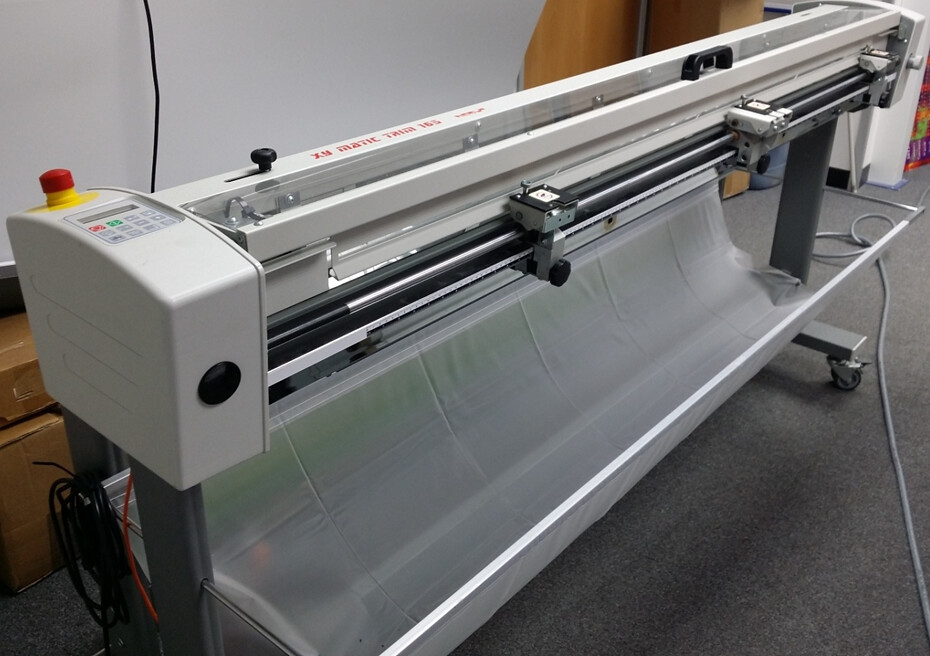

The Ultimate Buyer’s Guide for Purchasing Digital Cutting Machine

Advancement in technology has seen a rapid rise in the demand of the digital cutting machine. For its fair share of things, this machine is a user’s saver! The underlying reason for this is that if a user has this machine; they can use it to combine it with other digital knives or printers to start a different business altogether. By doing so, they will start a new league of their own.

The digital cutting machine is of tremendous use and, as mentioned, one can make different varieties of stuff; and as Peter Theil said, “by doing a new and different thing in a field one can elevate them from zero to one”.

However, before going in the depth of this digital cutting machine, let’s check out what this machine is all about.

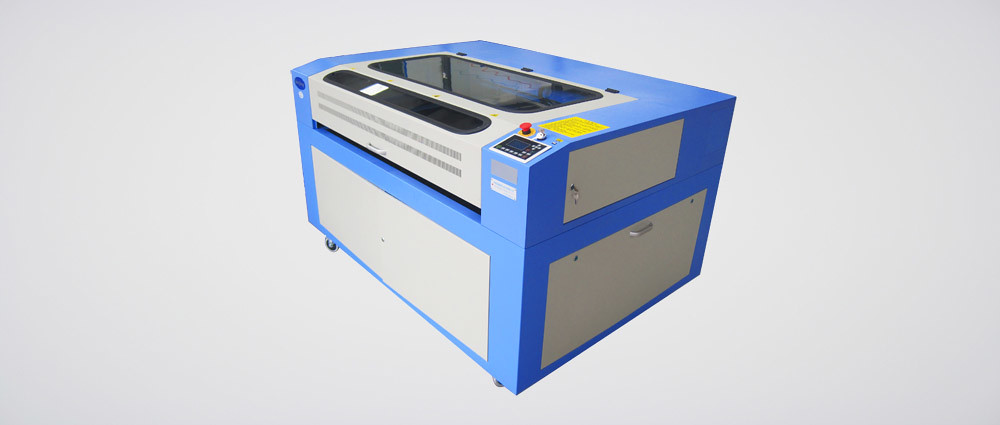

What is Digital Cutting Machine?

