Are you interested in starting your own fiber laser cutting machine business?

This could be a great opportunity for entrepreneurs who are looking to capitalize on the growing demand for laser cutting services.

With the right knowledge and resources, you can easily launch your own successful laser cutting business.

This comprehensive step-by-step guide will provide you with all the information you need to do so.

You’ll learn about the basics of fiber laser cutting machines, how to purchase and install one, as well as how to market your business and find customers.

With this guide, you’ll be able to launch your own fiber laser cutting machine business and start making money. So let’s get started!

Which Type Fiber Laser Cutting Machine Do you Need?

If you’re in the metal cutting industry, you probably heard of fiber laser cutting machines. There are several types of fiber laser cutting machine.

- According to the metal shapes:

Metal sheet fiber laser cutting machine

Metal Sheet & Tube Fiber Laser Cutting Machine

Tube fiber laser cutting machine

- According to laser power:

Fiber laser cutting machines could configure 1KW, 1.5KW, 2KW, 3KW, 4KW, 6KW, 12KW…

- According to the materials you gonna cut, you can choose

Metal Fiber Laser Cutting Machine on Sale

or

Purchasing and Installing Your Fiber Laser Cutting Machine

The first step to launching your own fiber laser cutting machine business is to purchase the machine itself.

When shopping for a fiber laser cutting machine, it’s important to consider all your options.

You’ll want to compare features, cost, and quality to find the best machine for your needs.

What to Consider When Selecting It?

When selecting a fiber laser cutting machine, there are a few key factors to consider:

- The type of material you will be cutting: Different materials require different cutting speeds and power levels. Copper, brass, bronze, silver, gold, and aluminum

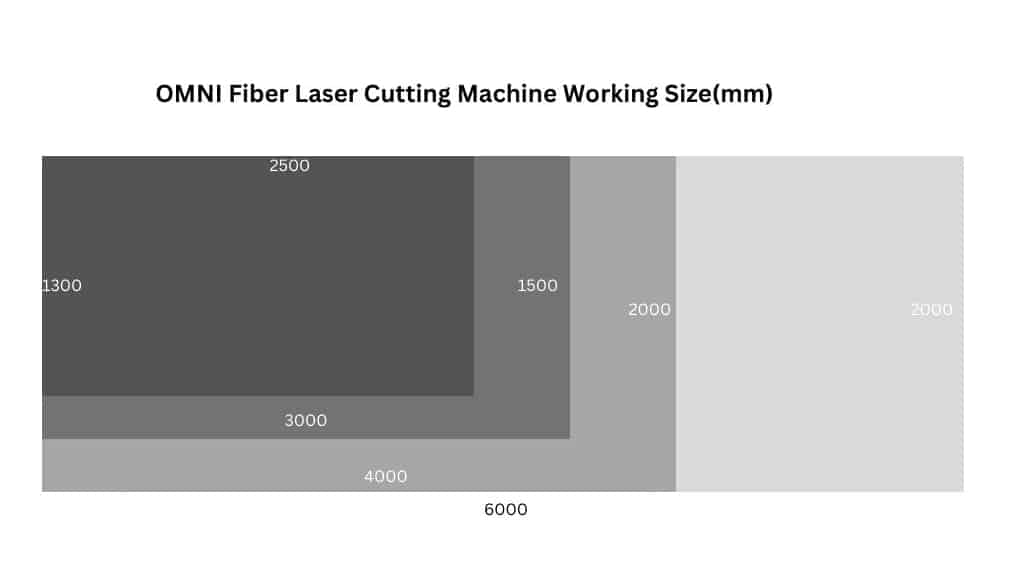

- The size of the material: Different machines have different capabilities when it comes to cutting larger pieces of material.

It is important to select a machine that is capable of cutting the size of material you will be using.

And we suggest you choose a bigger working size than your current Max. working size incase you gonna cut larger size in the future.

Usually, we offer below standard working size: 1300mm*2500mm, 1500mm*3000mm, 2000mm*4000mm, 2000mm * 6000mm and custom working size

- The speed of the machine:The cutting speed of a laser cutting process is determined by two major factors: laser power and material thickness.A high-powered laser can cut through comparatively thicker metals, but it can also make quicker cuts in thin metal sheets.The greater a laser’s power, the faster it can cut through a thin workpiece.Furthermore, cutting thick metal demands more laser energy. As a result, the laser’s cutting speed reduces as the thickness of the metal grows.Slowing down the cutting process extends the laser’s dwell time, increasing the amount of energy absorbed by the metal and generating more heat to evaporate it.

