How does Fiber Laser Cutting Machine Improves Cutting Efficiency?

The debate is never-ending. The constant chatter regarding Fiber laser cutting machine outclassing CO2 laser cutting machine is on the manufacturer’s mind. Comparisons, presentations, live tests, and many such key aspects dominate the fiber laser cutting industry, however, the future of industry is safe and poised to capture the market by 2026. The only thing to be seen is the constant change in technology.

1. Market Dynamics of Fiber Laser Cutting Machine

There are many factors that have resulted in the success and growing demand for fiber laser cutting machine. However, the main factor that drives the global success of fiber laser cutting machine is the need for efficiency and precision in the manufacturing unit across all economies.

Though a CO2 laser cutting machine was touted to deliver this aspect, the constant demand and innovation have resulted in the inception of fiber laser cutters. Besides, factors like growing activities in the industrial and manufacturing sector coupled with changes in technology for assembling processes is also a reason for the growing demand for fiber laser cutting machines.

As mentioned, the increasing demand for fiber laser cutting machine is due to rising concerns regarding the inefficiency of the traditional laser cutters while processing sheet metal operations. Also, the continuous and widespread development of the industrial sector in the East and South Asia shows that the market is preparing itself for a technological upgrade by anticipating the use of fiber laser cutting machine as the future of the market.

Apart from that, the performance and delivery of fiber laser cutting machines are second to none. Its features, that include:

- High operational efficiency

- Robust structure

- Precise operational accuracy

They are also one of the reasons why the manufacturers are increasing their production of this machine, thereby, anticipating a propel in the sales of this technology. Due to this, the machine has now gained a lot of markets and is recognized heavily in the automobile, metal processing, and aviation sectors.

1.1 How it is Expanding Itself in Different Regions of the World

A manufacturer is bound to come across these seven regions while segmenting the market regionally:

- Europe

- East Asia (China, Japan, and South Korea)

- South Asia (India, Thailand, Philippines, Indonesia, Rest of South Asia, and Malaysia)

- North America

- Oceania (Australia, New Zealand)

- MEA

- Latin America.

Countries like China, South Korea, and Japan are estimated to have a significant portion of the fiber laser cutting machine market. Hence, it comes as no surprise to see that South Asia is leading the race in manufacturing and is witnessing considerable growth in the global fiber laser cutting machines market. Further, due to the construction activities in the Middle East & Africa, this region is projected to put up a solid growth in the global market of fiber laser cutting machines in the near future.

2. How Fiber Laser Cutting Machine is better than CO2 Laser Cutting Machine

CO2 laser cutting machine needs a high-density infrared laser beam to process. This beam comes out from a nozzle, passes a series of mirrors, and, finally, processes the metal sheet.

When you are looking for a machine that can produce fine features at acute angles while cutting, then, there is no doubt over the ability of a CO2 laser cutting machine. With two axes and a movable table, this machine can achieve a cut that is hard to get in normal processing. And, its biggest strength is to process a material, which is less than ⅜ inches, at a very rapid speed.

Nevertheless, the invention of the high-power, efficient, and the high-speed machine in the form of a fiber laser cutting machine has changed the way people look at a CO2 laser cutting machine. The standout part of a fiber laser cutting machine is its accuracy on metal sheets along with providing quality with control.

A CO2 laser cutting machine is proficient when it works on non-metal materials. It can provide a better quality finish on a thicker material over a thinner surface. And, this is the reason why people are favoring a fiber laser cutter to process metal sheets like that of steel.

The dramatic growth of fiber laser cutter is proof that the market still wants to shrug off the old tech for new and trending technology. And by no means, the industry is compromising the quality of the product. This is evident in the fact that fiber laser cutter is providing superior quality over a CO2 laser cutting machine for cutting thinner material. In fact, the current market dynamics suggest that the sales and popularity of fiber laser cutting machines are outclassing CO2 laser cutting machines.

The main advantage of using a fiber laser cutting machine over a CO 2 laser cutting machine is that it can cut a thin sheet of metal quite efficiently. Due to its monolithic compact solid-state and configuration, this machine is free of overhead expenses and has a lower maintenance cost as compared to a CO2 laser cutting machine. Besides, it also provides leverage over a CO2 laser cutting machine by achieving the task in less time and lower operational cost.

Besides, the higher absorption of the fiber wavelength created by the focused beam at a high power density helps to achieve a cutting speed which is five times faster than a CO2 laser cutting machine.

3. How to Improve the Utilization of Sheet metal by a Fiber Laser Cutting Machine

China is leading the race when things center on the processing of a fiber laser cutting machine. Also, the continuous in favor of fiber laser cutting machine works to provide high-efficiency and precision as one of its many advantages while processing a metal sheet.