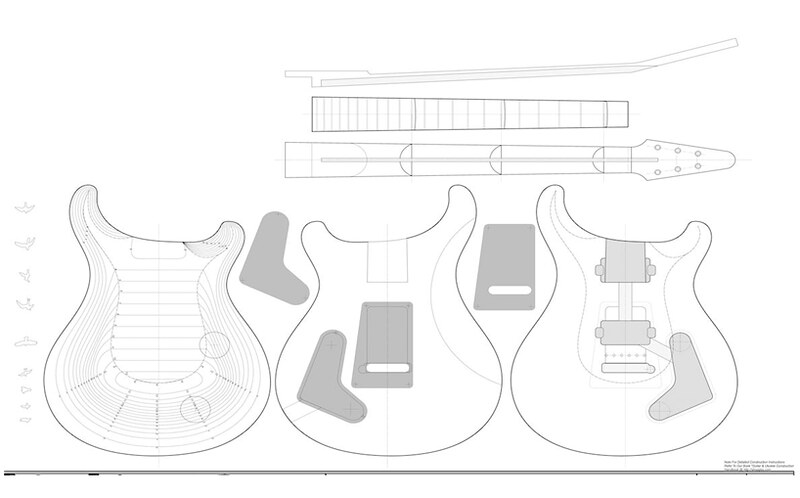

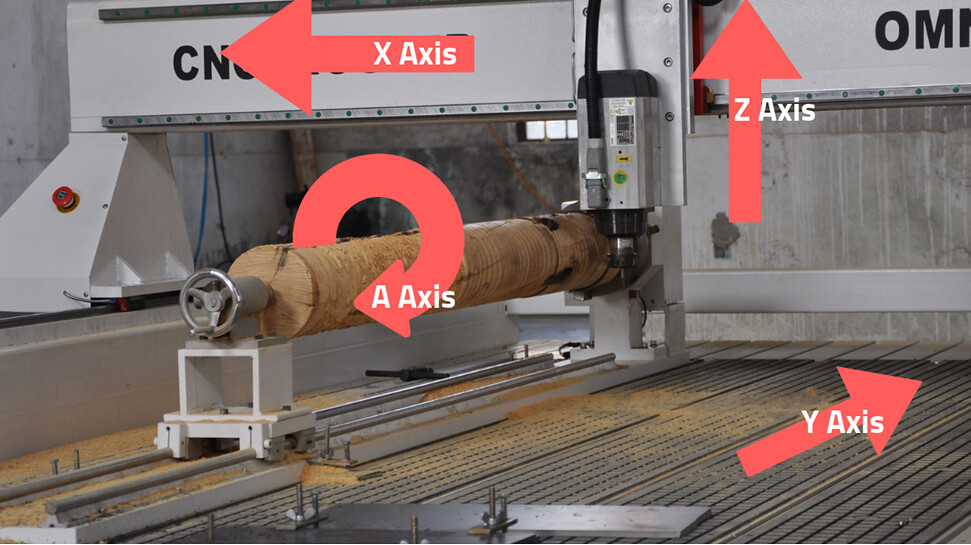

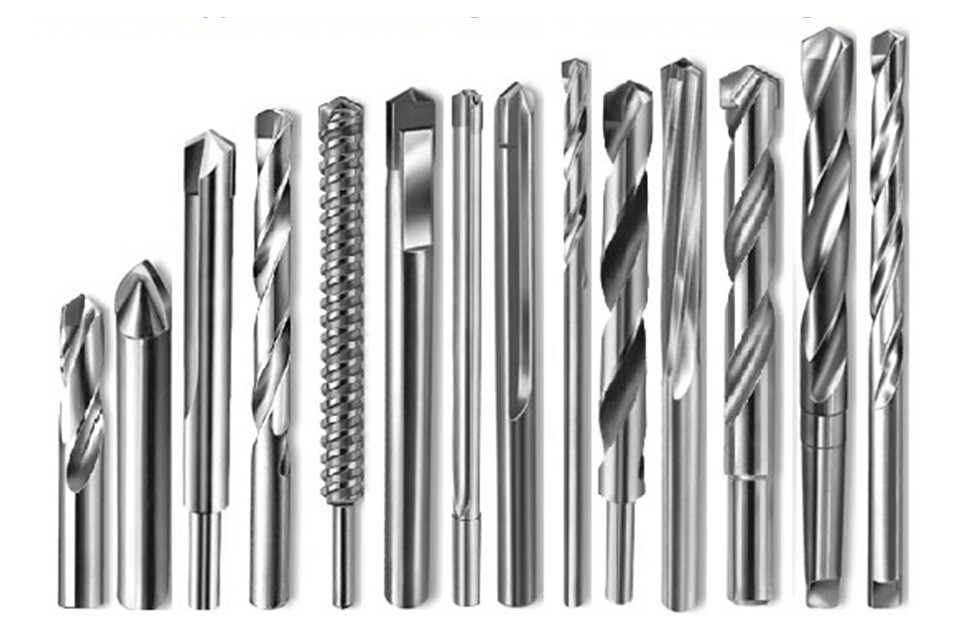

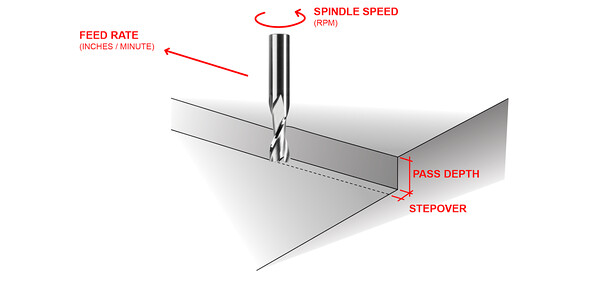

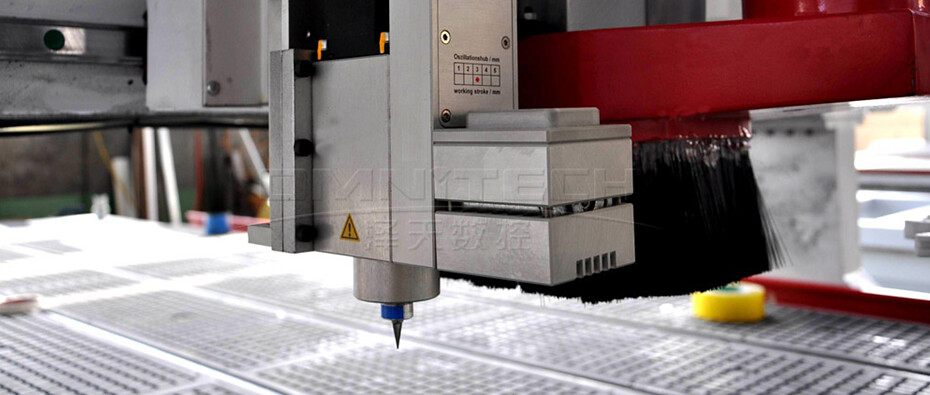

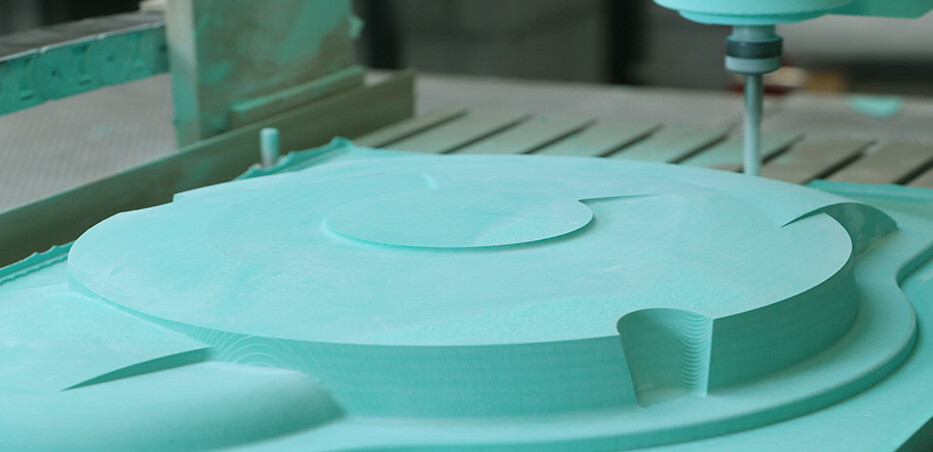

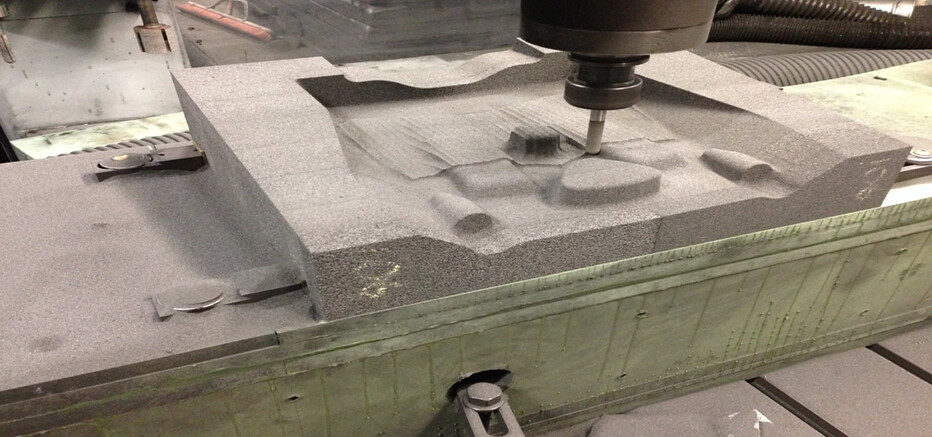

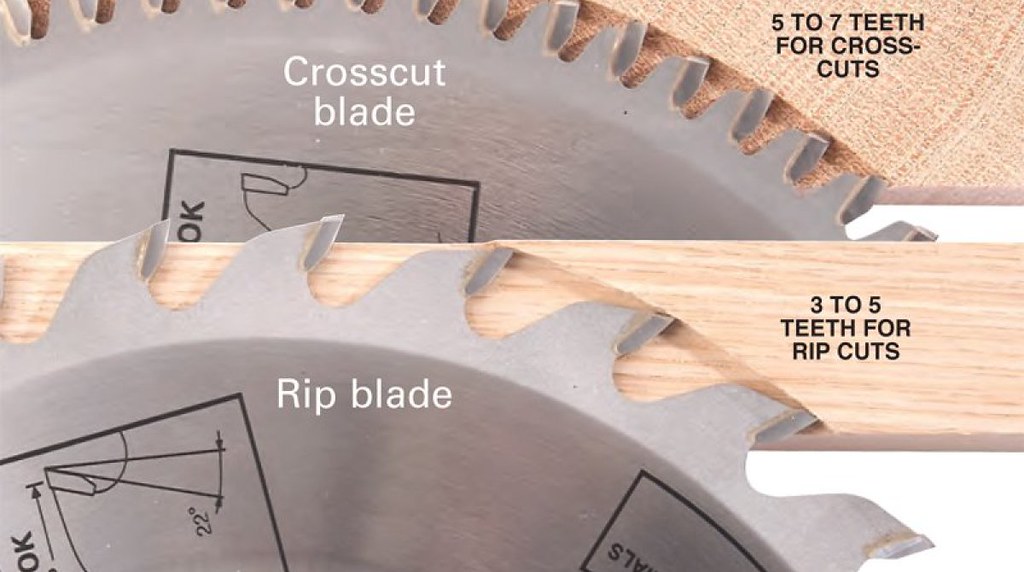

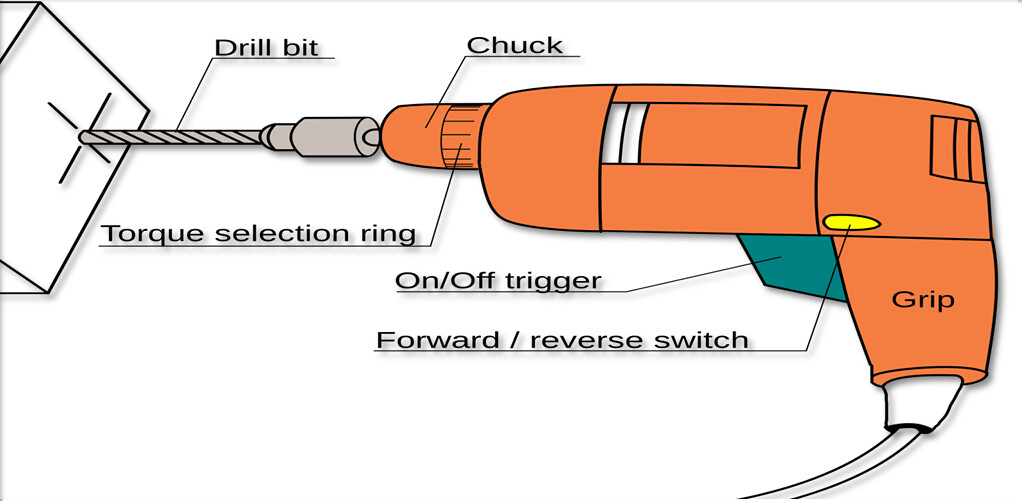

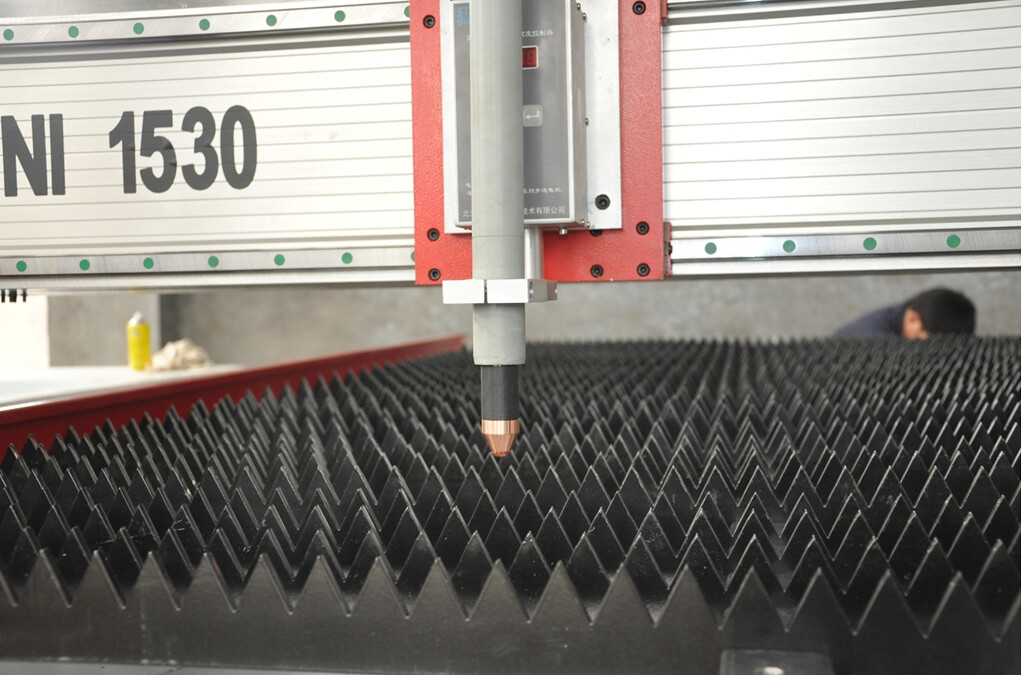

A combination of required knives and bits along with a working mat table constitutes a digital cutting machine. This versatile cutting machine is chiefly designed and used for high-precision cutting of flexible, higher, and semi-rigid materials.

As explained this high precision digital cutting machine is decked with a variety of tools, knife, and blades. The path of the tool is configured due to which the blade of this cutting machine moves on the surface of the material. Further, the user in this cutting machine can adjust the required tool and the material for cutting.

