Parameters you must know when using a fiber laser cutting machine

Buying a fiber laser cutting machine can be a tedious task but without working knowledge you cannot make a purchase. The most essential factor when purchasing a machine is to understand the different parameters that are used in the functioning of the machine.

If your parameters are not set according to the requirement of the material, it will directly affect the quality of tthe cutting.

Let’s take a look at the important parameters of setting up a fiber laser cutting machine.

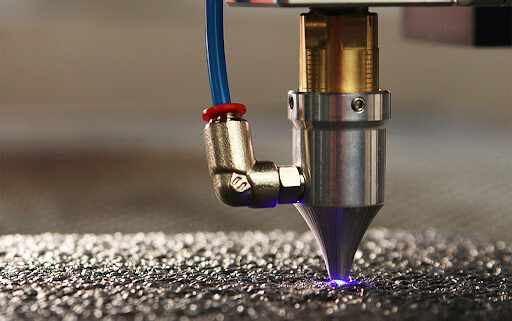

Auxiliary Pressure/Air Pressure

In the fiber laser cutting machine process, the role of auxiliary gas is for it to blow off slag, cool heat-affected zone, and prevent material from burning. We usually include oxygen, compressed air, nitrogen, and inert gases.

For some metallic materials and non-metallic ones (the cutting process), inert gas or compressed air is most suitable since they can prevent metal from burning. For most metals though, active gas (such as oxygen) is used in order to optimize efficiency.

Laser cutting quality is highly reliant on the purity of the gas. High-quality laser cutting requires the gas to be 95.5% pure or higher. It’s important to have a professional company handle the installation and maintenance of your gas infrastructure.

Laser Power

Fiber laser cutting machine has very specific method and set of parameters, but they all take into account the total power of the laser. For instance, one factor is the thickness – how thick is the material you want to cut.

When considering different types of lasers, thicker materials require more power. For example, 3kW can cut stainless steel up to 12mm; while 1kW can only go up to 5mm for aluminum.

However, in case you’re not able to cut through metal, you should consider getting more power. Along with this, you should also check out the cutting speeds, focal points, and gas pressure used in the machine. These parameters have to work together to give out the best results.

Type & Size of the Laser Head Nozzle

The type of nozzle and nozzle size selected in a laser head has a major impact on how your cutting will go. There are two typical types of nozzles. Single-layer nozzles use nitrogen auxiliary gas, and it is typically used to cut stainless steel, aluminum alloy, brass, etc.

Double-layer nozzles often use oxygen as their auxiliary gas and are typically used for cutting carbon steel. Make sure to check with the laser cutting machine manufacturer to see which type you need to make your work easy.

Some companies provide different types of nozzles for specific jobs like giving a ripped effect on fabrics or making holes in a thick metal sheet. It’s best for you to consult with your machine manufacturer before you buy or upgrade the nozzle on your own.

This will significantly reduce the chance of bad cuts or uncut material, many of which won’t make sense. For example, if your laser machine is cutting well when it’s in the center, it might not be cutting as well on the other side.

Focal lens & its specifics (like point, position, & length)

For best results, make sure that your laser lens is clean and focused. We recommend cleaning your lens after every use. The focal point of the laser needs to be centered in order to get quality cuts. The method of cutting varies depending on the material you’re trying to cut.

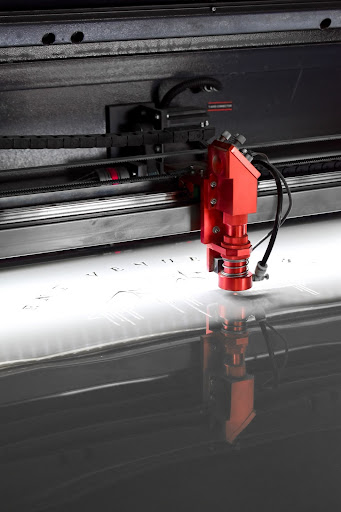

Cutting Speed

Fiber laser cutting machines use one or more high-power, high-speed lasers to cut materials such as paper and fabrics. When the speed of the laser is set too slow, the material’s shape will look drastically different than other times when it’s set too fast.

Cutting speed has an adverse effect on the cutting quality because when it’s too slow, a longer action time means that there is often a large difference between slits in the upper and lower parts of the material. As more power is used, action time gets shorter so that there is less diffusion, less heat transfer, and a smaller slit width.

Modes in Which Laser Operates

Laser machines can shoot a laser in two ways:

- Continuous Wave mode

- PWM.

In continuous wave mode, the laser continuously shoots out laser. So, you can think of a stream of water. In pulse mode, instead of shooting out the laser persistently, you shoot out the laser in great quantities at once. It feels like firing a shotgun. Continuous Wave mode is good for cutting straight lines and sharp corners and Pulse Wave mode is good for cutting small holes.

Type of Material You are Cutting

When cutting material, there are factors such as material properties that are also important when deciding how to set cutting parameters. It’s good to research what types of materials you’re going to cut and how they react with laser and heat.

Usually, metals with low silicon levels can be cut easily with lasers and high silicon levels are harder to cut. The presence of carbon (such as in carbon steel) makes it more difficult to cut through the material with a laser.

Level of Complexity of Design

When designing with a laser cutter, the shape of your design is something to consider. A simple design does not have any complex curves or small holes in it. Complicated designs, on the other hand, require different parameters and different equipment (like maybe a different nozzle type).

Figuring out all these necessary specifications for complicated designs can be tricky but it is an important part of the process. If you’re dealing with a design with a lot of curves, the cutting speed will be low to get the best cuts.

Conclusion

While a fiber laser cutting machine has helped in the manufacturing process and reduced labor cost, learning how to use it is equally important. One wrong setting in the parameters can cause major problems for the machine.

It is important to read the user guide for the machines before working with them which is why you should make your purchase from OMNI CNC. We offer guides and detailed videos about the machines to help you learn them quickly.