Looking for Your First CNC Plasma Cutting Machine? Here is a Comprehensive Buyers Guide

Are you are looking for a CNC plasma machine for your industry? If you have never owned a plasma cutting machine for sale and using it for the very first time then this buyer guide is for you. This guide points some important features that one should consider while purchasing CNC plasma cutting table:https://www.omni-cnc.com/plasma-buyer-guide/.

Moreover, through this blog, we will walk you through the entire process of understanding the work process of plasma cutter along with the tips for maintaining the machine and safety hazards that one should be aware of.

With the increasing technological innovation, more and more industries are demanding CNC plasma cutting machines as a great addition to their business. This computer-controlled device can create intricate as well as complex patterns on the surface of the material. The ability to cut and carve so precisely, CNC plasma cutting machine create a prototype of the objects.

If you are considering one for your industry as well, then you should meticulously research before buying plasma machine for saving a considerable amount of time and expenses of your company.

Moreover, Plasma cutting machine can be used in artwork, signs, ornaments, fabrication, etc. It also has the ability to cut straight steel tubes, drill holes, and gouge tubes. You can count on OMNI CNC plasma cutting machine that can effortlessly cut 5mm and 3 mm thick steel tubes and sheets.

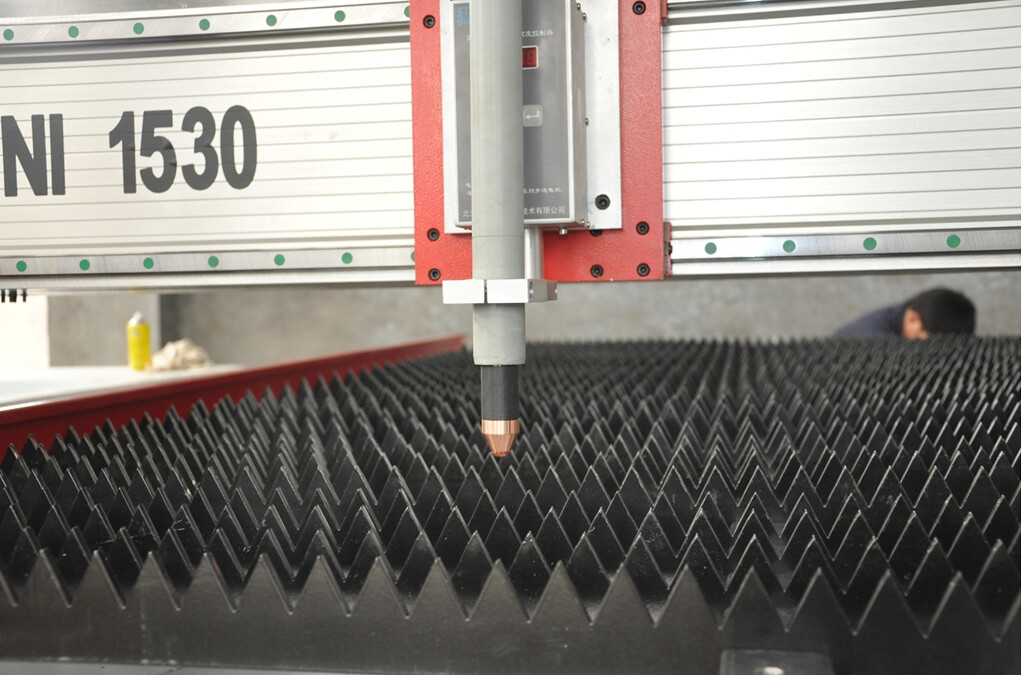

A CNC plasma machine carries the plasma torch and moves the torch in the path specially directed by the computer. Here are some important features that you must consider while operating a CNC machine. Let us take a look at them:

Important Factors You Should Consider

-

Determining the Thickness of The Metal

Thickness is one of the most important features that the operator should determine. Before using the cutter, it is important to measure the thickness of the metal that needs to be cut. Plasma cutting machine depends on the material that you choose for cutting. Take for instance; a 375 spectrum plasma machine can effectively cut 3/8 inches of steel.