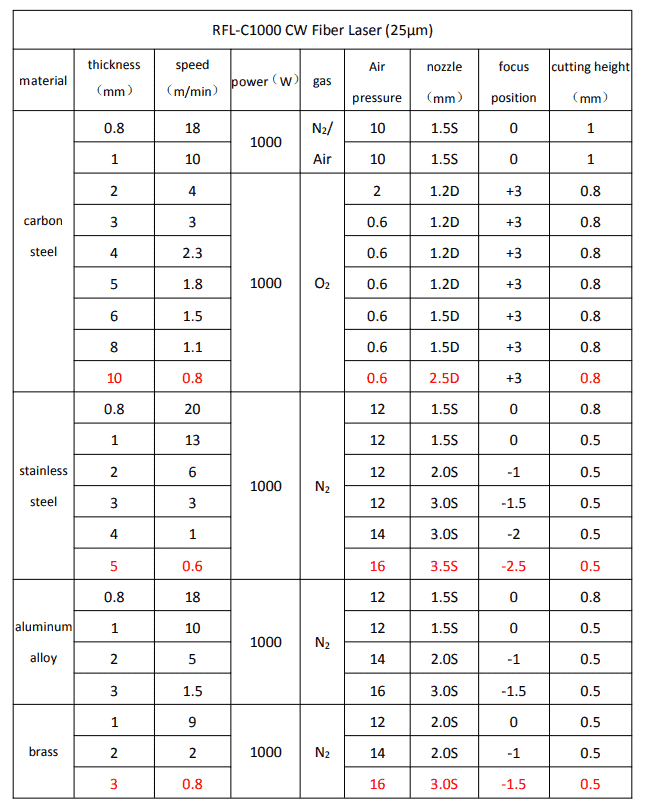

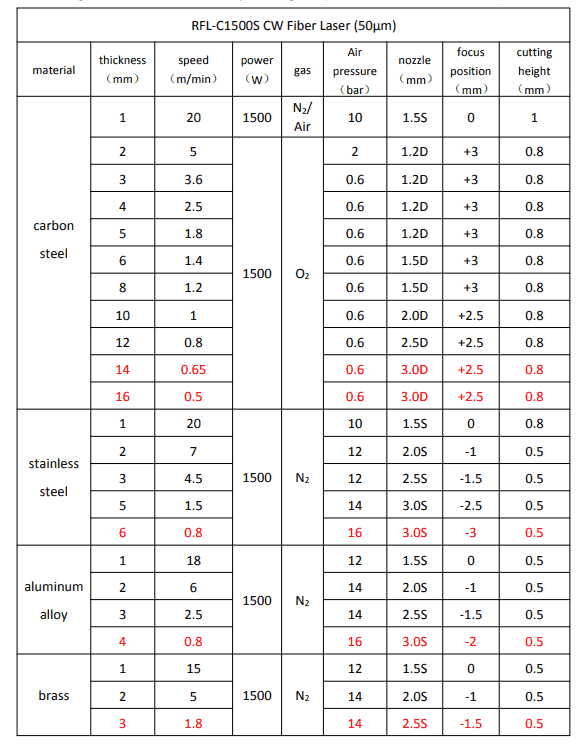

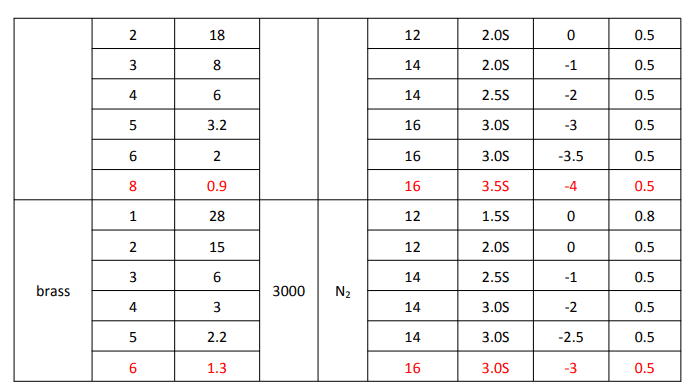

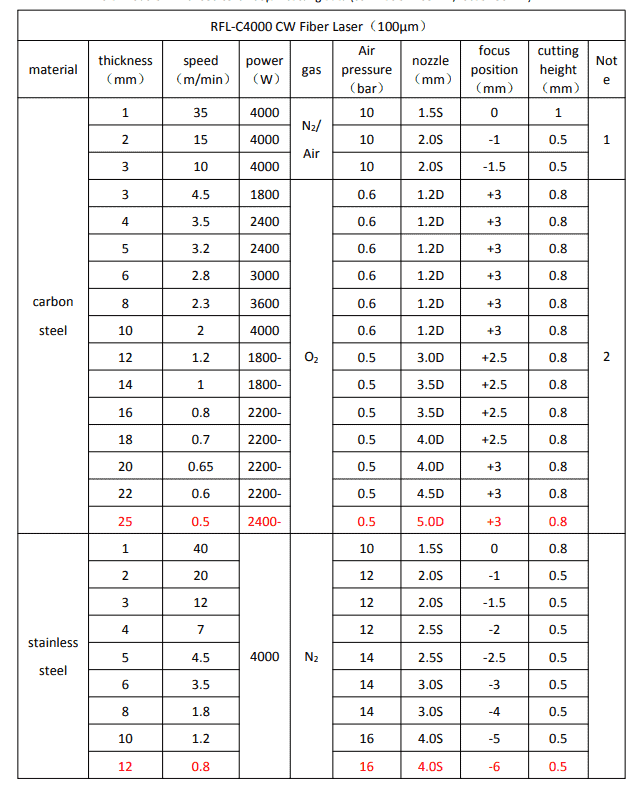

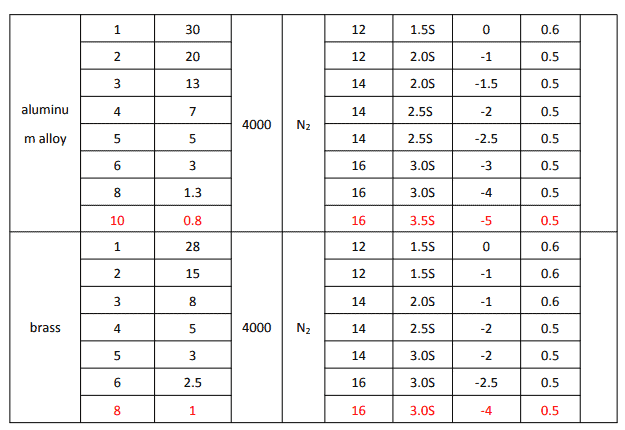

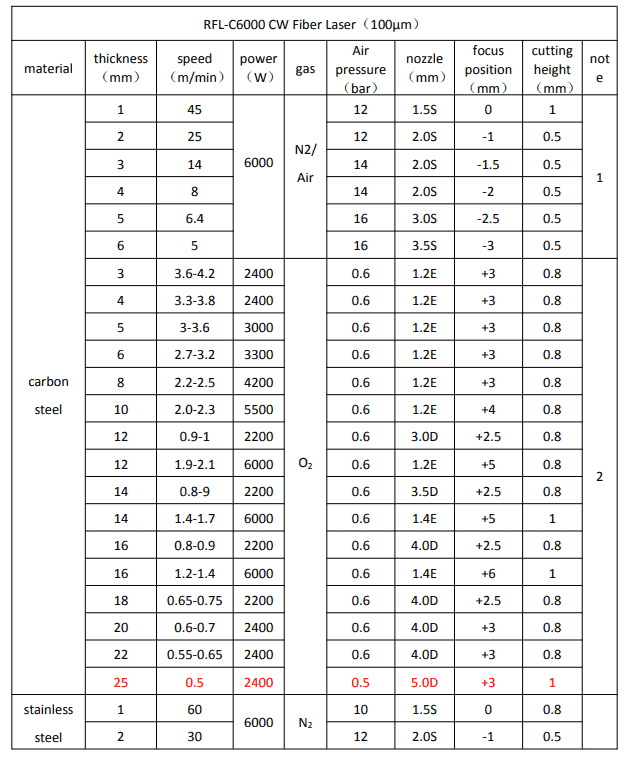

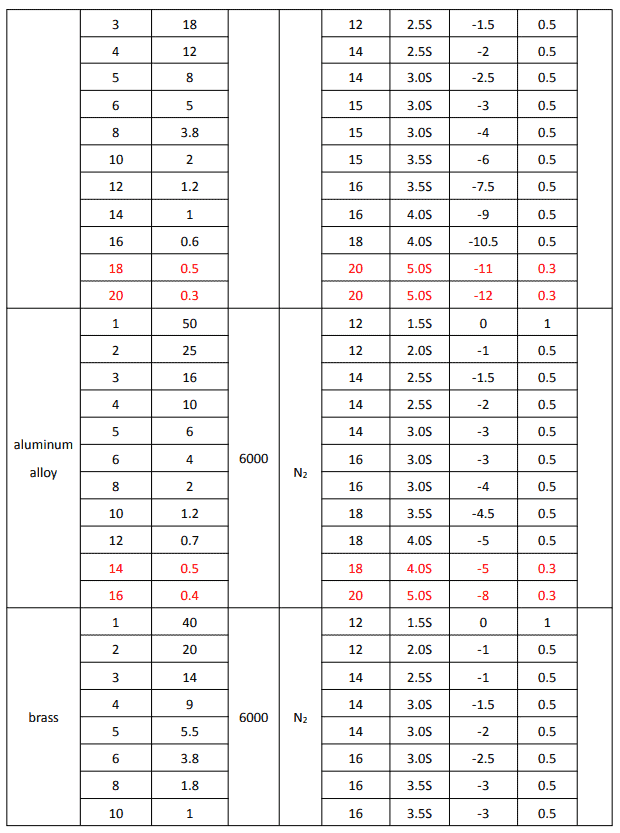

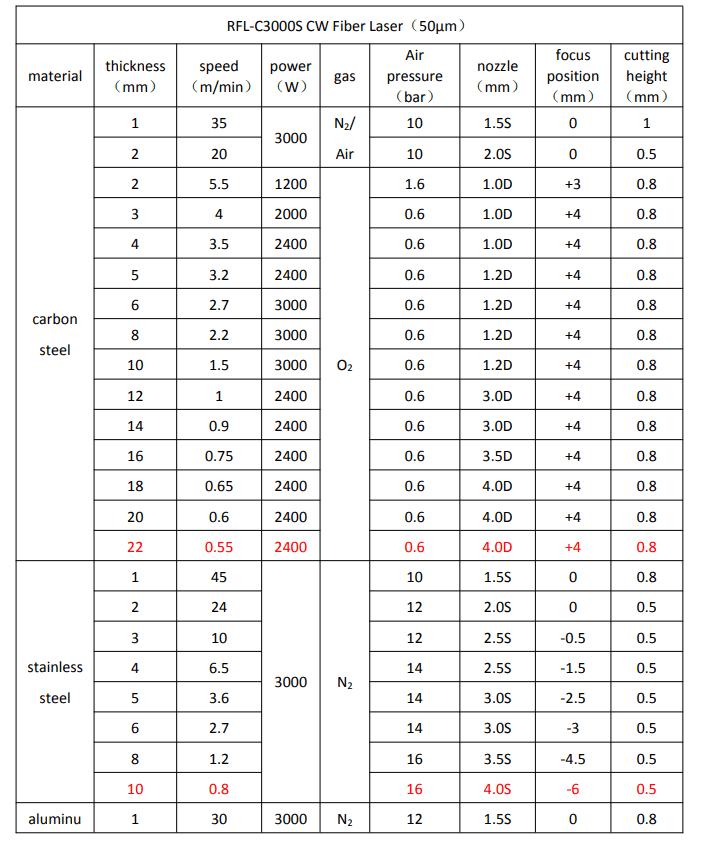

See below fiber laser cutting machine cutting speed, laser power source chart for different materials.

Fiber Laser Cutting Thickness and Speed Parameters from Raycus

Note: The red-labeled parameters in the table are proofing parameters, whicharegreatly affected by various factors in actual processing, and are only suitable for small batch production. Higher power lasers are recommended for mass production processing.

1000W Laser Power

1500W Laser Power Source

3000W Laser Power

4000W Laser Power

6000W Laser Power

LASER CUTTING THICKESS AND SPEED PARAMETERS (IPG LASER POWER)

