Different Types of Equipment that a Startup Cabinetmaking Business Should Own

Almost every building with kitchen and bathrooms certainly require cabinets, be it small or big in size. The demand for these cabinets increases with every new construction and remodeling.

Cabinet makers spend a lot of time and energy in cutting, carving, and etching beautiful designs on plain wooden material and delivering the finished product as per the expectation of the customers.

A woodworking business spends much time making wooden products. From creating any type of product to designing, cutting, sanding, and finally assembling pieces together is the task of a cabinet maker.

If your business revolves around a woodworking company or a manufacturing firm then having reliable equipment or tool is vital to your business operations.

What are the Basic Cabinetmaking Tools that Every Business Need?

Cabinets are built with the help of plywood, related materials, and tools that help in detailing, assembling, and finishing the end product.

No matter what kind of artistic shapes you give to your cabinets, without the help of a collection of tools, the task of etching and carving designs isn’t possible.

Axes, adzes, chisels, pull saws, and bow drills are among a few tools that make the task of woodworking easier and enhance the precision of woodworking.

Let us take a look at a few basic tools that every woodworking business must own:

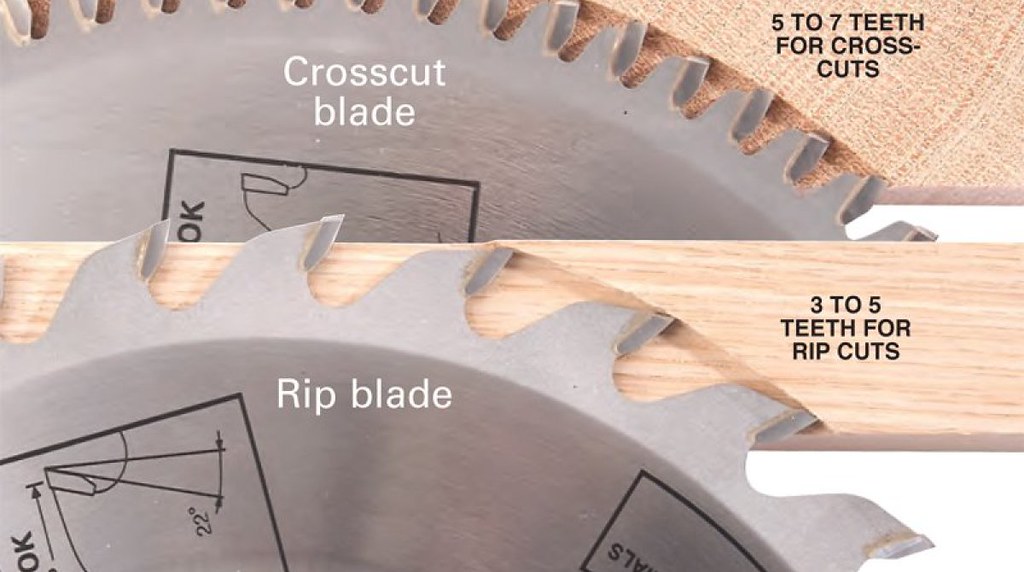

Crosscut Blades

This type of tool has knives shaped teeth to cut the fibers minutely. Moreover, this type of tool is designed for cutting and ripping the wood properly. Plywood is a very delicate material.

Using wrong blades can chip or splinter the wood. Therefore, you must ensure that the teeth of the blade should not have any rake.

Bar Clamps

Bar clamps are the most vital to cabinetmakers. Without this tool, the task of building cabinets won’t be easy. It is designed to withstand the pressure of holding large and heavy workpieces.

Bar clamps for cabinetmaking range from 24 inches to 72 inches in length and secures the workpiece tightly without scratching.

Pin Nailers

Pin nailer is a standard tool and primarily used for cabinet making. They are very slim and strong enough to attach two boards. They leave only a tiny hole when puttied and becomes almost invisible.

You can shoot pin nailers ranging between 5/8 and 1 1/2 inches. The adhesive coating of these nails grips plywood or solid lumber better than any other type of nail.

Spray Equipment

Spraying equipment or tool should not be overlooked. After the installation of cabinets gets finished, proper spraying is needed to maintain the smoothness of the end-product. This tool is either airless or a pressurized-air system accomplished by using the proper lacquer tip on the spray gun.

Detailing

This type of tool is used to etch beautiful designs on the door of the cabinets. For perfection, cabinetmakers use handheld rotary tools for detailed sanding. This versatile tool is significantly used to carve designs, route and cut profiled edges on doors.

Table Saw

It is primarily used for cutting boards for building cabinet frames. Table saw makes significant and accurate cuts in a very short time over cutting the boards by hand.

This tool is completely portable and you can set it up wherever you need it. Moreover, you can set the tool as per your needs and make precise cuts when you use this saw.

Random Orbital Sander

When cutting or carving a wooden product, you cannot forget sanding the end-product. Sanding is one of the important processes but doing it manually can be time taking.

If you want to save both time and money, then you must buy a random orbital sander. This sanding machine helps to sand cabinets very swiftly and gives a smooth finish to the product.

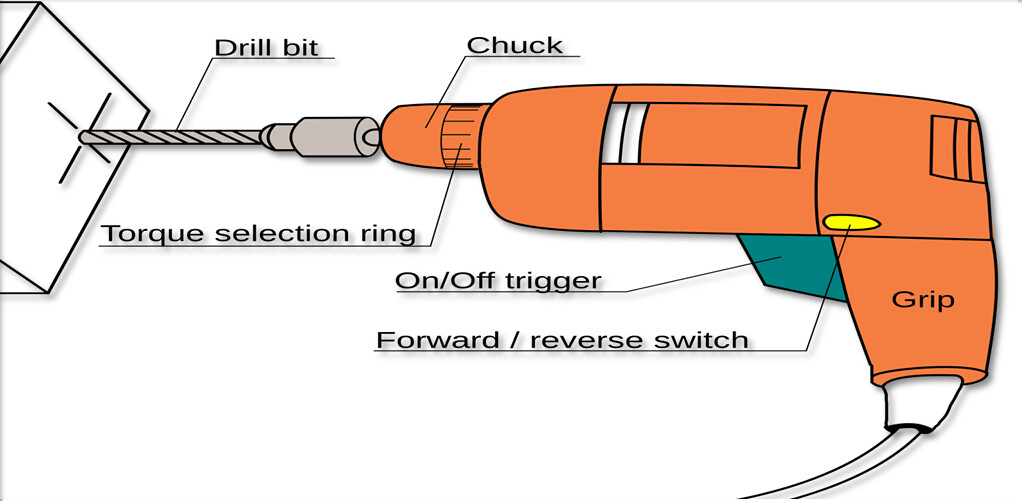

Power Drill

This tool is used for multiple reasons and used specifically for cabinet making. To install hinges to cabinet doors, you would need the help of a power drill. This essential and extremely useful tool can be carried anywhere and you can operate this power drill at length without any sort of problem.

Router

This is one of the most important tools that every cabinet making company should have. The router makes the task of joining the board a lot easier. You can simply make grooves in the door with the help of this high tech routing machine.

Coping Sled

This small hand tool proves its worth when you are making cabinet doors. Coping sled increases your control over the cuts giving a perfect precision. This machine helps in crafting the doors of the cabinets perfectly.

Moreover, you can the sled by adjusting it along with a variety of router tables or saws. Coping sled ensures that the entire process of cutting the wood becomes smoother.

However, with advancement in technology, even the small cabinet making companies are switching to CNC equipment for perfection in work and precision.

Why Cabinetmakers are switching to CNC Equipment

A modular kitchen can take a huge chunk on your budget. You might have been dreaming about your elegant kitchen for years and working hard to bring it to life.

No matter how proficient you are in the art of cabinet making, custom cabinets come with huge labor and time.

Level Up Your CNC Skill

So you will not be left in dust by your competitors.

With the advancements in the field of technology, more and more cabinetmaking owners are switching to a more innovative solution to help them stay competitive. CNC equipment and automated machines make the task of woodworking easier and drive the level of production.

CNC wood routing machine helps in maintaining precision in woodworking projects and enable to perform all the tasks efficiently. To provide an outstanding value to your kitchen cabinets, numerous handheld tools are used for shaping and accomplishing basic cabinet making operations. Each piece is custom made as per the dimensions and cabinet style suggested by the customer.

This blog further illustrates about the cabinet making equipment have power, control, and flexibility needed to create the highest level of craftsmanship and most notably quality over everything else.

How CNC Router is helpful for your business?

CNC routers have brought the industry standards to a new level of delivering high commitments of the companies and fulfilling the expectation of customers.

CNC machine uses the best manufacturing technique, improved production time, quality and consistency and right software system in just one machine. This wood CNC router is designed exclusively for the cabinet making industry.

OMNI CNC offers a complete solution with customized machine configuration, dedicated support and a range of specially designed machine options to ensure that the task of cabinet maker is made easier.

The high-quality CNC machine produces components at a higher average quality. CNC router is one of the most versatile woodworking tools that offer over 2000 bits.

With the advent of this advanced machinery, the work process and production capabilities have been significantly changed.

Now, the output of the work is tremendously increased with less labor and time. Numerous businesses today consider CNC router to expand their capabilities in the areas of cutting, carving, etching, etc.

If you are looking for a fast-paced and highly productive CNC router without compromising on the quality, then you should seek the help of OMNI CNC router. This is one of the most popular and highly configurable options for processing a variety of materials including wood, plastic, metal, etc.

Make Kitchen Cabinet Sections with CNC Machine

Cabinet making is one of the most popular applications of a CNC wood router. This machine has the ability to run any number of programs to cut, carve, drill and slice wood and produce high-quality results.

CNC machines have brought a radical change in the furniture making industry. Once a time taking process; became much easier with CNC application. CNC wood cutting machines are programmed in such a manner that the process of cutting, etching, and carving becomes easier.

This high-tech is widely used by manufacturing companies to produce a variety of furniture. The production time, the raw material used, the quality of the product is far above the traditional technique used for producing a wide range of materials.

CNC wood cutting machine ensures perfect precision every time you carve. It also has incredible flexibility to change the program in just single equipment.

Gone are the days when you meticulously carve wooden cabinets manually. With the help of this technically advanced machine, you can have the working model in your hands in a matter of minutes. There is no need to wait to carve each section of the product.

All you need to do is configure the machine and set the tool path before beginning the process. Moreover, the automatic tool changing function is extensively used by manufacturing firms.

If you are a manufacturing firm, then it is advised to buy a CNC routing machine. With OMNI CNC wood router, you can not only save money but also increase the production of your company.

How to Create Customized Cabinets with CNC Routers

Today’s master craftsmen are beginning to recognize – and embrace – the possibilities and consistency offered by CNC routers. CNC woodworking machine offers a complete solution along with customized machine configuration, dedicated support and a range of specially designed machine options to ensure that the task is made easier.

This advanced machine carves everything from small delicate wooden toys to intricate designs with perfect precision. CNC machinery is perfect for both small and medium-size businesses as well as large workshops.

The impressive technology of this automatic routing machine helps in boosting the productivity of the company and reduces the underlying cost.

Modern CNC machines are highly automated and use CAD and CAM programs. It is with the help of these programs that operating a particular machine has become easier. In CNC machines, the role of operators has been minimized.

The operator is only required to give instructions to the computer and load the tool, the rest of the work is done automatically by the machine. CNC machine works like a robot, you don’t have to worry about the accuracy of the work.

CNC machine beautifully controls the movement of the spindle and the table. It automatically cuts, drills, etches, carves, and gives a variety of shape to materials.

With a greater degree of precision and accuracy, this highly effective machine caters the demand of industries of all scales.

Moreover, OMNI CNC wood machine can be customized with compatible optional CNC parts that help in improving the flexibility, productivity, and accuracy of the machine.

Mass-production and reproducing the products at a much faster rate is the mainstay of the CNC machine. Today, numerous manual machines have been replaced by CNC machine tools. A CNC router has the ability to carve high detailed shapes and requires much less strength over handheld tools.

CNC routing machines offer high production capacity, yet uses less floor space and manpower than traditional manufacturing methods. If you are a startup cabinetmaker or an owner of a wooden manufacturing firm, then you should own all basic tools and equipment for cabinetmaking