How to Work on a Digital Cutting Machine:

These are the steps of how one should work on a digital cutting machine. Have a look at them:

1. Connect the vacuum pump and air compressor before starting to work on the machine.

2. After connecting both the things then only one should press the button to open the machine.

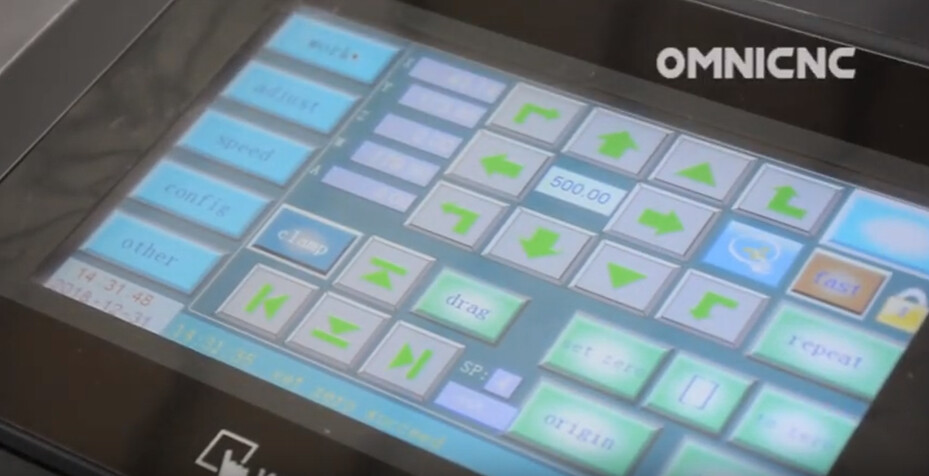

3. Then from the control panel, press the ‘origin’ button after which the machine will move to the origin automatically.

4. Transfer the files from the computer to the control panel by the keyboard and then click ‘drag’.

5. After this, the head of the machine will automatically drag the material over the mat table.

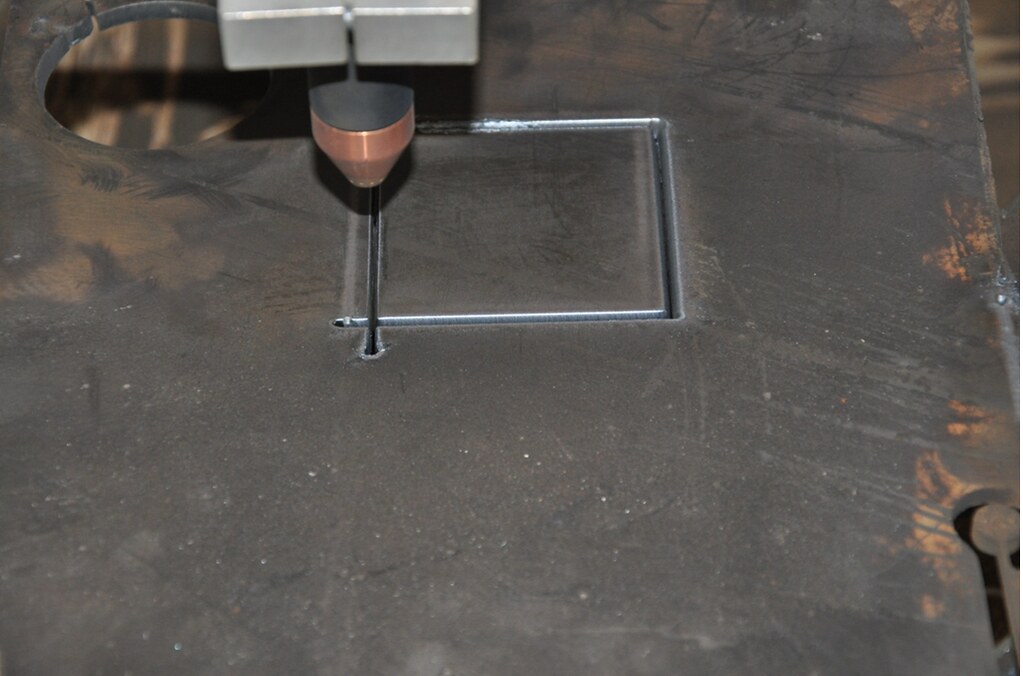

6. Next up is, checking the cutting depth. Click the Y-depth and then check whether the machine was able to cut through the material or not.

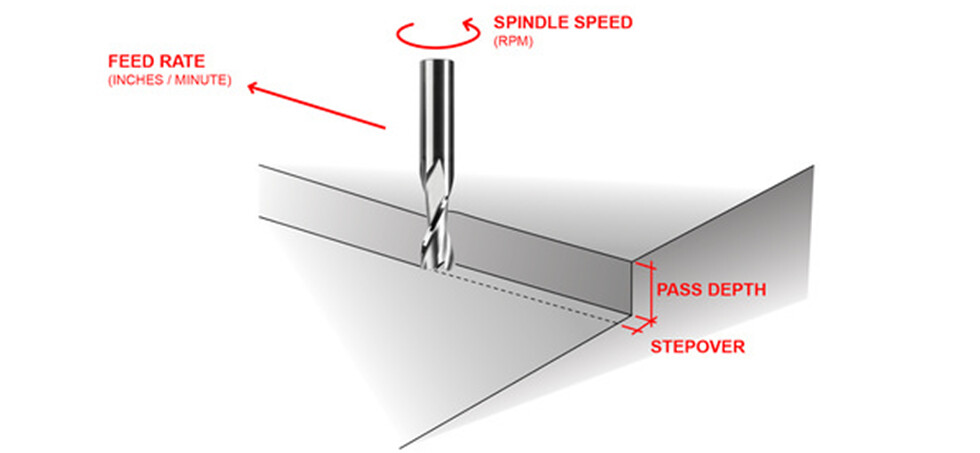

7. Now, click the ‘+’ button in the control panel and set the value to a certain value as per the intended cut.

8. Slowly move the head of the machine to the place where the intended cut is needed.

9. Now, press the ‘Y-test’ button again.

10. If it cuts the material completely then it is time to click the ‘absorb’ key to suck the material on the mat table.

11. Click zero to set the current head position at the origin.

12. Click ‘[ ]’ to cut the other area and click ‘other’ to absorb the area.

13. Pressing the ‘repeat’ button will ensure that the process is repeated.

Some exciting characteristics of Digital Cutting Machine:

To operate or achieve something, it is very important to follow the process and to achieve the desired results the aforementioned steps are something that will provide optimum results.

Nevertheless, the beauty of nature is that we as humans are interested and inclined to know the characteristics of the object we are dealing with. And, when the Digital cutting machine is the center of the conversation, there is a certain eagerness to know what this machine holds.

So, what are they? Let’s have a glance over them.

Workflow efficiency:

The digital cutting machine offers an experience that is new to the user. These machines come with a feature where the production and loading/unloading of materials happens to take place at the same time.

Further, the manufacturers and designers have planned this machine in a way where they have provided a green LED. The green LED signals the user about the area which can be safely used at that particular time.

Cutting surface:

What is a cutting machine if it does not provide a stable surface?

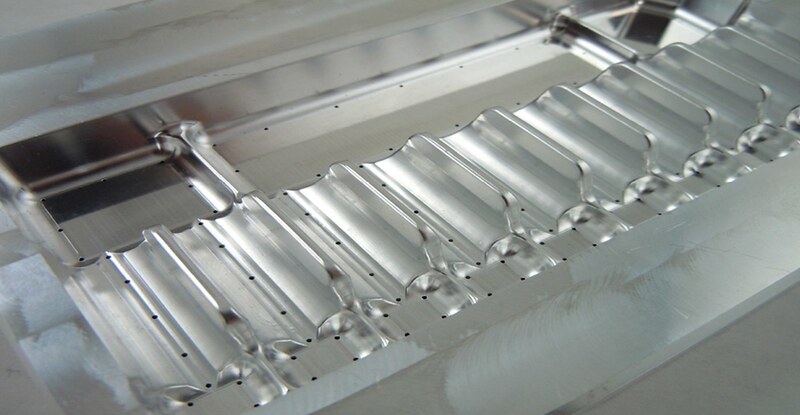

A digital cutting machine is a dream cutter for any user. This machine comes with a highly stable, perfectly constructed aluminium composite that works well for the operator so that they can deliver products that are cut to perfection.

Material hold-down:

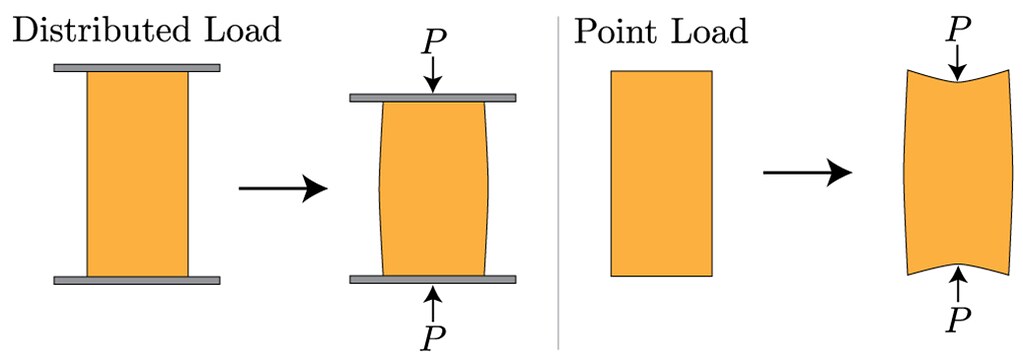

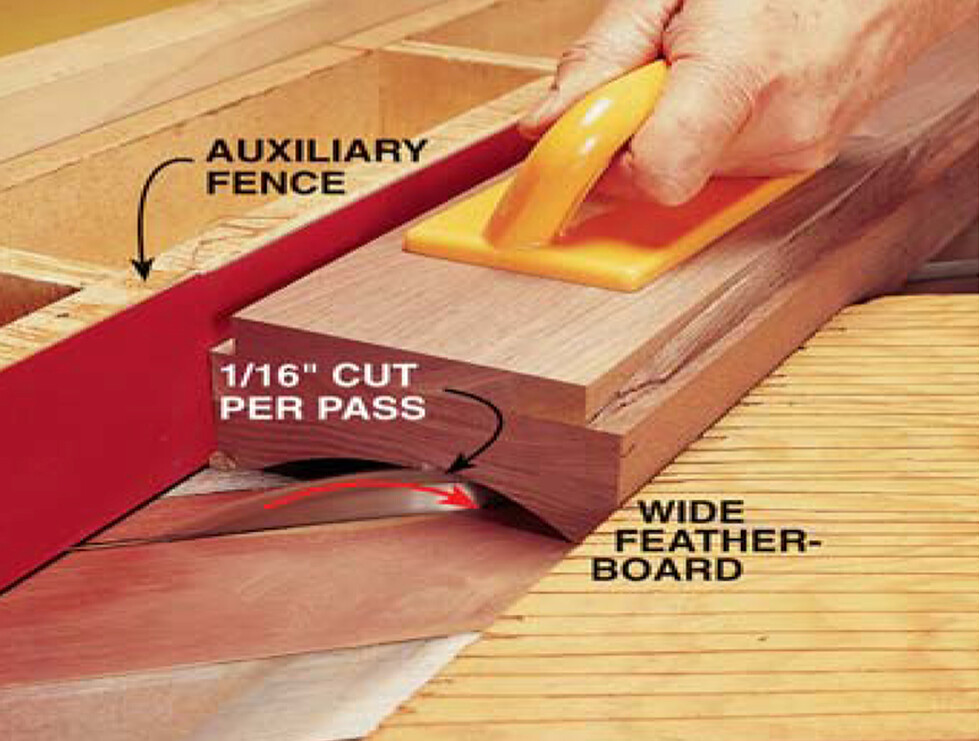

To get the maximum out of any cutting machine the user needs to make sure the material is properly held down on the mat table. By doing so, the users ensure that the material is tightly stretched for the cutter to work efficiently.

This is the reason why the digital cutting machine is the ideal choice for an operator. This machine comes with a cutting surface which is divided into individually controllable vacuum zones. A step-less variable vacuum turbine assures the user that the material is firmly in its place during the process.

Reliably precise:

If one has to define the digital cutting machine in a layman’s language then it will be defined as the production machine.

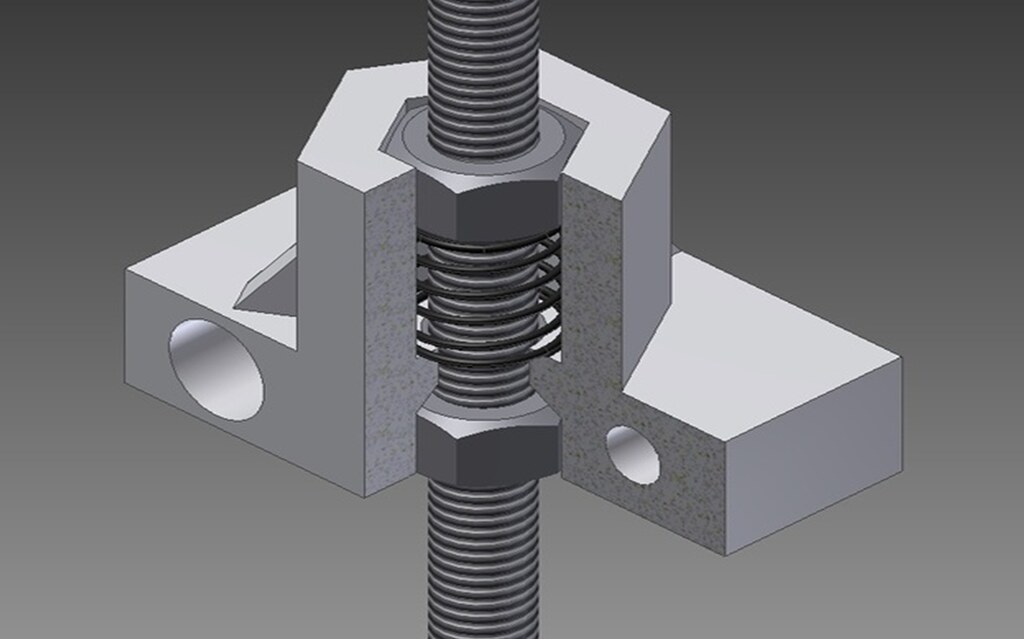

From the drive system to the blades, the components of a digital cutting machine are perfectly implanted to gain superior performance for an operator. Having such a set-up enables the user to complete orders efficiently and quickly. Thus, this also gives them the ability to convince their customers with results that can be termed as perfect.

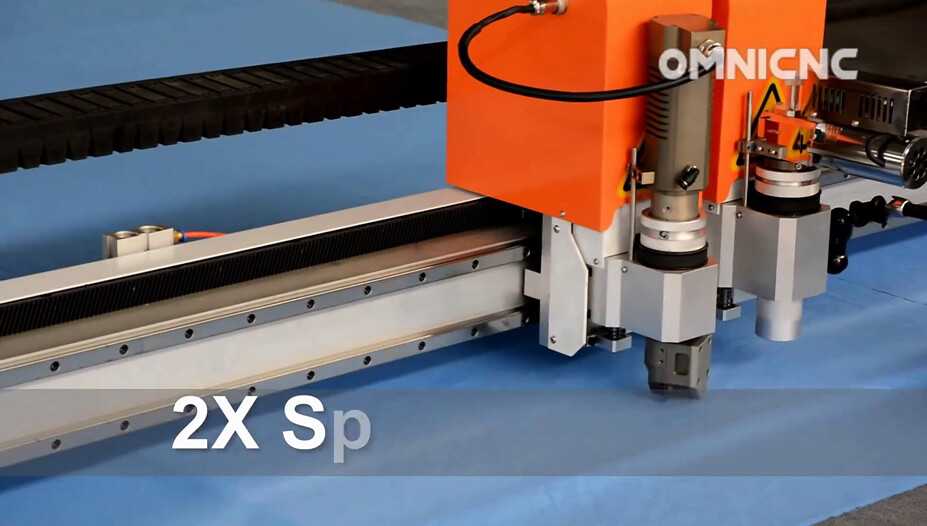

Speed by design:

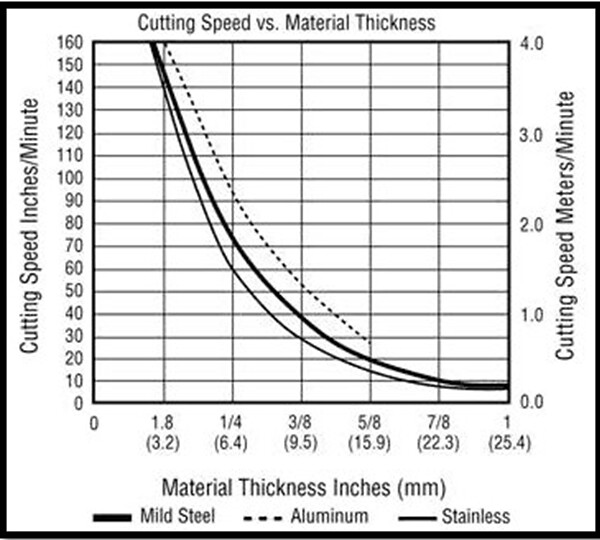

A cutter is nothing without speed. Speed is required to get the product ready for delivery on its due date. And, keeping this in mind, the manufacturers have designed a digital cutting machine whose speed is second to none.

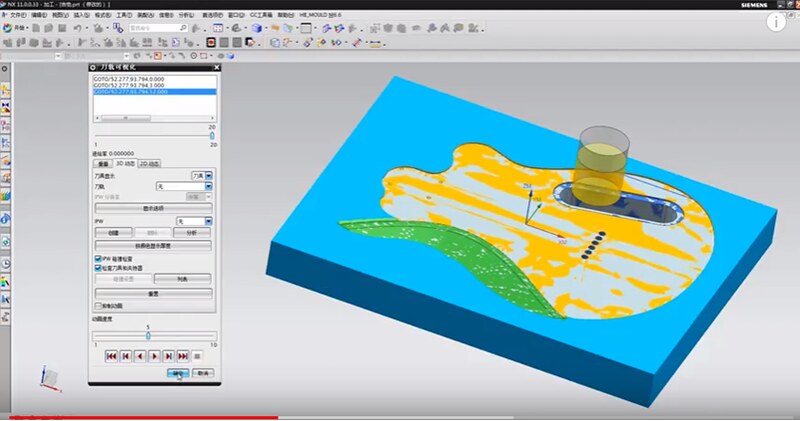

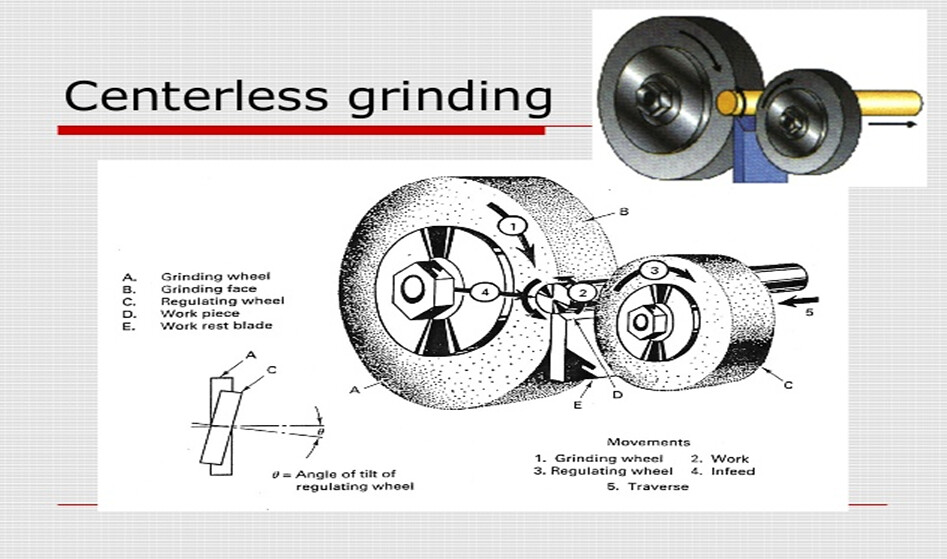

The exceptional productivity of the digital cutting machine comes from its precision based drive system, smart motion-based control system, and a cutting technology which is fine-tuned for optimal results.

Projection system:

An operator needs a system where they can oversee the process and understand the nuances of how the material is processing under the cutter.

