Looking For 5 Axis CNC Router Machine for Aluminum Machining? Find Solution Here.

5 axis CNC router machine for aluminum processing is a process that removes aluminum material from a work piece to create desired shapes and features. This process can be used on a variety of materials, including aluminum. In this article, we’ll discuss the benefits of using aluminum for 5-axis CNC machining, how to choose 5 axis cnc machine and machining case study.

What is 5 axis CNC router machine for aluminum machining?

5 axis CNC machining aluminum is a process that uses computer numerical control (CNC) technology to machine aluminum parts.

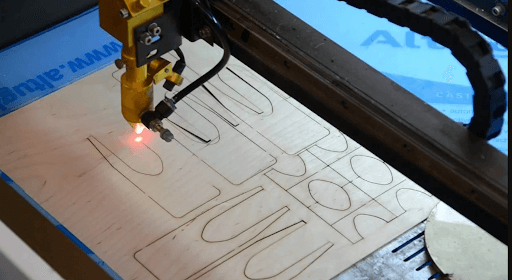

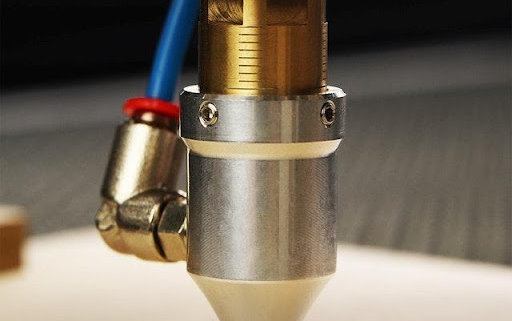

The aluminum material is first mounted on the CNC cutting machine and then the machine moves the cutting tool in various directions to create the desired shape.

This type of machining is usually used for creating complex shapes and designs. And which would be difficult to produce with traditional machining methods.

5 axis CNC machining can produce parts with very tight tolerances and smooth surfaces on aluminum. It is also a very versatile machining process, as it can be used to create parts with a wide range of shapes and sizes.

The benefits of aluminum machining on 5 Axis CNC Router machine?

5 axis cnc router is indispensable for your business, why?

Aluminum is a strong yet lightweight material that is easy to work with. It is also corrosion resistant, making it ideal for use in outdoor applications.

Aluminum CNC machining can be used to create parts with tight tolerances and precise details. It can also be used to create large parts quickly and efficiently.

5 axis CNC machining is the most advanced type of CNC machining available.It allows for the creation of parts with very complex shapes and geometry. This is often used for mold making, prototyping, large format parts carving applications where precision is critical.

Five-axis CNC machining allows a tool to stay continuously in line with the cutting surface. Ultimately, five-axis CNC machining eliminates the need for complicated fixtures. Since a part is held once and revolved through the process in order to achieve the desired geometry.

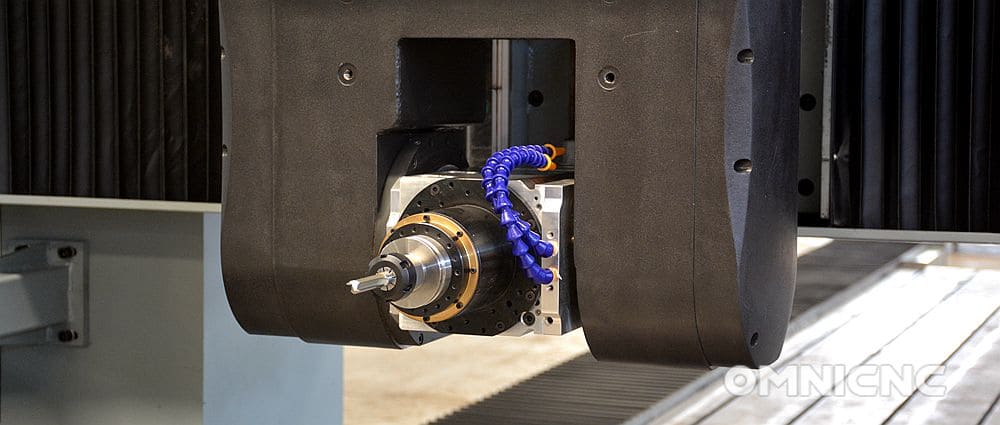

More advanced four-axis CNC machining devices introduce a fourth axis of rotational m A 5axis CNC machine moves cutting tools or parts through five axes simultaneously.