Mild Steel

| Thickness(mm) | IPG 1000W | IPG 1500W | IPG 2000W | IPG 3000W | IPG 4000W |

|---|---|---|---|---|---|

| Speed | Speed | Speed | Speed | Speed | |

| (m/min) | (m/min) | (m/min) | (m/min) | (m/min) | |

| 1 | 15.0-22.0 | 18.0-25.0 | 25.0-33.0 | 28.0-38.0 | 30.0-44.0 |

| 2 | 5.0-6.6 | 7.0-10 | 7.0-10 | 5.5-7.0 | 5.5-7.7 |

| 3 | 2.5-3.85 | 4.0-5.5 | 4.0-5.5 | 3.6-5 | 3.7-5.5 |

| 4 | 2.0-3.3 | 2.5-3.5 | 2.8-4.0 | 3.0-4.5 | 3.5-4.62 |

| 5 | 1.4-2.0 | 2.0-2.8 | 2.0-2.75 | 2.5-3.3 | 2.5-4.0 |

| 6 | 1.2-1.65 | 2.0-2.42 | 2.0-2.42 | 2.3-2.86 | 2.5-3.52 |

| 8 | 0.9-1.32 | 1.2-1.65 | 1.2-1.65 | 1.8-2.2 | 2.0-2.8 |

| 10 | 0.6-0.9 | 1.0-1.32 | 1.0-1.32 | 1.21-1.65 | 1.2-2.2 |

| 12 | 0.4-0.7 | 0.7-1.0 | 0.7-1.0 | 1.0-1.32 | 1.0-1.76 |

| 16 | 0.6-0.8 | 0.6-0.8 | 0.6-0.9 | 0.7-1.0 | |

| 20 | 0.5-0.8 | 0.6-0.9 | |||

| 22 | 0.66-0.9 |

| Thickness(mm) | IPG 6000W | IPG 8000W | IPG 10000W | IPG 12000W | IPG 15000W |

|---|---|---|---|---|---|

| Speed | Speed | Speed | Speed | Speed | |

| (m/min) | (m/min) | (m/min) | (m/min) | (m/min) | |

| 1 | 35.0-48.0 | 60.0-70.0 | 65.0-75.0 | 66.0-80.0 | 70.0-90.0 |

| 2 | 6.0-8.25 | 6.8-7.2 | 7.0-7.5 | 7.2-7.8 | 7.5-8.2 |

| 3 | 4.0-5.5 | 4.7-5.3 | 5.0-5.5 | 5.2-5.8 | 5.5-6.0 |

| 4 | 3.5-5.0 | 3.8-4.3 | 4.0-4.5 | 4.2-4.6 | 4.5-5.2 |

| 5 | 3.0-4.2 | 3.3-3.8 | 3.6-4.0 | 3.8-4.2 | 4.0-4.5 |

| 6 | 2.6-3.52 | 3.0-3.4 | 3.3-3.7 | 3.5-4.0 | 3.8-4.3 |

| 8 | 2.0-2.8 | 2.3-2.6 | 2.5-2.8 | 2.6-3.0 | 2.8-3.5 |

| 10 | 1.8-2.3 | 2.0-2.5 | 2.3-2.6 | 2.5-3.0 | 2.6-3.0 |

| 12 | 1.6-2.1 | 1.7-2.2 | 1.9-2.2 | 2.0-2.3 | 2.5-3.0 |

| 16 | 0.7-1.0 | 1.2-1.4 | 1.3-1.5 | 1.4-1.6 | 1.7-2.0 |

| 20 | 0.65-0.95 | 1.0-1.1 | 1.1-1.2 | 1.1-1.4 | 1.3-1.5 |

| 22 | 0.6-0.77 | 0.9-1.0 | 0.9-1.0 | 0.9-1.2 | 1.1-1.3 |

| 25 | 0.4-0.65 | 0.6-0.7 | 0.6-0.7 | 0.6-0.8 | 0.9-1.2 |

| 30 | 0.6-0.8 |

STAINLESS STEEL

| Thickness(mm) | IPG 1000W | IPG 1500W | IPG 2000W | IPG 3000W | IPG 4000W |

|---|---|---|---|---|---|

| Speed | Speed | Speed | Speed | Speed | |

| (m/min) | (m/min) | (m/min) | (m/min) | (m/min) | |

| 1 | 16.5-22.0 | 20.0-26.0 | 27.5-33.0 | 31.0-38.5 | 33.0-45.0 |

| 2 | 4.5-6.1 | 18.0-22.0 | 18.0-22.0 | 10.0-16.5 | 10.0-20.0 |

| 3 | 2.0-3.1 | 4.5-5.5 | 4.5-5.5 | 7.0-10 | 7.5-12.0 |

| 4 | 1.0-1.65 | 2.0-2.5 | 2.2-2.8 | 5.0-7.2 | 5.5-9.0 |

| 5 | 0.4-0.7 | 1.5-2.0 | 1.5-2.0 | 1.8-2.45 | 4.0-5.5 |

| 6 | 0.2-0.45 | 0.7-3.1 | 0.7-1.32 | 1.0-1.65 | 2.6-4.5 |

| 8 | 0.2-0.45 | 0.35-0.6 | 1.2-2.0 | 1.6-2.8 | |

| 10 | 0.7-1.0 | 0.7-1.65 | |||

| 12 | 0.5-0.9 |

| Thickness(mm) | IPG 6000W | IPG 8000W | IPG 10000W | IPG 12000W | IPG 15000W |

|---|---|---|---|---|---|

| Speed | Speed | Speed | Speed | Speed | |

| (m/min) | (m/min) | (m/min) | (m/min) | (m/min) | |

| 1 | 50.0-65.0 | 63.0-66.0 | 68.0-72.0 | 70.0-80.0 | 75.0-90.0 |

| 2 | 30.0-40.0 | 40.0-44.0 | 42.0-46.0 | 44.0-48.0 | 46.0-50.0 |

| 3 | 18.0-25.0 | 25.0-28.0 | 27.0-30.0 | 28.0-35.0 | 30.0-38.0 |

| 4 | 10.0-15.5 | 15.0-18.0 | 18.0-21.0 | 20.0-26.0 | 22.0-28.0 |

| 5 | 8.0-13.5 | 12.0-14.0 | 14.0-16.0 | 15.0-20.0 | 16.0-22.0 |

| 6 | 6.0-9.0 | 9.0-9.5 | 10.0-10.5 | 11.0-13.0 | 12.0-15.0 |

| 8 | 4.0-5.5 | 5.0-5.3 | 6.5-6.8 | 7.0-7.5 | 7.5-8.5 |

| 10 | 1.8-2.8 | 3.8-4.0 | 4.7-5.0 | 5.0-5.5 | 5.5-6.5 |

| 12 | 1.2-1.65 | 2.5-2.7 | 2.8-3.0 | 3.0-3.5 | 3.3-4.0 |

| 16 | 0.8-1.2 | 1.8-1.9 | 2.2-2.4 | 2.3-2.8 | 2.5-3.0 |

| 20 | 0.6-0.9 | 1.3-1.5 | 2.0-2.2 | 2.1-2.5 | 2.3-2.8 |

| 22 | 0.7-0.8 | 1.2-1.3 | 1.4-1.7 | 1.5-1.9 | |