As a consequence of that, the projection system of the digital cutting machine visually supports the user to supervise every phase of production, that is, from the setup and automatic or interactive nesting, to picking and sorting of cut parts.

Efficient features of the Digital cutting machine:

A machine is a weapon for any operator, and a digital cutting machine is no less than that. The digital cutting machine is one of those machines which can be termed as perfect. Nonetheless, one cannot tag a machine perfect just like that. Hence, to justify that, here are a few efficient features that make this machine a perfect machine.

Cutting detailed contours:

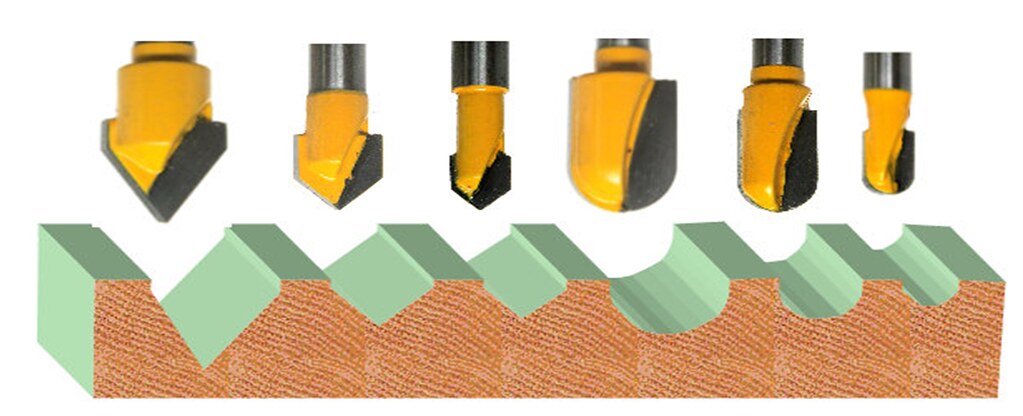

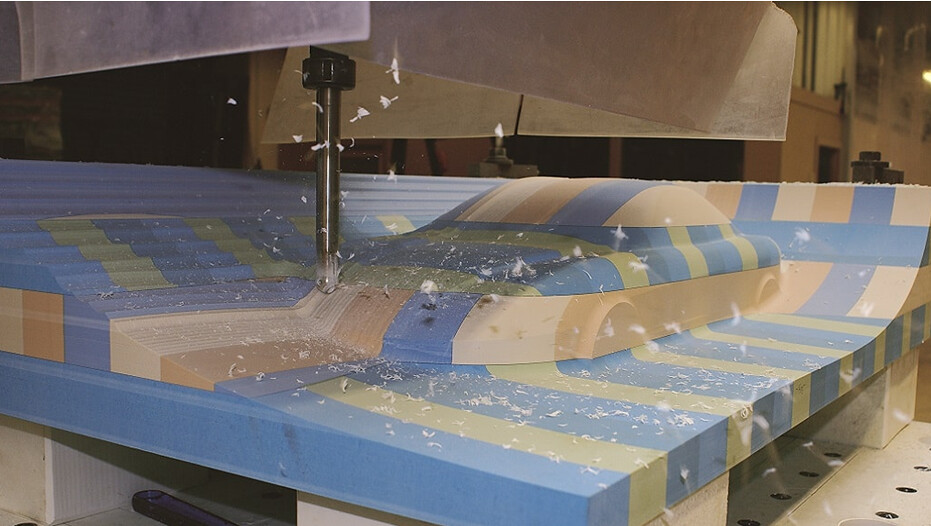

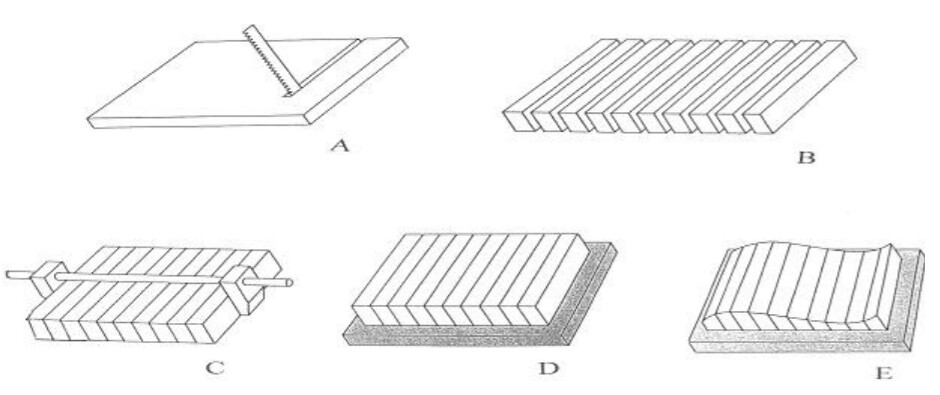

The digital cutting machine is the ideal machine for materials like soft or moderately dense leather. Electric Oscillating Tool – EOT makes this machine suitable for cutting soft, moderately dense, dense and detailed contours materials. Furthermore, the set-up of high oscillating frequencies allows the digital cutting machine to work at a very high processing speed.

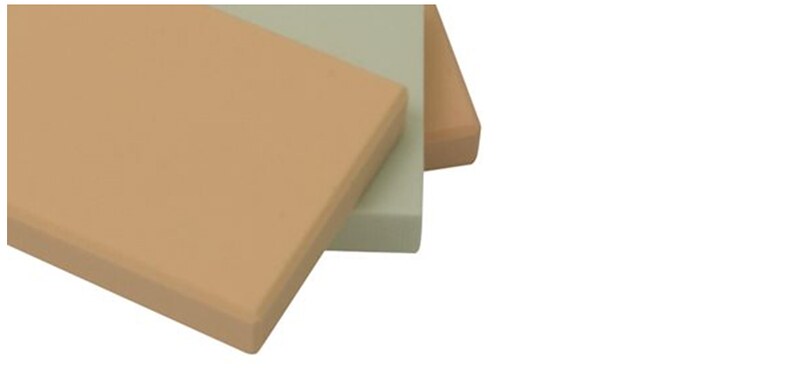

Cutting thick, tough material:

The digital cutting machine is made for material which is thick and tough. This machine comes with a powerful 8 mm stroke, which is specially made to suit the processing needs of dense and tough materials. Alongside the power stroke, this machine also has an air-driven Pneumatic Oscillating Tool – POT which is placed to make the process suitable for cutting.

Perforating:

The digital cutting machine is one of the best equipment in terms of cutting and engraving a tough material. Having said that, digital cutting machine perforates different types of materials such as leather, rubber, and different textile materials.

Furthermore, given its high-speed capability, a digital cutting machine is capable of punching up to 8 holes per second, thereby, making it a reliable source of cutting tough materials for an operator.

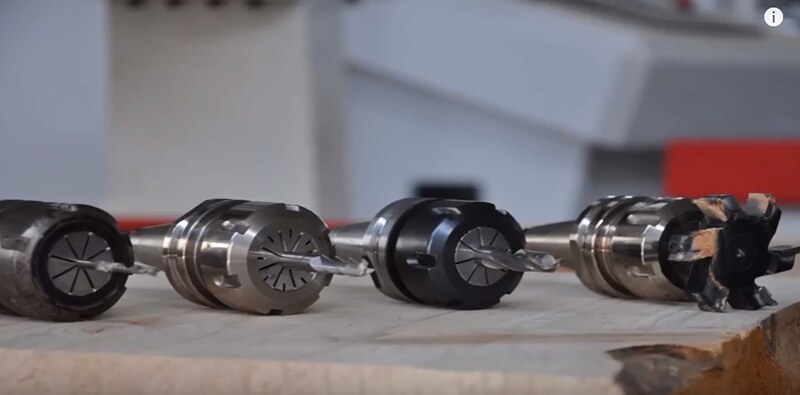

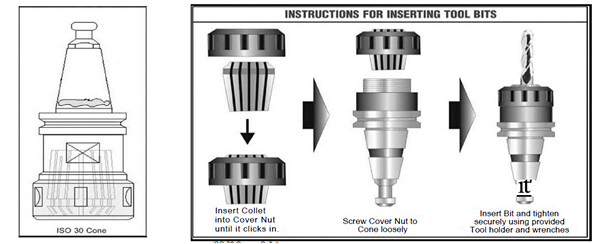

Integrated tool initialization:

An integrated system of tools is a must for a successful run of a machine. With a digital cutting machine, an operator gets just that.