A multi-axis CNC machine can produce parts with complex geometries, since it offers two additional spindle axes. The highly-customizable spindle and orientations of 5 axis CNC router machine can target particular areas, handle extreme cutting conditions, and accurately adjust designs.

In addition, shorter cutter tools reduce vibrations while operating at higher cutting speeds, allowing for a substantially better surface finish.

In 5-axis CNC machining, the cutting apparatus stays tangent to the cut surface, which allows for shorter cycle times, which helps to decrease the amount of material removed each time the apparatus passes. CNC routers are not as rigid as even metal CNC bench top mills, you can prop up the machine using long, stumpy tools, and small cutting depths each pass.

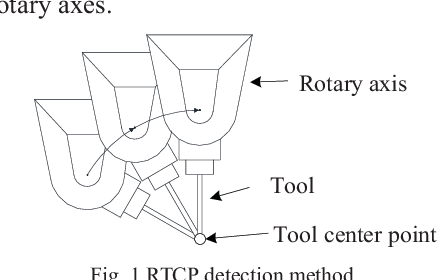

These machines can make intricate parts quicker and easier than ever by taking advantage of 5-axis machining in parallel, using RTCP (Rotating Tool Center Point) functionality.

Option, matched up with the X-axis, giving space to create more complex parts.

The drawbacks of 5 axis Aluminum machining

One potential drawback of aluminum 5 axis router machine is the potential for corrosion. Aluminum is a reactive metal and when exposed to oxygen, it forms a thin oxide film on its surface.

This film protects the aluminum from further corrosion but it can be damaged by abrasion or chemicals.

Another potential drawback of this is, it can be difficult to work with.

Aluminum is a soft metal and it can be easily damaged. It is also a very sticky metal, which can make it difficult to keep tools and machines clean.

Despite these potential drawbacks, there are many benefits as well.

It is a lightweight metal that is easy to work with and it has a high resistance to corrosion. It is also an excellent conductor of heat and electricity.

How to choose the right and best 5 axis CNC router for aluminum?

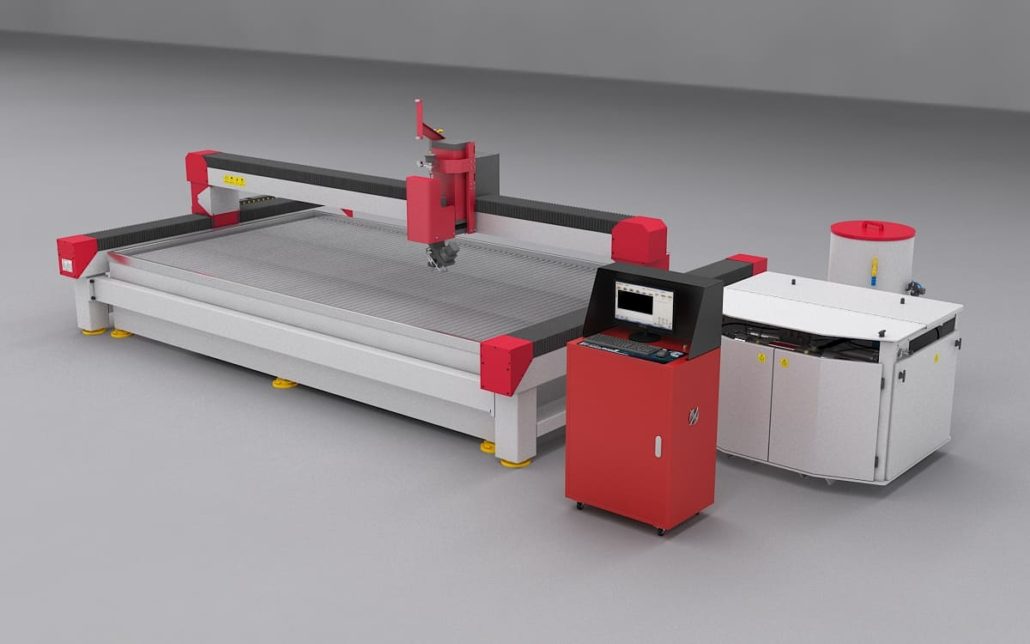

There are many different types of 5 axis CNC machines on the market today. With so many options available, it can be difficult to know which one is right for your specific needs.