| 25 | 0.5-0.6 | 0.7-0.8 | 0.7-1.0 | 0.9-1.2 | |

| 30 | 0.5 | 0.5-0.7 | 0.6-0.8 | ||

| 35 | 0.4-0.5 | 0.5 | |||

| 40 | 0.3 | 0.3 | |||

| 45 | 0.3 |

Aluminum

| Thickness(mm) | IPG 1000W | IPG 1500W | IPG 2000W | IPG 3000W | IPG 4000W |

|---|---|---|---|---|---|

| Speed | Speed | Speed | Speed | Speed | |

| (m/min) | (m/min) | (m/min) | (m/min) | (m/min) | |

| 1 | 10.0-13.2 | 15.0-27.5 | 25.0-31.0 | 25.0-40.0 | 26.0-44.0 |

| 2 | 2.0-4.5 | 7.0-8.6 | 10.0-13.2 | 10.0-20.0 | 10.0-22.0 |

| 3 | 0.6-1.32 | 5.0-6.5 | 5.0-6.6 | 5.0-6.6 | 8.0-12.0 |

| 4 | 1.0-1.65 | 1.5-2.2 | 3.0-4.0 | 4.5-8.25 | |

| 5 | 0.6-0.9 | 1.0-1.32 | 2.0-2.65 | 3.5-5.5 | |

| 6 | 0.4-0.7 | 0.6-0.9 | 1.0-1.65 | 2.2-4.5 | |

| 8 | 0.4-0.7 | 0.5-0.8 | 1.2-2.0 | ||

| 10 | 0.3-0.45 | 0.8-1.65 | |||

| 12 | 0.6-0.9 | ||||

| 14 | 0.3-0.66 |

| Thickness(mm) | IPG 6000W | IPG 8000W | IPG 10000W | IPG 12000W | IPG 15000W |

|---|---|---|---|---|---|

| Speed | Speed | Speed | Speed | Speed | |

| (m/min) | (m/min) | (m/min) | (m/min) | (m/min) | |

| 1 | 50.0-60.0 | 53.0-65.0 | 55.0-70.0 | 60.0-80.0 | 65.0-85.0 |

| 2 | 25.0-38.5 | 30.0-40.0 | 33.0-42.0 | 35.0-45.0 | 38.0-50.0 |

| 3 | 13.0-20.0 | 15.0-23.0 | 18.0-26.0 | 22.0-35.0 | 25.0-38.0 |

| 4 | 10.0-13.2 | 12.0-16.0 | 15.0-18.0 | 17.0-24.0 | 20.0-26.0 |

| 5 | 5.0-8.8 | 7.0-10 | 11.0-15.0 | 14.0-20.0 | 17.0-22.0 |

| 6 | 4.0-6.6 | 5.0-7.0 | 9.0-11.0 | 12.0-17.0 | 14.0-18.0 |

| 8 | 2.0-3.3 | 2.5-4.0 | 4.0-6.0 | 9.0-11.0 | 11.0-15.0 |

| 10 | 1.0-2.3 | 1.5-2.8 | 2.5-3.5 | 3.5-4.5 | 4.0-5.0 |

| 12 | 0.8-1.55 | 1.0-1.6 | 1.5-2.0 | 2.0-3.0 | 2.3-3.2 |

| 14 | 0.6-0.9 | 0.8-1.2 | 1.0-1.5 | 1.5-1.8 | 1.7-2.1 |

| 16 | 0.4-1.0 | 0.6-0.8 | 0.7-1.0 | 1.1-1.4 | 1.3-1.6 |

| 20 | 0.5-0.7 | 0.5-0.8 | 1.0-1.2 | 1.1-1.4 | |

| 25 | 0.3 | 0.5-0.7 | 0.7-1.0 | 1.0-1.2 | |

| 30 | 0.3-0.5 | 0.5-0.7 | 0.6-0.8 | ||

| 35 | 0.3 | 0.4-0.5 | 0.5-0.6 | ||

| 40 | 0.3 | 0.4-0.5 | |||

| 50 | 0.3 | 0.3 | |||

| 55 | 0.3 |

BRASS

| Thickness(mm) | IPG 1000W | IPG 1500W | IPG 2000W | IPG 3000W | IPG 4000W |

|---|---|---|---|---|---|

| Speed | Speed | Speed | Speed | Speed | |

| (m/min) | (m/min) | (m/min) | (m/min) | (m/min) | |

| 1 | 14.0-20.0 | 30.0-38.5 | 30.0-38.5 | 20.0-31.0 | 25.0-38.5 |

| 2 | 3.0-4.5 | 4.0-7.2 | 7.7-8.8 | 7.0-13.2 | 8.0-13.2 |

| 3 | 1.0-1.55 | 2.5-3.1 | 3.0-4.5 | 5.0-7.2 | 5.5-7.7 |

| 4 | 1.0-1.2 | 1.32-1.8 | 1.8-2.42 | 3.5-5.5 | |

| 5 | 0.6-0.9 | 0.6-0.9 | 1.0-1.65 | 2.0-3.52 | |

| 6 | 0.4-0.66 | 0.8-1.32 | 1.4-2.2 | ||

| 8 | 0.3-0.45 | 0.8-1.32 | |||

| 10 | 0.2-0.45 |

| Thickness(mm) | IPG 6000W | IPG 8000W | IPG 10000W | IPG 12000W | IPG 15000W |

|---|---|---|---|---|---|

| Speed | Speed | Speed | Speed | Speed | |

| (m/min) | (m/min) | (m/min) | (m/min) | (m/min) | |

| 1 | 45.0-55.0 | 48.0-60.0 | 50.0-62.0 | 55.0-65.0 | 60.0-75.0 |

| 2 | 25.0-33.0 | 27.0-32.0 | 30.0-35.0 | 32.0-40.0 | 35.0-45.0 |

| 3 | 12.0-20.0 | 13.0-20.0 | 15.0-21.0 | 16.0-22.0 | 18.0-25.0 |

| 4 | 8.0-11.0 | 10.0-12.0 | 11.0-13.0 | 12.0-15.0 | 14.0-18.0 |

| 5 | 6.0-7.7 | 7.0-9.0 | 8.0-11.0 | 10.0-14.0 | 12.0-16.0 |

| 6 | 3.5-50 | 4.0-5.5 | 5.0-7.5 | 8.0-13.0 | 10.0-13.0 |

| 8 | 1.6-2.42 | 2.0-2.5 | 3.0-4.5 | 5.5-6.5 | 7.0-8.5 |

| 10 | 0.8-1.32 | 1.6-2.2 | 2.0-2.5 | 3.5-4.7 | 5.0-6.5 |

| 12 | 0.8-1.2 | 1.1-2.0 | 1.7-2.8 | 2.0-3.5 | |

| 15 | 0.8-1.2 | 1.0-1.6 | 1.5-2.2 | ||

| 18 | 0.6-0.8 | 0.8-1.2 | |||

| 20 | 0.6-0.8 | 0.5-0.8 |

- The power of the machine: Different machines have different power levels.