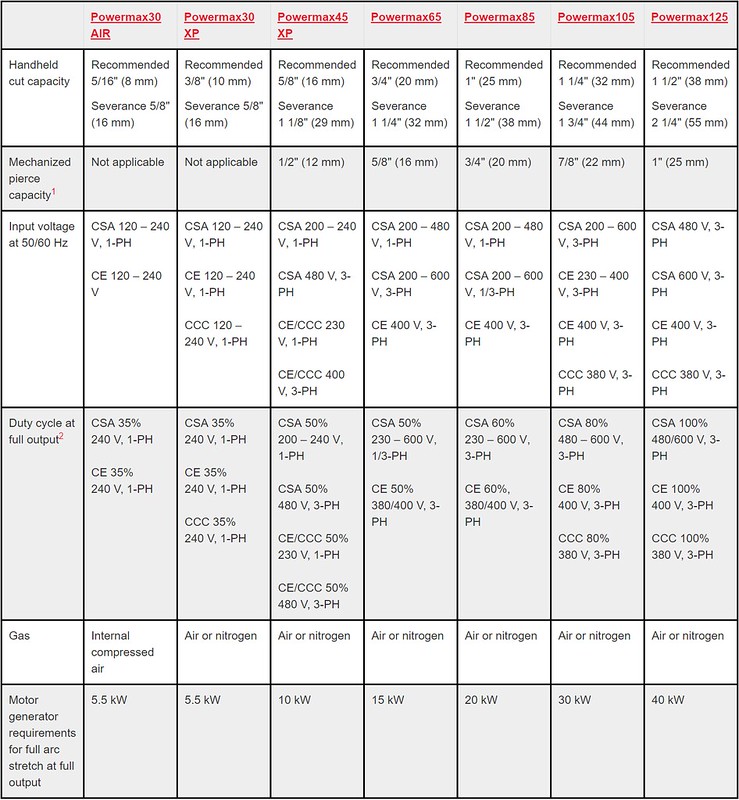

In addition, you can also use a powermax plasma cutter that can help you cut a metal sheet 55 mm (2-1/4″). Also, select a compatible system with interface options for automation equipment like a CNC table, robot and track cutters.

Plasma machine works best on conductive metal including mild steel, aluminum, copper, stainless steel, etc. If you have ample knowledge and a bit of practice, you can achieve smooth, clean, and consistent gouges. This machine also helps in reducing the amount of noise and debris created in the environment.

- Optimum Speed of Cutting

The CNC plasma cutter kit is used in a variety of environments. It is ideal for cutting steel and other types of non-ferrous materials that support the process of oxidizing but it does not rely on oxidization to operate.

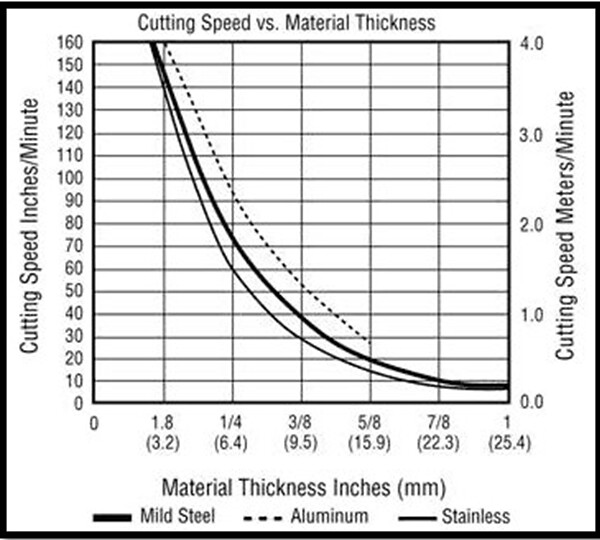

This plasma machine comes in a variety of shapes and sizes and provides the cutting speed for the thickness of the metal measured in inches per minute (IPM). You should choose a machine that handles twice the normal thickness approximately twice your normal cutting thickness.