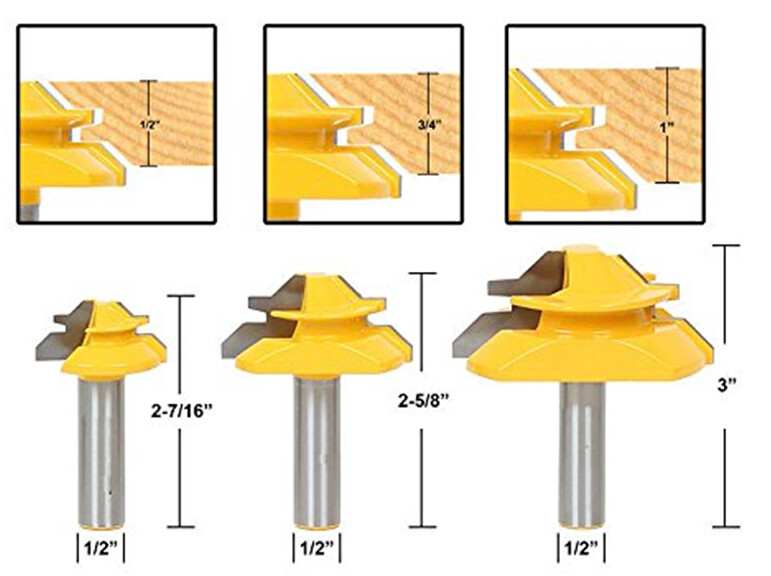

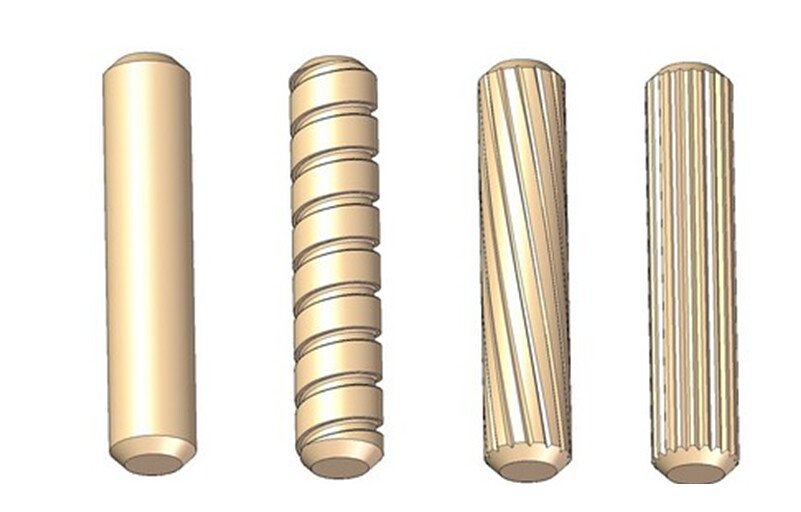

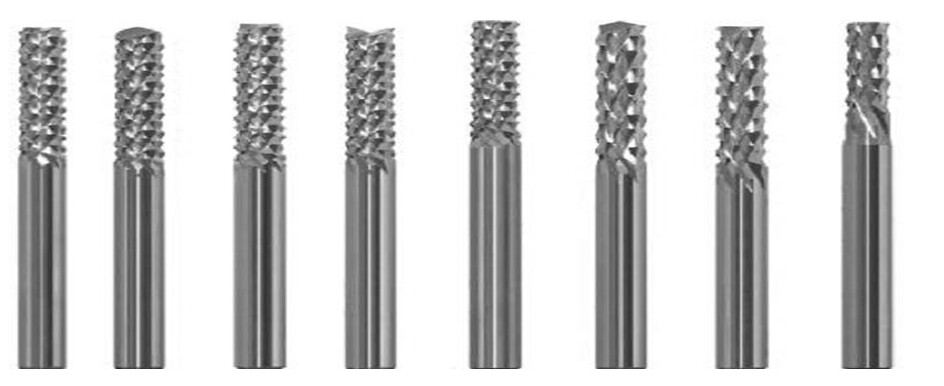

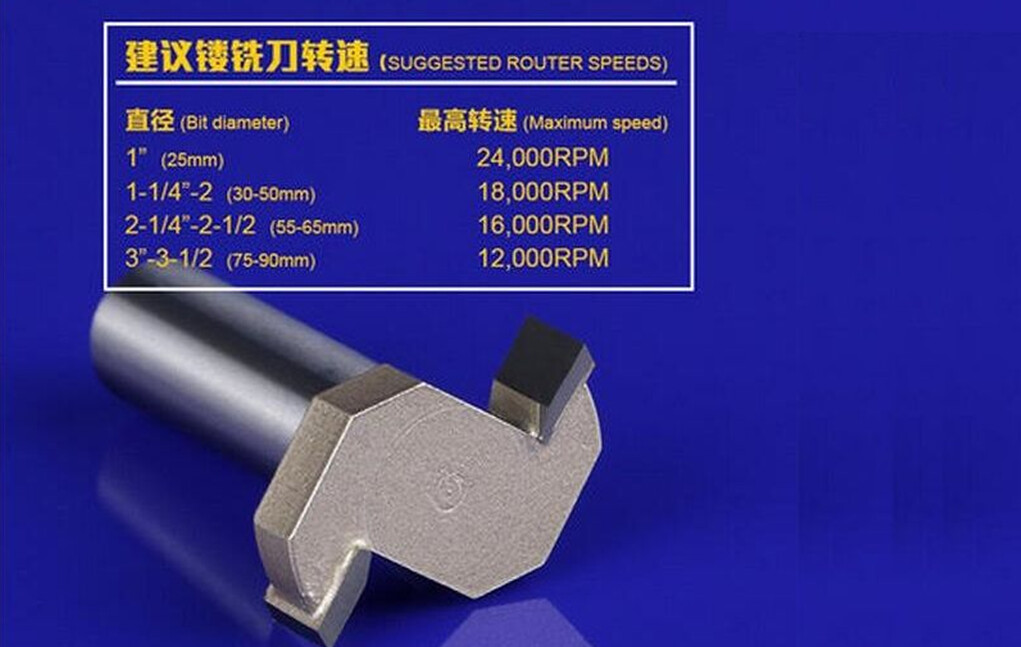

The digital cutting machine promises to come with a fast, efficient and precise set-up of bladed and bits that automatically occurs with an integrated tool calibration system. Having such a set-up helps in eliminating manual errors and any manual steps where the operator had to determine the depth of a proper cut.

Adaptability at work:

Features of a machine can work up to a certain extent. However, what is the use of the machine if it cannot adjust to the requirements of the material? With a digital cutting machine, one thing is sure that the machine can adjust as per the needs of the work. With several features, this machine is a match made on earth for an operator.

Nevertheless, the question is what are they? Let’s have a view.

Sole materials:

Designed to cut rigid, tough materials, this machine has a perfect combination of robust blades and oscillating tools EOT or POT for processing sole materials.

Stencil materials:

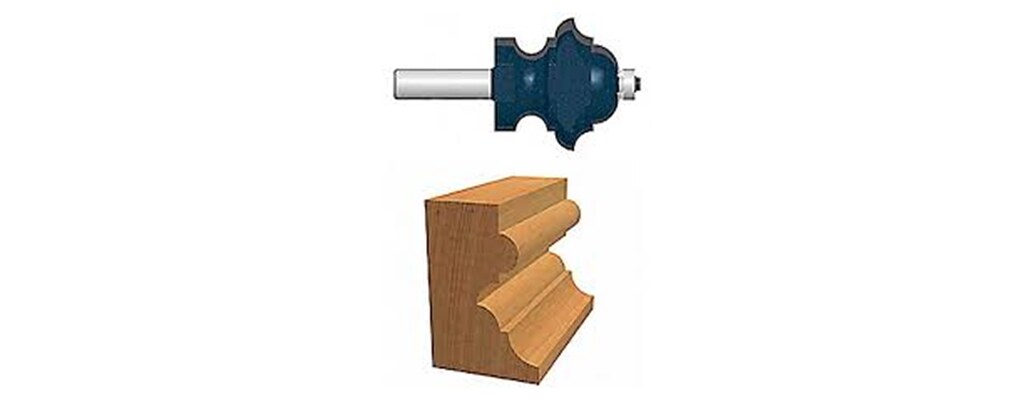

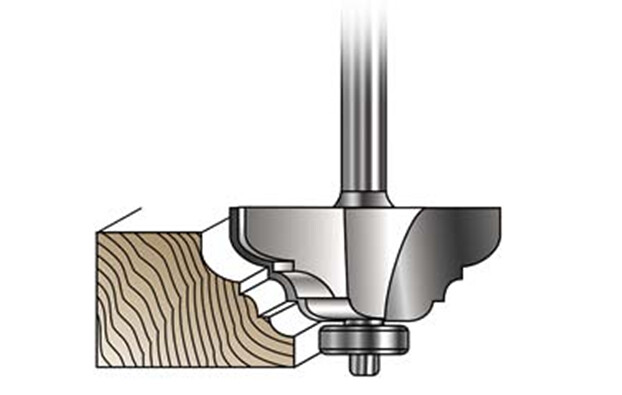

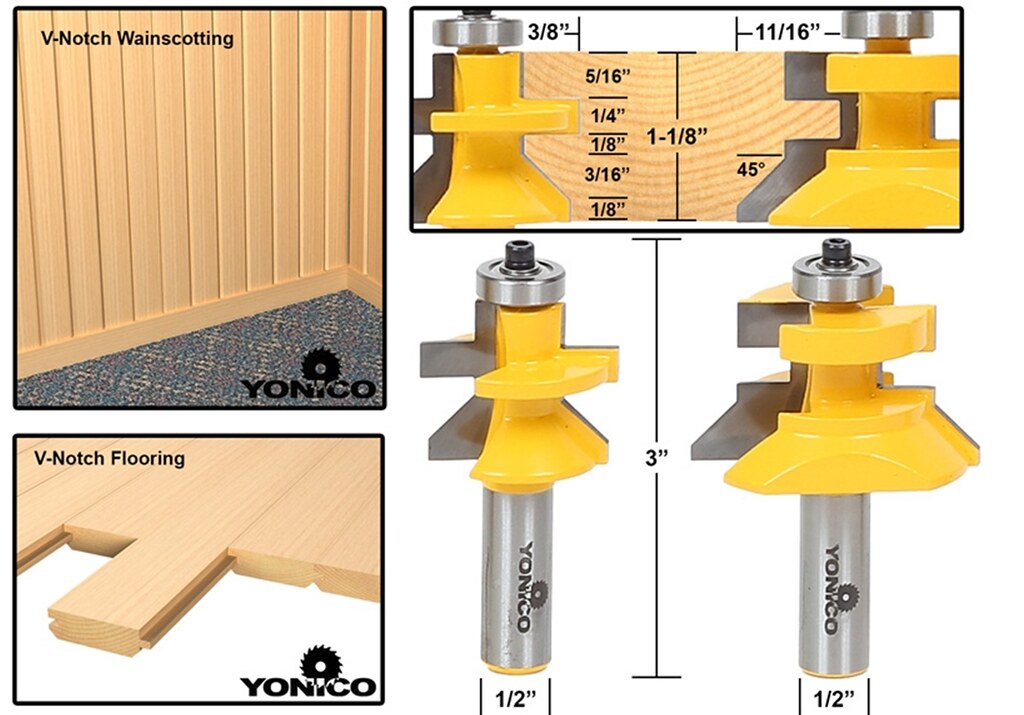

The digital cutting machine is made to process stencil material of all kinds. This machine comes with the right routing tool which offers to cut materials that are tough for a knife to get through.

Rolled materials:

Coming with an optional roll-off unit, the digital cutting machine enables the operator to process rolls up to a width of 2000 mm/90“ and a weight of 70 kg/154 lbs easily and efficiently.