It is important to select a machine that is capable of providing the power you require.For effective laser cutting of metals, a laser power of a few kilowatts is suggested.

The laser power of industrial metal laser cutters appropriate for large-scale organizations can range from 3 to 12 kW.

A fiber laser with a power rating of more than 1000W, on the other hand, can get you started on laser cutting thin sheets of metal in numerous passes.

- The cost of the machine: Fiber laser cutting machines can be expensive. It is important to select a machine that is within your budget. Contact OMNI to get price of fiber laser cutting machine.

Factors to Consider When Selecting a Fiber Laser Cutting Machine

When selecting a fiber laser cutting machine, there are a few key factors to consider:

- Beam quality: The beam quality of a laser cutting machine is one of the most important factors to consider. High power output and beam quality, which creates a cleaner cutting edge

- Laser power: The laser power of a machine is another important factor to consider. A higher laser power will result in faster cutting speeds.

- Cutting area: The cutting area of a machine is another factor to consider. A larger cutting area will allow for larger parts and components to be cut.

- Durability: The durability of a laser cutting machine is also important to consider. A machine with a longer lifespan will save you money in the long run.

- Cost: The cost of the machine is an important factor to consider. A machine that is within your budget will help to save money in the long run.

Popular Fiber Laser Cutter Brands

Global Top Fiber Laser Cutting Machine Brands

There are some popular brands of fiber laser cutting machines globally on the market. Some of the most popular brands include

Trumpf

Mazak

Mitsubishi

Amada

Top Fiber Laser Cutter Manufacturers from China

Well, China now is a manufacturing center for fiber laser cutting machine in recent 10 years.

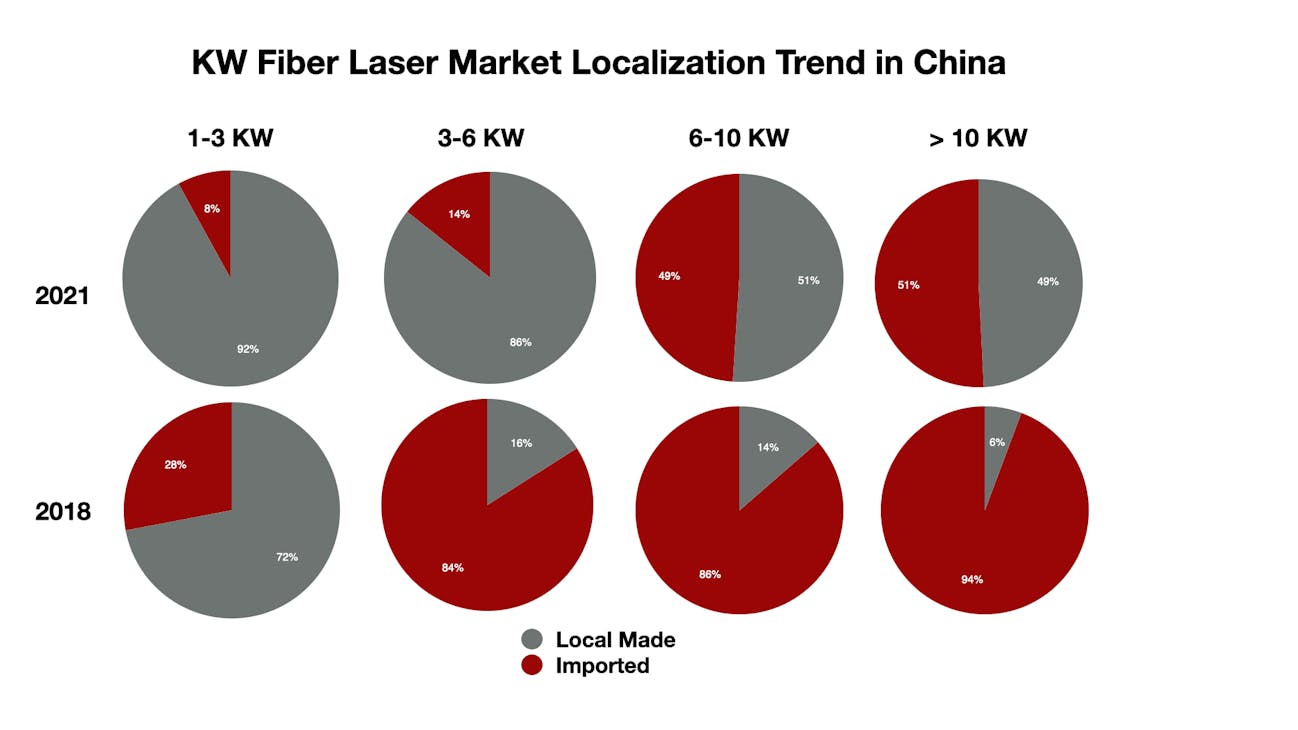

China is the largest market for fiber lasers in the world. Its fiber laser market grew by 15.3% in 2021 to 1.713 billion USD, accounting for 63% of the global market. Shipment of 6 kW power-level lasers has increased significantly. And even more explosive is the sales of 10 kW, 12 kW, and 20 kW lasers that became the main laser sources in sheet metal cutting in China.

The price of fiber lasers dropped dramatically as more fiber lasers components are manufactured by domestic makers.

Figure. The fiber laser localization trend in China, 2018 VS 2021. From LASERFOCUSWORLD

There are many famous brands who occupied more and more market in the world. Here list some of them:

HANS LASER

Han’s Laser, founded in 1996 in Shenzhen, China, has established itself as a leading player in China’s laser machine manufacturing business. The firm is proud of its global competitiveness and has several subsidiaries that provide laser cutting devices.