Take for instance; to perform long, fast, quality production cuts on ¼” steel choose a 1/2″ class (60 amps) machine.

- Machines Working Quality

The plasma cutting technology has been increasingly improving for about 30 years and more and continues to do so. The quality of the equipment is better than the manual process of cutting. With the help of this advanced technology, you can easily cut a work-piece and create different designs.

The working quality of the machine depends on the cut quality on metal. The better is the quality on the metal, the effective is the tool. Therefore, it is very important to consider a few factors like type of the machine, plasma cutting system, motion control devices, process variables, and external variables while attempting to improve the appearance of the cut.

OMNI adopts world well known brand for plasma cutting machine, like PowerMAX/CutMaster plasma generator and cutting torch. The torch height control system allows the torch could sense the cutting heightness and could cut the high quality even the metal sheet is not very flat.

While operating the CNC plasma machine, ensure that your follow appropriate specifications along with correct process for metal type, metal thickness, the quality of the cut, and productivity goals. Also, ensure that the plasma arc cutting is at an appropriate direction and correct process is selected for cutting the material.

While operating the machine, always adjust the cutting speed of the machine, set a proper torch-to-work distance, and identify and repair any leaks or restrictions.

Work Process of a Plasma Cutter

- What is a Plasma Cutter?

Plasma CNC cutter is a process that cuts through the electrically conductive material with the help of hot plasma. Plasma cutting machines use a high-velocity jet of ionized gas that is delivered from the orifice. Plasma conducts electricity from the torch of the plasma cutter to the workpiece and heats the object, thereby melting the material. The high-velocity stream of ionized gas mechanically blows the molten metal away, splitting the materials.

In the simplest term, plasma machine can be used in various types of conductive metals such as mild steel, aluminum, and stainless. The milder is the consistency of the steel; the operator can experience thicker as well as faster cuts.

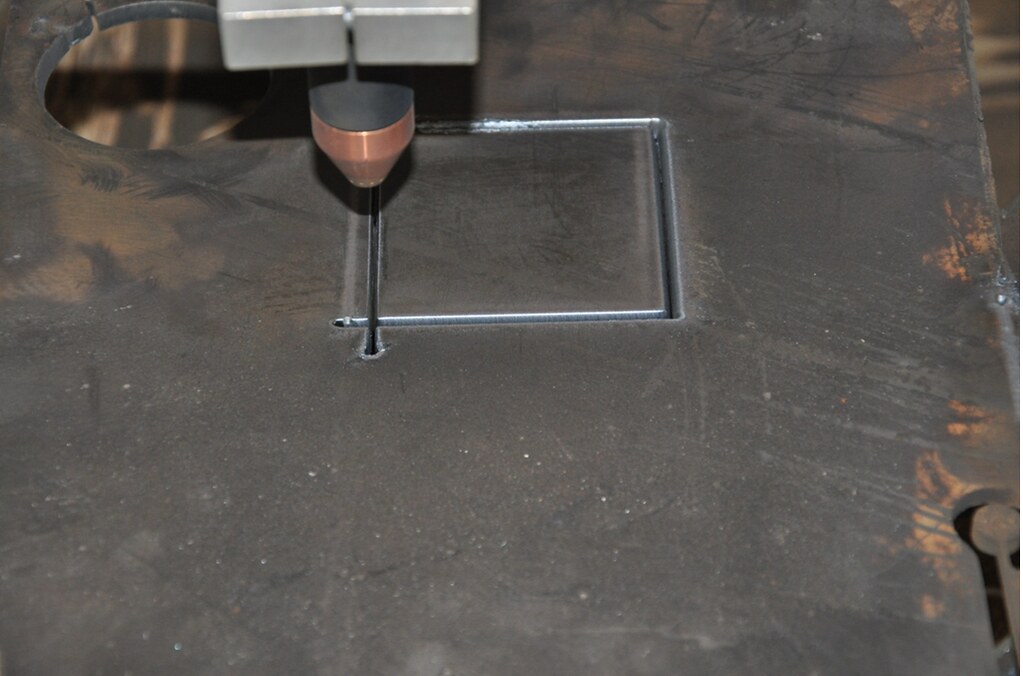

OMNI CNC plasma cutting machines are good at smooth cutting edges of the material giving a clean and precise cut. Products are ideally suited for automotive fabrication, structural steel cutting, construction, sign shops, metal fabrication, decorative fencing. See below the window fence project, which was built by OMNI client.