If you are looking for a machine that can handle aluminum machining, then you will need to make sure that the machine is specifically designed for this material.

There are a few things that you should look for when choosing a 5 axis CNC machine for aluminum machining.

- First, you will want to make sure that the machine has a high speed spindle. This is necessary for machining aluminum at high speeds.4w

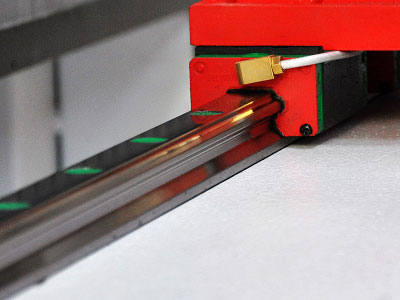

- Second, you will want to make sure that the machine has a strong and rigid construction. This is necessary to prevent vibrations and ensure accuracy during the machining process.

- Third, you will want to make sure that the machine has a large work envelope. This will allow you to machined larger parts without having to worry about the machine being too small.

Find a reliable 5 axis cnc router supplier is crucial, especially when you have limited budget.

Aluminum 5 axis CNC machining performance

CNC machining is a popular manufacturing process that uses computer-controlled tools to cut and shape materials. Aluminum is a popular material to use with CNC machining because it is strong yet lightweight.

There are many benefits to using aluminum for CNC machining.

Aluminum is easy to work with and can be machined quickly. It is also corrosion resistant and has a high strength-to-weight ratio.

Aluminum is an ideal material for many applications, including aerospace, automotive, and medical parts.

In fact, aluminum best 5 axis cnc machine is often used to create complex parts. And it would be difficult or impossible to create with other metal fabrication manufacturing methods.

If you are considering using aluminum for your next project, check out below aluminum machining performance.

Custom 5 axis cnc router machine building for aluminum machining

Custom build CNC router can be a great option for those looking for a versatile and durable material. With the right machine, aluminum can be machined to tight tolerances. And is strong enough to withstand high loads.