Over 200 industrial laser equipment and intelligent equipment, including laser welding machines, laser cutting machines, new energy laser welding equipment, industrial robots, and automation solutions, are part of their product offer.

Bystronic

Through years of committed research, development, production, and sales of metal laser cutting machines, Bystronic DNE was formed in Shenzhen and has earned considerable market impact, distinctive service appeal, and market share in the field of laser cutting machines in China.

High-power fiber laser cutting machines (varying from 2000W to 12000W) and medium-power fiber laser cutting machines (2000W) are their primary products.

HGTECH

Huagong Laser and FARLEY LASERLAB are two brands owned by Wuhan Huagong Laser Engineering Co., Ltd. The firm, which was established in 1993, specializes in laser marking, welding systems, cutting, and other laser processing equipment, as well as plasma cutting equipment.

BODOR

Jinan Bodor Laser was founded in 2008 and pursues a brand development strategy that prioritizes staff development as well as product innovation.

SENFENG LASER

SENFENG offers a comprehensive selection of fiber laser cutting machines, laser welding equipment, and cleaning equipment. Steel metallurgy, nonferrous metals, automotive, military electronics, precision instrumentation, equipment production, hardware tools, integrated circuits, and solar energy are all businesses that employ these machines.

HSG LASER

Foshan HSG Laser is a high-tech firm that delivers laser intelligent equipment solutions to customers all over the world. It has devoted itself to the development of laser intelligent equipment, with an emphasis on efficiency, intelligence, environmental friendliness, and compatibility.

OMNI LASER

OMNI is a high tech manufacturer since 2011. OMNI focus on the fiber laser cutting machine, laser welding machine and robotic laser welding machine for high precision metal cutting, fabricating, welding industry.

Steel metallurgy, nonferrous metals, automotive, military electronics, precision instrumentation, equipment production, hardware tools, integrated circuits, and solar energy are all businesses that employ these machines.

CHUTIAN LASER

Wuhan Chutian Laser (Group) Co., Ltd. was established in 1985 in Wuhan and is the flagship firm of Wuhan’s Optics Valley. The enterprise employs over 1,000 people and has drawn the attention of both domestic and international dignitaries, with 22 national and 5 foreign officials visiting the facility.

Chutian Laser has been named a “Shenzhou Six Aerospace Engineering Meritorious Unit” and has been authorized as a laser application service provider for the Shenzhou spacecraft series, from Shenzhou-1 to Shenzhou-8.

Each brand has its own advantages and disadvantages, so it is important to do your research and compare them to find the one that best suits your needs.

Import Fiber Laser Cutting Machine to Your Country

It seems complicated even when you have no idea of importing goods from China.

Do not worry, international shipping is just like purchasing stuff in domestic. You pay VAT for goods in domestic, and now you just pay custom duty when import it from China.

Shipping company and cargo agency will handle your fiber laser cutting machine shipping and customs clearance. You can pick up the machine from cargo warehouse or just request to delivery the machine to your door.

Get to know more about import fiber laser cutting machine to USA from China and import laser cutting machine to Austrlia from China .

Marketing Your Fiber Laser Cutting Machine Business

Now that you have the equipment set up, it’s time to start marketing your business.

You’ll want to create a website or social media presence to introduce your business and showcase your work.

You can also use online advertising to get the word out.

Make sure to include information about the services you offer and the quality of your work. This will help you stand out from the competition and attract more customers.

You can also use traditional methods of marketing, such as attending trade shows or networking events.

This will give you the opportunity to meet potential customers in person and show off your skills.

Don’t forget about word of mouth either. You’ll want to make sure to spread the word about your business to friends, family, and anyone else who might be interested.

Finding Customers for Your Fiber Laser Cutting Machine Business

Once you have your business up and running, it’s time to start finding customers.

You can use a combination of online and offline methods to find customers.

You can use search engine optimization (SEO) to make sure your website is ranking high in search results.

You can also use online directories to list your business and attract customers.

You can also use traditional methods such as cold calling or direct mail.

This will allow you to reach out to potential customers directly and make a personal connection.

You can also attend trade shows and other events to meet potential customers in person. Don’t forget about referrals either.

Ask your existing customers to recommend your business to their friends and family.

Tips for Running a Successful Fiber Laser Cutting Machine Business

Running a successful laser cutting machine business is not an easy task. Here are some tips to help you succeed:

- Have a clear plan and set realistic goals.

- Stay organized and keep accurate records.

- Provide excellent customer service.

- Stay up to date on industry trends.

- Invest in high-quality equipment.

- Follow safety protocols.

- Have basic maintenance knowledge of fiber laser cutting machine

Common Problems with Fiber Laser Cutting Machines

Fiber laser cutting machines are reliable and durable, but they can experience problems from time to time. Common problems include dirty optics, misaligned laser beam, and power supply problems. It is important to regularly inspect and maintain your machine to ensure that it is running properly.

Maintenance and Repair of Fiber Laser Cutting Machines

Regular maintenance and repair is essential to ensure that your fiber laser cutting machine is running properly. It is important to inspect the machine regularly and clean the optics and laser heads. It is also important to check the power supply and make sure that all connections are secure.

If you encounter any problems with your machine, it is important to contact a qualified technician for assistance. They can diagnose and repair any problems that you may be experiencing.

Understanding the Financial Side of Starting a Fiber Laser Cutting Machine Business

Before you launch your business, it’s important to understand the financial aspects. You’ll need to plan for start-up costs, such as the cost of the machine, installation, and any other equipment you may need. You’ll also need to consider ongoing costs such as rent, utilities, and supplies. You’ll also need to budget for marketing and advertising.

Once you have an understanding of the financial side of your business, you can start creating a budget. This will help you understand how much money you need to start and keep your business running. It will also help you plan for the future and anticipate any potential problems.

What Equipment Do You Need for Your Fiber Laser Cutting Machine Business?

In addition to the laser cutting machine, there are a few other pieces of equipment you’ll need to get started. You’ll need a computer with a CAD program to design your projects. You’ll also need a ventilation system to keep the air clean and safe. And you’ll need safety equipment such as goggles, gloves, and protective clothing.

What Equipment Do You Need for Your Fiber Laser Cutting Machine Business?