Reasons to opt for Digital cutting service:

Features and adaptability only add to one part of why these machines should be bought for work. Besides them, there are many more reasons which make the digital cutting machine an operator-friendly machine; here are a few of them.

Better service:

What constitutes the digital cutting systems is that these machines provide better service than any other machine with their exceptional performance, precision, and reliability. With adequately trained and highly experienced operators this cutting machine can provide optimal quality work.

Profitability:

Along with solid performance and outstanding quality; digital cutting machine helps the owner to produce non-stop and unparalleled profitability. With continuous innovation in technology and superior standards of construction, it results in low maintenance costs.

Further, outstanding energy efficiency is also a benefit of having a digital cutting machine. Besides that, optimal processing methods, sophisticated material-advance systems, and state-of-the-art vacuum generators keep the energy demands low. This, further, contributes to the eco-friendliness and sustainability of the digital cutting machine.

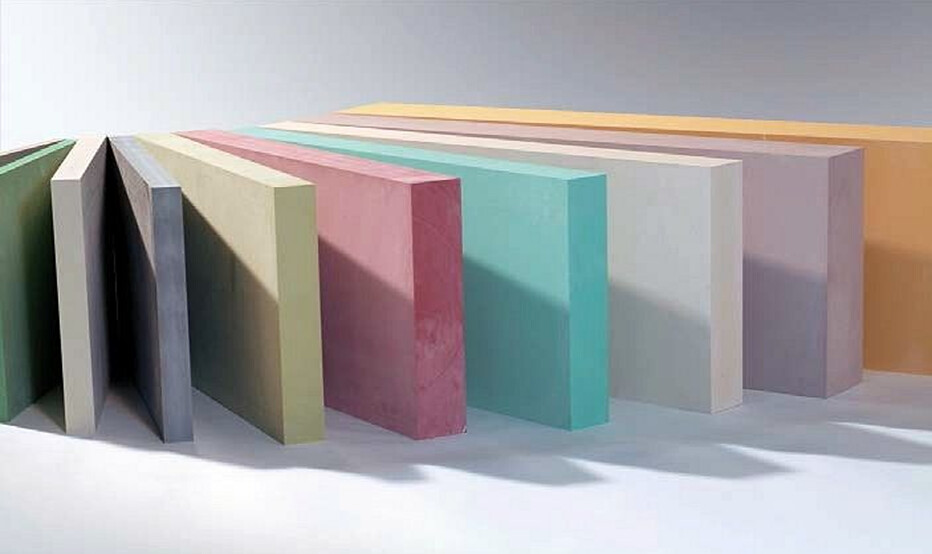

Modularity:

Based on the concept that adds adaptability and flexibility, digital cutting machines provide features that rarely any other machine can offer.

This unique modularity of digital cutting machine makes way for cost-effective configuration and upgrade cutters for constantly changing the cutting needs of the material. This feature not only contributes to the machines’ exceptional ROI but also makes it a valuable asset who retains its value for many years.

Industries that use Digital Cutting Machine:

As mentioned, the digital cutting machine is efficient enough to the toughest of materials with high precision. With the assistance of a cutting machine, an operator has the luxury to reduce their manual work and improve the level of quality of production exponentially.

Industries a digital cutting machine is used include:

Leather Industry:

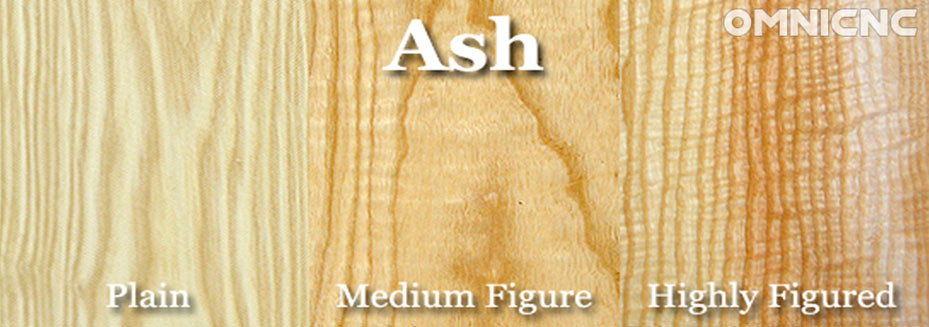

With the presence of a digital cutting machine in the market has made processing leather economical. As mentioned, the digital cutting machine helps in increases productivity and flexibility in an industry and it gradually reaches another level when it is the leather industry.

Be it processing leather shoe sole, lining, or shoe upper, the usage of this machine ensures that the operator gets an optimum level of accuracy.

Apparel Industry:

Just like the leather industry, the presence of a digital cutting machine in the fabric industry has been a blessing for the industrialist. This cutting machine has helped the leading apparel manufacturing companies in terms of maximizing the quality and profitability of their fabric.

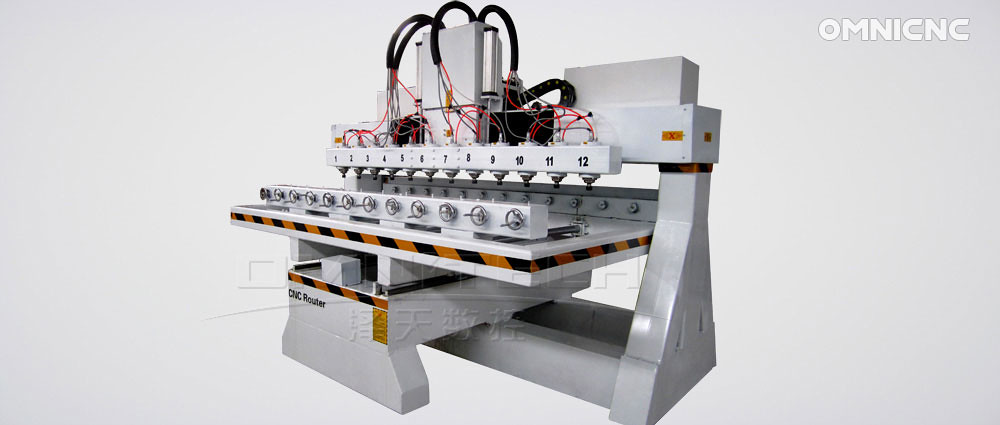

Apart from that, it has also worked wonders on their products as the companies can regulate the market at a faster, smarter and better rate. OMNI CNC digital cutting machine has a pen plotting feature that is 5 times higher plotting speed. This fast and precise machine helps in 3 aspects, such as fabric cutting, pattern cutting, and templates/design cutting.

Large manufacturing companies should purchase high tech digital cutting machines to reduce cost, enhance productivity, and enlarge benefits of their business.

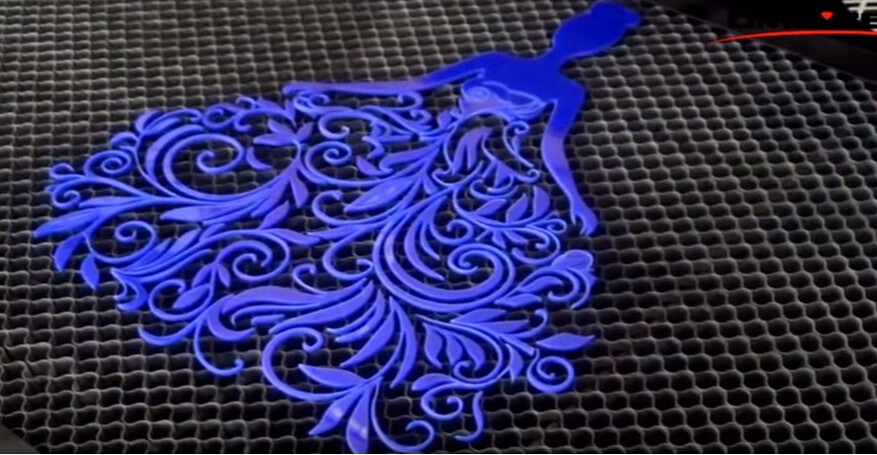

Graphics Industry:

From cutting out complicated graphics to banners, digital cutting machine’s help has made cutting easier over the classical method.

An operator can create shelf signage, hanging signs, floor graphics, textile fabric banners, vehicle graphics, lightboxes, etc. with the help of a digital cutting machine.