The plasma cutting process uses a high-velocity jet of ionized gas that gets transferred from a constricting orifice. The plasma conducts electricity from the torch of the plasma cutter and transfers that heat to the workpiece. The plasma heats the workpiece and the high-velocity stream of ionized gas blows the molten metal away thereby making a clean and clear cut on the material.

- How to Operate a Plasma Cutter?

A plasma cutters tables for sale is capable of cutting thick metal sheets in any shape and size. This computer-controlled machine gives instructions through a computer over the manual handheld plasma cutter. It is compatible with optional CNC parts and improves the accuracy, flexibility, and productivity.

When you purchase this plasma cutting machine, you will receive plasma cutting software that needs to be installed before operating the machine.

- Software Used to Operate the Plasma Cutter

The software that comes with the plasma cutter is indubitably one of the most important parts of the machine. It allows the operator to successfully design, cut, and control the operation of the plasma torch. To create top quality designs with the plasma cutter, the operator must use AutoCAD for the CAD part and EXG Code for the CAM portion. The software that actually controls the plasma usually comes along with the CNC plasma table.

CNC plasma cutting software STARCAM is very easy to operate. It consists of 3 modules, first drawing module (StarCAD), nesting module, (StarCUT), and numerical control emulation module (StarTEST). Any layman can read the manual and understand the working process. A short training is also given to the new user to make comprehend with the basics of a 4*8 plasma cutting machine. If you are interested in seeing the work process of this machine, you must read plasma machine software in action.

- How CNC Plasma Cutting Evolved?

Plasma cutting machines have come a long way. It has evolved to a great extent and considered as one of the most effective productive equipment for cutting metal sheets and plates.

The plasma machine has greater flexibility and ability to cut diverse shaped materials on the basis of the instructions programmed. The machines were generally limited to cutting various patterns using X and Y axis of motion.

Maintenance Tips

Neglecting the maintenance of the plasma CNC table would cause damage to the machine. The mechanical parts of the machine will wear causing abrasion.

When the components of the machinery fail, troubleshooting or maintenance of the machine is a must thereby preventing any type of hazards.

Here are some maintenance tips that you should consider preventing injuries and any sort of fatalities that may occur if the machine is not properly maintained.

- Check the Torch Body

Remove the parts of the torch and clean inner parts of the torch with cotton dabbed in the cleaner. Separate the torch from its mounting tube and slide it back. Also, ensure that the torch body has no leaks or damage to any of the connections.

- Clean the Torch Leads

Wipe out the torch leads and remove the metal dust and dirt that is accumulated in the torch leads. The metal dust can cause dissipation of the high voltage needed to start the plasma arc. Also, check kinked or worn hoses, exposed wires, and damaged fittings that can be a reason for injuries and fatalities.

- Clean the Power Supply

Clear accumulated metal dust with the help of clean, dry, shop air. Metal dust can cause damage to power-supply components, especially PC boards. Moreover, contractors, relays, and spark-gap assemblies can also malfunction due to excessive formation of metal dust. Ensure that the air filters are clean so that the power supply is not hindered.

- Check Torch Cooling Components

Check the coolant stream in the tank for signs of aspirated air or reduced flow. Check that flow switches and ensure the return flow functions properly. Insufficient flow of the coolant can cause the torch to overheat. Check the coolant filters, pump screens, and clean/replace them as per the situation. Check the coolant resistivity with the help of a conductivity meter. The resistivity of the coolant should not exceed 10 micro-ohms for most of the systems.

