.

One of the important goals of this personalization is to ensure that the client can keep the closet organized and functional.

c. Embrace Technology

With the changing trends, technology also changes and so do the expectations of clients. The designs include the latest devices, such as soft hardware for heavy doors, innovative drawer slides, advanced cabinet locks, pop-up power decks, exclusive lights, and stylish mirrors. Designers design every nook or cranny of the closet and ensure that they give 100% satisfaction to customers.

2. Advanced Technology used for Manufacturing Closets

Many manufacturing companies make use of advanced technology to improve the processes and products that are within the supply chain. When talking about advanced manufacturing technology, it means the spectrum of a highly advanced CNC machine is discussed. The fabrication process is automated, so you do not have to worry about the negligence of the workers. The operation time involved is very less and this high tech machine can cut different parts of the product in different shapes and sizes.

CNC machining delivers superior accuracy, precision, and speed for high quantities of products, and that makes it the right choice in most situations. Manufacturing companies gain an edge through efficiency, consistency, precision, and accuracy. CNC routing machine transforms the raw material to a customized and easily tackle complex decorative engraving on a closet panel.

3. Application of the CNC Routing Machine

These days CNC machines are found in almost all industries, from a small scale to big companies. There is hardly any facet of manufacturing that is left untouched by the CNC machine. Owing to the extensive need for the CNC machines in various industries, there is a great surge in the demand of the CNC programmers. To cope with this difference, training on the operations and programming of the CNC machine should be given so that people can take advantage of the technology.

CAD/CAM Applications

CNC machines use software CAD Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) to automate the manufacturing processes. While CAD focuses on the design of the product, CAM focuses on the manufacturing of the product as per the design. Once the CAD model is imported into CAM, the CNC machine starts transforming the raw material and gives it definite shape through different actions like cutting, engraving, boring, and drilling.

CAD/CAM applications are used to both design a product and program manufacturing processes, specifically, CNC machining. CAM software (US site) uses the models and assemblies created in CAD software to generate tool paths that drive machine tools to turn designs into physical parts. CAD/CAM software is used to design and manufacture prototypes, finished parts and production run.

The CAD machining process begins with the creation of a vector design allowing designers and manufacturers to cut and produce external boundaries with CAM software. CNC routing machines can cut any shape or external boundary in your drawings. The routing machine cuts the material with precision and ensures the perfect shape and size of the material cut.

The design of the CAD runs through CAM software to extract the part of curves/geometry and generate a programming code that will control the CNC machine and ensure that the tool produces the custom-designed part. These geometric codes are also known as G-code. After this, the machine ensures that the material is loaded perfectly before starting the operation. After that, the material is autoloaded by the machine and works as the G-code of CAD.

The CNC machine runs as per the program. It gives the command to the tool and move as per the instructions. The program prompts the CNC machine and guides the machine throughout the process of operation (cutting, carving, engraving, etc) to produce a custom-designed part.

4. Closet Manufacturing Companies Stay Ahead of Trends with CNC machines

Many manufacturing companies are now using CNC machines to design closets and do other woodworking tasks. Every piece of the wood can be customized with the CNC machine thereby bringing the interior of your home to life. CNC machine plays an important role in cutting, carving, and creating closets for the interior of the residential or corporate place. CNC woodcarving machine can also mass-produce and reproduce products efficiently. Carving, cutting, and engraving that were once a complicated task can be completed in lesser time than before.

CNC machine helps in designing the closet as per your requirement. The first and foremost thing that you should know even before designing a closet is how big or small you want your closet to be. It is obviously tempting to see big, spacious, and walk-in closets but organizing a closet as per your space can be a difficult task. Maximize the space as much as you can! Do not waste even an inch when planning to build a closet. Design your closet more ergonomically. CAD software beautifully designs the closet as per requirements of customer and CAM software cuts and carves the raw wood giving proper shape and size and customizing as required.

5. Design and Organize your Storage Space

Over the last few years, a noticeable improvement in technology has been witnessed. Cabinet and closet manufacturing companies have shifted to newer technologies like CNC machines for cutting and engraving materials thereby streamlining the design to the production process and eliminating the possibility of errors that can occur when translating drawings to CNC. CNC machines use CAD drawing software that is specifically used for meeting the needs and requirements of the closet industry. CNC machines have eliminated redundancies and variances in closet parts and provide users with consistent and quality based products.

Every custom storage solution that is manufactured by the CNC machine guarantees 100 percent customization. With CNC routing machines, cabinetmakers can reduce lead times and minimize material handling. OMNI CNC routing machines have manufactured doors of the closet, countertops, shelves, drawers, and drawer fronts ranging from small to mid-size and large. The CNC machine allows closet making companies to use a manufacturing technique that enhances the production time, quality, and consistency.

A job that previously used to take a multitude of machines to get complete now can be done with the help of a single machine with 100% efficiency and accuracy. If you are also looking for customized closets, then seek the help of manufacturers who use CNC woodworking machines. This computer-controlled machine takes information input directly from our cabinet design software and performs necessary operations to build the closet. The closet doors, drawers, and cabinet parts are cut with precision, routed and drilled properly for adding adjustable drawers. OMNI CNC guarantees 100% custom, made as per the specifications of customers and stand expectations of the customer.

Customer Story: