Benefits of Fiber Laser Machine in Sheet Metal Cutting

Did you know that Leonardo Da Vinci was one of the first to use roller gutter and press technology to process industrial sheet metal? Yeah, he did! And, this highlights the importance of one of the basic elements of the metalworking industry: industrial sheet metal.

Despite the everyday presence of sheet metal in our lives, there is so much about it that we have to learn about. Be it its uses, processes, or the machine used for processing.

However, the complexity of processing sheet metal has increased. With the advancement in technology, the range of applications on metals like that of stainless steel has become more extensive. Hence the demand to deliver more work in small intervals also increased. Due to that, tools that can match the top-to notch requirement by delivering precision at high-speed are the need of the hour. Still, the question is: To process a sheet metal like the traditional metal sheet, which involves an intense and comprehensive cold working, which tool can meet the high-end demands?

The first name that strikes our mind is a CO2 laser cutter. Howbeit, given its credibility in the market where the manufacturers and users have started to withdraw their attention from this metal processor which tends to garner more power and deliver results of less than the required quality, is it really wise to opt for the tool? And, if not a CO2 laser cutter then is there an alternative?

To the delight of many workers, the technology has found a way to satisfy each and every need for metal processing. And, with the inception of a fiber laser cutter, manufacturers have started to deliver according to the needs of the market.

Nonetheless, there a few questions:

- What is a fiber laser cutter machine?

- How can it improve metal cutting?

- What’s the working principle of this machine?

- Is there a key advantage of using fiber laser machines for sheet metal cutting?

1. What is a Fiber Laser Cutting Machine?

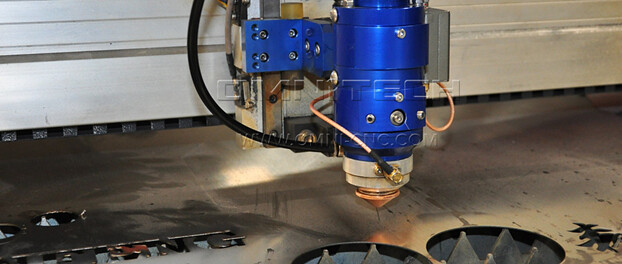

A CNC machine that works efficiently by using a laser as a medium to cut sheet metals by working at higher speed levels to provide high-quality products at optimal accuracy is called a fiber laser cutter. The embedded diodes create the fiber laser light which is directed and intensified with the help of fiber optic cable.

After exiting the fiber cable, this intensified light is then straightened and concentrated onto the material by the lens. With the focusing lens sealed in the cutting head, the machine manufacturers and the technology used ensures that the creation of fiber laser cutting light is 200% more efficient than any other laser cutting machine. Besides, the machine’s framework allows lasers simpler delivery on the cutting object without demanding any expensive optical mirrors.

However, a user needs to be in light of the fact that power is a determining factor of this machine. Yes, it can fluctuate as per the need of the hour but having a powerful machine assures high-quality products.

As mentioned, the chief working of this machine depends on the laser. To get distinctive cuts at high-efficiency and optimal accuracy, metal sheets like stainless steel, electrical steel, copper, iron, titanium alloy, galvanized steel, brass, aluminum zinc plate, etc., require a cutting machine with a fiber laser of power either equivalent to or more than that of 1500 W.

Apart from that, there are works that require lasers of more power, hence, when you research you will find that there are lasers with 1500W, 2000W, 3000W, 4000W, 6000W, 8000W power respectively. Nevertheless, there are cutting machines that are available in 500W, 750W, and 1000W much lower than the mentioned range. These machines are used or light works that don’t require deep penetration of incision like that of producing exotic designs.

Having this machine is both a blessing and an ideal technology boost to the arsenal of a metal sheet worker.

2. How can it Improve Sheet Metal Cutting?

One is bound to find a lot of advantages of a fiber laser cutting machine over a traditional fiber laser cutter in terms of high precision, flexibility in processing, etc. However, the above question is still penetrating the industry and holds some relevance given the skepticism regarding a fiber laser cutting machine.

Over time, the advancements of technology have ensured that the pragmatic time-taking methods should be replaced with something which is efficient and quick. Hence, it comes as no surprise to see CNC punching machines and shearing equipment lose their grip from the market. Besides, a CO2 laser cutting machine is a recent addition in this list of replacement. The reason being it was tedious, required a lot of money, had more overhead expenses, and the quality was also low as compared to the power input.

With the improvement in the power lasers cutting machine and the introduction of fiber laser cutters has ensured an increment by 200% in the rate of efficiency for processing reflecting mediums like stainless and carbon steel.

Besides the constant development of fiber technology has resulted in a fiber laser that features direct and rapid tuning of laser spot size. The feeding fiber has a range that is thrice more than accurate in terms of its cutting quality that too at various speeds without any drawback.

Facilitating the development of tools, this fiber laser has promoted more optimized cutting that works on the varying thicknesses of metal. Along with that fiber laser beams’ output has a tunable range of ~100 µm to ~300 µm.

An advantage of using these highly developed fiber lasers is that the beam tuning of these lasers is very rapid with smaller transition time. Hence, without an index change, these fiber lasers are able to continuously operate at full power that too without the need of turning off or blanking the laser beam while changing its shape.

For each cutting process, this feature determines and triggers the use of optimum beam characteristics without limiting its ability to cut a particular material of a specified thickness.

However, the general metal cutting market is generally dominated by the processing of thick steel cutting. The giber lasers too offer a wide range of unique benefits in terms of edge quality and maximum thickness for cutting thick metal sheets as compared to the traditional laser cutting systems.

Featuring a 1.5x magnification fixed optic cutting head and complemented by adequate assistance of oxygen, this machine has the capability to process all metal sheets.

Be it the thinnest sample of 0.25 inches or a thicker sample, these highly developed fiber lasers can provide better edge quality along with thrice reduced roughness as compared to the traditional fiber laser cutters.

3. What’s the Working Principle of This Machine?

Apart from providing the information regarding how fiber laser cutting machine has drastically improved the sheet cutting in the industry, it’s working principle provides enough evidence as to why it’s time for sheet workers to invest in this potential industry-changing machine.

Though the fiber laser cutting machine’s working principle is pretty identical to that of laser welding yet there are a few key differences that enhance the reputation of this machine. As already introduced, the fiber laser cutting machine depends on the high power density of its laser beam. The laser beam scans over the material surface in a very short span of time and heats it to an approximate temperature of 11000o Celcius.

This leads to the process of melting or gasification of the metal sheet. This high-pressure gas melting or gasified material is blown away from the slit. This flow of inert gas allows the incision to melt the metal. Thus, it creates smooth and straight cuts. Along with that, the jet’s flowing oxygen acts as a catalyst in the process. It increases the speed of the cutting process by allowing the machine to provide narrow, precise, smooth, and fewer scratches but high-quality cuts on the metal surface.

4. Advantages of Using Fiber Laser Machines for Sheet Metal Cutting

With the constant chatter around the development and profitability of fiber laser cutting machine, the underlying question is left unanswered: Is this machine really advantageous for a metalworker to process sheet metals?

Well, the answer to this question is, yes. As mentioned, a fiber laser cutting machine has completely evolved the sheet metal cutting industry. Besides being fast, accurate, and efficient, here are a few advantages this machine has offered to the sheet metal workers:

4.1 Cost-Effective

What’s better than a machine saving your hard-earned money? Perhaps, this is the biggest advantage of a fiber laser cutting machine.

This machine offers opportunities for massive savings by reducing overhead expenses. With a systematic and comprehensive structure along with a laser that guarantees to operate over a lifetime, this machine only demands heavy investment during its purchase.

Aside, it does not require you to buy the expensive optical mirrors which are required in other laser traditional machines. Moreover, the focusing lens of a fiber laser cutter is sealed within the cutting head; hence, it is not exposed to damaging factors.

With proper maintenance of the fiber optics, one can ensure its lifetime working instead of becoming prone to small damages.

4.2 Fixed parts

The traditional laser machine required higher maintenance and operating cost over fiber laser cutting machine. The reason was moving parts of the traditional machine. Fiber laser machines do not require moving mirrors to increase the laser’s power.

However, if the optic mirror is not maintained properly, the chances of damaging can grow significantly thus forcing the laser to be taken off along with a substantial increase in the amount of fiber laser cutter.

4.3 Ability to cut Reflective Material

Another big aspect of fiber laser cutting machine is its ability to cur reflective materials. While traditional laser cutting machines have failed significantly due to laser bouncing back off the reflective surface, this machine has excelled in this aspect. The aesthetic of this machine is designed in such a way that it can adapt to any reflective surface and produce near to perfect results. Its ability to cut sheets of stainless steel, aluminum, brass, copper, etc., is the reason why it is becoming so popular among the metal sheet cutting industry.

4.4 Electrically Efficient

A fiber laser cutting machine also outclasses a traditional laser cutting machine in this field. A 2kW fiber laser cutting machine uses one-third power as compared to a traditional 4kW laser cutter. This implies that the configuration of the fiber laser machine not only saves power every time it operates but also has a lower level of energy requirement which is a reason for its greater life expectancy.

The fiber laser cutting machine has been a good invention for the sheet cutting industry. Due to its ability to provide high-speed quality precision work at a fairly economical price, this machine is a blessing for workers who wanted a machine to work vast volumes of thin/thick material.