- Align and Adjust Gears and Bearings

Adjust and align gears of the CNC plasma cutting machine for sale so that the gears do not overlap the rack. Ensure that the adjustments are made properly for rail and cross drives. The alignment of the bearings should be minimal. Alter the gears and bearings accordingly and do not over-tighten them. Adjust the beam till the time it rolls freely with very little vibration and resistance.

- Check Safety Limits

While operating the plasma CNC cutter, ensure safety measures so as to prevent any sort of damage to the machine. Make sure the machine stops when each switch is reached and also inspect mechanical stops to confirm that the machine is working properly.

How to Stay Safe While Operating the CNC Plasma Machine?

Plasma cutting machine is used to cut a variety of materials very efficiently but it does not come without any hazards. It is extremely important to keep one’s head out while operating this CNC plasma cutting machine.

- Wear Plasma Helmet or Mask

Protect yourself with plasma helmet to shield yourself from the plasma sparks that might hit your eyes, if remained unprotected. Plasma helmet also protects eyes from experiencing damage due to the bright plasma cutting light.

In addition, the clothes and the gloves which you wear should be flame resistant, so that your body doesn’t get affected by the sparks. Also, the CNC plasma cutter operator must not carry matches or butane lighter with themselves. You should wear high-top leather shoes or boots so as to keep sparks from hitting your feet and injuring you. Needless to say, looking at the sparks of the plasma can cause damage to your eyes and may further lead to blindness.

- Protect Yourself and Others

Processes like welding, cutting, and gouging are quite noisy and require ear protection. The plasma machine throws ultraviolet and harmful radiations. Thus, it is necessary to cover your face as well as the entire head to prevent any type of hazards. Use a tightly fitted face shield with correct filters and cover plates to protect face, neck, eyes, and ears from harmful sparks while operating the plasma machine. Even bystanders should wear protective goggles to protect eyes. In addition, use tongs and wear protective gloves when handling the hot cut materials.

- Welding Gloves to Protect Your Hands

While working with the CNC plasma cutter, one should inevitably wear hand gloves to protect their hands from getting injured by hazards. Hand protection is one of the important precaution measures that the operator must take care while handling these types of components.

Also, remember that if you are operating a plasma machine and the gloves which you are wearing do not have the right amount of grip, then you should definitely get it changed.

Moreover, when you are handling and or loading heavy and awkward metallic parts that are often greasy, then you should wear gloves to avoid the contact of slippery agents. Be it manual lathes, milling machines or pedestal drills, there is always need for a secure grip so as to reduce the risk injury or trapped fingers.

- Cover Your Legs While Operating the Machine

Of course, it is impossible to avoid wearing shorts in summers but it is advised to wear jeans and covered clothes while operating the plasma machine.

Exposure to EMF fields during cutting or gouging may increase the probability of getting harmed by the hot sparks while operating the machine.

Therefore, it is of utmost importance to cover your entire body when using the machinery.

- Laced and Tied Boots To Protect Your Feet from Both Sparks and Dropping Pieces of Metal

It is recommended to cover your feet and prevent any metal from dropping inside of your boot. Moreover, lace your boots properly and protect your feet from the hot sparks or hot metal that might fall through cracks or crevices. Ensure that the openings are secured properly keeping your feet safe from any type of hazards.

- Fire Extinguisher

Sparks and hot slags of the plasma cutter CNC can cause fire and explosion. Therefore, it is necessary to remove all combustible materials including wood, cloth, sawdust, liquid and gas fuels, solvents, paints and coatings, paper, etc., away from the work area and cover the materials with a protective non-flammable covering.

- Proper Ventilation

The area where you are using the plasma machine should be properly ventilated.

Do not weld, cut or gouge the materials unless mechanical ventilation is provided. It is advised not to breathe fumes from the materials.

For instance, if you developed eye or nose irritation while operating the machine, you should take care of the ventilation. Stop working and improve ventilation in the work area, so that no physical discomfort persists.

In the bottom line, if you are a beginner, then this guide would turn to be beneficial for you. Read this guide carefully before operating the CNC plasma machine.

Plasma cutter review

Product link