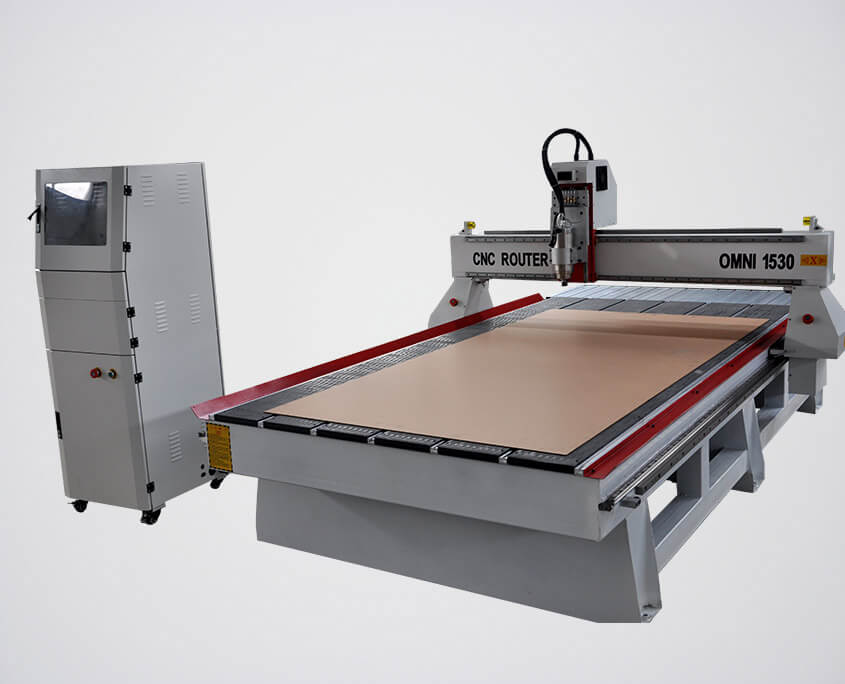

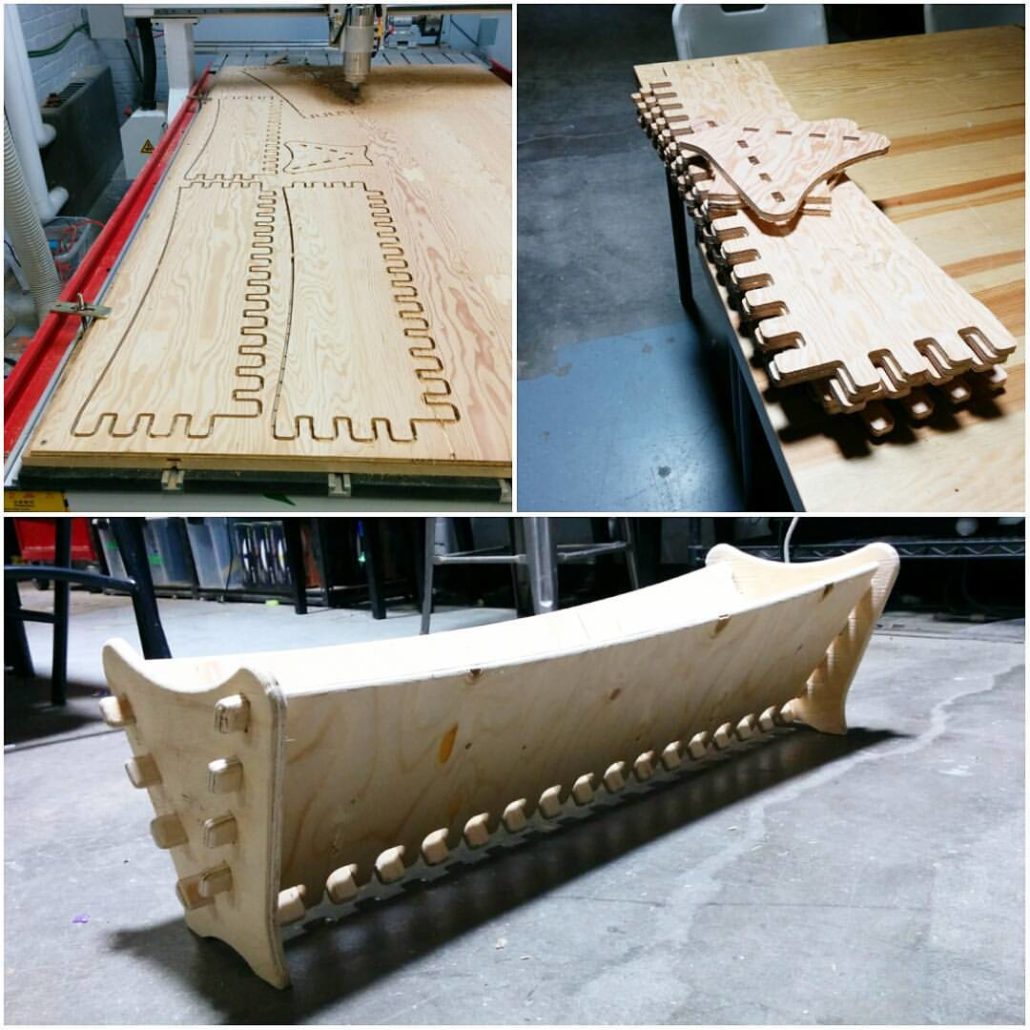

When choosing a machine for aluminum 5 axis CNC machining, it is important to consider the size and capability of the machine. Also need consider the software that will be used. OMNI design and build custom cnc router. Check below cases.

With the right tools and knowledge, this machine can be a great addition.

Conclusion

When doing 5 axis milling, you want to model and test your CNC programs before running them in your machine. The best choice is a CNC machine, like a router or mill, which cuts materials according to instructions sent to it from your CNC software.

For instance, if you plan on starting a business and making money with your CNC router by making metal parts, you are far better off investing in a more industrial-grade CNC machine, one that can produce parts faster and cut harder materials more efficiently.

By mastering the basic 5 axis CNC machine tooling technologies, no matter what the hardest, complex CNC parts are, precision machining parts, we are guaranteed to offer you an awesome edge over the competition and prompt delivery.

Resource

https://infosys.beckhoff.com/content/1033/tccncprogramming/html/rotationtoolcenterpointrtcp.htm