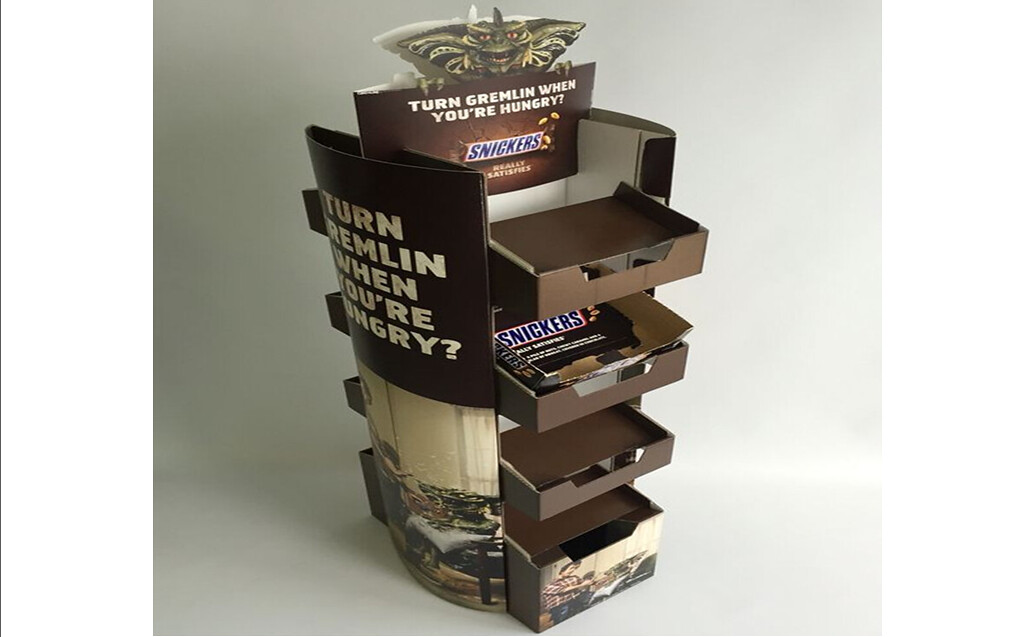

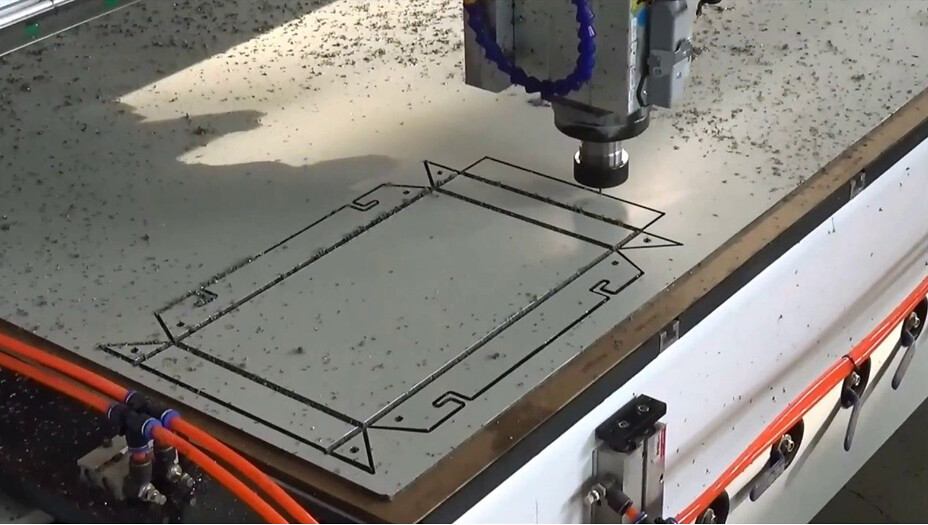

Advertising/Printing/Packaging Industry:

The digital cutting machine plays a bigger part in the packaging industry. The packaging is required to protect the product and also ensure that the product is delivered safely. A good packaging cardboard box, folding boxes, cardboard folder, etc. are created with an easy to use a digital cutting machine. This helps in enhancing the efficiency and potency of the firm.

The multi-function cutting head designs interactive cutting punching and scribing can be availed from a single machine. The oscillating knife cutting head, crimping reel, V-cutting head, and high-speed milling head of the digital cutting machine has the ability to cut 30 or 60mm honeycomb paperboard, acrylic sheet, corrugated paper, plastic corrugated board, gray board paper, white cardboard, film, composite material, leather, cloth, rubber sheet, pearl cotton, aluminum composite board, etc.

It also reduces downtime, production cost, downtime, and waste. The digital cutting machine assists in converting the ideas into reality and presents the proposed design in a few seconds.

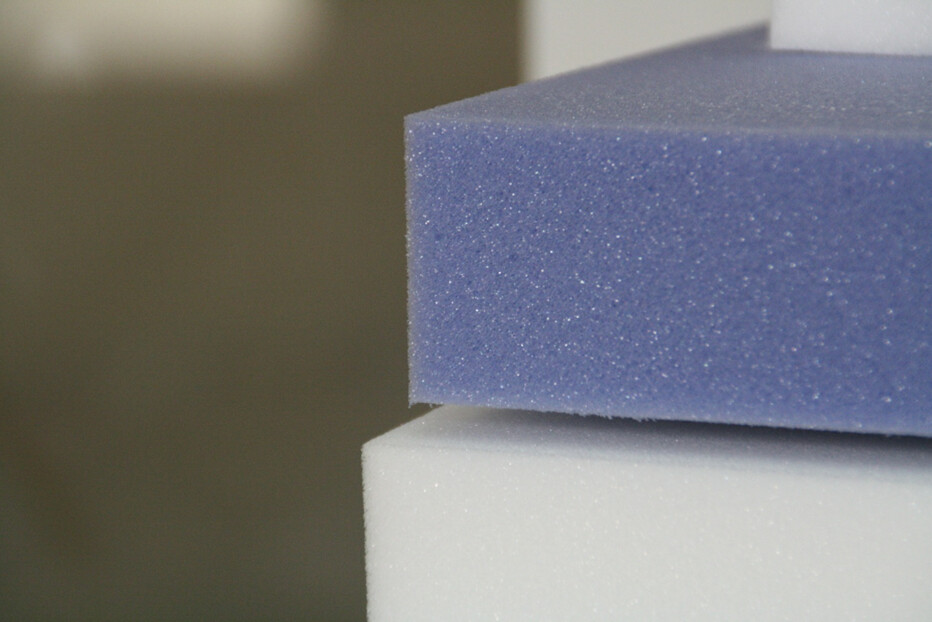

Automotive-interior industry

Digital cutting machines serve the need of automotive and interior industry. It helps in cutting materials like wire ring pads, plush carpets, EVA rubber soles, latex mats, PVC mats, TPE rubber mats, faux leather, leather, PU sponge composites, etc. Both interior and exterior products are cut with this advanced machinery. If you belong to the automotive industry and you are looking for a tool that meets different cutting needs, then the digital cutting machine help serves your purpose.

This machine establishes an intelligent production system providing accurate computerized designs and meeting the multi-style production goals of the company. Also, the automatic feeding system of the machine is used to realize auto conveying and auto-correction of the fabric, ensuring the accuracy of feeding.

Upholstery Industry

The digital cutting machine has made cutting more flexible options than ever before. With this advanced cutting solution, the upholstery industry can better meet the demands and expectations of its customers. The digital cutting solution solves the problem of increased production costs due to market customization. The automatic feeding system and intelligent feeding correction system reduces labour dependency and saves a huge amounts of cost of manual production and management. Over manual nesting, the digital cutting machine saves fabric cost and avoid wastage of the fabric that can be caused by artificial nesting.

The upholstery industry uses a digital cutting solution to digitally manage every piece of the sofa, check and resolve changes in the size of the sofa, color scheme, and design, and complete the nesting of the sofa pieces in the span of a few minutes. The digital cutting machine saves the time involved in production, nesting, and cutting. This machine improves the efficiency and shortens the delivery time involved.

Textile Industry:

Irrespective of the material an operator deals within the textile industry, a digital cutting machine is something that will provide faster and efficient service to the manufacturer. Be it garments, airbags, sun-shades/umbrellas, flags, airplane seats or car seats, the digital cutting machine has the capability to cut through the toughest of material for the manufacturing of the aforementioned parts of the textile industry.

Also, the use of the digital cutting machine is quite prevalent in paper-made, cardboard, or plastic-made textile industry. Unmatched and flawless precision is the reason why the digital cutting machine is preferred over other machines in a textile firm.

Cardboard Industry:

As mentioned, the digital cutting machine automates its design; besides it improves the productivity of the cutting process by minimizing labour output.

Henceforth, a digital cutting machine is a machine that maintains the design with optimal precision.

Apart from that, a digital cutting machine is a perfect fit for cutting complex patterns on materials like honeycomb cardboard, which requires maintaining high precision while cutting. The digital cutting machine is superior over other cutting machines when making smooth and clean edges is the topic of conversation.

This machine is user-friendly in a way that it neither causes smoke nor any sort of smell during the process that can affect the health of the operator.

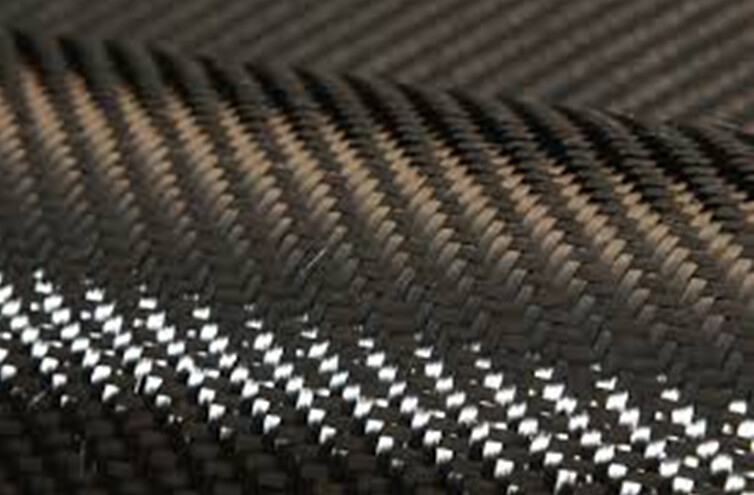

Composite Industry:

Coming with a modular, flexible and cost-effective expandable way of cutting, a digital cutting machine is a manufacturer’s machine. With a highly advanced system, this machine is capable of processing several materials with an unmatched level of precision. Moreover, it is tailor-made for industrial applications such as defense, functional textiles, rotor blades for wind turbines, aircraft, and automotive parts, etc.

The digital cutting machine offers manufacturing companies the need to cut a wide range of materials. With its robust design, accuracy, and precision, the digital cutting solution is widely accepted by manufacturing companies.

So, here was an overview of why a digital cutting machine is a smart investment for anyone who has a manufacturing firm/industry. It is very important to understand that in this ever-changing market, a digital cutting machine is a business solution that provides a competitive edge to the manufacturer over its competitors.

The bottom line of this is to achieve productive results at a lower cost; a businessman must add a solution like this which is capable enough of performing a different task at any given point of time.

Use Poor Quality Bits and Never Check it Before Starting the Work

Use Poor Quality Bits and Never Check it Before Starting the Work

Like Not Wearing Safety Glasses and Earmuffs

Like Not Wearing Safety Glasses and Earmuffs

Lack of Safety Measures

Lack of Safety Measures

Troubleshoot and Rectify Minor Errors

Troubleshoot and Rectify Minor Errors Defective Equipment Should be Tagged and Removed

Defective Equipment Should be Tagged and Removed Stand Close to the Machine

Stand Close to the Machine Unfamiliar G-code/G Programming Language

Unfamiliar G-code/G Programming Language

Inexperienced and Altering the Tools /Accessory of the Machine

Inexperienced and Altering the Tools /Accessory of the Machine

Leave the Machine Unattended

Leave the Machine Unattended

Ignore Best Friend: MPG SIM(Syntec Controller), Feed override/hold

Ignore Best Friend: MPG SIM(Syntec Controller), Feed override/hold

Pay No Heed to Maintenance

Pay No Heed to Maintenance