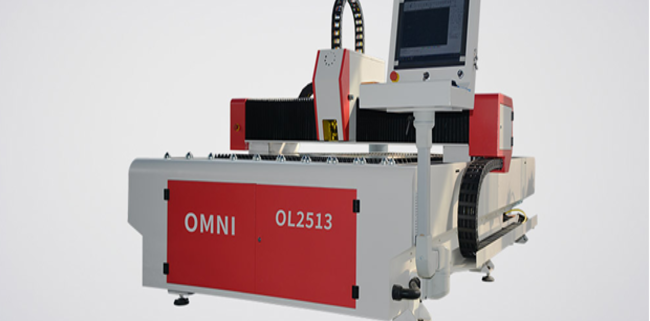

However, there are still sectors that a sheet worker wants to know before putting his bet on this machine. Hence, it is very important for the worker to know that the fiber laser cutting system comprises mainly three parts of the machine’s tool host along with the laser and control system.

The best part of the fiber laser cutting machine is that the design of the machine is worker-friendly. The method of programming is simple and easy. Further, the precision control capability is very suitable and works for different processing requirements. Hence, making it an underlying reason for improved productivity.

With the change in technology comes a little complexity, and the same can be said for fiber laser cutting machine. The problem that arises while working with this machine is that the worker is unable to properly utilize the metal sheet. Hence, to maximize the usage of the sheet and reduce the problem, here is the solution.

To make proper use of sheet metal, one must start from the edge. Doing this will help you calculate the remainder of the sheet, thus, giving you an idea regarding how you can properly achieve the maximum use of sheet metal. Besides, it can help you in saving the material for future use. This is very important and will help in improving the efficiency of utilizing sheet for work pieces.

Not only all this, but the accurate cutting of sheet metal also saves the additional manpower required to perform cutting functions. This directly saves a lot of time, unnecessary material waste, and cost required processing the work piece.

Be it simple or complex, a fiber laser cutting machine with its high flexibility, fast speed, high efficiency, and short production cycle can provide rapid cutting and prototyping, just by using a laser, within the same processing period, at low cost, more incisive cutting effect, and operating the machine is very convenient.

Besides, the unique advantages of the fiber laser cutting machine allow better laser processing, thus, laying the road for development. This is because of the fiber laser cutting machine that the metal processing industry across China and in different regions os is becoming more efficient and good.

4. How Fiber Laser Technology has Improved Metal Cutting

With numerous advantages of a fiber laser cutting machine, the question that still creates a lot of noise among the industry is how has fiber laser cutting machine improved the status of metal cutting?

Technology has seen its share of invention and innovation; however, these things have still not rattled the good old belief of sheet cutters using the traditional cutting machine. Though the industry is moving toward better and efficient equipment, it’s time for the old users to understand and bend their heads in the direction of a potential industrial revolution of laser cutters.

There was a time when CNC punching machines and searing equipment took the market by storm but soon this vigorous zeal lost its craze in the market thereby losing its grip to another better invention in form of a CO2 laser the cutter machine. The CO2 laser cutting machine was better than the CNC punching or shearing machine.

It was providing pleasure of speed cutting but somehow lacked efficiency. Besides, the constant overhead expenses and a show of tedious performance raised a lot of questions from the metalworkers. Further, the recurring need to feed immense power as an input for their proper functioning soon started to become a burden on the pocket of the user.

However, technology is the second name of improvement. The questions were heard and swoon manufacturers came up with a better power laser cutter machine in the form of the fiber laser cutter. These fiber laser cutters ensured that the metalworkers get an efficiency which they deserve, that is, 200% more than that of a traditional cutting machine.

The constant enhancement of fiber technology also ensures that when a metal is being processed the rapid tuning of laser spot size helps in guiding the laser directly on the cutting surface. Also, the range of the feeding fiber is thrice more than the traditional cutter. This range helps the worker to achieve accurate cutting at different speeds without any technical difficulties.

5. How Fiber Laser has made Production More Efficient

A fiber laser cutting machine processes with a focused high energy density, the high-powered laser beam is used to cut/melt the material, thus vaporizing it, triggering it to reach an ignition point where the high-pressure airflow beam blows off the molten material, thus, and cutting the sheet.

With characteristics like:

- Intelligence

- High-efficiency

- High-quality

- High-degree of flexibility

- A short production cycle

This process is getting a prominent status in various industries. These industries include:

- Rail transit

- Automobiles

- Engineering machinery

- Electrical manufacturing

- Household appliances

Thus, showcasing that this the processing industry has very broad applications. These fiber laser cutting machines have been developed after doing some intense research to improve product performance and meet various challenges of the metal processing industry.

To deal with the varying levels of thickness, width, and processing complexity of a metal sheet the inception of fiber lasers machine is a blessing for manufactures as it provides high-power, co-edge, bright surface cutting, besides using high-pressure air as its source to make cutting more powerful.