In addition to the laser cutting machine, there are a few other pieces of equipment you’ll need to get started. You’ll need a computer with a CAD program to design your projects. You’ll also need a ventilation system to keep the air clean and safe. And you’ll need safety equipment such as goggles, gloves, and protective clothing.

Safety Considerations for Your Fiber Laser Cutting Machine Business

Safety is an important consideration when running a laser cutting machine business. You’ll need to make sure that your employees are properly trained and that all safety protocols are followed. You’ll also need to make sure that your machine is properly maintained and that all safety features are enabled.

How to Start Running Your Fiber Laser Cutting Machine Daily?

Please remember to switch on the industrial chiller before beginning work to ensure that the water temperature is between 20 and 25 degrees. Make sure this is the first thing to do every day after you turn on the general power in workshop.

To make it easier for you to understand the details, below is the brief introduction of start fiber laser cutting machine.

How to ensure the safety operation?

First and foremost, it is essential to provide comprehensive training for any personnel who will be operating the fiber laser cutting machine. They should be thoroughly familiar with the machine’s operation and safety features, and be aware of the potential hazards associated with the machine.

Protective Gear

Additionally, all workers should be provided with the appropriate protective gear, such as safety glasses and gloves, to minimize the risk of injury.

Regular Maintanance

Another important aspect of safety for fiber laser cutting machines is regular maintenance. As with any machine, regular maintenance is essential to ensure that it is in optimal working condition and free of defects or malfunctions. This may include checking the machine for any loose components, inspecting the cutting head for any signs of wear or damage, and conducting routine cleaning and lubrication of the machine.

Work Environment Safety Protection

Finally, it is important to remember that fiber laser cutting machines produce a great deal of heat and noise. Therefore, it is essential to have good ventilation throughout the workspace and to provide hearing protection for any personnel working near the machine.

To ensure the safety of your business and your personnel, it is essential to take the necessary steps to ensure the safe operation of your fiber laser cutting machine.

This may include providing training, conducting regular maintenance, and ensuring that the machine is properly grounded.

Additionally, it is important to remember to provide adequate ventilation and hearing protection for personnel working near the machine.

By taking the necessary precautions and following the proper safety protocols, you can help to ensure the safety and efficiency of your fiber laser cutting machine maintenance.

Understanding the Legal and Regulatory Requirements for Your Fiber Laser Cutting Machine Business

Before you launch your business, it’s important to understand the legal and regulatory requirements. You’ll need to make sure that you comply with all local laws and regulations. You’ll also need to make sure that your employees are properly trained and that all safety protocols are followed.

PRICE

We can deliver laser cutting machines at a reasonable cost (far lower than many of our more costly competitors), yet they nonetheless cut metal precisely and quickly.

Our metal LASER cutters will provide the durability, precision, and dependability that your metal cutting operation requires.

Figure. Below is the price of fiber laser cutting machine in China in 2021. from machinemfg

| Model | Power (W) | Laser Source | ||

|---|---|---|---|---|

| IPG (USD) | nLight (USD) | Raycus (USD) | ||

| 1530 | 500 | 18,571 | 17,857 | 17,500 |

| 700 | 21,786 | 21,429 | 20,714 | |

| 1000 | 26,429 | 25,714 | 23,214 | |

| 1500 | 33,929 | 32,143 | 28,929 | |

| 2000 | 48,214 | 45,000 | 41,429 | |

| 3000 | 75,714 | 61,071 | 51,429 | |

| 4000 | 84,286 | 82,143 | 64,286 | |

| 1540 | 500 | 20,000 | 19,286 | 18,571 |

| 700 | 23,571 | 22,500 | 22,143 | |

| 1000 | 27,857 | 27,143 | 24,286 | |

| 1500 | 35,357 | 33,571 | 30,357 | |

| 2000 | 49,286 | 46,429 | 42,500 | |

| 3000 | 77,143 | 62,143 | 52,857 | |

| 4000 | 86,429 | 83,571 | 65,714 | |

| 2040 | 500 | 21,429 | 20,714 | 20,000 |

| 700 | 24,286 | 23,571 | 23,214 | |

| 1000 | 28,929 | 28,571 | 25,714 | |

| 1500 | 36,429 | 35,000 | 31,429 | |

| 2000 | 50,714 | 47,857 | 43,929 | |

| 3000 | 78,571 | 63,571 | 54,286 | |

| 4000 | 87,500 | 83,571 | 67,143 | |

| 1560 | 500 | 22,500 | 22,143 | 21,429 |

| 700 | 25,714 | 25,000 | 24,643 | |

| 1000 | 30,357 | 29,643 | 27,143 | |

| 1500 | 37,857 | 36,071 | 32,857 | |

| 2000 | 52,143 | 48,929 | 45,000 | |

| 3000 | 80,000 | 65,000 | 55,714 | |

| 4000 | 88,571 | 86,429 | 68,571 | |

| 6020 | 500 | 24,286 | 23,214 | 22,857 |

| 700 | 27,143 | 26,429 | 25,714 | |

| 1000 | 31,429 | 31,071 | 28,571 | |

| 1500 | 39,286 | 37,500 | 34,286 | |

| 2000 | 53,571 | 50,357 | 46,429 | |

| 3000 | 81,071 | 66,429 | 56,786 | |

| 4000 | 90,000 | 87,500 | 69,643 | |

| 2560 | 500 | 25,000 | 24,643 | 23,929 |

| 700 | 28,571 | 27,857 | 27,143 | |

| 1000 | 32,857 | 32,143 | 29,643 | |

| 1500 | 40,714 | 38,571 | 35,714 | |

| 2000 | 54,643 | 51,429 | 47,857 | |

| 3000 | 82,143 | 67,857 | 57,857 | |

| 4000 | 91,429 | 101,429 | 70,714 | |

Conclusion

Starting a fiber laser cutting machine business can be a great opportunity for entrepreneurs.

With the right knowledge and resources, you can easily launch your own successful laser cutting business. This comprehensive step-by-step guide has provided you with all the information you need to do so.

You’ve learned about the basics of fiber laser cutting machines, how to purchase and install one, as well as how to market your business and find customers. With this guide, you’ll be able to launch your own fiber laser cutting machine business and start making money.

So what are you waiting for? Get started today!